ASTM D3794-00

(Guide)Standard Guide for Testing Coil Coatings (Withdrawn 2009)

Standard Guide for Testing Coil Coatings (Withdrawn 2009)

SIGNIFICANCE AND USE

This guide represents a collection of pertinent ASTM test methods used within the coil coatings industry. In the past, coil coaters world wide depended on industry standards written by the National Coil Coaters Association. That association, working cooperatively with ASTM, will no longer issue new, nor update old, standards.

SCOPE

1.1 This guide covers procedures for testing coil coatings. The test methods included are listed in Table 1. Where more than one test method is listed for the same characteristic, no attempt is made to indicate superiority of one method over another. Selection of methods to be followed must be governed by the requirements in each individual case, together with agreement between the producer and user.

1.2 This guide also refers to methods developed specifically for the Coil Industry by the National Coil Coaters Association.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This guide covers procedures for testing coil coatings. Where more than one test method is listed for the same characteristic, no attempt is made to indicate superiority of one method over another. Selection of test methods to be followed must be governed by the requirements in each individual case, together with agreement between the producer and user.

Formerly under the jurisdiction of Committee D01 on Paint and Related Coatings, Materials, an Applications, this guide was withdrawn in March 2009 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3794–00

Standard Guide for

Testing Coil Coatings

This standard is issued under the fixed designation D 3794; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 823 Practices for Producing Films of Uniform Thickness

of Paint, Varnish, and Related Products on Tests Panels

1.1 This guide covers procedures for testing coil coatings.

D 870 Practice for Testing Water Resistance of Coatings

The test methods included are listed in Table 1. Where more

Using Water Immersion

than one test method is listed for the same characteristic, no

D 968 Test Methods for Abrasion Resistance of Organic

attempt is made to indicate superiority of one method over

Coatings by Falling Abrasive

another. Selection of test methods to be followed must be

D 1005 Test Method for Measurement of Dry-Film Thick-

governed by the requirements in each individual case, together

ness of Organic Coatings Using Micrometers

with agreement between the producer and user.

D 1014 Practice for Conducting Exterior Exposure Tests of

1.2 The values stated in SI units are to be regarded as the

Paints on Steel

standard. The values given in parentheses are for information

D 1186 Test Methods for Nondestructive Measurement of

only.

Dry Film Thickness of Nonmagnetic Coatings Applied to

1.3 This standard does not purport to address all of the

a Ferrous Base

safety concerns, if any, associated with its use. It is the

D 1193 Specification for Reagent Water

responsibility of the user of this standard to establish appro-

D 1200 Test Method for Viscosity by Ford Viscosity Cup

priate safety and health practices and determine the applica-

D 1210 TestMethodforFinenessofDispersionofPigment-

bility of regulatory limitations prior to use.

Vehicle Systems by Hegman-Type Gage

2. Referenced Documents D 1212 Test Methods for Measurement of Wet Film Thick-

ness of Organic Coatings

2.1 ASTM Standards:

D 1308 Test Method for Effect of Household Chemicals on

B117 PracticeforOperatingofSaltSpray(Fog)Apparatus

Clear and Pigmented Organic Finishes

B 368 Test Method for Copper-Accelerated Acetic Acid-

D 1400 Test Method for Nondestructive Measurement of

Salt Spray (Fog) Testing (Cass Test)

DryFilmThicknessofNonconductiveCoatingsAppliedto

D 522 Test Methods for Mandrel Bend Test of Attached

a Nonferrous Metal Base

Organic Coatings

D 1474 Test Methods for Indentation Hardness of Organic

D 523 Test Methods for Specular Gloss

Coatings

D 610 Test Method for Evaluating Degree of Rusting on

D 1475 Test Method for Density of Paint,Varnish, Lacquer,

Painted Steel Surfaces

and Related Products

D 660 Test Method for Evaluating Degree of Checking

D 1654 Test Method for Evaluation of Painted or Coated

Exterior Paints

Specimens Subjected to Corrosive Environments

D 661 Test Method for Evaluating Degree of Cracking of

D 1729 Practice for Visual Appraisal of Colors and Color

Exterior Paints

Differences of Diffusely-Illuminated Opaque Materials

D 714 Test Method for Evaluating Degree of Blistering of

D 1735 Practice for Testing Water Resistance of Coatings

Paints

Using Water Fog Apparatus

D 822 Practice for Conducting Tests on Paint and Related

D 1823 Test Method for Apparent Viscosity of Plastisols

Coatings and Materials Using Filtered Open-Flame

and Organosols at High Shear Rates by ExtrusionViscom-

Carbon-Arc Apparatus

eter

D 1824 Test Method for Apparent Viscosity of Plastisols

and Organosols at Low Shear Rates by Brookfield Vis-

This guide is under the jurisdiction of ASTM Committee D01 on Paint and

cometer

Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.53 on Coil Coated Metal. D 2092 Guide for Treatment of Zinc-Coated (Galvanized)

Current edition approved June 10, 2000. Published August 2000.

Annual Book of ASTM Standards, Vol 03.02.

Annual Book of ASTM Standards, Vol 02.05.

4 6

Annual Book of ASTM Standards, Vol 06.01. Annual Book of ASTM Standards, Vol 11.01.

5 7

Annual Book of ASTM Standards, Vol 06.02. Annual Book of ASTM Standards, Vol 08.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3794–00

Steel Surfaces for Painting D 4518 Test Methods for Measuring Static Friction of

Coating Surfaces

D 2196 Test Methods for Rheological Properties of Non-

D 4585 Practice for Testing Water Resistance of Coatings

Newtonian Materials by Rotational (Brookfield) Viscom-

Using Controlled Condensation

eter

D 4587 Practice for Conducting Tests on Paint and Related

D 2197 Test Method for Adhesion of Organic Coatings by

Coatings and Materials Using a Fluorescent UV-

Scrape Adhesion

Condensation Light- and Water-Exposure Apparatus

D 2244 Test Method for Calculation of Color Differences

D 5031 Practice for ConductingTests on Paints and Related

from Instrumentally Measured Color Coordinates

Coatings and Materials Using Enclosed Carbon-Arc Light

D 2247 PracticeforTestingWaterResistanceofCoatingsin

and Water Exposure Apparatus

100 % Relative Humidity

D 5178 Test Method for Mar Resistance of Organic Coat-

D 2248 Practice for Detergent Resistance of Organic Fin- 4

ings

ishes

D 5402 Practice for Assessing the Solvent Resistance of

D 2369 Test Method for Volatile Content of Coatings

Organic Coatings Using Solvent Rubs

D 2454 Practice for Determining the Effect of Overbaking D 5531 Guide for Preparation, Maintenance and Distribu-

on Organic Coatings tion of Physical Product Standards for Color and Geomet-

ric Appearance of Coatings

D 2697 Test Method for Volume Nonvolatile Matter in

D 5723 Practice for Determination of Chromium Treatment

Clear or Pigmented Coatings

Weight on Metal Substrates by X-Ray Fluorescence

D 2794 Test Method for Resistance of Organic Coatings to

D 5796 Test Method for Measurement of Dry Film Thick-

the Effects of Rapid Deformation (Impact)

ness of Thin Film Coil-Coated Systems by Destructive

D 2803 Guide for Testing Filiform Corrosion Resistance of

Means Using a Boring Device

Organic Coatings on Metal

D 5894 Practice for Cyclic Salt Fog-UV Exposure of

D 3003 Test Method for Pressure Mottling and Blocking

Painted Metal (Alternating Exposure in a Fog/Dry Cabinet

Resistance of Organic Coatings on Metal Substrates

and UV/Condensation Cabinet)

D 3134 Practice for Establishing Color and Gloss Toler-

D 6093 TestMethodforPercentVolumeNonvolatileMatter

ances

in Clear or Pigmented Coatings Using a Helium Gas

D 3170 Test Method for Chipping Resistance of Coatings

Pycnometer

D 3278 Test Methods for Flash Point of Liquids by Small

D 6491 Practice for Evaluation of Aging Resistance of

4 5

Scale Closed-Cup Apparatus

Prestressed Prepainted Metal in a Dry Heat Test

D 6492 Practice for Detection of Hexavalent Chromium On

D 3359 Test Methods for Measuring Adhesion by Tape

Zinc and Zinc/Aluminum Alloy Coated Steel

Test

E70 Test Method for pH of Aqueous Solutions with the

D 3361 Practice for Operating Light- and Water-Exposure

Glass Electrode

Apparatus (Unfiltered Open-Flame Carbon-Arc Type) for

E84 Test Method for Surface Burning Characteristics of

Testing Paint, Varnish, Lacquer, and Related Products

Building Materials

Using the Dew Cycle

E 284 Terminology of Appearance

D 3363 Test Method for Film Hardness by Pencil Test

E 308 Practice for Computing the Colors of Objects by

D 3960 Practice for Determining Volatile Organic Com-

Using the CIE System

pound (VOC) Content of Paints and Related Coatings

E 408 TestMethodsforTotalNormalEmittanceofSurfaces

D 4060 Test Method for Abrasion Resistance of Organic 11

Using Inspection-Meter Techniques

Coatings by the Taber Abraser

E 643 Test Method for Ball Punch Deformation of Metallic

D 4138 Test Method for Measurement of Dry Film Thick-

Sheet Material

ness of Protective Coating Systems by Destructive Means

E 903 Test Method for SolarAbsorptance, Reflectance, and

D 4141 PracticeforConductingAcceleratedOutdoorExpo- Transmittance of Materials Using Integrating Spheres

sure Tests of Coatings

E 1164 Practice for Obtaining Spectrophotometric Data for

Object-Color Evaluation

D 4145 Test Method for Coating Flexibility of Prepainted

E 1356 Test Method for Glass Transition Temperatures by

Sheet

Differential Scanning Calorimetry or Differential Thermal

D 4146 Test Method for Formability of Zinc-Rich Primer/

Analysis

Chromate Complex Coatings on Steel

E 1541 Practice for Specifying and Matching Color Using

D 4147 Practice for Applying Coil Coatings Using the

Wire-Wound Drawdown Bar

D 4212 Test Method for Viscosity by Dip-Type Viscosity

Discontinued; see 1999 Annual Book of ASTM Standards, Vol 06.01.

Cups

Annual Book of ASTM Standards, Vol 15.05.

D 4214 Test Methods for Evaluating Degree of Chalking of Annual Book of ASTM Standards, Vol 04.07.

Annual Book of ASTM Standards, Vol 15.03.

Exterior Paint Films

Annual Book of ASTM Standards, Vol 03.01.

D 4287 TestMethodforHigh-ShearViscosityUsingtheICI

Annual Book of ASTM Standards, Vol 12.02.

Cone/Plate Viscometer Annual Book of ASTM Standards, Vol 14.02.

D3794–00

the Colorcurve System 3. Terminology

E 1545 Test Method forAssignment of the Glass Transition

3.1 Definitions:

Temperature by Thermomechanical Analysis

3.1.1 coil coating—application of coatings or films to con-

E 1640 Test Method forAssignment of the Glass Transition

tinuous metal coil stock.

Temperature by Dynamic Mechanical Analysis

3.1.2 direct roller coat—coating with the applicator or

E 1808 Guide for Designing and ConductingVisual Experi-

4 coating roll revolving in the same direction as the strip.

ments

3.1.3 metal pretreatment—chemical treatment normally ap-

E 1918 Test Method for Measuring Solar Reflectance of

plied to the metal substrate prior to prime or finish coating.

Horizontal and Low-Sloped Surfaces in the Field

3.1.3.1 Discussion—The treatment is designed to react with

G7 Practice for Atmospheric Environmental Exposure

Testing of Nonmetallic Materials andmodifythemetalsubstratetoproduceasurfacesuitablefor

coating or adhesive bonding.

G60 Test Method for Conducting Cyclic Humidity Tests

G85 Practice for Modified Salt Spray (Fog) Testing

3.1.4 reverse roller coat—coating with the applicator or

G87 Practice for Conducting Moist SO Tests

coatingrollrevolvinginadirectionoppositetothatofthestrip.

G90 Practice for Performing Accelerated Outdoor Weath-

3.2 The definitions given in Terminology G113 are appli-

ering of Nonmetallic Materials Using Concentrated Natu-

cable to this guide.

ral Sunlight

G113 Terminology Relating to Natural and Artificial

4. Significance and Use

Weathering Tests of Nonmetallic Materials

4.1 This guide represents a collection of pertinent ASTM

G 151 Practice for Exposing Nonmetallic Materials in Ac-

test methods used within the coil coatings industry. In the past,

celerated Test Devices that Use Laboratory Light

15 coilcoatersworldwidedependedonindustrystandardswritten

Sources

by the National Coil Coaters Association. That association,

G 152 PracticeforOperatingOpenFlameCarbonArcLight

working cooperatively with ASTM, will no longer issue new,

Apparatus for Exposure of Nonmetallic Materials

nor update old, standards.

G 153 Practice for Operating Enclosed Carbon Arc Light

Apparatus for Exposure of Nonmetallic Materials

5. General Requirements

G 154 Practice for Operating Fluorescent Light Apparatus

for UV Exposure of Nonmetallic Materials

5.1 All standard tests shall be made at 25 6 3°C (77 6

G 155 Practice for Operating Xenon Arc Light Apparatus

25°F) and 50 6 5 % relative humidity, immediately after

for Exposure of Nonmetallic Materials

baking unless otherwise specified.

G 159 TablesforReferencesSolarSpectralIrradianceatAir

Mass 1.5: Direct Normal and Hemispherical for a 37°

6. Sampling

Tilted Surface

6.1 The number of samples per unit of production shall be

agreed upon between the producer and user.

Annual Book of ASTM Standards, Vol 14.04.

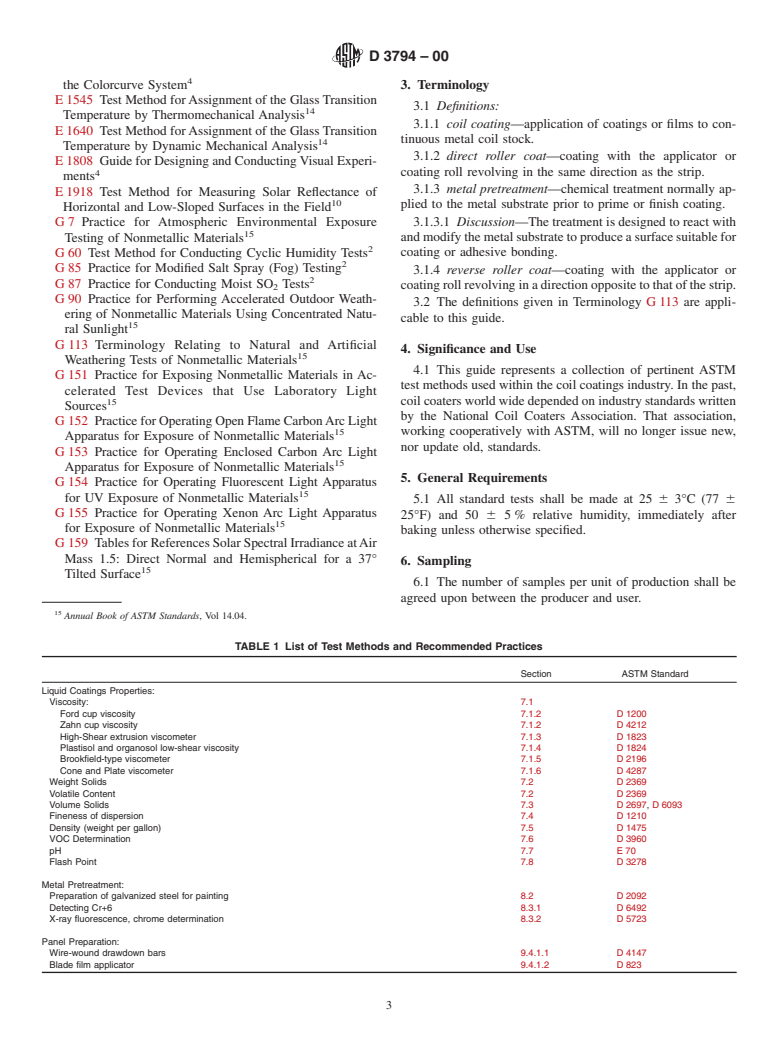

TABLE 1 List of Test Methods and Recommended Practices

Section ASTM Standard

Liquid Coatings Properties:

Viscosity: 7.1

Ford cup viscosity 7.1.2 D 1200

Zahn cup viscosity 7.1.2 D 4212

High-Shear extrusion viscometer 7.1.3 D 1823

Plastisol and organosol low-shear viscosity 7.1.4 D 1824

Brookfield-type viscometer 7.1.5 D 2196

Cone and Plate viscometer 7.1.6 D 4287

Weight Solids 7.2 D 2369

Volatile Content 7.2 D 2369

Volume Solids 7.3 D 2697, D 6093

Fineness of dispersion 7.4 D 1210

Density (weight per gallon) 7.5 D 1475

VOC Determination 7.6 D 3960

pH 7.7 E 70

Flash Point 7.8 D 3278

Metal Pretreatment:

Preparation of galvanized steel for painting 8.2 D 2092

Detecting Cr+6 8.3.1 D 6492

X-ray fluorescence, chrome determination 8.3.2 D 5723

Panel Preparation:

Wire-wound drawdown bars 9.4.1.1 D 4147

Blade film applicator 9.4.1.2 D 823

D3794–00

TABLE 1 Continued

Section ASTM Standard

Wet film thickness 9.5 D 1212

Material Properties of a Cured Coil Coating System: 10

Dry film thickness (DFT) 10.1 .

DFT, destructive methods 10.1.1 .

DFT, micrometer 10.1.1.1 D 1005

DFT, microscope 10.1.1.2 D 4138

DFT, boring method 10.1.1.3 D 5796

DFT, non-destructive methods 10.1.2 .

DFT, eddy current, non-ferrous base 10.1.2.1 D 1400

DFT, magnetic flux, ferrous base 10.1.2.2 D 1186

Color 10.2

Glossary of color 10.2.1 E 284

Preparation and control of color standards 10.2.1 D 5531

Color and gloss tolerances 10.2.1 D 3134

Conducting visual experiments 10.2.1 E 1808

Color differences by visual evaluation 10.2.2 .

Visual evaluation of color and color difference 10.2.2.1 D 1729

Color differences by instrumental evaluation 10.2.3 .

Color matching, color curve system 10.2.3 E 1541

CIE color difference 10.2.3 E 308

Obtaining spectral data 10.2.3 E 1164

Calculation of color differences 10.2.3 D 2244

Specular gloss measurement 10.3 D 523

Hardness 10.4

Pencil hardness 10.4.1 D 3363

Indentation hardness 10.4.2 D 1474

Flexibility 10.5 —

Impact resistance 10.5.2 D 2794

Mandrel bend 10.5.3 D 522

T bends 10.5.4 D 4145

Ball punch deformation 10.5.5 E 643

Draw test 10.5.6 D 4146

Adhesion: 10.6

Cross hatch tape adhesion 10.6.2 D 3359

Scrape adhesion 10.6.3 D 2197

Degree of Cure:

Glass transition TMA 10.7.2 E 1545

Glass transition, DMA 10.7.2 E 1640

Glass transition, DSC 10.7.2 E 1356

Solvent resistance 10.7.3 D 5402

Dry heat test 10.7.4 D 6491

Other Tests: 10.8

Pressure mottling/blocking resistance 10.8.1 D 3003

Effect of ove

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.