ASTM D5969-11e1

(Test Method)Standard Test Method for Corrosion-Preventive Properties of Lubricating Greases in Presence of Dilute Synthetic Sea Water Environments

Standard Test Method for Corrosion-Preventive Properties of Lubricating Greases in Presence of Dilute Synthetic Sea Water Environments

SIGNIFICANCE AND USE

5.1 This test method differentiates the relative corrosion-preventive capabilities of lubricating greases under the test conditions.

SCOPE

1.1 This test method covers the determination of the corrosion-preventive properties of greases using grease-lubricated tapered roller bearings exposed to various concentrations of dilute synthetic sea water stored under wet conditions. It is based on Test Method D1743, which is practiced using a similar procedure and distilled water. The reported result is a pass or fail rating as determined by at least two of three bearings.

1.2 Apparatus Dimensions—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 All Other Values—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D5969 − 11

StandardTest Method for

Corrosion-Preventive Properties of Lubricating Greases in

1

Presence of Dilute Synthetic Sea Water Environments

This standard is issued under the fixed designation D5969; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Fig. 6 was editorially reinstated in January 2013.

1. Scope* 3. Terminology

3.1 Definitions of Terms Specific to This Standard:

1.1 This test method covers the determination of the

corrosion-preventive properties of greases using grease-

3.1.1 corrosion—the chemical or electrochemical reaction

lubricated tapered roller bearings exposed to various concen-

between a material, usually a metal, and its environment that

trations of dilute synthetic sea water stored under wet condi-

produces a deterioration of the material and its properties.

tions. It is based on Test Method D1743, which is practiced

3.1.1.1 Discussion—In this test method, corrosion is mani-

using a similar procedure and distilled water. The reported

fested by red rust or black stains on the bearing race. Stains,

result is a pass or fail rating as determined by at least two of

through which the underlying metal surface is still visible, are

three bearings.

not considered corrosion in Test Method D5969 and shall be

1.2 Apparatus Dimensions—The values stated in inch- ignored. D1743

pound units are to be regarded as standard.The values given in

parentheses are mathematical conversions to SI units that are 4. Summary of Test Method

provided for information only and are not considered standard.

4.1 New, cleaned, and lubricated bearings are run under a

1.3 All Other Values—The values stated in SI units are to be

light thrust load for 60 6 3 s to distribute the lubricant in a

regarded as standard. No other units of measurement are

pattern that might be found in service. The bearings are

included in this standard.

exposedtoasolutionofsyntheticseawateratsomepercentage

1

in distilled water, then stored for 24 6 ⁄2hat52 6 1°C and

1.4 This standard does not purport to address all of the

100 % relative humidity. After cleaning, the bearing cups are

safety concerns, if any, associated with its use. It is the

examined for evidence of corrosion.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Significance and Use

bility of regulatory limitations prior to use.

5.1 This test method differentiates the relative corrosion-

2. Referenced Documents

preventive capabilities of lubricating greases under the test

2

2.1 ASTM Standards: conditions.

D665 Test Method for Rust-Preventing Characteristics of

Inhibited Mineral Oil in the Presence of Water 6. Apparatus

D1193 Specification for Reagent Water

6.1 Bearings, Timken bearing cone and roller assembly

D1743 Test Method for Determining Corrosion Preventive

3

LM11949 and cup LM11910.

Properties of Lubricating Greases

1

6.2 Motor, 1750-rpm (approximate) speed, ⁄15 hp (min).

6.3 Bearing Holder, (see Fig. 1) consists of a 1 6 0.01-kg

1

This test method is under the jurisdiction of ASTM Committee D02 on

mass, upper and lower plastic collars for the bearing cone

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

(PartsAand B), a metal screw, and a plastic collar for the cup

D02.G0.06 on Functional Tests - Contamination.

(Part C).

Current edition approved May 1, 2011. Published May 2011. Originally

approved in 1996. Last previous edition approved in 2008 as D5969–08. DOI:

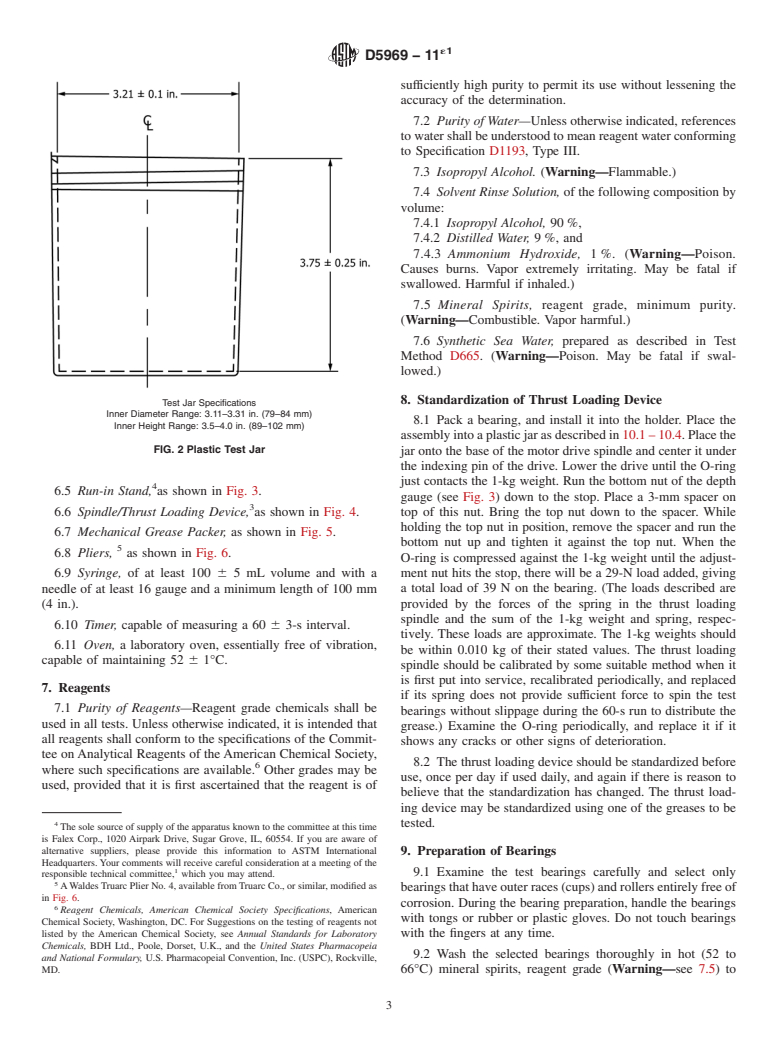

6.4 Plastic Test Jar, as shown in Fig. 2.

10.1520/D5969-11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

3

the ASTM website. Manufactured by the Timken Co., Canton, OH 44706.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D5969 − 11

KEY DESCRIPTION QUANTITY

1 PISTON 1

2 O RING 1

3 WEIGHT 1

4 UPPER FLANGE 1

5 LOWER FLANGE 1

1 1

6 ⁄4−20×1- ⁄4 FILLISTER HD. MACH. SCREW S.S. 1

7 O RING 1

8 BEARING HOLDER 1

9 PLASTIC JAR 1

10 O RING 1

FIG. 1 Test Method D1743 Bearing Holder Assembly

2

---------------------- Page: 2 ----------------------

´1

D5969 − 11

sufficiently high purity to permit its use without lessening the

accuracy of the determination.

7.2 Purity of Water—Unless otherwise indicated, referenc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.