ASTM F459-84(2001)

(Test Method)Standard Test Methods for Measuring Pull Strength of Microelectronic Wire Bonds

Standard Test Methods for Measuring Pull Strength of Microelectronic Wire Bonds

SCOPE

1.1 These test methods cover tests to determine the pull strength of a series of wire bonds. Instructions are provided to modify the methods for use as a referee method. The methods can be used for wire bonds made with wire having a diameter of from 0.0007 to 0.003 in. (18 to 76 m).

Note 1--Common usage at the present time considers the term "wire bond" to include the entire interconnection: both welds and the intervening wire span.

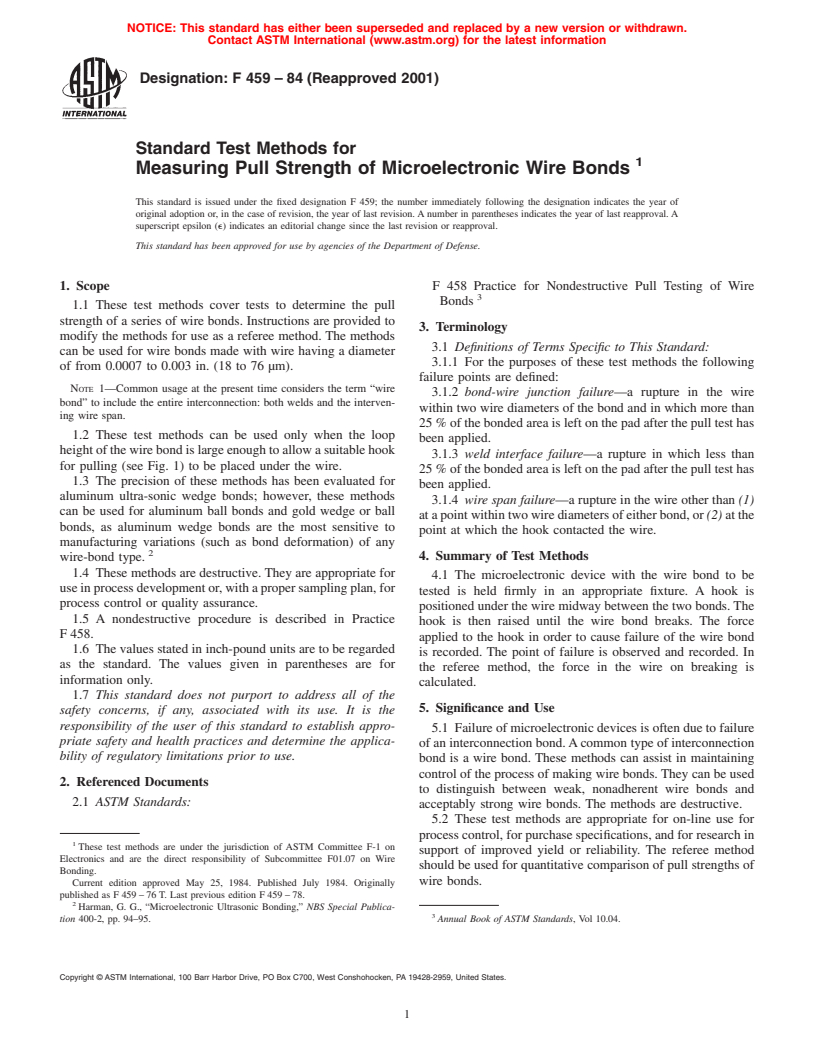

1.2 These test methods can be used only when the loop height of the wire bond is large enough to allow a suitable hook for pulling (see Fig. 1 ) to be placed under the wire.

1.3 The precision of these methods has been evaluated for aluminum ultra-sonic wedge bonds; however, these methods can be used for aluminum ball bonds and gold wedge or ball bonds, as aluminum wedge bonds are the most sensitive to manufacturing variations (such as bond deformation) of any wire-bond type.

1.4 These methods are destructive. They are appropriate for use in process development or, with a proper sampling plan, for process control or quality assurance.

1.5 A nondestructive procedure is described in Practice F458.

1.6 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 459 – 84 (Reapproved 2001)

Standard Test Methods for

Measuring Pull Strength of Microelectronic Wire Bonds

This standard is issued under the fixed designation F 459; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope F 458 Practice for Nondestructive Pull Testing of Wire

Bonds

1.1 These test methods cover tests to determine the pull

strength of a series of wire bonds. Instructions are provided to

3. Terminology

modify the methods for use as a referee method. The methods

3.1 Definitions of Terms Specific to This Standard:

can be used for wire bonds made with wire having a diameter

3.1.1 For the purposes of these test methods the following

of from 0.0007 to 0.003 in. (18 to 76 µm).

failure points are defined:

NOTE 1—Common usage at the present time considers the term “wire

3.1.2 bond-wire junction failure—a rupture in the wire

bond” to include the entire interconnection: both welds and the interven-

within two wire diameters of the bond and in which more than

ing wire span.

25 % of the bonded area is left on the pad after the pull test has

1.2 These test methods can be used only when the loop

been applied.

heightofthewirebondislargeenoughtoallowasuitablehook

3.1.3 weld interface failure—a rupture in which less than

for pulling (see Fig. 1) to be placed under the wire.

25 % of the bonded area is left on the pad after the pull test has

1.3 The precision of these methods has been evaluated for

been applied.

aluminum ultra-sonic wedge bonds; however, these methods

3.1.4 wire span failure—a rupture in the wire other than (1)

can be used for aluminum ball bonds and gold wedge or ball

atapointwithintwowirediametersofeitherbond,or (2)atthe

bonds, as aluminum wedge bonds are the most sensitive to

point at which the hook contacted the wire.

manufacturing variations (such as bond deformation) of any

4. Summary of Test Methods

wire-bond type.

1.4 These methods are destructive. They are appropriate for

4.1 The microelectronic device with the wire bond to be

useinprocessdevelopmentor,withapropersamplingplan,for

tested is held firmly in an appropriate fixture. A hook is

process control or quality assurance.

positioned under the wire midway between the two bonds. The

1.5 A nondestructive procedure is described in Practice

hook is then raised until the wire bond breaks. The force

F 458.

applied to the hook in order to cause failure of the wire bond

1.6 The values stated in inch-pound units are to be regarded

is recorded. The point of failure is observed and recorded. In

as the standard. The values given in parentheses are for

the referee method, the force in the wire on breaking is

information only.

calculated.

1.7 This standard does not purport to address all of the

5. Significance and Use

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5.1 Failure of microelectronic devices is often due to failure

priate safety and health practices and determine the applica-

of an interconnection bond.Acommon type of interconnection

bility of regulatory limitations prior to use.

bond is a wire bond. These methods can assist in maintaining

control of the process of making wire bonds. They can be used

2. Referenced Documents

to distinguish between weak, nonadherent wire bonds and

2.1 ASTM Standards:

acceptably strong wire bonds. The methods are destructive.

5.2 These test methods are appropriate for on-line use for

process control, for purchase specifications, and for research in

These test methods are under the jurisdiction of ASTM Committee F-1 on

support of improved yield or reliability. The referee method

Electronics and are the direct responsibility of Subcommittee F01.07 on Wire

should be used for quantitative comparison of pull strengths of

Bonding.

wire bonds.

Current edition approved May 25, 1984. Published July 1984. Originally

published as F 459 – 76 T. Last previous edition F 459 – 78.

Harman, G. G., “Microelectronic Ultrasonic Bonding,” NBS Special Publica-

tion 400-2, pp. 94–95. Annual Book of ASTM Standards, Vol 10.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 459

FIG. 1 Suggested Configuration for a Pulling Hook

6. Interferences either a horizontal or a tipped position so that both bonds are

in the same horizontal plane, for Method B. For the referee

6.1 Failure to center the hook along the loop between the

Method C, the device holder should provide a measurement, to

two bonds or pulling in a direction not lying in the plane

within2°,oftheanglefromthehorizontal(whichmaybezero)

containingtheundisturbedloopmayinvalidatethetestsincean

through which the device has been tipped.

unbalanced distribution of forces between the two bonds may

7.1.5 Calibration Masses—At least five masses (weights)

result.

with mass values known to within 0.5 % sized to cover the

6.2 Slippage of the hook along the wire span during pulling

lifting-and-gaging mechanism range of force measurement,

may invalidate the test because an unbalanced distribution of

and suitably configured so that they may be supported by the

forces between the two bonds may result.

pulling mechanism for calibration.

6.3 Careless insertion of the hook may damage either bond

or wire and thus invalidate the test.

8. Sampling

6.4 The presence of vibration or mechanical shock may

causetheapplicationofanextraneousforceandthusinvalidate

8.1 Since the pull-test method is destructive, it shall be

the test.

performed on a sampling basis. The sample selected should be

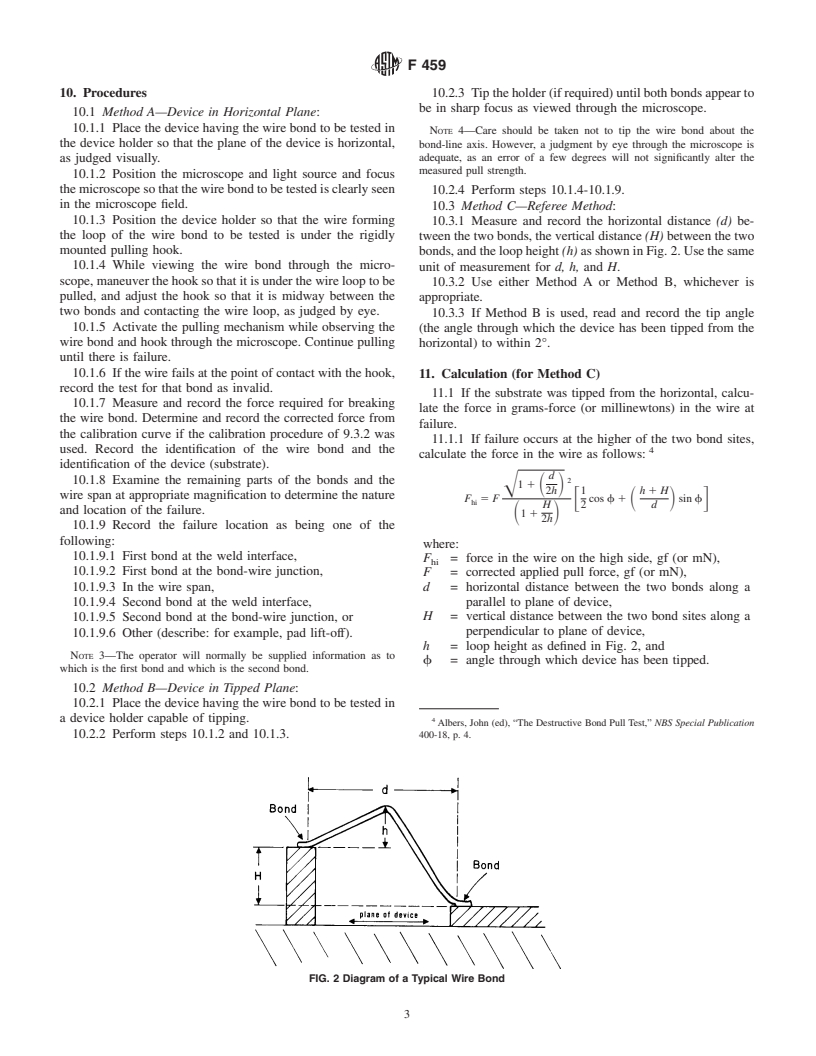

6.5 Measured bond-pull force is strongly dependent on the

representative of the wire bonds of interest. The size of the

height of the loop (H+h, as defined in 11.1.1) and the

sample and the method of selection shall be agreed upon by the

bond-to-bond spacing (d, as defined in 11.1.1).

parties to the test.

7. Apparatus

9. Calibration

7.1 Bond-Pulling Machine—Apparatus for measuring wire-

9.1 Calibrate the bond-pulling machine at the beginning of

bond pull strength with the following components:

eachseriesoftests,ordailyifaseriesspansmorethanoneday.

7.1.1 Hook—Pulling hook made from rigid wire such as

9.2 Assemble the bond-pulling machine in the same con-

tungsten.Thediameterofthatpartofthehookthatcontactsthe

figuration to be used to perform the wire-bond pull test.

wire loop should be approximately 2.5 times the diameter of

9.3 Calibrate the lifting-and-gaging mechanism.

the wire used to make the wire bond. A suggested hook

configurationisshowninFig.1.Thehookshouldappearunder

9.3.1 For mechanisms incorporating a calibration adjust-

visual inspection to have a smooth polished surface with no ment, either calibrate the mechanism in accordance with the

sharp edges in any part of the hook that contacts the wire loop. manufacturer’s instructions or in accordance with the proce-

The hook should be rigidly mounted in the pulling apparatus. dure of 9.3.2.

7.1.2 Lifting-and-Gaging Mechanism—Mechanism for ap-

9.3.2 For mechanisms without a calibration adjustment, use

plying a measured vertical force to the hook. The mechanism

the following procedure:

shall incorporate a means for recording the maximum force

9.3.2.1 Select masses that will provide at least five calibra-

appliedandshallbecapableofapplyingforceatarateconstant

tion points over the mechanism range.

to within 2 gf/s (20 mN/s) in the range from 1 to 30 gf/s (10 to

9.3.2.2 Attach a selected calibration mass to the lifting-and-

290 mN/s) inclusive. A mechanism with a single fixed scale

gaging mechanism. If a lever-arm mechanism (dynamometer

shallhaveamaximumscalereadingnogreaterthanthreetimes

or gram gage) is used, rotate the body of the gage in a manner

the nominal bond pull strength anticipated.

that maintains the arm (carrying the hook) in a horizontal

orientation.

NOTE 2—Mechanisms of the dynamometer type known as “gram

gages” have been found satisfactory.

9.3.2.3 Observe and rec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.