ASTM E2208-02(2010)

(Guide)Standard Guide for Evaluating Non-Contacting Optical Strain Measurement Systems

Standard Guide for Evaluating Non-Contacting Optical Strain Measurement Systems

ABSTRACT

This guide assists potential users in understanding the issues related to the accuracy of non-contacting strain measurement systems and to provide a common framework for quantitative comparison of optical systems. The output from a non-contacting optical strain and deformation measurement system is generally divided into optical data and image analysis data. Each non-contacting optical strain measurement system must be evaluated to determine reliable estimates for the accuracy of the resulting Derived Data.

SCOPE

1.1 The purpose of this document is to assist potential users in understanding the issues related to the accuracy of non-contacting strain measurement systems and to provide a common framework for quantitative comparison of optical systems. The output from a non-contacting optical strain and deformation measurement system is generally divided into optical data and image analysis data. Optical data contains information related to specimen strains and the image analysis process converts the encoded optical information into strain data. The enclosed document describes potential sources of error in the strain data and describes general methods for quantifying the error and estimating the accuracy of the measurements when applying non-contacting methods to the study of events for which the optical integration time is much smaller than the inverse of the maximum temporal frequency in the encoded data (that is, events that can be regarded as static during the integration time). A brief application of the approach, along with specific examples defining the various terms, is given in the Appendix.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2208 – 02 (Reapproved 2010)

Standard Guide for

Evaluating Non-Contacting Optical Strain Measurement

Systems

This standard is issued under the fixed designation E2208; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E399 Test Method for Linear-Elastic Plane-Strain Fracture

Toughness K of Metallic Materials

1.1 The purpose of this document is to assist potential users Ic

E1823 Terminology Relating to Fatigue and Fracture Test-

in understanding the issues related to the accuracy of non-

ing

contacting strain measurement systems and to provide a

common framework for quantitative comparison of optical

3. Terminology

systems. The output from a non-contacting optical strain and

3.1 Definitions of Terms Specific to This Standard:

deformation measurement system is generally divided into

3.1.1 accuracy—quantitative relationship of the measure-

optical data and image analysis data. Optical data contains

ments to the value obtained by standard measurement tech-

information related to specimen strains and the image analysis

niques

process converts the encoded optical information into strain

3.1.2 basic data—data obtained directly by the measure-

data. The enclosed document describes potential sources of

ment system. For optical, non-contacting methods, a two-

error in the strain data and describes general methods for

dimensional array of image intensity data is generally the basic

quantifying the error and estimating the accuracy of the

data.

measurements when applying non-contacting methods to the

3.1.3 coherent illumination—light source where the differ-

study of events for which the optical integration time is much

ence in phase is solely a function of optical path differences;

smallerthantheinverseofthemaximumtemporalfrequencyin

interference is a direct consequence.

the encoded data (that is, events that can be regarded as static

3.1.4 decoded data—measurement information related to

during the integration time). A brief application of the ap-

the displacement or displacement gradient field.

proach, along with specific examples defining the various

3.1.5 decoded data bandwidth—spatial frequency range of

terms, is given in the Appendix.

the information after decoding of the optical data.

2. Referenced Documents 3.1.6 derived data—data obtained through processing of the

basic data. Typically, this is displacement field data.

2.1 ASTM Standards:

3.1.7 dynamic range—the range of physical parameter val-

E8 Test Methods for Tension Testing of Metallic Materials

ues for which measurements can be acquired with the mea-

E83 Practice for Verification and Classification of Exten-

surement system.

someter Systems

3.1.8 illumination wavelength—wavelength of illumination,

E251 Test Methods for Performance Characteristics of Me-

z.

tallic Bonded Resistance Strain Gauges

3.1.9 incoherent illumination—light source with random

variations in optical path differences; constructive or destruc-

This guide is under the jurisdiction of ASTM Committee E08 on Fatigue and

tive interference of waves is not possible.

Fracture and is the direct responsibility of Subcommittee E08.03 on Advanced

3.1.10 maximum temporal frequency of encoded data—

Apparatus and Techniques.

reciprocal of the shortest event time contained in the encoded

Current edition approved Nov. 1, 2010. Published January 2011. Originally

data (for example, time variations in displacement field).

approved in 2002. Last previous edition approved in 2002 as –02. DOI: 10.1520/

E2208-02R10.

3.1.11 measurement noise—variations in the measurements

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

that are not related to actual changes in the physical property

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

being measured. May be quantified by statistical properties

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. such as standard deviation.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2208 – 02 (2010)

3.1.12 measurement resolution—smallest change in the 3.1.22 systematic errors—biased variations in the measure-

physical property that can be reliably measured. ments due to the effects of test environment, hardware and/or

3.1.13 numerical aperture, (N.A.)—non-dimensional mea-

software.Test environment effects include changes in tempera-

sure of diffraction-limitation for imaging system; N.A. = D/f ture, humidity, lighting, out-of-plane displacements (for 2-D

for a simple lens system, where D is lens diameter and f is lens

systems) etc. Hardware effects include lens aberrations, ther-

focal length.

mal drift in recording media, variations in sensing elements,

3.1.14 optical data—recorded images of specimen, contain-

interlacingoflines,phaselagduetorefreshrates,depthoffield

ing encoded information related to the displacement or dis-

for recording system, etc. Software effects include interpola-

placement gradient field, or both.

tion errors, search algorithm processes, image boundary ef-

3.1.15 optical data bandwidth—spatial frequency range of

fects, etc.

the optical pattern (for example, fringes, speckle pattern, etc.)

that can be recorded in the images without aliasing or loss of

4. Description of General Optical Non-Contacting Strain

information.

Measurement Systems

3.1.16 optical integration time—time over which digital

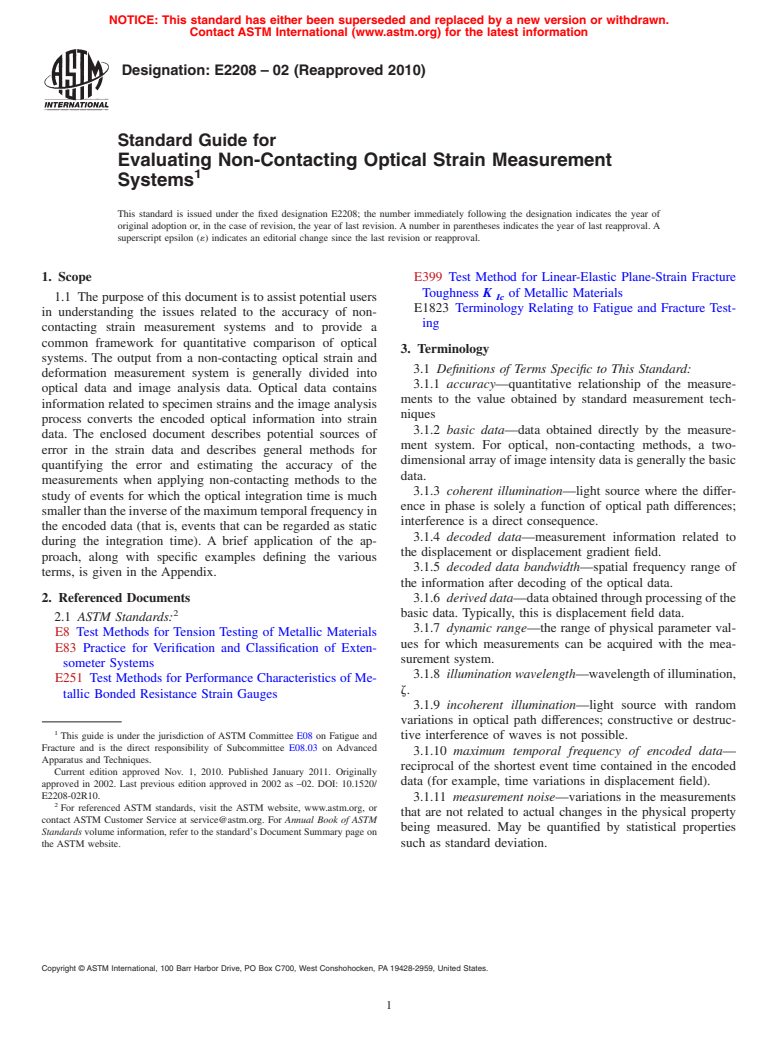

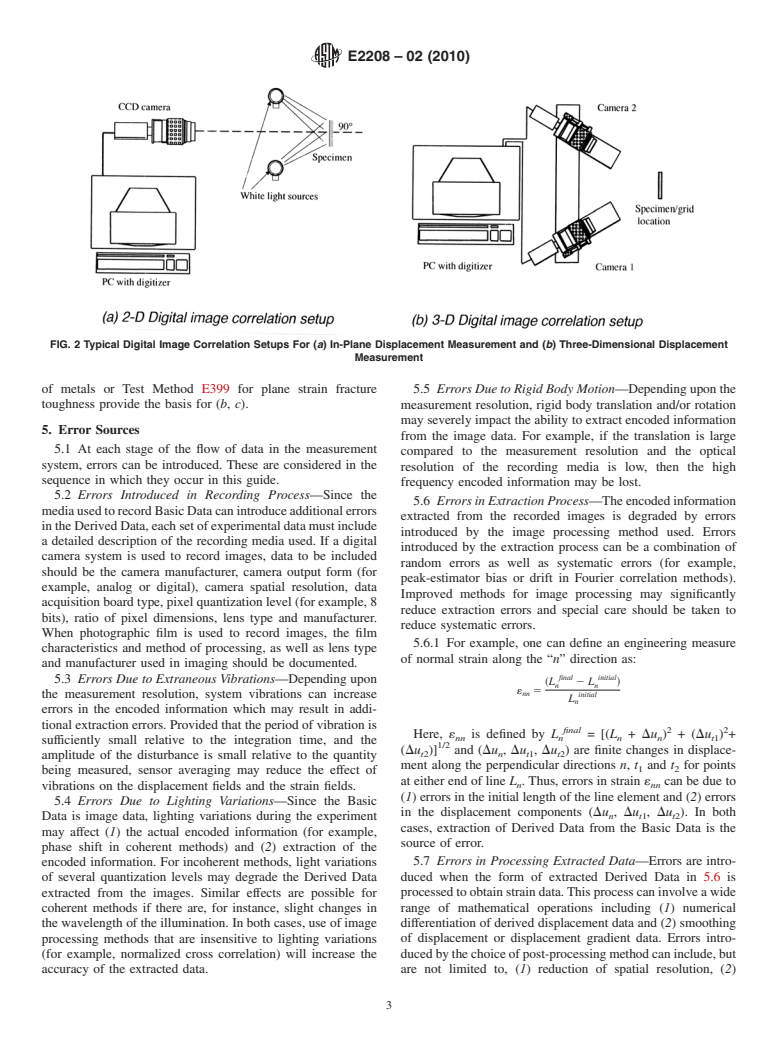

4.1 Figs. 1 and 2 show schematics of typical moiré and

image data is averaged to obtain a discretely sampled repre-

digital image correlation setups used to make displacement

sentation of the object.

field measurements. In its most basic form, an optical non-

3.1.17 optical resolution, (OR)—distance, d = z / (2 N.A.),

contacting strain measurement system such as shown in Figs. 1

between a pair of lines that can be quantatively determined.

and 2, consists of five components. The five components are

3.1.18 quantization level—numberofbitsusedinthedigital

(a) an illumination source, (b) a test specimen, (c) a method to

recording of optical data by each sensor for image analysis.

apply forces to the specimen, (d) a recording media to obtain

The quantization level is one of the parameters determining the

images of the object at each load level of interest and (e)an

fidelity of the recorded optical images. It is determined by the

image analysis procedure to convert the encoded deformation

camera selected for imaging and typically is 8 bits for most

information into strain data. Since the encoded information in

cameras.

the optical images may be related either to displacement field

3.1.19 recording resolution (pixels/length), k—number of

components or to the displacement gradient field components,

optical sensor elements (pixels) used to record an image of a

image analysis procedures will be somewhat different for each

region of length L on object.

case. However, regardless of which form is encoded in the

3.1.20 spatial resolution for encoded data—one-half of the

images, the images are the Basic Data and the displacement

period of the highest frequency component contained in the

fieldsandthestrainfieldswillbepartoftheDerivedData.This

frequency band of the encoded data.

guide is primarily concerned with general features of (a) the

3.1.21 spatial resolution for optical data—one-half of the

period of the highest frequency component contained in the illumination source, (d) image recording components, and (e)

image analysis procedures. ASTM standards for specimen

frequency band of the optical data. Note that decoded data may

have a lower spatial resolution due to the decoding process. design and loading, such as Test Methods E8 for tensile testing

FIG. 1 Typical Optical Moiré Systems for In-Plane Displacement Measurement

E2208 – 02 (2010)

FIG. 2 Typical Digital Image Correlation Setups For (a) In-Plane Displacement Measurement and (b) Three-Dimensional Displacement

Measurement

of metals or Test Method E399 for plane strain fracture 5.5 Errors Due to Rigid Body Motion—Depending upon the

toughness provide the basis for (b, c). measurement resolution, rigid body translation and/or rotation

may severely impact the ability to extract encoded information

5. Error Sources

from the image data. For example, if the translation is large

5.1 At each stage of the flow of data in the measurement

compared to the measurement resolution and the optical

system, errors can be introduced. These are considered in the

resolution of the recording media is low, then the high

sequence in which they occur in this guide.

frequency encoded information may be lost.

5.2 Errors Introduced in Recording Process—Since the

5.6 Errors in Extraction Process—Theencodedinformation

mediausedtorecordBasicDatacanintroduceadditionalerrors

extracted from the recorded images is degraded by errors

intheDerivedData,eachsetofexperimentaldatamustinclude

introduced by the image processing method used. Errors

a detailed description of the recording media used. If a digital

introduced by the extraction process can be a combination of

camera system is used to record images, data to be included

random errors as well as systematic errors (for example,

should be the camera manufacturer, camera output form (for

peak-estimator bias or drift in Fourier correlation methods).

example, analog or digital), camera spatial resolution, data

Improved methods for image processing may significantly

acquisition board type, pixel quantization level (for example, 8

reduce extraction errors and special care should be taken to

bits), ratio of pixel dimensions, lens type and manufacturer.

reduce systematic errors.

When photographic film is used to record images, the film

5.6.1 For example, one can define an engineering measure

characteristics and method of processing, as well as lens type

of normal strain along the “n” direction as:

and manufacturer used in imaging should be documented.

final initial

5.3 Errors Due to Extraneous Vibrations—Depending upon

~L 2 L !

n n

´ 5

nn

initial

the measurement resolution, system vibrations can increase

L

n

errors in the encoded information which may result in addi-

tional extraction errors. Provided that the period of vibration is

final 2 2

Here, ´ is defined by L =[(L + Du ) +(Du ) +

nn n n n t1

sufficiently small relative to the integration time, and the

1/2

(Du )] and (Du , Du , Du ) are finite changes in displace-

t2 n t1 t2

amplitude of the disturbance is small relative to the quantity

ment along the perpendicular directions n, t and t for points

1 2

being measured, sensor averaging may reduce the effect of

at either end of line L . Thus, errors in strain ´ can be due to

n nn

vibrations on the displacement fields and the strain fields.

(1) errors in the initial length of the line element and (2) errors

5.4 Errors Due to Lighting Variations—Since the Basic

in the displacement components (Du , Du , Du ). In both

n t1 t2

Data is image data, lighting variations during the experiment

cases, extraction of Derived Data from the Basic Data is the

may affect (1) the actual encoded information (for example,

source of error.

phase shift in coherent methods) and (2) extraction of the

5.7 Errors in Processing Extracted Data—Errors are intro-

encoded information. For incoherent methods, light variations

of several quantization levels may degrade the Derived Data duced when the form of extracted Derived Data in 5.6 is

processedtoobtainstraindata.Thisprocesscaninvolveawide

extracted from the images. Similar effects are possible for

coherent methods if there are, for instance, slight changes in range of mathematical operations including (1) numerical

differentiation of derived displacement data and (2) smoothing

the wavelength of the illumination. In both cases, use of image

processing methods that are insensitive to lighting variations of displacement or displacement gradient data. Errors intro-

(for example, normalized cross correlation) will increase the ducedbythechoiceofpost-processingmethodcaninclude,but

accuracy of the extracted data. are not limited to, (1) reduction of spatial resolution, (2)

E2208 – 02 (2010)

systematic under-prediction of strain in areas of high strain Methods E251)) whenever possible is the most reliable way to

gradients, (3) phase errors in the signal due to non-symmetric obtainquantitativeestimatesfortheaccuracyofaveragevalues

operators etc.

obtained from the Derived Data. If this approach is used, all

data acquisition and analysis procedures must remain the same

6. System Evaluation Process

as used in the actual tests, with clear documentation provided

6.1 Each non-contacting optical strain measurement system

to demonstrate that the same procedure has been used for both

must be evaluated to determine reliable estimates for the

tests.

accuracy of the resulting Derived Data. Given the wide range

6.4 Comparison to Standard Measurement Methods for

of methods that have been developed, this guide will not

Simulated Test Conditions in Laboratory Environments—For

address specific details involving the application of any tech-

those cases where laboratory tests can be used to approximate

nique. Rather, the guidelines are provided as a general frame-

actual test conditions, calibration tests should be performed on

work for evaluation of non-contacting optical strain measure-

laboratory specimens for accuracy assessment. In this ap-

ment systems.

proach, the effects of phenomena present in actual test condi-

6.2 In the following sections, a direct comparison between

tions must be accounted for in laboratory tests so that potential

established measurement methods and non-contacting methods

errors associated with the testing environment are included.

is recommended. However, it must be noted that, even though

For these tests, direct comparison of the non-contacting mea-

this approach does provide a direct, quantitative measure of

surements to independent measurements by established meth-

agreement between two, independent measurement data sets.

odsusingdocumentedASTMprocedures(seePracticeE83and

Practice E83 and Test Methods E251 provide only average

Test Methods E251) whenever possible are recommended to

values for strain over a specific area on the specimen. Thus,

obtain quantitative estimates of the accuracy of the Derived

good agreement with the average value obtained from the

Data. If this approach is used, all data acquisition and analysis

Derived Data in the s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.