ASTM D542-00(2006)

(Test Method)Standard Test Method for Index of Refraction of Transparent Organic Plastics

Standard Test Method for Index of Refraction of Transparent Organic Plastics

SIGNIFICANCE AND USE

This test method measures a fundamental property of matter which is useful for the control of purity and composition for simple identification purposes, and for optical parts design. This test method is capable of readability to four figures to the right of the decimal point.

SCOPE

1.1 This test method covers a procedure for measuring the index of refraction of transparent organic plastic materials.

1.2 A refractometer method is presented. This procedure will satisfactorily cover the range of refractive indices found for such materials. Refractive index measurements require optically homogeneous specimens of uniform refractive index.Note 1This test method and ISO 489-1983 are technically equivalent.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D542 − 00(Reapproved 2006)

Standard Test Method for

Index of Refraction of Transparent Organic Plastics

This standard is issued under the fixed designation D542; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 3.1.1 For definitions of terms used in this test method, see

Terminologies D883 and E284.

1.1 This test method covers a procedure for measuring the

3.1.2 dispersion—variation of refractive index with wave

index of refraction of transparent organic plastic materials.

length of light. C162, C14

1.2 A refractometer method is presented. This procedure

3.1.3 index of refraction, n—thenumericalexpressionofthe

will satisfactorily cover the range of refractive indices found

ratio of the velocity of light in a vacuum to the velocity of light

for such materials. Refractive index measurements require

in a substance at a specified wavelength. E284, E12

optically homogeneous specimens of uniform refractive index.

NOTE 1—This test method and ISO 489-1983 are technically equiva-

4. Significance and Use

lent.

4.1 This test method measures a fundamental property of

1.3 This standard does not purport to address all of the

matterwhichisusefulforthecontrolofpurityandcomposition

safety concerns, if any, associated with its use. It is the

for simple identification purposes, and for optical parts design.

responsibility of the user of this standard to establish appro-

This test method is capable of readability to four figures to the

priate safety and health practices and determine the applica-

right of the decimal point.

bility of regulatory limitations prior to use.

5. Apparatus

2. Referenced Documents

5.1 The apparatus for this test method shall consist of an

2.1 ASTM Standards:

Abbe’ refractometer (Note 2), a suitable source of white light,

C162 Terminology of Glass and Glass Products

and a small quantity of a suitable contacting liquid (Note 2 and

D618 Practice for Conditioning Plastics for Testing

Note 3).

D883 Terminology Relating to Plastics

D1898 Practice for Sampling of Plastics (Withdrawn 1998)

NOTE 2—Other suitable refractometers can be used with appropriate

modification to this procedure as described in Section 7.

E284 Terminology of Appearance

NOTE3—Asatisfactorycontactingliquidisonewhichwillnotsoftenor

E691 Practice for Conducting an Interlaboratory Study to

otherwiseattackthesurfaceoftheplasticwithinaperiodof2hofcontact.

Determine the Precision of a Test Method

The index of refraction of the liquid must be higher, but not less than one

2.2 ISO Standard:

unit in the second decimal place, than the index of the plastic being

ISO 489-1983 Determination of the Refractive Index of

measured; for example, n of the sample = 1.500, n of the contacting

d d

liquid ≥1.510.

Transparent Plastics—Part A

3. Terminology

6. Sampling

3.1 Definitions:

6.1 Samples shall be in accordance with the pertinent

considerations outlined in Practice D1898.

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

6.2 Samples may be drawn from any materials presentation

and is the direct responsibility of Subcommittee D20.40 on Optical Properties.

(for example, pellets, film, sheet, fabricated articles, etc.)

Current edition approved Sept. 1, 2006. Published September 2006. Originally

which permits preparation of a satisfactory specimen as de-

approved in 1939. Last previous edition approved in 2000 as D542 - 00. DOI:

10.1520/D0542-00R06. scribed herein.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7. Test Specimens

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

7.1 The test specimen shall be of a size that will conve-

The last approved version of this historical standard is referenced on

niently fit on the face of the fixed half of the refractometer

www.astm.org.

prisms(Note4).Aspecimenmeasuring6.3by12.7mmonone

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036. face is usually satisfactory.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D542 − 00 (2006)

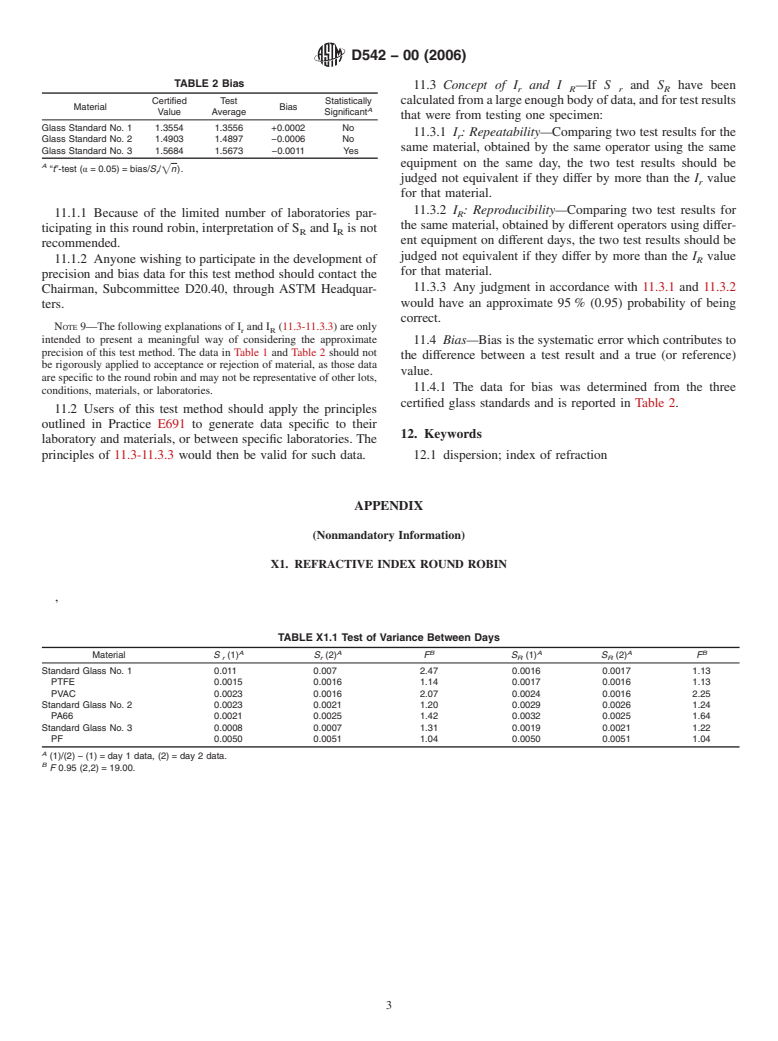

NOTE 4—For maximum accuracy in the refractometer method, the TABLE 1 Precision

surface contacting the prism must be flat. This surface can be judged for A B C D

Material Average S S I I

r R r R

flatness, provided the specimen has been satisfactorily polished, by

Glass Standard No. 1 1.356 0.001 0.002 0.003 0.006

observing the sharpness of the dividing line between the light and dark

PTFE 1.366 0.001 0.002 0.003 0.006

field as viewed in the ocular. A sharply defined straight dividing line

PVCA 1.477 0.002 0.002 0.006 0.006

indicates satisfactory contact between the specimen and prism surfaces.

Glass Standard No. 2 1.490 0.002 0.003 0.006 0.008

PA66 0.537 0.002 0.003 0.006 0.008

7.2 The surface to be used in contact with the prism shall be

Glass Standard No. 3 1.567 0.001 0.002 0.002 0.006

flat and shall have a good polish. A second edge surface

PF 1.614 0.004 0.004 0.011 0.011

perpendicular to the first and on one end of the specimen shall A

S = within-laboratory standard deviation.

r

B

be prepared with a fair polish (Note 5). The polished surfaces S = between-laboratories standard deviation.

R

C

I = 2.83 S .

r r

shall intersect without a beveled or rounded edge.

D

I = 2.83 S .

R R

NOTE 5—It has been found possible to prepare a satisfactorily polished

surfacebyhandpolishingsmallspecimensonanabrasivematerialbacked

by a piece of plate glass. Fine emery paper (for example, No. 000

Behr-Manning polishing paper) followed by a polishing rouge compound

suspended in water on a piece of parchment paper has successfully been 10. Report

used as the abrasive to produce a polished surface.

10.1 Report the following information:

7.3 A minimum of three specimens should be prepared and

10.1.1 The index of refraction to the nearest significant

measured.

figure warranted by the accuracy and duplicability of the

measurement. If the index is specified to more than three

8. Conditioning

significant figures, the wavelength of light for which the

measurement was made shall be specified.

8.1 Conditioning—Condition the test specimens at 23 6

2°Cand50 65 %relativehumidityfornotlessthan40hprior

NOTE 7—In the case of nonisotropic materials, for example, injection-

andcompression-moldedmaterials,theindexobservedwillbetheaverage

to the test in accordance with ProcedureAof Practice D618.In

value for a thin layer of small area at a point of contact near the center of

cases of disagreement, the tolerances should be 61°C and

the refractometer prism. For a complete and accurate determination of the

62 % relative humidity.

variationoftheindexthroughoutthetestspecimen,itisnecessarytomake

the measurement at more than one point on the surface and within the

8.2 Test Conditions—Conduct tests at 23 6 2°C and 50 6

body of the material. This can be done by preparing a contacting surface

5 % relative humidity, unless otherwise directed in a pertinent

both perpendicular and parallel to the molding pressure or flow.After the

specification. In cases of disagreement, the tolerances shall be

test specimen is contacted to the prism it may be translated carefully for

61°C and 62 % relative humidity. If the index of refraction of

short distances along the prism surface in the direction of the light source

the material is found to be highly temperature dependent, then while the variation of index is foll

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.