ASTM D6130-11(2018)

(Test Method)Standard Test Method for Determination of Silicon and Other Elements in Engine Coolant by Inductively Coupled Plasma-Atomic Emission Spectroscopy

Standard Test Method for Determination of Silicon and Other Elements in Engine Coolant by Inductively Coupled Plasma-Atomic Emission Spectroscopy

SIGNIFICANCE AND USE

4.1 Some engine coolants are formulated with silicon containing additives. This test method provides a means of determining the concentration of dissolved or dispersed elements which give an indication of this additive content in the engine coolant.

SCOPE

1.1 This test method covers the determination of silicon in engine coolant by inductively coupled plasma-atomic emission spectroscopy (ICP-AES). Silicon can be determined as low as the range of 5 ppm by this test method. Other elements also found in engine coolant can be determined by this method. This test method is applicable to the determination of dissolved or dispersed elements.

1.2 This test method is applicable to both new and used engine coolant.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6130 − 11 (Reapproved 2018)

Standard Test Method for

Determination of Silicon and Other Elements in Engine

Coolant by Inductively Coupled Plasma-Atomic Emission

Spectroscopy

This standard is issued under the fixed designation D6130; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 This test method covers the determination of silicon in

E691 Practice for Conducting an Interlaboratory Study to

engine coolant by inductively coupled plasma-atomic emission

Determine the Precision of a Test Method

spectroscopy (ICP-AES). Silicon can be determined as low as

2.2 U.S. EPA Standards:

the range of 5 ppm by this test method. Other elements also

Method 6010, Inductively Coupled Plasma Method, SW-

found in engine coolant can be determined by this method.

846, Test Methods for Evaluating Solid Waste

Thistestmethodisapplicabletothedeterminationofdissolved

Method 200.7, Inductively Coupled Plasma - Atomic Emis-

or dispersed elements.

sion Spectrometric Method for Trace ElementAnalysis of

1.2 This test method is applicable to both new and used

Water And Wastes, EPA-600/4-79-020, revised 1984

engine coolant.

3. Summary of Test Method

1.3 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

3.1 Elements in solution are determined, either sequentially

standard. or simultaneously, by ICP-AES. New or used engine coolants

are prepared by dilution. Samples and standards are introduced

1.4 This standard does not purport to address all of the

to the nebulizer using a peristaltic pump and the aerosol is

safety concerns, if any, associated with its use. It is the

injected into an argon-supported inductively coupled plasma.

responsibility of the user of this standard to establish appro-

The high temperature of the plasma atomizes the sample and

priate safety, health, and environmental practices and deter-

produces atomic emission intensities at wavelengths associated

mine the applicability of regulatory limitations prior to use.

with the desired elements. Emission intensity is proportional to

1.5 This international standard was developed in accor-

concentration. Elemental determinations are made by compar-

dance with internationally recognized principles on standard-

ing standard and sample emission intensities.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

4. Significance and Use

mendations issued by the World Trade Organization Technical

4.1 Some engine coolants are formulated with silicon con-

Barriers to Trade (TBT) Committee.

taining additives. This test method provides a means of

2. Referenced Documents determining the concentration of dissolved or dispersed ele-

2 ments which give an indication of this additive content in the

2.1 ASTM Standards:

engine coolant.

D1193 Specification for Reagent Water

D1176 Practice for Sampling and Preparing Aqueous Solu-

5. Interferences

tions of Engine Coolants orAntirusts forTesting Purposes

5.1 Interferences may be categorized as follows:

5.1.1 Spectral—Light emission from spectral sources other

1 than the element of interest may contribute to apparent net

This test method is under the jurisdiction ofASTM Committee D15 on Engine

Coolants and Related Fluids and is the direct responsibility of Subcommittee signal intensity. Sources of spectral interference include direct

D15.04 on Chemical Properties.

spectral line overlaps, broadened wings of intense spectral

Current edition approved March 1, 2018. Published March 2018. Originally

lines, ion-atom recombination continuum emission, molecular

approved in 1997. Last previous edition approved in 2011 as D6130–11. DOI:

band emission and stray (scattered) light from the emission of

10.1520/D6130-11R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from U.S. Environmental Protection Agency, Environmental Moni-

the ASTM website. toring and Support Laboratory, Cincinnati, OH 45268.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6130 − 11 (2018)

TABLE 1 Analytical Wavelengths for ICP-AES Determination of

elements at high concentrations. Avoid overlaps by selecting

Elements in Engine Coolant

alternate analytical wavelengths.

Element Wavelength, nm

5.1.2 Physical—Physical interferences are effects associated

Mixed Standard 1

with sample nebulization and transport processes such as

Silicon 251.612, 288.158, 252.851, 252.411

viscosity and particulate contamination.

Molybdenum 202.030, 204.598

Boron 249.773

5.1.3 Background—High background effects from scattered

Phosphorus 214.914, 178.29

light, etc., can be compensated for by background correction

Mixed Standard 2

adjacent to the analyte line. Aluminum 308.215, 394.401, 369.152

Lead 220.353

5.1.4 Chemical—Chemical interferences are caused by mo-

Zinc 213.856

lecular compound formation, ionization effects, and thermo-

Iron 259.94, 259.837, 238.204

chemical effects associated with sample vaporization and Copper 324.754, 219.226

Magnesium 279.079, 280.270, 279.553

atomization in the plasma. Normally these effects are not

Calcium 317.933, 393.37, 396.847, 315.887

pronounced and can be minimized by careful selection of

Sodium 588.995, 589.592

operating conditions (incident power, plasma observation

position, etc.).

6. Apparatus

boron. Calibration should be validated and stability of stan-

dards should be monitored.

6.1 Spectrometer—An inductively coupled plasma emission

spectrometer of the simultaneous or sequential type including

10. Sample Preparation

RF generator, torch, nebulizer, spray chamber, recommended

peristaltic pump and host computer. 10.1 Dilute the sample with deionized water so the concen-

tration of the element(s) of interest is in the linear detection

1 1

7. Reagents and Materials range of the instrument. Generally a ⁄20 or ⁄50 dilution for used

engine coolant and a ⁄100 dilution for engine coolant concen-

7.1 PurityofChemicals—Reagent grade or better chemicals

trate are sufficient. Samples may be prepared by weight to

shall be used for preparation of all standards and samples.

volume or by volume to volume. Be certain when preparing

Other grades may be used provided it is first ascertained that

dilutions by volume that the entire sample aliquot is trans-

the reagent is of sufficiently high purity to permit its use

ferred. Filter or centrifuge samples that contain particulate.

without lessening the accuracy of the determination.

7.2 Purity of Water—References to water shall be under-

11. Procedure

stood to mean deionized water.

11.1 Aspirate the prepared samples into the calibrated

7.3 Standard Stock Solutions—Certified solutions may be

instrument using the same conditions established for the

purchased or prepared from high purity grade chemicals or

calibration procedure. Rinse sufficiently to prevent carryover.

metals (See Method 6010, SW-846, Method 200.7). Standards

Run water an additional 60 s between samples containing

contain 1000 mg/L of the element of interest. Salts should be

boron.

dried as indicated.

11.2 Run a blank and an instrument check standard (a

7.4 Calibration Standards—Prepare the standards in volu-

calibration standard, calibration verification or standard engine

metric flasks using appropriate volumes of each stock solution

coolant) every ten samples or as established to be necessary for

to cover the expected concentration range of the samples.

the instrument. Analyze a blank and check standard at the end

Elements in multielement standards should be shown to be

of each run. The concentration shall be within 65 % of the

compatible and stable. Compensate for differences in standard/

expected value. If the concentration is out of range, correct the

sample matrix by using an appropriate amount of ethylene

problem, recalibrate the instrument and rerun the samples in

glycoland/oraninternalstandard.Suggestedcombinationsand

question.

analytical lines are in Table 1. Validate calibration standards.

11.3 Matrix spikes and duplicates may be performed as

Monitor stability.

quality control procedures if sample concentrations are suspect

due to contamination, spectral interferences or trace levels of

8. Sampling

the element of interest.

8.1 Collect sample in accordance with Practice D1176.

11.4 Perform the corrections and calculations, including

dilution factors, using the instrument host computer.

9. Calibration and Standardization

9.1 Set the up instrument according to the manufacturer’s 12. Report

instructions. Warm it up at least 20 min.

12.1 Samplespreparedbyweighttovolumedilutionmaybe

9.2 Profile and calibrate the instrument according to manu- reported in ppm by weight or % by weight depending on the

facturer’s recommended procedures with the blank and concentration of the element of interest. Samples prepared by

standards, aspirating the standard for at

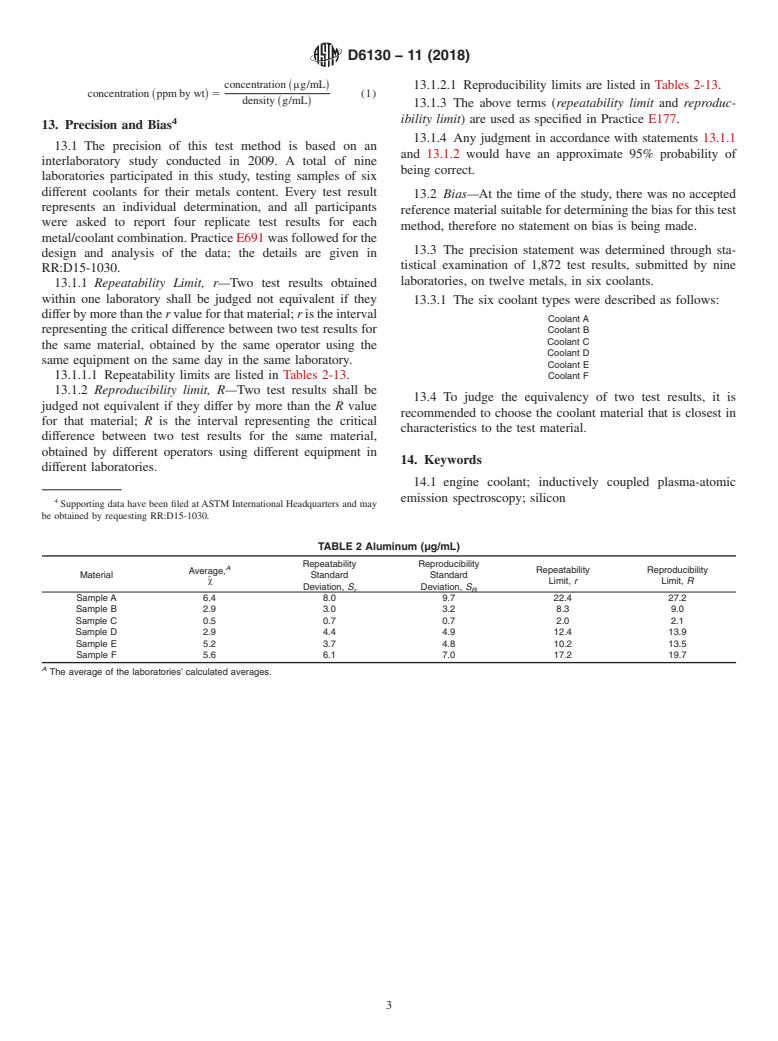

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.