ASTM E1488-12(2023)

(Guide)Standard Guide for Statistical Procedures to Use in Developing and Applying Test Methods

Standard Guide for Statistical Procedures to Use in Developing and Applying Test Methods

ABSTRACT

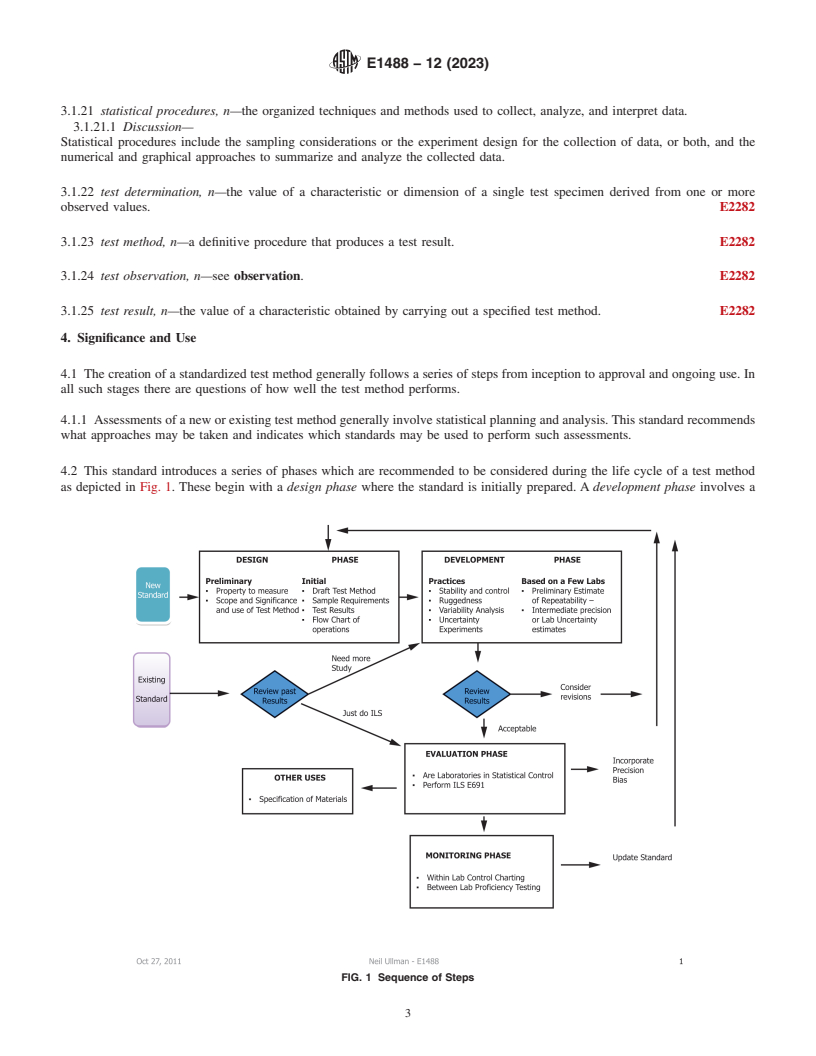

This guide identifies statistical procedures for use in developing new test methods or revising or evaluating existing test methods, or both. It also cites statistical procedures especially useful in the application of test methods. This standard recommends what approaches may be taken and indicates which standards may be used to perform such assessments.

SIGNIFICANCE AND USE

4.1 The creation of a standardized test method generally follows a series of steps from inception to approval and ongoing use. In all such stages there are questions of how well the test method performs.

4.1.1 Assessments of a new or existing test method generally involve statistical planning and analysis. This standard recommends what approaches may be taken and indicates which standards may be used to perform such assessments.

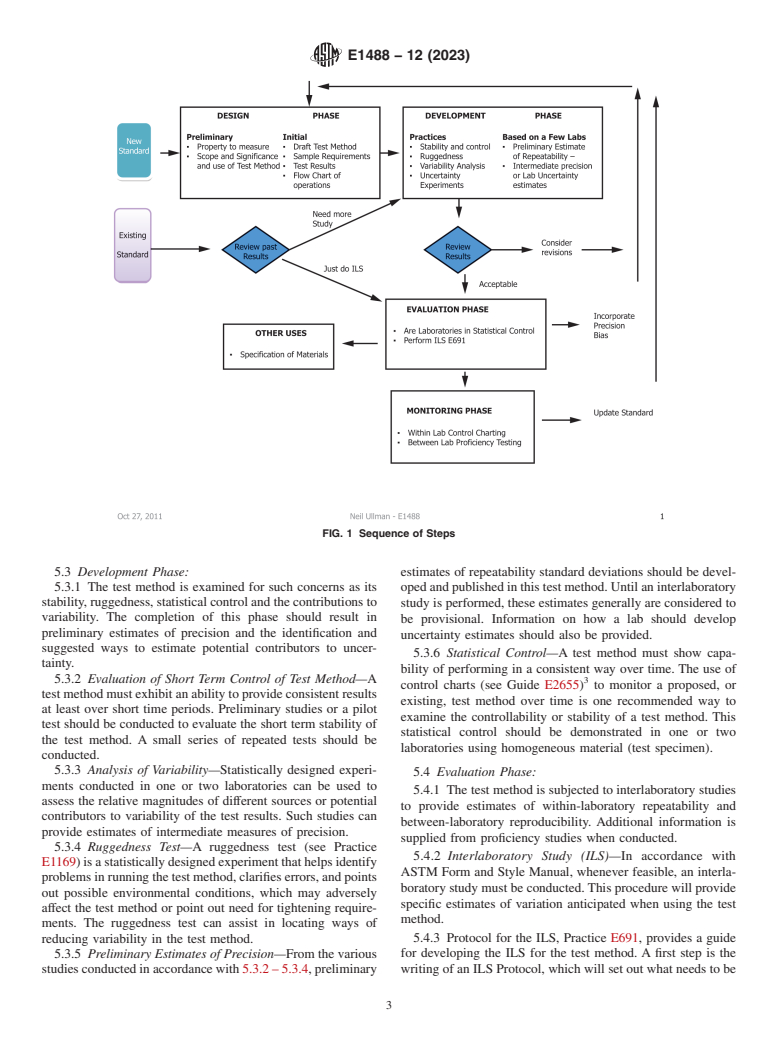

4.2 This standard introduces a series of phases which are recommended to be considered during the life cycle of a test method as depicted in Fig. 1. These begin with a design phase where the standard is initially prepared. A development phase involves a variety of experiments that allow further refinement and understanding of how the test method performs within a laboratory. In an evaluation phase the test method is then examined by way of interlaboratory studies resulting in precision and bias statistics which are published in the standard. Finally, the test method is subject to a monitoring phase.

FIG. 1 Sequence of Steps

4.3 All ASTM test methods are required to include statements on precision and bias.3

4.4 Since ASTM began to require all test methods to have precision and bias statements that are based on interlaboratory test methods, there has been increased concern regarding what statistical experiments and procedures to use during the development of the test methods. Although there exists a wide range of statistical procedures, there is a small group of generally accepted techniques that are beneficial to follow. This guide is designed to provide a brief overview of these procedures and to suggest an appropriate sequence of carrying out these procedures.

4.5 Statistical procedures often result in interpretations that are not absolutes. Sometimes the information obtained may be inadequate or incomplete, which may lead to additional questions and the need for further experimentation. Information outside the data is al...

SCOPE

1.1 This guide identifies statistical procedures for use in developing new test methods or revising or evaluating existing test methods, or both.

1.2 This guide also cites statistical procedures especially useful in the application of test methods.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1488 − 12 (Reapproved 2023) An American National Standard

Standard Guide for

Statistical Procedures to Use in Developing and Applying

Test Methods

This standard is issued under the fixed designation E1488; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E2655 Guide for Reporting Uncertainty of Test Results and

Use of the Term Measurement Uncertainty in ASTM Test

1.1 This guide identifies statistical procedures for use in

Methods

developing new test methods or revising or evaluating existing

test methods, or both.

3. Terminology

1.2 This guide also cites statistical procedures especially

3.1 Definitions—For a more extensive list of terms in E11

useful in the application of test methods.

standards, see Terminology E456.

1.3 This international standard was developed in accor-

3.1.1 bias, n—the difference between the expectation of the

dance with internationally recognized principles on standard-

test results and an accepted reference value. E177

ization established in the Decision on Principles for the

3.1.1.1 Discussion—Statistical procedures include the sam-

Development of International Standards, Guides and Recom-

pling considerations or the experiment design for the collection

mendations issued by the World Trade Organization Technical

of data, or both, and the numerical and graphical approaches to

Barriers to Trade (TBT) Committee.

summarize and analyze the collected data.

2. Referenced Documents

3.1.2 coeffıcient of variation, CV, n—for a nonnegative

characteristic, the ratio of the standard deviation to the mean

2.1 ASTM Standards:

for a population or sample. E2586

E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

3.1.3 component of variance, n—a part of a total variance

E178 Practice for Dealing With Outlying Observations

identified with a specified source of variability.

E456 Terminology Relating to Quality and Statistics

3.1.4 control chart, n—chart on which are plotted a statis-

E691 Practice for Conducting an Interlaboratory Study to

tical measure of a subgroup versus time of sampling along with

Determine the Precision of a Test Method

limits based on the statistical distribution of that measure so as

E1169 Practice for Conducting Ruggedness Tests

to indicate how much common, or chance, cause variation is

E1402 Guide for Sampling Design

inherent in the process or product. E2587

E2282 Guide for Defining the Test Result of a Test Method

3.1.5 observation, n—the process of obtaining information

E2489 Practice for Statistical Analysis of One-Sample and

Two-Sample Interlaboratory Proficiency Testing Programs regarding the presence or absence of an attribute of a test

specimen, or of making a reading on a characteristic or

E2554 Practice for Estimating and Monitoring the Uncer-

tainty of Test Results of a Test Method Using Control dimension of a test specimen. E2282

Chart Techniques

3.1.6 observed value, n—the value obtained by making an

E2586 Practice for Calculating and Using Basic Statistics

observation. E2282

E2587 Practice for Use of Control Charts in Statistical

3.1.7 precision, n—the closeness of agreement between

Process Control

independent test results obtained under stipulated conditions.

E177

This guide is under the jurisdiction of ASTM Committee E11 on Quality and

3.1.8 proficiency testing, n—determination of laboratory

Statistics and is the direct responsibility of Subcommittee E11.20 on Test Method

testing performance by means of interlaboratory comparisons.

Evaluation and Quality Control.

E2489

Current edition approved April 1, 2023. Published April 2023. Originally

approved in 1992. Last previous edition approved in 2018 as E1488 – 12 (2018).

3.1.9 repeatability, n—precision under repeatability condi-

DOI: 10.1520/E1488-12R23.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or tions. E177

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.1.10 repeatability conditions, n—conditions where inde-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. pendent test results are obtained with the same method on

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1488 − 12 (2023)

identical test items in the same laboratory by the same operator 4.1.1 Assessments of a new or existing test method gener-

using the same equipment within short intervals of time. E177 ally involve statistical planning and analysis. This standard

recommends what approaches may be taken and indicates

3.1.11 repeatability limit r, n—the value below which the

which standards may be used to perform such assessments.

absolute difference between two individual test results obtained

under repeatability conditions may be expected to occur with a

4.2 This standard introduces a series of phases which are

probability of approximately 0.95 (95 %). E177

recommended to be considered during the life cycle of a test

method as depicted in Fig. 1. These begin with a design phase

3.1.12 repeatability standard deviation, s , n—the standard

r

where the standard is initially prepared. A development phase

deviation of test results obtained under repeatability condi-

involves a variety of experiments that allow further refinement

tions. E177

and understanding of how the test method performs within a

3.1.13 reproducibility, n—precision under reproducibility

laboratory. In an evaluation phase the test method is then

conditions. E177

examined by way of interlaboratory studies resulting in preci-

3.1.14 reproducibility conditions, n—conditions where test

sion and bias statistics which are published in the standard.

results are obtained with the same method on identical test

Finally, the test method is subject to a monitoring phase.

items in different laboratories with different operators using

4.3 All ASTM test methods are required to include state-

different equipment. E177

ments on precision and bias.

3.1.15 reproducibility limit, R, n—the value below which

4.4 Since ASTM began to require all test methods to have

the absolute difference between two test results obtained under

precision and bias statements that are based on interlaboratory

reproducibility conditions may be expected to occur with a

test methods, there has been increased concern regarding what

probability of approximately 0.95 (95 %). E177

statistical experiments and procedures to use during the devel-

3.1.16 reproducibility standard deviation, s , n—the stan-

R

opment of the test methods. Although there exists a wide range

dard deviation of test results obtained under reproducibility

of statistical procedures, there is a small group of generally

conditions. E177

accepted techniques that are beneficial to follow. This guide is

3.1.17 ruggedness, n—insensitivity of a test method to

designed to provide a brief overview of these procedures and to

departures from specified test or environmental conditions.

suggest an appropriate sequence of carrying out these proce-

E1169

dures.

3.1.18 ruggedness test, n—a planned experiment in which

4.5 Statistical procedures often result in interpretations that

environmental factors or test conditions are deliberately varied

are not absolutes. Sometimes the information obtained may be

in order to evaluate the effects of such variation. E1169

inadequate or incomplete, which may lead to additional ques-

3.1.19 standard deviation, n—of a population, σ, the square tions and the need for further experimentation. Information

root of the average or expected value of the squared deviation

outside the data is also important in establishing standards and

of a variable from its mean – of a sample x¯, the square root of in the interpretation of numerical results.

the sum of the squared deviations of the observed values in the

5. Summary of Guide

sample divided by the sample size minus 1. E2586

5.1 Outlined below is a suggested sequence of four phases

3.1.20 state of statistical control, n—process condition

useful in the development of a test method. A flowchart is

when only common causes are operating on the process. E2587

provided in Fig. 1. Such a sequence of analyses may need to be

3.1.21 statistical procedures, n—the organized techniques

modified in specific situations. The assistance of a qualified

and methods used to collect, analyze, and interpret data.

statistician is recommended at each review phase.

3.1.21.1 Discussion—Statistical procedures include the

sampling considerations or the experiment design for the 5.2 Design Phase:

5.2.1 This phase includes the formalization of the scope and

collection of data, or both, and the numerical and graphical

approaches to summarize and analyze the collected data. the significance and use sections. It may include determining

the purpose and describing a general approach to the test

3.1.22 test determination, n—the value of a characteristic or

method but usually does not involve statistical studies.

dimension of a single test specimen derived from one or more

5.2.2 Studies may be conducted to evaluate the basic

observed values. E2282

performance of the method. The draft test method is prepared

3.1.23 test method, n—a definitive procedure that produces

and sampling requirements and the test result (see Guide

a test result. E2282

E2282) are clearly defined.

3.1.24 test observation, n—see observation. E2282

5.2.3 A flow chart is extremely valuable to identify the

sequence of operations involved in a test method, for example,

3.1.25 test result, n—the value of a characteristic obtained

the sampling steps required to obtain the test specimens,

by carrying out a specified test method. E2282

definition of the test determination, how a test result is to be

4. Significance and Use

computed, and running the tests on the specimens.

4.1 The creation of a standardized test method generally

follows a series of steps from inception to approval and

See the Form and Style Manual for ASTM Standards that specifies, when

ongoing use. In all such stages there are questions of how well

possible, precision statements shall be estimated based on the results of an

the test method performs. interlaboratory test program.

E1488 − 12 (2023)

FIG. 1 Sequence of Steps

5.3 Development Phase: estimates of repeatability standard deviations should be devel-

5.3.1 The test method is examined for such concerns as its

oped and published in this test method. Until an interlaboratory

stability, ruggedness, statistical control and the contributions to study is performed, these estimates generally are considered to

variability. The completion of this phase should result in

be provisional. Information on how a lab should develop

preliminary estimates of precision and the identification and

uncertainty estimates should also be provided.

suggested ways to estimate potential contributors to uncer-

5.3.6 Statistical Control—A test method must show capa-

tainty.

bility of performing in a consistent way over time. The use of

5.3.2 Evaluation of Short Term Control of Test Method—A

control charts (see Guide E2655) to monitor a proposed, or

test method must exhibit an ability to provide consistent results

existing, test method over time is one recommended way to

at least over short time periods. Preliminary studies or a pilot

examine the controllability or stability of a test method. This

test should be conducted to evaluate the short term stability of

statistical control should be demonstrated in one or two

the test method. A small series of repeated tests should be

laboratories using homogeneous material (test specimen).

conducted.

5.3.3 Analysis of Variability—Statistically designed experi-

5.4 Evaluation Phase:

ments conducted in one or two laboratories can be used to

5.4.1 The test method is subjected to interlaboratory studies

assess the relative magnitudes of different sources or potential

to provide estimates of within-laboratory repeatability and

contributors to variability of the test results. Such studies can

between-laboratory reproducibility. Additional information is

provide estimates of intermediate measures of precision.

supplied from proficiency studies when conducted.

5.3.4 Ruggedness Test—A ruggedness test (see Practice

5.4.2 Interlaboratory Study (ILS)—In accordance with

E1169) is a statistically designed experiment that helps identify

ASTM Form and Style Manual, whenever feasible, an interla-

problems in running the test method, clarifies errors, and points

boratory study must be conducted. This procedure will provide

out possible environmental conditions, which may adversely

specific estimates of variation anticipated when using the test

affect the test method or point out need for tightening require-

method.

ments. The ruggedness test can assist in locating ways of

reducing variability in the test method. 5.4.3 Protocol for the ILS, Practice E691, provides a guide

for developing the ILS for the test method. A first step is the

5.3.5 Preliminary Estimates of Precision—From the various

studies conducted in accordance with 5.3.2 – 5.3.4, preliminary writing of an ILS Protocol, which will set out what needs to be

E1488 − 12 (2023)

done before the test specimens (or test materials) are distrib- 6.3.1 Control charting, ruggedness tests, and variability

uted to the participating laboratories. analyses will be useful, especially if they have not previously

been conducted. Such tests may provide better information

5.4.4 Precision Statements—Using the estimates of varia-

tion obtained in the interlaboratory test, one may prepare about variation and necessary tolerances than has previously

been available.

precision statements using Practices E691 and E177 or equiva-

lent procedures. 6.3.2 If precision estimates have not been established

through an actual interlaboratory test program, then such a

5.5 Monitoring Phase:

program should be initiated.

5.5.1 After a test method is approved and in use it is

important to ensure that the published precision and bias

7. Data and Sampling

statistics for the test method remain achievable and consistent

7.1 Sample Determination:

over time or amongst different groups conducting the tests.

7.1.1 The sampling section of a standard should indicate

5.5.2 Monitoring Within a Single Location—It is important

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1488 − 12 (Reapproved 2023) An American National Standard

Standard Guide for

Statistical Procedures to Use in Developing and Applying

Test Methods

This standard is issued under the fixed designation E1488; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E2655 Guide for Reporting Uncertainty of Test Results and

Use of the Term Measurement Uncertainty in ASTM Test

1.1 This guide identifies statistical procedures for use in

Methods

developing new test methods or revising or evaluating existing

test methods, or both.

3. Terminology

1.2 This guide also cites statistical procedures especially

3.1 Definitions—For a more extensive list of terms in E11

useful in the application of test methods.

standards, see Terminology E456.

1.3 This international standard was developed in accor-

3.1.1 bias, n—the difference between the expectation of the

dance with internationally recognized principles on standard-

test results and an accepted reference value. E177

ization established in the Decision on Principles for the

3.1.1.1 Discussion—Statistical procedures include the sam-

Development of International Standards, Guides and Recom-

pling considerations or the experiment design for the collection

mendations issued by the World Trade Organization Technical

of data, or both, and the numerical and graphical approaches to

Barriers to Trade (TBT) Committee.

summarize and analyze the collected data.

2. Referenced Documents

3.1.2 coeffıcient of variation, CV, n—for a nonnegative

characteristic, the ratio of the standard deviation to the mean

2.1 ASTM Standards:

for a population or sample. E2586

E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

3.1.3 component of variance, n—a part of a total variance

E178 Practice for Dealing With Outlying Observations

identified with a specified source of variability.

E456 Terminology Relating to Quality and Statistics

3.1.4 control chart, n—chart on which are plotted a statis-

E691 Practice for Conducting an Interlaboratory Study to

tical measure of a subgroup versus time of sampling along with

Determine the Precision of a Test Method

limits based on the statistical distribution of that measure so as

E1169 Practice for Conducting Ruggedness Tests

to indicate how much common, or chance, cause variation is

E1402 Guide for Sampling Design

inherent in the process or product. E2587

E2282 Guide for Defining the Test Result of a Test Method

E2489 Practice for Statistical Analysis of One-Sample and 3.1.5 observation, n—the process of obtaining information

regarding the presence or absence of an attribute of a test

Two-Sample Interlaboratory Proficiency Testing Programs

E2554 Practice for Estimating and Monitoring the Uncer- specimen, or of making a reading on a characteristic or

dimension of a test specimen. E2282

tainty of Test Results of a Test Method Using Control

Chart Techniques

3.1.6 observed value, n—the value obtained by making an

E2586 Practice for Calculating and Using Basic Statistics

observation. E2282

E2587 Practice for Use of Control Charts in Statistical

3.1.7 precision, n—the closeness of agreement between

Process Control

independent test results obtained under stipulated conditions.

E177

This guide is under the jurisdiction of ASTM Committee E11 on Quality and

3.1.8 proficiency testing, n—determination of laboratory

Statistics and is the direct responsibility of Subcommittee E11.20 on Test Method

testing performance by means of interlaboratory comparisons.

Evaluation and Quality Control.

E2489

Current edition approved April 1, 2023. Published April 2023. Originally

approved in 1992. Last previous edition approved in 2018 as E1488 – 12 (2018).

3.1.9 repeatability, n—precision under repeatability condi-

DOI: 10.1520/E1488-12R23.

tions. E177

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.1.10 repeatability conditions, n—conditions where inde-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. pendent test results are obtained with the same method on

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1488 − 12 (2023)

identical test items in the same laboratory by the same operator 4.1.1 Assessments of a new or existing test method gener-

using the same equipment within short intervals of time. E177 ally involve statistical planning and analysis. This standard

recommends what approaches may be taken and indicates

3.1.11 repeatability limit r, n—the value below which the

which standards may be used to perform such assessments.

absolute difference between two individual test results obtained

under repeatability conditions may be expected to occur with a

4.2 This standard introduces a series of phases which are

probability of approximately 0.95 (95 %). E177

recommended to be considered during the life cycle of a test

method as depicted in Fig. 1. These begin with a design phase

3.1.12 repeatability standard deviation, s , n—the standard

r

where the standard is initially prepared. A development phase

deviation of test results obtained under repeatability condi-

involves a variety of experiments that allow further refinement

tions. E177

and understanding of how the test method performs within a

3.1.13 reproducibility, n—precision under reproducibility

laboratory. In an evaluation phase the test method is then

conditions. E177

examined by way of interlaboratory studies resulting in preci-

3.1.14 reproducibility conditions, n—conditions where test

sion and bias statistics which are published in the standard.

results are obtained with the same method on identical test

Finally, the test method is subject to a monitoring phase.

items in different laboratories with different operators using

4.3 All ASTM test methods are required to include state-

different equipment. E177

ments on precision and bias.

3.1.15 reproducibility limit, R, n—the value below which

4.4 Since ASTM began to require all test methods to have

the absolute difference between two test results obtained under

precision and bias statements that are based on interlaboratory

reproducibility conditions may be expected to occur with a

test methods, there has been increased concern regarding what

probability of approximately 0.95 (95 %). E177

statistical experiments and procedures to use during the devel-

3.1.16 reproducibility standard deviation, s , n—the stan-

R

opment of the test methods. Although there exists a wide range

dard deviation of test results obtained under reproducibility

of statistical procedures, there is a small group of generally

conditions. E177

accepted techniques that are beneficial to follow. This guide is

3.1.17 ruggedness, n—insensitivity of a test method to

designed to provide a brief overview of these procedures and to

departures from specified test or environmental conditions.

suggest an appropriate sequence of carrying out these proce-

E1169

dures.

3.1.18 ruggedness test, n—a planned experiment in which

4.5 Statistical procedures often result in interpretations that

environmental factors or test conditions are deliberately varied

are not absolutes. Sometimes the information obtained may be

in order to evaluate the effects of such variation. E1169

inadequate or incomplete, which may lead to additional ques-

3.1.19 standard deviation, n—of a population, σ, the square

tions and the need for further experimentation. Information

root of the average or expected value of the squared deviation outside the data is also important in establishing standards and

of a variable from its mean – of a sample x¯, the square root of

in the interpretation of numerical results.

the sum of the squared deviations of the observed values in the

5. Summary of Guide

sample divided by the sample size minus 1. E2586

5.1 Outlined below is a suggested sequence of four phases

3.1.20 state of statistical control, n—process condition

useful in the development of a test method. A flowchart is

when only common causes are operating on the process. E2587

provided in Fig. 1. Such a sequence of analyses may need to be

3.1.21 statistical procedures, n—the organized techniques

modified in specific situations. The assistance of a qualified

and methods used to collect, analyze, and interpret data.

statistician is recommended at each review phase.

3.1.21.1 Discussion—Statistical procedures include the

5.2 Design Phase:

sampling considerations or the experiment design for the

collection of data, or both, and the numerical and graphical 5.2.1 This phase includes the formalization of the scope and

the significance and use sections. It may include determining

approaches to summarize and analyze the collected data.

the purpose and describing a general approach to the test

3.1.22 test determination, n—the value of a characteristic or

method but usually does not involve statistical studies.

dimension of a single test specimen derived from one or more

5.2.2 Studies may be conducted to evaluate the basic

observed values. E2282

performance of the method. The draft test method is prepared

3.1.23 test method, n—a definitive procedure that produces

and sampling requirements and the test result (see Guide

a test result. E2282

E2282) are clearly defined.

3.1.24 test observation, n—see observation. E2282

5.2.3 A flow chart is extremely valuable to identify the

sequence of operations involved in a test method, for example,

3.1.25 test result, n—the value of a characteristic obtained

the sampling steps required to obtain the test specimens,

by carrying out a specified test method. E2282

definition of the test determination, how a test result is to be

4. Significance and Use

computed, and running the tests on the specimens.

4.1 The creation of a standardized test method generally

follows a series of steps from inception to approval and

See the Form and Style Manual for ASTM Standards that specifies, when

ongoing use. In all such stages there are questions of how well

possible, precision statements shall be estimated based on the results of an

the test method performs. interlaboratory test program.

E1488 − 12 (2023)

FIG. 1 Sequence of Steps

5.3 Development Phase: estimates of repeatability standard deviations should be devel-

5.3.1 The test method is examined for such concerns as its oped and published in this test method. Until an interlaboratory

stability, ruggedness, statistical control and the contributions to

study is performed, these estimates generally are considered to

variability. The completion of this phase should result in

be provisional. Information on how a lab should develop

preliminary estimates of precision and the identification and

uncertainty estimates should also be provided.

suggested ways to estimate potential contributors to uncer-

5.3.6 Statistical Control—A test method must show capa-

tainty.

bility of performing in a consistent way over time. The use of

5.3.2 Evaluation of Short Term Control of Test Method—A 3

control charts (see Guide E2655) to monitor a proposed, or

test method must exhibit an ability to provide consistent results

existing, test method over time is one recommended way to

at least over short time periods. Preliminary studies or a pilot

examine the controllability or stability of a test method. This

test should be conducted to evaluate the short term stability of

statistical control should be demonstrated in one or two

the test method. A small series of repeated tests should be

laboratories using homogeneous material (test specimen).

conducted.

5.3.3 Analysis of Variability—Statistically designed experi-

5.4 Evaluation Phase:

ments conducted in one or two laboratories can be used to

5.4.1 The test method is subjected to interlaboratory studies

assess the relative magnitudes of different sources or potential

to provide estimates of within-laboratory repeatability and

contributors to variability of the test results. Such studies can

between-laboratory reproducibility. Additional information is

provide estimates of intermediate measures of precision.

supplied from proficiency studies when conducted.

5.3.4 Ruggedness Test—A ruggedness test (see Practice

5.4.2 Interlaboratory Study (ILS)—In accordance with

E1169) is a statistically designed experiment that helps identify

ASTM Form and Style Manual, whenever feasible, an interla-

problems in running the test method, clarifies errors, and points

boratory study must be conducted. This procedure will provide

out possible environmental conditions, which may adversely

specific estimates of variation anticipated when using the test

affect the test method or point out need for tightening require-

method.

ments. The ruggedness test can assist in locating ways of

5.4.3 Protocol for the ILS, Practice E691, provides a guide

reducing variability in the test method.

5.3.5 Preliminary Estimates of Precision—From the various for developing the ILS for the test method. A first step is the

studies conducted in accordance with 5.3.2 – 5.3.4, preliminary writing of an ILS Protocol, which will set out what needs to be

E1488 − 12 (2023)

done before the test specimens (or test materials) are distrib- 6.3.1 Control charting, ruggedness tests, and variability

uted to the participating laboratories. analyses will be useful, especially if they have not previously

5.4.4 Precision Statements—Using the estimates of varia- been conducted. Such tests may provide better information

about variation and necessary tolerances than has previously

tion obtained in the interlaboratory test, one may prepare

precision statements using Practices E691 and E177 or equiva- been available.

6.3.2 If precision estimates have not been established

lent procedures.

through an actual interlaboratory test program, then such a

5.5 Monitoring Phase:

program should be initiated.

5.5.1 After a test method is approved and in use it is

important to ensure that the published precision and bias

7. Data and Sampling

statistics for the test method remain achievable and consistent

7.1 Sample Determination:

over time or amongst different groups conducting the tests.

7.1.1 The sampling section of a standard should indicate

5.5.2 Monitoring Within a Single Location—It is important

clearly what constitutes the primary sampling unit, how that

for any laboratory or organization that will use a particular test

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1488 − 12 (Reapproved 2018) E1488 − 12 (Reapproved 2023)An American National Standard

Standard Guide for

Statistical Procedures to Use in Developing and Applying

Test Methods

This standard is issued under the fixed designation E1488; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide identifies statistical procedures for use in developing new test methods or revising or evaluating existing test

methods, or both.

1.2 This guide also cites statistical procedures especially useful in the application of test methods.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E178 Practice for Dealing With Outlying Observations

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E1169 Practice for Conducting Ruggedness Tests

E1402 Guide for Sampling Design

E2282 Guide for Defining the Test Result of a Test Method

E2489 Practice for Statistical Analysis of One-Sample and Two-Sample Interlaboratory Proficiency Testing Programs

E2554 Practice for Estimating and Monitoring the Uncertainty of Test Results of a Test Method Using Control Chart Techniques

E2586 Practice for Calculating and Using Basic Statistics

E2587 Practice for Use of Control Charts in Statistical Process Control

E2655 Guide for Reporting Uncertainty of Test Results and Use of the Term Measurement Uncertainty in ASTM Test Methods

3. Terminology

3.1 Definitions—For a more extensive list of terms in E11 standards, see Terminology E456.

3.1.1 bias, n—the difference between the expectation of the test results and an accepted reference value. E177

3.1.1.1 Discussion—

This guide is under the jurisdiction of ASTM Committee E11 on Quality and Statistics and is the direct responsibility of Subcommittee E11.20 on Test Method Evaluation

and Quality Control.

Current edition approved April 1, 2018April 1, 2023. Published May 2018April 2023. Originally approved in 1992. Last previous edition approved in 20122018 as

ɛ1

E1488 – 12 (2018). . DOI: 10.1520/E1488-12R18.10.1520/E1488-12R23.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1488 − 12 (2023)

Statistical procedures include the sampling considerations or the experiment design for the collection of data, or both, and the

numerical and graphical approaches to summarize and analyze the collected data.

3.1.2 coeffıcient of variation, CV, n—for a nonnegative characteristic, the ratio of the standard deviation to the mean for a

population or sample. E2586

3.1.3 component of variance, n—a part of a total variance identified with a specified source of variability.

3.1.4 control chart, n—chart on which are plotted a statistical measure of a subgroup versus time of sampling along with limits

based on the statistical distribution of that measure so as to indicate how much common, or chance, cause variation is inherent in

the process or product. E2587

3.1.5 observation, n—the process of obtaining information regarding the presence or absence of an attribute of a test specimen,

or of making a reading on a characteristic or dimension of a test specimen. E2282

3.1.6 observed value, n—the value obtained by making an observation. E2282

3.1.7 precision, n—the closeness of agreement between independent test results obtained under stipulated conditions. E177

3.1.8 proficiency testing, n—determination of laboratory testing performance by means of interlaboratory comparisons. E2489

3.1.9 repeatability, n—precision under repeatability conditions. E177

3.1.10 repeatability conditions, n—conditions where independent test results are obtained with the same method on identical test

items in the same laboratory by the same operator using the same equipment within short intervals of time. E177

3.1.11 repeatability limit r, n—the value below which the absolute difference between two individual test results obtained under

repeatability conditions may be expected to occur with a probability of approximately 0.95 (95 %). E177

3.1.12 repeatability standard deviation, s , n—the standard deviation of test results obtained under repeatability conditions. E177

r

3.1.13 reproducibility, n—precision under reproducibility conditions. E177

3.1.14 reproducibility conditions, n—conditions where test results are obtained with the same method on identical test items in

different laboratories with different operators using different equipment. E177

3.1.15 reproducibility limit, R, n—the value below which the absolute difference between two test results obtained under

reproducibility conditions may be expected to occur with a probability of approximately 0.95 (95 %). E177

3.1.16 reproducibility standard deviation, s , n—the standard deviation of test results obtained under reproducibility conditions.

R

E177

3.1.17 ruggedness, n—insensitivity of a test method to departures from specified test or environmental conditions. E1169

3.1.18 ruggedness test, n—a planned experiment in which environmental factors or test conditions are deliberately varied in order

to evaluate the effects of such variation. E1169

3.1.19 standard deviation, n—of a population, σ, the square root of the average or expected value of the squared deviation of a

variable from its mean – of a sample x¯, the square root of the sum of the squared deviations of the observed values in the sample

divided by the sample size minus 1. E2586

3.1.20 state of statistical control, n—process condition when only common causes are operating on the process. E2587

E1488 − 12 (2023)

3.1.21 statistical procedures, n—the organized techniques and methods used to collect, analyze, and interpret data.

3.1.21.1 Discussion—

Statistical procedures include the sampling considerations or the experiment design for the collection of data, or both, and the

numerical and graphical approaches to summarize and analyze the collected data.

3.1.22 test determination, n—the value of a characteristic or dimension of a single test specimen derived from one or more

observed values. E2282

3.1.23 test method, n—a definitive procedure that produces a test result. E2282

3.1.24 test observation, n—see observation. E2282

3.1.25 test result, n—the value of a characteristic obtained by carrying out a specified test method. E2282

4. Significance and Use

4.1 The creation of a standardized test method generally follows a series of steps from inception to approval and ongoing use. In

all such stages there are questions of how well the test method performs.

4.1.1 Assessments of a new or existing test method generally involve statistical planning and analysis. This standard recommends

what approaches may be taken and indicates which standards may be used to perform such assessments.

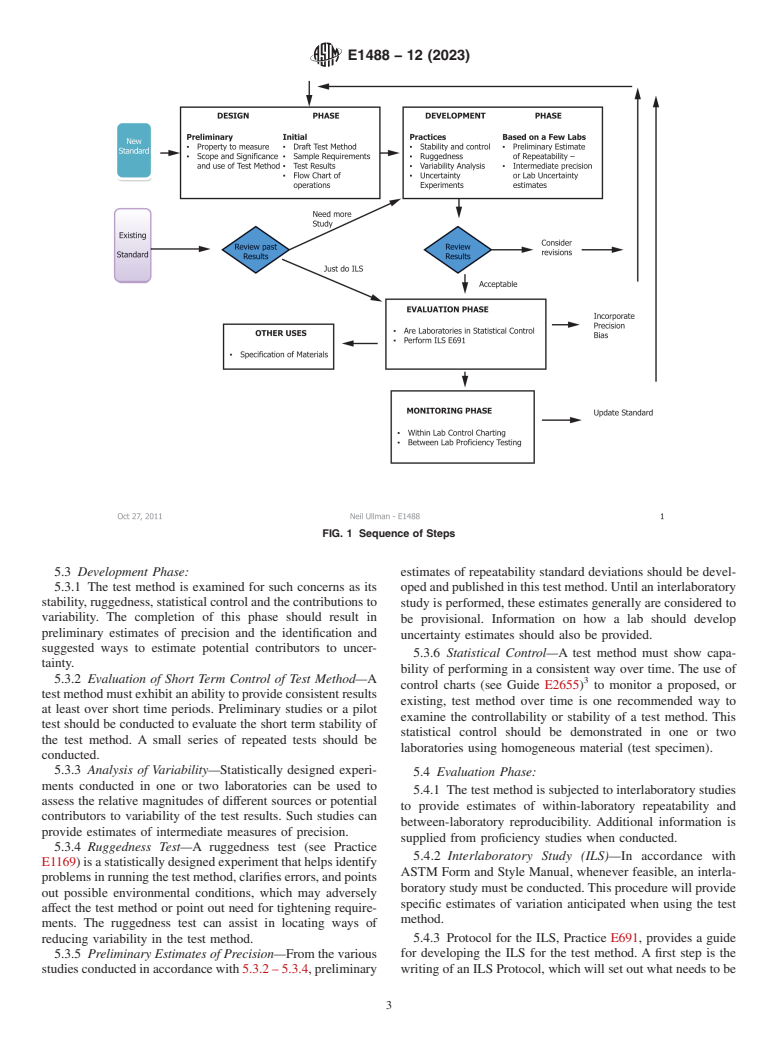

4.2 This standard introduces a series of phases which are recommended to be considered during the life cycle of a test method

as depicted in Fig. 1. These begin with a design phase where the standard is initially prepared. A development phase involves a

FIG. 1 Sequence of Steps

E1488 − 12 (2023)

variety of experiments that allow further refinement and understanding of how the test method performs within a laboratory. In

an evaluation phase the test method is then examined by way of interlaboratory studies resulting in precision and bias

statistics which are published in the standard. Finally, the test method is subject to a monitoring phase.

4.3 All ASTM test methods are required to include statements on precision and bias.

4.4 Since ASTM began to require all test methods to have precision and bias statements that are based on interlaboratory test

methods, there has been increased concern regarding what statistical experiments and procedures to use during the development

of the test methods. Although there exists a wide range of statistical procedures, there is a small group of generally accepted

techniques that are beneficial to follow. This guide is designed to provide a brief overview of these procedures and to suggest an

appropriate sequence of carrying out these procedures.

4.5 Statistical procedures often result in interpretations that are not absolutes. Sometimes the information obtained may be

inadequate or incomplete, which may lead to additional questions and the need for further experimentation. Information outside

the data is also important in establishing standards and in the interpretation of numerical results.

5. Summary of Guide

5.1 Outlined below is a suggested sequence of four phases useful in the development of a test method. A flowchart is provided

in Fig. 1. Such a sequence of analyses may need to be modified in specific situations. The assistance of a qualified statistician is

recommended at each review phase.

5.2 Design Phase:

5.2.1 This phase includes the formalization of the scope and the significance and use sections. It may include determining the

purpose and describing a general approach to the test method but usually does not involve statistical studies.

5.2.2 Studies may be conducted to evaluate the basic performance of the method. The draft test method is prepared and sampling

requirements and the test result (see Guide E2282) are clearly defined.

5.2.3 A flow chart is extremely valuable to identify the sequence of operations involved in a test method, for example, the

sampling steps required to obtain the test specimens, definition of the test determination, how a test result is to be computed, and

running the tests on the specimens.

5.3 Development Phase:

5.3.1 The test method is examined for such concerns as its stability, ruggedness, statistical control and the contributions to

variability. The completion of this phase should result in preliminary estimates of precision and the identification and suggested

ways to estimate potential contributors to uncertainty.

5.3.2 Evaluation of Short Term Control of Test Method—A test method must exhibit an ability to provide consistent results at least

over short time periods. Preliminary studies or a pilot test should be conducted to evaluate the short term stability of the test

method. A small series of repeated tests should be conducted.

5.3.3 Analysis of Variability—Statistically designed experiments conducted in one or two laboratories can be used to assess the

relative magnitudes of different sources or potential contributors to variability of the test results. Such studies can provide estimates

of intermediate measures of precision.

5.3.4 Ruggedness Test—A ruggedness test (see Practice E1169) is a statistically designed experiment that helps identify problems

in running the test method, clarifies errors, and points out possible environmental conditions, which may adversely affect the test

method or point out need for tightening requirements. The ruggedness test can assist in locating ways of reducing variability in

the test method.

5.3.5 Preliminary Estimates of Precision—From the various studies conducted in accordance with 5.3.2 – 5.3.4, preliminary

See the Form and Style Manual for ASTM Standards that specifies, when possible, precision statements shall be estimated based on the results of an interlaboratory test

program.

E1488 − 12 (2023)

estimates of repeatability standard deviations should be developed and published in this test method. Until an interlaboratory study

is performed, these estimates generally are considered to be provisional. Information on how a lab should develop uncertainty

estimates should also be provided.

5.3.6 Statistical Control—A test method must show capability of performing in a consistent way over time. The use of control

charts (see Guide E2655) to monitor a proposed, or existing, test method over time is one recommended way to examine the

controllability or stability of a test method. This statistical control should be demonstrated in one or two laboratories using

homogeneous material (test specimen).

5.4 Evaluation Phase:

5.4.1 The test method is subjected to interlaboratory studies to provide estimates of within-laboratory repeatability and

between-laboratory reproducibility. Additional information is supplied from proficiency studies when conducted.

5.4.2 Interlaboratory Study (ILS)—In accordance with ASTM Form and Style Manual, whenever feasible, an interlaboratory study

must be conducted. This procedure will provide specific estimates of variation anticipated when using the test method.

5.4.3 Protocol for the ILS, Practice E691, provides a guide for developing the ILS for the test method. A first step is the writing

of an ILS Protocol, which will set out what needs to be done before the test specimens (or test materials) are distributed to the

participating laboratories.

5.4.4 Precision Statements—Using the estimates of variation obtained in the interlaboratory test, one may prepare precision

statements using Practices E691 and E177 or equivalent procedures.

5.5 Monitoring Phase:

5.5.1 After a test method is approved and in use it is important to ensure that the published precision and bias statistics for the

test method remain achievable and consistent over time or amongst different groups conducting the tests.

5.5.2 Monitoring Within a Single Location—It is important for any laboratory or organization that will use a particular test method

over time that a means of monitoring to ensure the method results using quality control samples are stable and in control. Regular

evaluation of the uncertainty (Practice E2554) or use of a control ch

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.