ASTM E1277-02

(Test Method)Standard Test Method for Chemical Analysis of Zinc-5% Aluminum-Mischmetal Alloys by ICP Emission Spectrometry

Standard Test Method for Chemical Analysis of Zinc-5% Aluminum-Mischmetal Alloys by ICP Emission Spectrometry

SIGNIFICANCE AND USE

This test method for the chemical analysis of metals and alloys is primarily intended to test such materials for compliance with compositional specifications. It is assumed that all those who use this test method will be trained analysts capable of performing common laboratory procedures skillfully and safely. It is expected that work will be performed in a properly equipped laboratory.

SCOPE

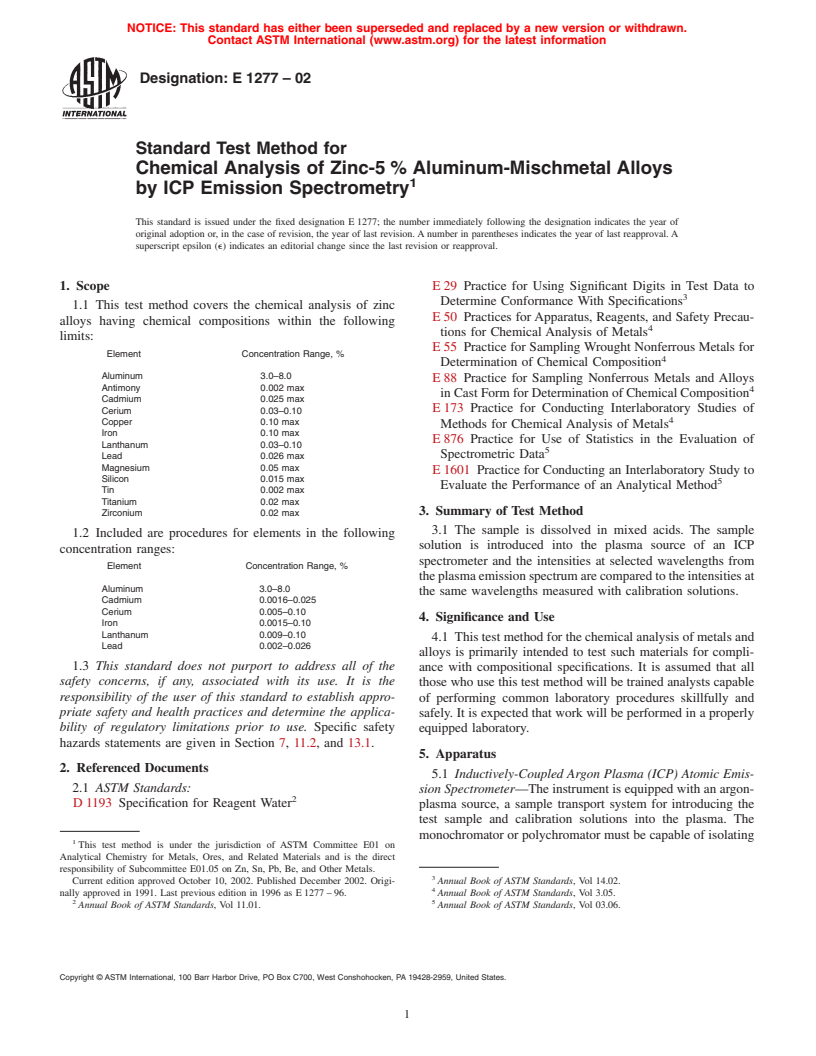

1.1 This test method covers the chemical analysis of zinc alloys having chemical compositions within the following limits:ElementConcentration Range, %Aluminum3.0-8.0Antimony0.002 maxCadmium0.025 maxCerium0.03-0.10Copper0.10 maxIron0.10 maxLanthanum0.03-0.10Lead0.026 maxMagnesium0.05 maxSilicon0.015 maxTin0.002 maxTitanium0.02 maxZirconium0.02 max

1.2 Included are procedures for elements in the following concentration ranges:ElementConcentration Range, %Aluminum3.0-8.0Cadmium0.0016-0.025Cerium0.005-0.10Iron0.0015-0.10Lanthanum0.009-0.10Lead0.002-0.026

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific safety hazards statements are given in Section 7, 11.2, and 13.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1277–02

Standard Test Method for

Chemical Analysis of Zinc-5% Aluminum-Mischmetal Alloys

1

by ICP Emission Spectrometry

This standard is issued under the fixed designation E 1277; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E29 Practice for Using Significant Digits in Test Data to

3

Determine Conformance With Specifications

1.1 This test method covers the chemical analysis of zinc

E50 Practices for Apparatus, Reagents, and Safety Precau-

alloys having chemical compositions within the following

4

tions for Chemical Analysis of Metals

limits:

E55 Practice for Sampling Wrought Nonferrous Metals for

Element Concentration Range, %

4

Determination of Chemical Composition

Aluminum 3.0–8.0

E88 Practice for Sampling Nonferrous Metals and Alloys

Antimony 0.002 max

4

in Cast Form for Determination of Chemical Composition

Cadmium 0.025 max

E 173 Practice for Conducting Interlaboratory Studies of

Cerium 0.03–0.10

4

Copper 0.10 max

Methods for Chemical Analysis of Metals

Iron 0.10 max

E 876 Practice for Use of Statistics in the Evaluation of

Lanthanum 0.03–0.10

5

Spectrometric Data

Lead 0.026 max

Magnesium 0.05 max

E 1601 Practice for Conducting an Interlaboratory Study to

Silicon 0.015 max

5

Evaluate the Performance of an Analytical Method

Tin 0.002 max

Titanium 0.02 max

3. Summary of Test Method

Zirconium 0.02 max

3.1 The sample is dissolved in mixed acids. The sample

1.2 Included are procedures for elements in the following

solution is introduced into the plasma source of an ICP

concentration ranges:

spectrometer and the intensities at selected wavelengths from

Element Concentration Range, %

theplasmaemissionspectrumarecomparedtotheintensitiesat

Aluminum 3.0–8.0

the same wavelengths measured with calibration solutions.

Cadmium 0.0016–0.025

Cerium 0.005–0.10

4. Significance and Use

Iron 0.0015–0.10

Lanthanum 0.009–0.10

4.1 This test method for the chemical analysis of metals and

Lead 0.002–0.026

alloys is primarily intended to test such materials for compli-

1.3 This standard does not purport to address all of the

ance with compositional specifications. It is assumed that all

safety concerns, if any, associated with its use. It is the those who use this test method will be trained analysts capable

responsibility of the user of this standard to establish appro-

of performing common laboratory procedures skillfully and

priate safety and health practices and determine the applica-

safely. It is expected that work will be performed in a properly

bility of regulatory limitations prior to use. Specific safety

equipped laboratory.

hazards statements are given in Section 7, 11.2, and 13.1.

5. Apparatus

2. Referenced Documents

5.1 Inductively-Coupled Argon Plasma (ICP) Atomic Emis-

2.1 ASTM Standards:

sion Spectrometer—The instrument is equipped with an argon-

2

D 1193 Specification for Reagent Water

plasma source, a sample transport system for introducing the

test sample and calibration solutions into the plasma. The

monochromator or polychromator must be capable of isolating

1

This test method is under the jurisdiction of ASTM Committee E01 on

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct

responsibility of Subcommittee E01.05 on Zn, Sn, Pb, Be, and Other Metals.

3

Current edition approved October 10, 2002. Published December 2002. Origi- Annual Book of ASTM Standards, Vol 14.02.

4

nally approved in 1991. Last previous edition in 1996 as E 1277 – 96. Annual Book of ASTM Standards, Vol 3.05.

2 5

Annual Book of ASTM Standards, Vol 11.01. Annual Book of ASTM Standards, Vol 03.06.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1277–02

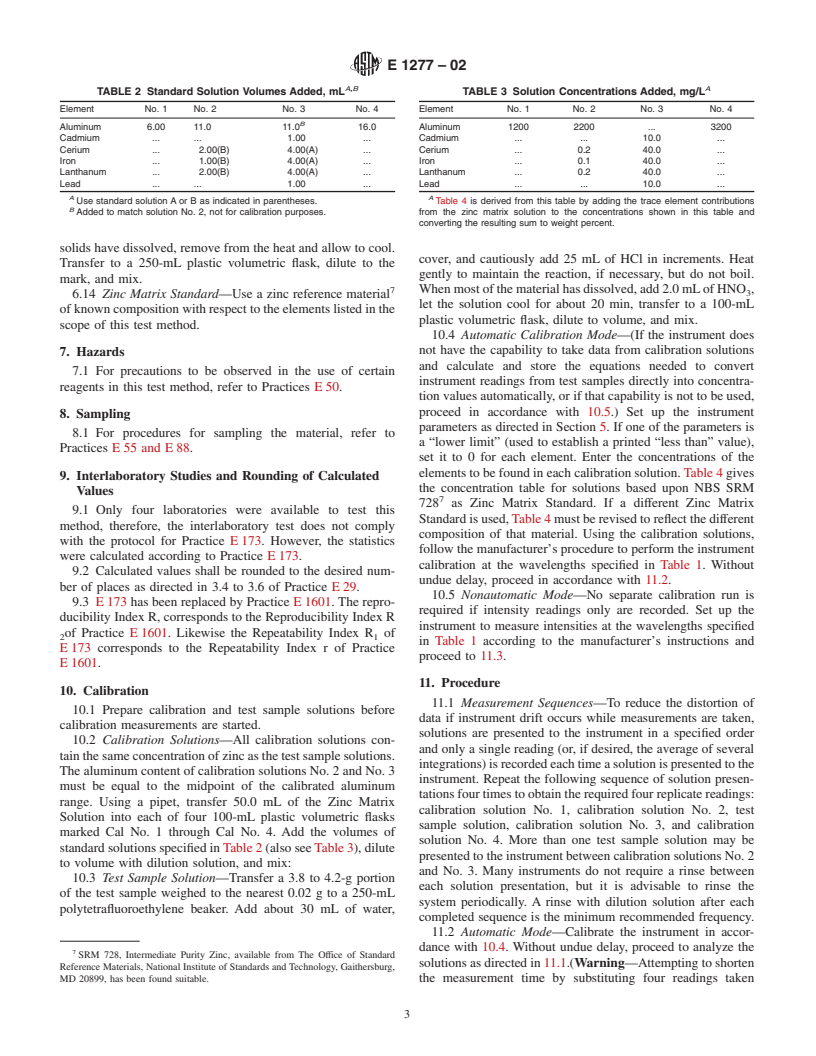

A

TABLE 1 Wavelengths and Instrument Conditions

remain undissolved). Transfer the solution to a 100-mL volu-

Element Wavelength Time, s No. Integ. BCor1 BCor2 metric flask, dilute to volume, and mix. Store in a polyethylene

bottle.

Al 3092.7 1.0 3 . .

Cd 2265.02 .5 3 2264.46 2265.58

6.4 Cadmium, Standard Solution (1 mL = 1.00 mg Cd)—

Ce 4186.6 .5 2 . .

Transfer 1.000 g of cadmium (purity: 99.95 % min) to a

Fe 2599.4 .5 2 . .

La 3988.5 .5 2 3987.54 3989.06 250-mLbeaker. Cover and add 40 mLof HNO (1 + 1) and 10

3

Pb 2832.97 1.0 3 . 2833.36

mL of HCl. After dissolution is complete, heat to boiling to

A

The tabulated conditions were those found satisfactory on one instrument.

remove oxides of nitrogen. Cool, transfer to a 1-L volumetric

Wavelengths are expressed in angstroms. Time=seconds for each integr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.