ASTM A1023/A1023M-07

(Specification)Standard Specification for Stranded Carbon Steel Wire Ropes for General Purposes

Standard Specification for Stranded Carbon Steel Wire Ropes for General Purposes

ABSTRACT

This specification covers stranded steel wire ropes of various grades and constructions manufactured from uncoated or metallic coated wire and cord products manufactured from metallic coated wire. Dimensional characteristics include the diameter and lay length of the rope. Mechanical property requirements include: rope breaking force, spinning loss factor, and stretch; and wire torsions, tensile strength, tensile grade, and level. Cores of stranded ropes shall normally either be of steel or fiber composition. All wire ropes shall be lubricated and impregnated in the manufacturing process. Wire finish may be final-galvanized rope or drawn-galvanized (zinc coated) rope. Rope workmanship and finish; testing and compliance; acceptance tests; and packaging and identification are also detailed.

SCOPE

1.1 This specification covers the general requirements for the more common types of stranded steel wire ropes. Included in this specification are wire ropes in various grades and constructions from 1/4 in. (6 mm) to 23/8 in. (60 mm) manufactured from uncoated or metallic coated wire. Also included are cord products from 1/32 in. (0.8 mm) to 3/8 in. (10 mm) manufactured from metallic coated wire. For specific applications, additional or alternative requirements may apply.

1.2 The values stated in either inch-pounds or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A1023/A1023M – 07

Standard Specification for

1

Stranded Carbon Steel Wire Ropes for General Purposes

This standard is issued under the fixed designation A1023/A1023M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3.2 Lubrication:

3.2.1 impregnating compound, n—material used in the

1.1 This specification covers the general requirements for

manufacture of natural fiber cores, covers, or inserts for the

the more common types of stranded steel wire ropes. Included

purpose of providing protection against rotting and decay of

in this specification are wire ropes in various grades and

1 3 the fiber material.

constructions from ⁄4 in. (6 mm) to 2 ⁄8 in. (60 mm) manufac-

3.2.2 preservation compound, n—material, usually contain-

tured from uncoated or metallic coated wire.Also included are

1 3 ing some form of blocking agent, applied during, after, or both

cord products from ⁄32 in. (0.8 mm) to ⁄8 in. (10 mm)

during and after manufacture of the rope to fiber inserts, fillers,

manufactured from metallic coated wire. For specific applica-

and coverings for the purpose of providing protection against

tions, additional or alternative requirements may apply.

corrosion.

1.2 The values stated in either inch-pounds or SI units are to

3.2.3 rope lubricant, n—general term used to signify mate-

be regarded separately as standard.Within the text, the SI units

rial applied during the manufacture of a strand, core, or rope

are shown in brackets.The values stated in each system are not

for the purpose of reducing internal friction, providing protec-

exact equivalents; therefore, each system shall be used inde-

tion against corrosion, or both.

pendentlyoftheother.Combiningvaluesfromthetwosystems

3.3 rope cores, n—central element, usually of fiber or steel

may result in nonconformance with the specification.

(but may be a combination of both), of a round rope around

2. Referenced Documents

which are laid helically the strands of a stranded rope or the

2

unit ropes of a cable-laid rope (Fig. 1).

2.1 ASTM Standards:

3.3.1 fiber core (FC), n—an element made from either

A931 Test Method for Tension Testing of Wire Ropes and

natural or synthetic fibers.

Strand

3.3.2 solid polymer core, n—a single element of solid

A1007 Specification for Carbon Steel Wire for Wire Rope

3

polymer material that is either cylindrical or shaped (grooved).

2.2 ISO Standards:

It may also include an element or elements of wire or fiber.

ISO 2232 Round Drawn Wire for General-Purpose Non-

3.3.3 steel core, n—a stranded rope (IWRC), or a round

alloy Steel Wire Ropes

strand (WSC) construction. The round strand or the stranded

ISO 3108 Steel Wire Ropes for General Purposes—

rope core or its outer strands, or both, may also be covered or

Determination of Actual Breaking

filled with either fiber or solid polymer. Steel cores are

3. Terminology

normally made as a separate independent element, the excep-

tion being rope with a stranded rope core closed parallel with

Description of Terms Specific to this Specification

the outer strands.

3.1 inserts, n—fiber or solid polymer so positioned as to

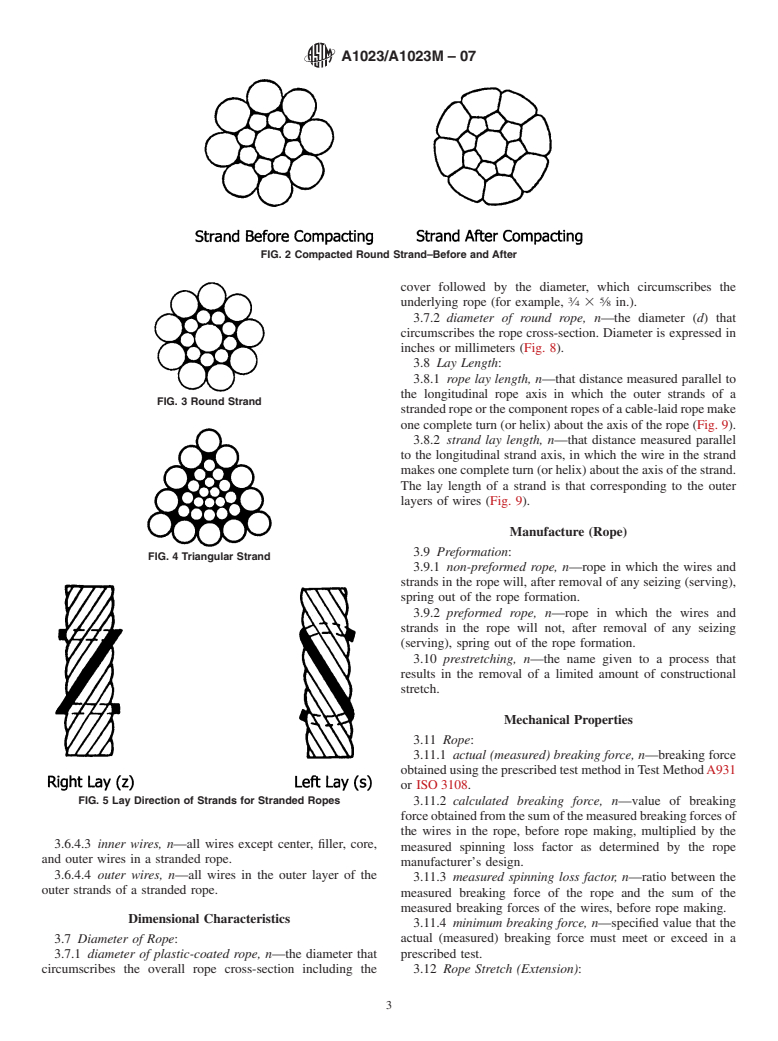

3.4 strand, n—an element of rope normally consisting of an

separate adjacent strands or wires in the same or overlying

assembly of wires of appropriate shape and dimensions laid

layers or to fill interstices of the rope.

helically in one or more layers around a center.The center may

consist of one round or shaped wire, of several round wires

forming a built-up center, or of fiber or some other material. If

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

multiple wires are used in a strand center, they may be counted

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.03 on Steel Rod and Wire. as one wire.

Current edition approved Sept. 1, 2007. Published October 2007. Originally

3.4.1 Cross-Section Shape:

approved in 2002. Last previous edition approved in 2002 asA1023/A1023M – 02.

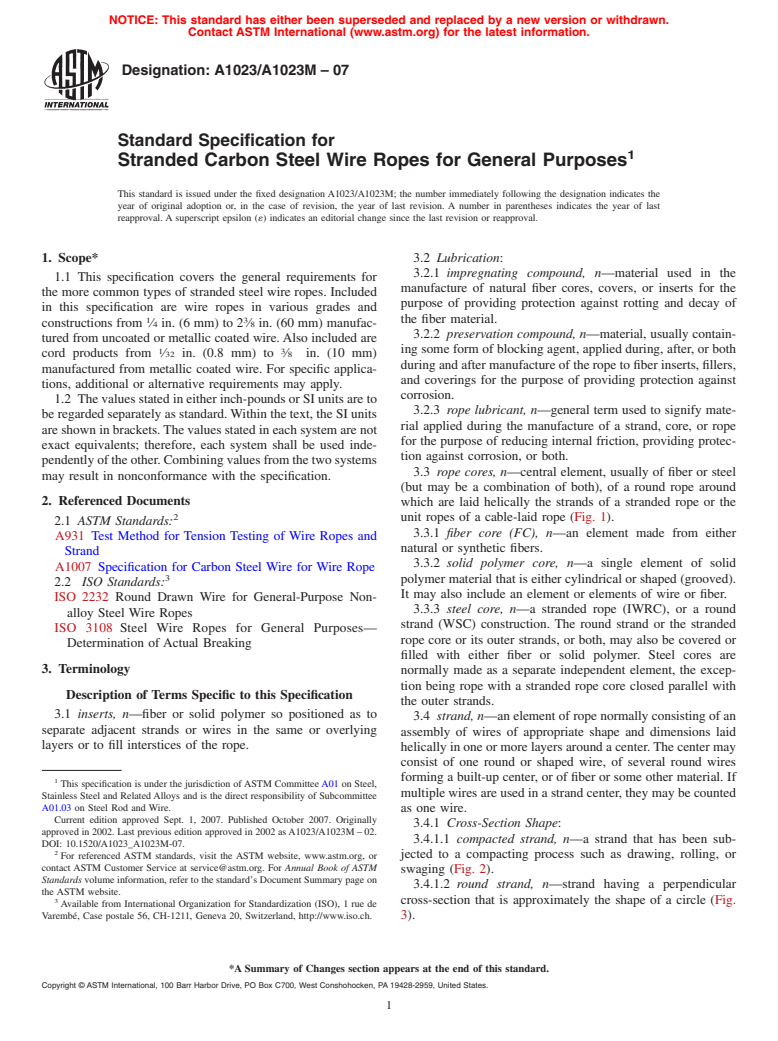

3.4.1.1 compacted strand, n—a strand that has been sub-

DOI: 10.1520/A1023_A1023M-07.

2

jected to a compacting process such as drawing, rolling, or

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

swaging (Fig. 2).

Standards volume information, refer to the standard’s Document Summary page on

3.4.1.2 round strand, n—strand having a perpendicular

the ASTM website.

3

cross-section that is approximately the shape of a circle (Fig.

Available from International Organization for Standardization (ISO), 1 rue de

Varembé, Case postale 56, C

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.