ASTM E1169-18

(Practice)Standard Practice for Conducting Ruggedness Tests

Standard Practice for Conducting Ruggedness Tests

ABSTRACT

This practice covers conducting ruggedness tests. The purpose of a ruggedness test is to identify those factors that strongly influence the measurements provided by a specific test method and to estimate how closely those factors need to be controlled. This practice restricts itself to designs with two levels per factor. The designs require the simultaneous change of the levels of all of the factors, thus permitting the determination of the effects of each of the factors on the measured results. Conducting a ruggedness test requires making systematic changes in the variables, called factors, and then observing the subsequent effect of those changes upon the test result of each run.

This practice recommends statistically designed experiments involving two levels of multiple factors. The steps to be conducted include identification of relevant factors; selection of appropriate levels (two for each factor) to be used in experiment runs; display of treatment combinations in cyclic shifted order, which assigns factors and levels to runs; execution of runs arranged in a random order; statistical analysis to determine the effect of factors on the test method results; and possible revision of the test method as needed.

SIGNIFICANCE AND USE

5.1 A ruggedness test is a special application of a statistically designed experiment. It is generally carried out when it is desirable to examine a large number of possible factors to determine which of these factors might have the greatest effect on the outcome of a test method. Statistical design enables more efficient and cost effective determination of the factor effects than would be achieved if separate experiments were carried out for each factor. The proposed designs are easy to use in developing the information needed for evaluating quantitative test methods.

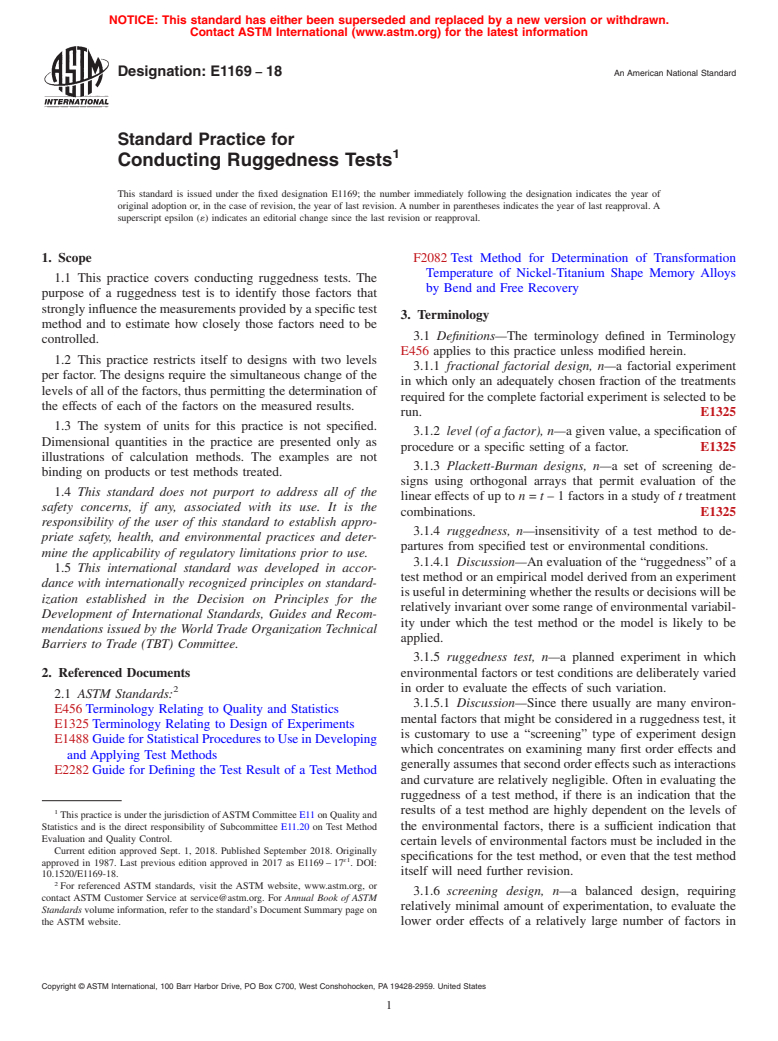

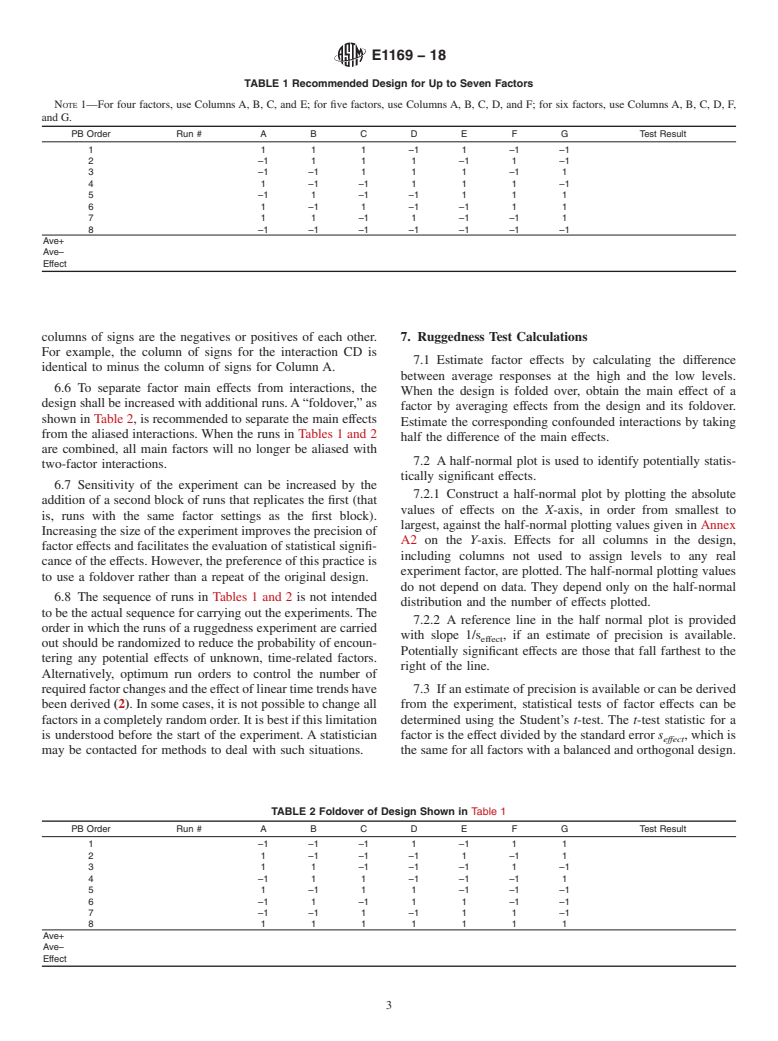

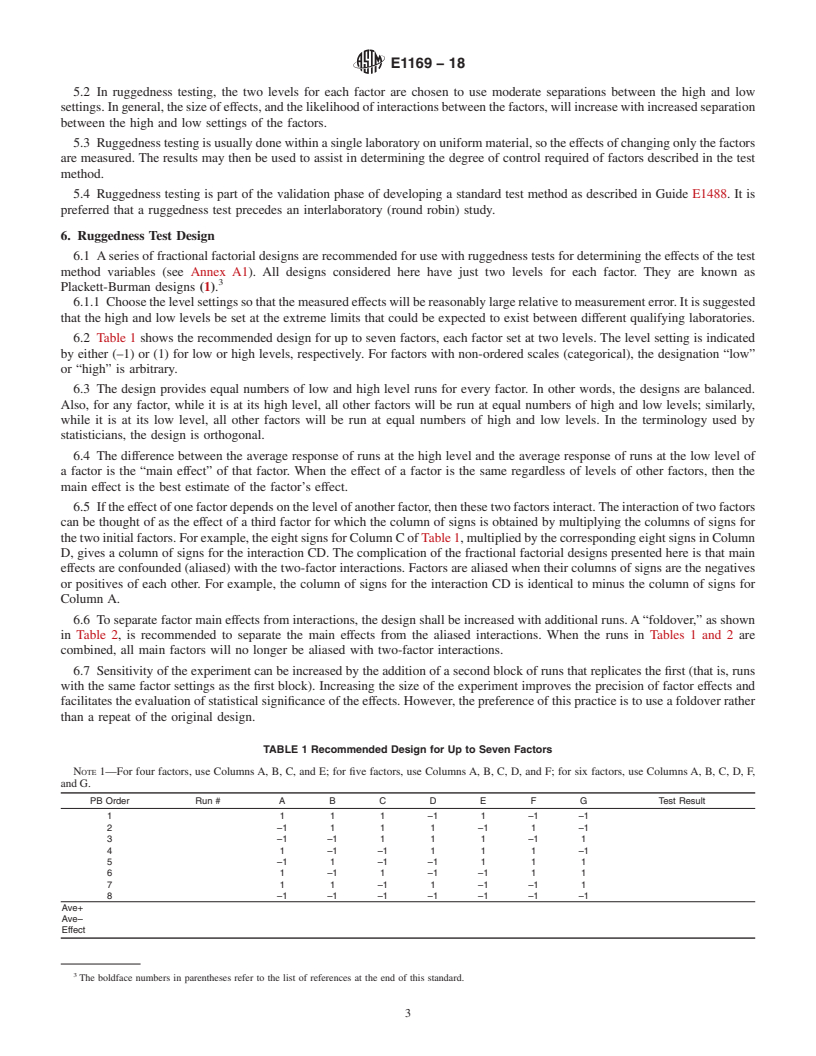

5.2 In ruggedness testing, the two levels for each factor are chosen to use moderate separations between the high and low settings. In general, the size of effects, and the likelihood of interactions between the factors, will increase with increased separation between the high and low settings of the factors.

5.3 Ruggedness testing is usually done within a single laboratory on uniform material, so the effects of changing only the factors are measured. The results may then be used to assist in determining the degree of control required of factors described in the test method.

5.4 Ruggedness testing is part of the validation phase of developing a standard test method as described in Guide E1488. It is preferred that a ruggedness test precedes an interlaboratory (round robin) study.

SCOPE

1.1 This practice covers conducting ruggedness tests. The purpose of a ruggedness test is to identify those factors that strongly influence the measurements provided by a specific test method and to estimate how closely those factors need to be controlled.

1.2 This practice restricts itself to designs with two levels per factor. The designs require the simultaneous change of the levels of all of the factors, thus permitting the determination of the effects of each of the factors on the measured results.

1.3 The system of units for this practice is not specified. Dimensional quantities in the practice are presented only as illustrations of calculation methods. The examples are not binding on products or test methods treated.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical ...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1169 − 18 An American National Standard

Standard Practice for

1

Conducting Ruggedness Tests

This standard is issued under the fixed designation E1169; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F2082Test Method for Determination of Transformation

Temperature of Nickel-Titanium Shape Memory Alloys

1.1 This practice covers conducting ruggedness tests. The

by Bend and Free Recovery

purpose of a ruggedness test is to identify those factors that

stronglyinfluencethemeasurementsprovidedbyaspecifictest

3. Terminology

method and to estimate how closely those factors need to be

3.1 Definitions—The terminology defined in Terminology

controlled.

E456 applies to this practice unless modified herein.

1.2 This practice restricts itself to designs with two levels

3.1.1 fractional factorial design, n—a factorial experiment

per factor. The designs require the simultaneous change of the

in which only an adequately chosen fraction of the treatments

levelsofallofthefactors,thuspermittingthedeterminationof

required for the complete factorial experiment is selected to be

the effects of each of the factors on the measured results.

run. E1325

1.3 The system of units for this practice is not specified.

3.1.2 level (of a factor), n—a given value, a specification of

Dimensional quantities in the practice are presented only as

procedure or a specific setting of a factor. E1325

illustrations of calculation methods. The examples are not

3.1.3 Plackett-Burman designs, n—a set of screening de-

binding on products or test methods treated.

signs using orthogonal arrays that permit evaluation of the

1.4 This standard does not purport to address all of the

linear effects of up to n = t – 1 factors in a study of t treatment

safety concerns, if any, associated with its use. It is the

combinations. E1325

responsibility of the user of this standard to establish appro-

3.1.4 ruggedness, n—insensitivity of a test method to de-

priate safety, health, and environmental practices and deter-

partures from specified test or environmental conditions.

mine the applicability of regulatory limitations prior to use.

3.1.4.1 Discussion—An evaluation of the “ruggedness” of a

1.5 This international standard was developed in accor-

test method or an empirical model derived from an experiment

dance with internationally recognized principles on standard-

isusefulindeterminingwhethertheresultsordecisionswillbe

ization established in the Decision on Principles for the

relativelyinvariantoversomerangeofenvironmentalvariabil-

Development of International Standards, Guides and Recom-

ity under which the test method or the model is likely to be

mendations issued by the World Trade Organization Technical

applied.

Barriers to Trade (TBT) Committee.

3.1.5 ruggedness test, n—a planned experiment in which

2. Referenced Documents environmental factors or test conditions are deliberately varied

2 in order to evaluate the effects of such variation.

2.1 ASTM Standards:

3.1.5.1 Discussion—Since there usually are many environ-

E456Terminology Relating to Quality and Statistics

mental factors that might be considered in a ruggedness test, it

E1325Terminology Relating to Design of Experiments

is customary to use a “screening” type of experiment design

E1488GuideforStatisticalProcedurestoUseinDeveloping

which concentrates on examining many first order effects and

and Applying Test Methods

generallyassumesthatsecondordereffectssuchasinteractions

E2282Guide for Defining the Test Result of a Test Method

and curvature are relatively negligible. Often in evaluating the

ruggedness of a test method, if there is an indication that the

1 results of a test method are highly dependent on the levels of

ThispracticeisunderthejurisdictionofASTMCommitteeE11onQualityand

Statistics and is the direct responsibility of Subcommittee E11.20 on Test Method the environmental factors, there is a sufficient indication that

Evaluation and Quality Control.

certain levels of environmental factors must be included in the

Current edition approved Sept. 1, 2018. Published September 2018. Originally

specifications for the test method, or even that the test method

ɛ1

approved in 1987. Last previous edition approved in 2017 as E1169–17 . DOI:

itself will need further revision.

10.1520/E1169-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1.6 screening design, n—a balanced design, requiring

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

relatively minimal amount of experimentation, to evaluate the

Standards volume information, refer to t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E1169 − 17 E1169 − 18 An American National Standard

Standard Practice for

1

Conducting Ruggedness Tests

This standard is issued under the fixed designation E1169; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorial corrections were made throughout in April 2018.

1. Scope

1.1 This practice covers conducting ruggedness tests. The purpose of a ruggedness test is to identify those factors that strongly

influence the measurements provided by a specific test method and to estimate how closely those factors need to be controlled.

1.2 This practice restricts itself to designs with two levels per factor. The designs require the simultaneous change of the levels

of all of the factors, thus permitting the determination of the effects of each of the factors on the measured results.

1.3 The system of units for this practice is not specified. Dimensional quantities in the practice are presented only as illustrations

of calculation methods. The examples are not binding on products or test methods treated.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E456 Terminology Relating to Quality and Statistics

E1325 Terminology Relating to Design of Experiments

E1488 Guide for Statistical Procedures to Use in Developing and Applying Test Methods

E2282 Guide for Defining the Test Result of a Test Method

F2082 Test Method for Determination of Transformation Temperature of Nickel-Titanium Shape Memory Alloys by Bend and

Free Recovery

3. Terminology

3.1 Definitions—The terminology defined in Terminology E456 applies to this practice unless modified herein.

3.1.1 fractional factorial design, n—a factorial experiment in which only an adequately chosen fraction of the treatments

required for the complete factorial experiment is selected to be run. E1325

3.1.2 level (of a factor), n—a given value, a specification of procedure or a specific setting of a factor. E1325

3.1.3 Plackett-Burman designs, n—a set of screening designs using orthogonal arrays that permit evaluation of the linear effects

of up to n = t – 1 factors in a study of t treatment combinations. E1325

3.1.4 ruggedness, n—insensitivity of a test method to departures from specified test or environmental conditions.

3.1.4.1 Discussion—

1

This practice is under the jurisdiction of ASTM Committee E11 on Quality and Statistics and is the direct responsibility of Subcommittee E11.20 on Test Method

Evaluation and Quality Control.

Current edition approved Oct. 1, 2017Sept. 1, 2018. Published January 2018September 2018. Originally approved in 1987. Last previous edition approved in 20142017

ɛ1

as E1169 – 14.E1169 – 17 . DOI: 10.1520/E1169-17E01.10.1520/E1169-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1169 − 18

An evaluation of the “ruggedness” of a test method or an empirical model derived from an experiment is useful in determining

whether the results or decisions will be relatively invariant over some range of environmental variability under which the test

method or the model is likely to be applied.

3.1.5 ruggedness test, n—a planned experiment in which environmental factors or test conditions are deliberately varied in order

to evaluate the effects of such variation.

3.1.5.1 Discussion—

Since there usually are many environmental factors that might be considered in a ruggedness test, it is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.