ASTM D3775-08

(Test Method)Standard Test Method for Warp (End) and Filling (Pick) Count of Woven Fabrics

Standard Test Method for Warp (End) and Filling (Pick) Count of Woven Fabrics

SIGNIFICANCE AND USE

This test method is considered satisfactory for acceptance testing of commercial shipments because it has been used extensively in the trade for that purpose.

If there are differences of practical significance between reported test results for two laboratories (or more), comparative test should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, use the samples for such a comparative test that are as homogeneous as possible, drawn from the same lot of material as the samples that resulted in disparate results during initial testing and randomly assigned in equal numbers to each laboratory. The test results from the laboratories involved should be compared using a statistical test for unpaired data, a probability level chosen prior to the testing series. If bias is found, either its cause must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

SCOPE

1.1 This test method covers the measurement of warp end count and filling pick count and is applicable to all types of woven fabrics.

Note 1—Historically, the term fabric count has been used to describe the end and pick count of woven fabrics. The terms warp (end) and filling (pick) count are replacing the term fabric count, to provide clarity.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3775 − 08

StandardTest Method for

1

Warp (End) and Filling (Pick) Count of Woven Fabrics

This standard is issued under the fixed designation D3775; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.1 The following terms are relevant to this standard:

count, end, end count, filling, pick, pick count, thread count.

1.1 This test method covers the measurement of warp end

thread count

count and filling pick count and is applicable to all types of

woven fabrics. 3.2 For all terminology related to Home Furnishings, refer

to Terminology D7023.

NOTE 1—Historically, the term fabric count has been used to describe

the end and pick count of woven fabrics. The terms warp (end) and filling

3.3 For all other terms related to textiles, refer to Terminol-

(pick) count are replacing the term fabric count, to provide clarity.

ogy D123.

1.2 The values stated in SI units are to be regarded as the

4. Summary of Test Method

standard. The values given in parentheses are for information

only.

4.1 The number of warp yarns (ends) per unit distance and

1.3 This standard does not purport to address all of the filling yarns (picks) per unit distance are determined using

safety concerns, if any, associated with its use. It is the

suitable magnifying and counting devices or by raveling yarns

responsibility of the user of this standard to establish appro- from fabrics. See ANSI Z1.4.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 5. Significance and Use

5.1 This test method is considered satisfactory for accep-

2. Referenced Documents

tancetestingofcommercialshipmentsbecauseithasbeenused

2

2.1 ASTM Standards:

extensively in the trade for that purpose.

D123 Terminology Relating to Textiles 5.1.1 If there are differences of practical significance be-

D1776 Practice for Conditioning and Testing Textiles tween reported test results for two laboratories (or more),

D4850 Terminology Relating to Fabrics and Fabric Test comparative test should be performed to determine if there is a

Methods statistical bias between them, using competent statistical assis-

D7023 Terminology Relating to Home Furnishings tance. As a minimum, use the samples for such a comparative

test that are as homogeneous as possible, drawn from the same

2.2 Other Standard:

3

lot of material as the samples that resulted in disparate results

ANSI/ASQC Z1.4—Inspection by Attributes

during initial testing and randomly assigned in equal numbers

to each laboratory. The test results from the laboratories

3. Terminology

involved should be compared using a statistical test for

3.1 For all terminology related to D13.59, Fabric Test

unpaired data, a probability level chosen prior to the testing

Methods, General, refer to Terminology D4850

series. If bias is found, either its cause must be found and

corrected, or future test results for that material must be

adjusted in consideration of the known bias.

1

This test method is under the jurisdiction of ASTM Committee D13 on Fabric

Test Methods, Specific

6. Apparatus

Current edition approved July 1, 2008. Published July 2008. Replaces Sections

6.1 Use any suitable device, such as pick glass, rule and

28 to 34 of Methods D1910 – 64 (1975). Originally approved in 1979 as

D3775 – 79. Last previous edition approved in 2007 as D3775 – 07a. DOI:

pointer, microfilm reader, or projection equipment. The use of

10.1520/D3775-08.

optical sensing equipment may be used as agreed upon by the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

purchaser and supplier.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer tot he standard’s Document Summary page on

1

6.2 Use a scale graduated in mm ( ⁄16 in.) to measure the

the ASTM website.

3

width of the fabric test specimen to be raveled for a count of

Available from American National Standards Institute, 11 W. 42nd St., 13th

Floor, New York, NY 10036. yarns.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3775 − 08

7. Sampling 9.3 Specific Fabric Counts

9.3.1 For fabrics containing less than 1 yarn per mm (25

7.1 Lot Sample—As a lot sample for acceptance testing,

yarns per in), count the number of warp yarns (ends) over a 75

take at random the number of rolls of fabric as directed in an

mm (3 in.) width, in five randomly selected places ac

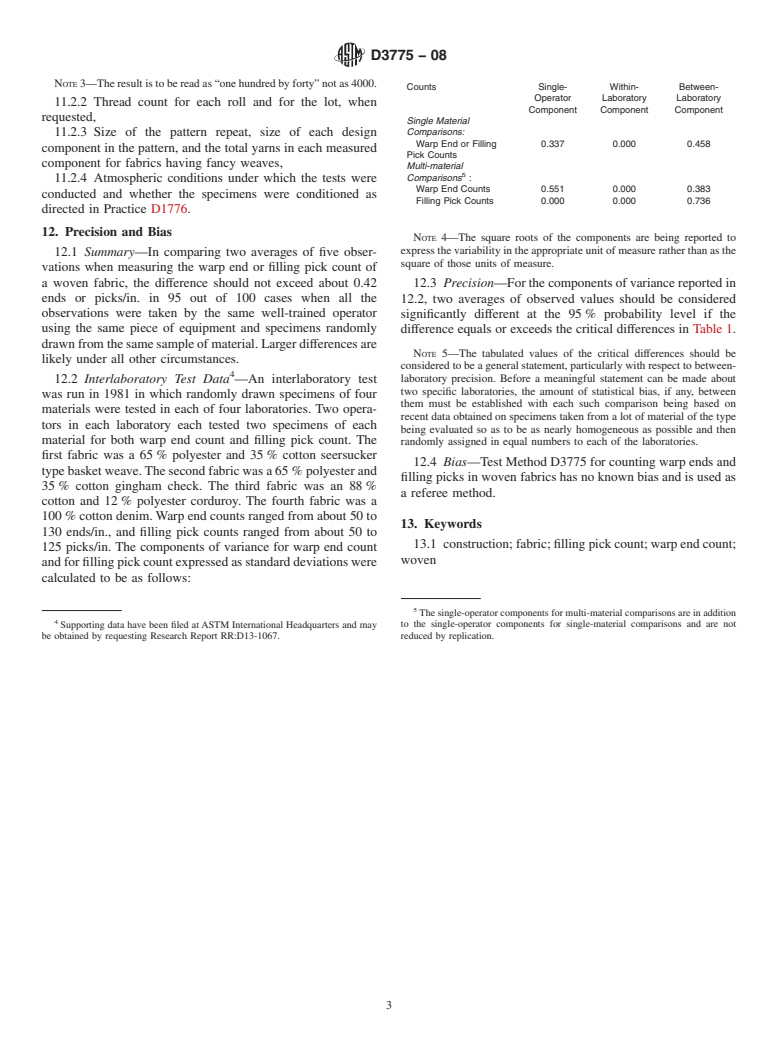

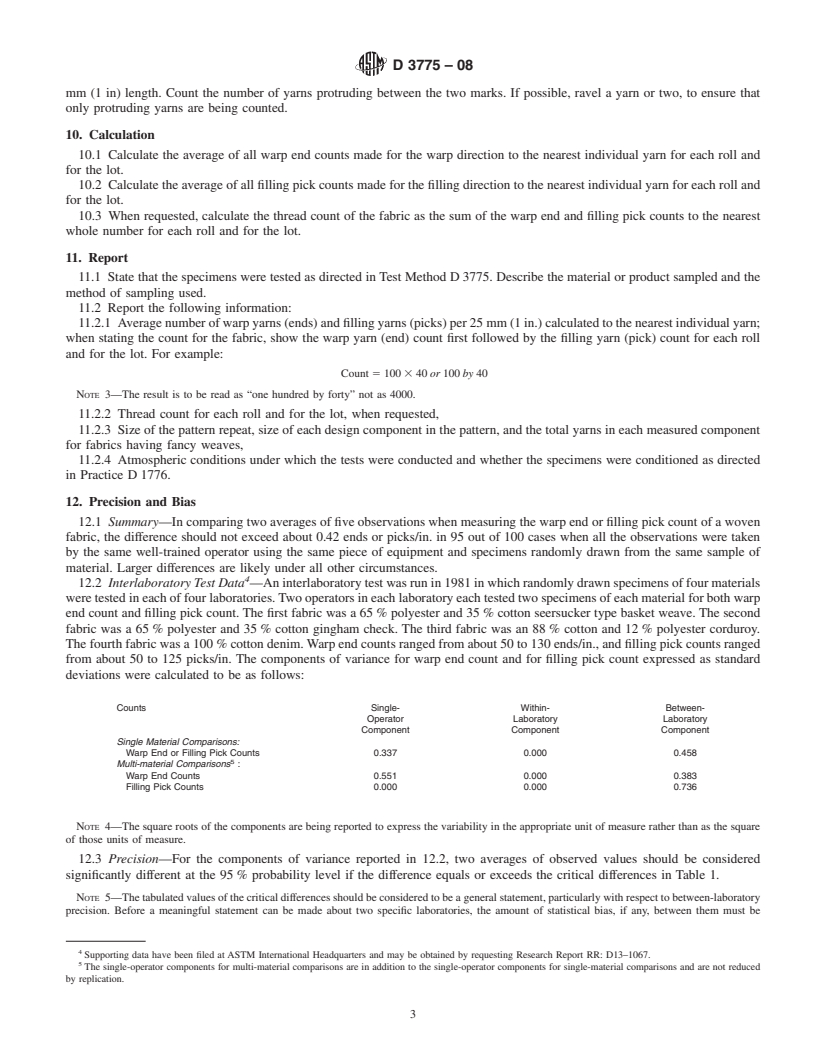

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D 3775–07a Designation:D 3775–08

Standard Test Method for

1

Warp (End) and Filling (Pick) Count of Woven Fabrics

This standard is issued under the fixed designation D 3775; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the measurement of warp end count and filling pick count and is applicable to all types of woven

fabrics.

NOTE 1—Historically, the term fabric count has been used to describe the end and pick count of woven fabrics. The terms warp (end) and filling (pick)

count are replacing the term fabric count, to provide clarity.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 123 Terminology Relating to Textiles

D 1776 Practice for Conditioning and Testing Textiles

D 4850 Terminology Relating to Fabric

D 7023 Terminology Relating to Home Furnishings

2.2 Other Standard:

3

ANSI/ASQC Z1.4—Inspection by Attributes

3. Terminology

3.1 For all terminology related to D13.59, Fabric Test Methods, General, refer to Terminology D 4850

3.1.1 Thefollowingtermsarerelevanttothisstandard:count,end,endcount,filling,pick,pickcount,threadcount.threadcount

3.2 For all terminology related to Home Furnishings, refer to Terminology D 7023.

3.3 For all other terms related to textiles, refer to Terminology D 123.

4. Summary of Test Method

4.1 The number of warp yarns (ends) per unit distance and filling yarns (picks) per unit distance are determined using suitable

magnifying and counting devices or by raveling yarns from fabrics. See ANSI Z1.4.

5. Significance and Use

5.1 This test method is considered satisfactory for acceptance testing of commercial shipments because it has been used

extensively in the trade for that purpose.

5.1.1 If there are differences of practical significance between reported test results for two laboratories (or more), comparative

test should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a

minimum, use the samples for such a comparative test that are as homogeneous as possible, drawn from the same lot of material

as the samples that resulted in disparate results during initial testing and randomly assigned in equal numbers to each laboratory.

The test results from the laboratories involved should be compared using a statistical test for unpaired data, a probability level

chosenpriortothetestingseries.Ifbiasisfound,eitheritscausemustbefoundandcorrected,orfuturetestresultsforthatmaterial

must be adjusted in consideration of the known bias.

1

This test method is under the jurisdiction of ASTM Committee D13 on Fabric Test Methods, Specific

Current edition approved Dec.July 1, 2007.2008. Published January 2008 . July 2008. Replaces Sections 28 to 34 of Methods D 1910 – 64 (1975). Originally approved

in 1979 as D 3775 – 79. Last previous edition approved in 2007 as D 3775 – 07a.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer tot he standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute, 11 W. 42nd St., 13th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 3775–08

6. Apparatus

6.1Use any suitable device, such as pick glass, rule and pointer, microfilm reader, or projection equipment.

6.1 Use any suitable device, such as pick glass, rule and pointer, microfilm reader, or projection equipment. The use of optical

sensing equipment may be used as agreed upon by the purchaser and supplier.

1

6.2 Use a scale graduated in mm ( ⁄16 in.) to measure the width of the fabric test specimen to be raveled for a count of yarns.

7. Sampling

7.1 Lot Sample—Asalotsampleforacceptancetesting,takeatrandomthenumber

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.