ASTM D2255/D2255M-09(2020)e1

(Test Method)Standard Test Method for Grading Spun Yarns for Appearance

Standard Test Method for Grading Spun Yarns for Appearance

SIGNIFICANCE AND USE

6.1 This method is considered satisfactory for acceptance grading of commercial shipments because it has been used extensively in the trade for this purpose.

6.1.1 If there are differences of practical significance between reported test results for two laboratories (or more), comparative tests should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, use the samples for such a comparative tests that are as homogeneous as possible, drawn from the same lot of material as the samples that resulted in disparate results during initial testing and randomly assigned in equal numbers to each laboratory. The test results from the laboratories involved should be compared using a statistical test for unpaired data, a probability level chosen prior to the testing series. If a bias is found, either its cause must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

6.2 The appearance of a woven or knitted fabric depends to a large extent on the smoothness, cleanliness, and general appearance of the yarns from which the fabric is manufactured. Instruments are available for the measurement of unevenness and for counting neps and other imperfections in yarn, but the values obtained from such tests are not easily integrated into an over-all expression for actual fabric appearance. Yarn appearance grading affords additional information which the manufacturer of woven or knitted goods may, through experience, correlate with the appearance to be expected in fabrics made from the yarns.

SCOPE

1.1 This test method covers the grading of singles spun yarns for appearance.

1.2 This test method does not apply to plied yarns.

1.3 The values stated in either inch-pound or SI units are to be regarded separately as the standard. The values stated in each system are not exact equivalents, therefore, each system must be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.2

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D2255/D2255M − 09 (Reapproved 2020)

Standard Test Method for

Grading Spun Yarns for Appearance

This standard is issued under the fixed designation D2255/D2255M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Footnote 4 and Section 14.2.6 were editorially corrected in September 2023.

INTRODUCTION

Cotton yarn appearance standards were first adopted in 1938 and revised in 1964, with Series III

being revised again in 1975. The 1964 boards had different yarn sizes for the four-grade exhibits on

each board. The 1975 Series III board used the same yarn number for each grade.

The appearance grade of yarn is based on the composite evaluation of several factors, such as

unevenness, fuzziness, and neppiness. The differences in the yarn numbers in the 1964 standards along

with the differences in other factors distort the comparison between grades and makes grading more

difficult.

To overcome this shortcoming, in 1975 the Series III board was revised using the same size yarn

for all four grades. After evaluating the improvements, it was decided to revise all of the series using

a mid-range yarn number for each grade in the series, and narrow the range in the most active series.

This was accomplished by adding a new board, Series VI. A near mid-range yarn number was selected

to represent equal steps between adjacent grades for all the factors considered in yarn appearance

grading. These yarns were produced with current commercial manufacturing equipment and practices.

Finally, to obtain better yarn definition and better reproducibility from set to set, it was decided to

use offset photo printing.

Shortly after these new boards were published in 1979, it became apparent that in the Series II-79

Board the A and B grades were not clearly defined and appeared to be switched. This was corrected

in the 1987 Series II Board.

In 1987 a world wide survey was conducted on how the Yarn Appearance Boards were being used.

From responses it became apparent that the boards are being used for grading yarns other than 100 %

cotton combed or carded yarns. Respondents were using the boards to grade yarn blends, ring spun

yarns, open-end spun yarns and other spinning systems. The boards are used both for process quality

control and customer acceptance.

In view of the above findings, it was decided to revise the method to include grading of all single

spun yarns.

1. Scope must be used independently of the other. Combining values

from the two systems may result in non-conformance with the

1.1 This test method covers the grading of singles spun

standard.

yarns for appearance.

1.4 This standard does not purport to address all of the

1.2 This test method does not apply to plied yarns.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

1.3 The values stated in either inch-pound or SI units are to

priate safety, health, and environmental practices and deter-

be regarded separately as the standard. The values stated in

mine the applicability of regulatory limitations prior to use.

each system are not exact equivalents, therefore, each system

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

This test method is under the jurisdiction of ASTM Committee D13 on Textiles

and is the direct responsibility of Subcommittee D13.58 on Yarns and Fibers.

Current edition approved Feb. 1, 2020. Published February 2020. Originally

ɛ1 2

approved in 1964. Last previous edition approved in 2013 as D2255 – 09(2013) . The requirements for the appearance of cotton yarns are covered in Tolerances

DOI: 10.1520/D2255_D2255M-09R20. D2645, Roller-Drafted Yarns.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D2255/D2255M − 09 (2020)

Development of International Standards, Guides and Recom- yarn may have fewer neps than Grade C yarn. Grade D yarn

mendations issued by the World Trade Organization Technical may have an over-all rougher appearance than Grade C yarn.

Barriers to Trade (TBT) Committee.

4.5 Yarn Below Grade D—Yarn below Grade D may have

more defects and an overall rougher appearance than Grade D

2. Referenced Documents

yarn.

2.1 ASTM Standards:

NOTE 1—The permitted number of defects for any grade should always

D123 Terminology Relating to Textiles

be determined by comparison with the official “ASTM Spun Yarn

D2258 Practice for Sampling Yarn for Testing

Appearance Standards” photographs.

D2645 Tolerances for Yarns Spun on the Cotton or Worsted

Systems

5. Summary of Test Method

D3888 Terminology for Yarn Spinning Systems

5.1 Yarn specimens, wound on black boards, are compared

D3990 Terminology Relating to Fabric Defects

with photographs of specimens representing the appearance

D4849 Terminology Related to Yarns and Fibers

grades. The grade is based on fuzziness, neppiness,

2.2 ASTM Adjuncts:

unevenness, and visible foreign matter.

Spun Yarn Appearance Standards (6 Boards with Photos)

6. Significance and Use

3. Terminology

6.1 This method is considered satisfactory for acceptance

3.1 For definitions of textile terms used in this method:

grading of commercial shipments because it has been used

bunch, cover, fuzz, nep, slub, thick place, thin place, and yarn

extensively in the trade for this purpose.

appearance, refer to Terminology D4849. For other textile

6.1.1 If there are differences of practical significance be-

terms used in this test method, refer to Terminology D123,

tween reported test results for two laboratories (or more),

Terminology D3888, and Terminology D3990.

comparative tests should be performed to determine if there is

a statistical bias between them, using competent statistical

4. Description of Yarn Grades

assistance. As a minimum, use the samples for such a com-

4.1 Grade A Yarn—Grade A yarn may have no large neps parative tests that are as homogeneous as possible, drawn from

which are over three times the normal diameter of the yarn and the same lot of material as the samples that resulted in disparate

very few small ones. Grade A yarn must have good uniformity results during initial testing and randomly assigned in equal

from 25 mm to 25 mm (inch to inch), and good cover without numbers to each laboratory. The test results from the labora-

excessive fuzziness. No foreign matter may be present in

tories involved should be compared using a statistical test for

Grade A yarn. unpaired data, a probability level chosen prior to the testing

series. If a bias is found, either its cause must be found and

4.2 Grade B Yarn—Grade B Yarn may have no large neps,

corrected, or future test results for that material must be

but may have a few small ones. Grade B yarn may have no

adjusted in consideration of the known bias.

more than three small pieces of foreign matter per board or

specimen providing they do not form slubs. Grade B yarn may 6.2 The appearance of a woven or knitted fabric depends to

be slightly more irregular and may have slightly more fuzz than

a large extent on the smoothness, cleanliness, and general

a Grade A yarn. appearance of the yarns from which the fabric is manufactured.

Instruments are available for the measurement of unevenness

4.3 Grade C Yarn—Grade C yarn may have more neps, and

and for counting neps and other imperfections in yarn, but the

larger ones as well as more fuzziness and a greater amount of

values obtained from such tests are not easily integrated into an

foreign matter than Grade B yarn. The contrast between the

over-all expression for actual fabric appearance. Yarn appear-

thick and thin places and the normal diameter of the yarn may

ance grading affords additional information which the manu-

be greater than in Grade B yarn resulting in an over-all rougher

facturer of woven or knitted goods may, through experience,

appearance.

correlate with the appearance to be expected in fabrics made

4.4 Grade D Yarn—Grade D yarn may have some slubs that

from the yarns.

are more than three times the average diameter of the yarn.

Grade D yarn may have more neps, neps of a larger size, more

thick and thin places, more fuzz and more foreign matter than

TABLE 1 Requirements for Preparations of Specimens

Grade C yarn. When slubs or large neps are present, Grade D

B

Range of Yarn Numbers Wraps

A

Series Count

Single Cot-

Tex per in. per cm

ton Count

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 1 1 to 12 590 to 50 8 20 8

2 12 to 24 50 to 25 18 22 9

Standards volume information, refer to the standard’s Document Summary page on

3 24 to 36 25 to 16 30 26 10

the ASTM website.

4 36 to 50 16 to 12 42 32 13

Available from the ASTM International Headquarters. Request adjunct No. as

5 50 to 75 12 to 8 60 38 15

follows:

6 75 to 135 8 to 4 100 48 19

ADJD225501 (Series 1-79) ADJD225504 (Series 4-79)

A

ADJD225502 (Series 2-09) ADJD225505 (Series 5-79)

Actual single yarn count used on boards.

B

ADJD225503 (Series 3-09) ADJD225506 (Series 6-79)

The specified number of wraps is subject to a tolerance of ± 10 %.

ADJD2255ALL

´1

D2255/D2255M − 09 (2020)

7. Apparatus 7.4 Yarn Board Winder—A small machine to rotate a yarn

4 board end-over-end, and fitted with a traversing guide to

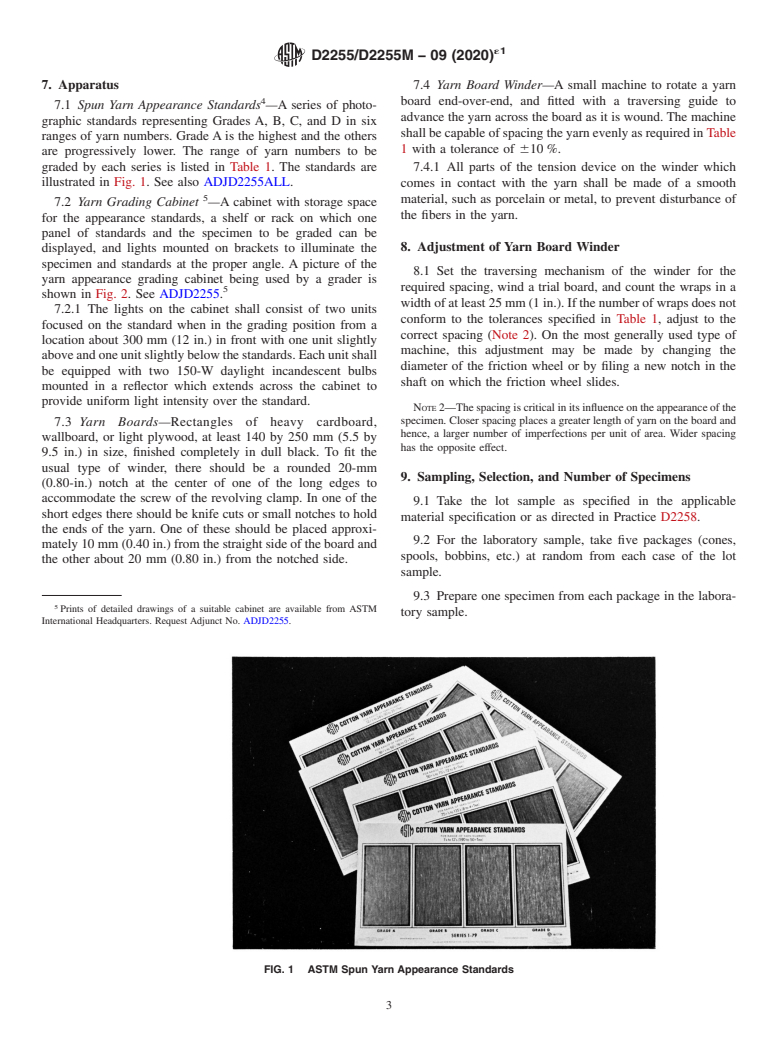

7.1 Spun Yarn Appearance Standards —A series of photo-

advance the yarn across the board as it is wound. The machine

graphic standards representing Grades A, B, C, and D in six

shall be capable of spacing t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.