ASTM E562-19

(Test Method)Standard Test Method for Determining Volume Fraction by Systematic Manual Point Count

Standard Test Method for Determining Volume Fraction by Systematic Manual Point Count

SIGNIFICANCE AND USE

5.1 This test method is based upon the stereological principle that a grid with a number of regularly arrayed points, when systematically placed over an image of a two-dimensional section through the microstructure, can provide, after a representative number of placements on different fields, an unbiased statistical estimation of the volume fraction of an identifiable constituent or phase (1, 2, 3).3

5.2 This test method has been described (4) as being superior to other manual methods with regard to effort, bias, and simplicity.

5.3 Any number of clearly distinguishable constituents or phases within a microstructure (or macrostructure) can be counted using the method. Thus, the method can be applied to any type of solid material from which adequate two-dimensional sections can be prepared and observed.

5.4 A condensed step-by-step guide for using the method is given in Annex A1.

SCOPE

1.1 This test method describes a systematic manual point counting procedure for statistically estimating the volume fraction of an identifiable constituent or phase from sections through the microstructure by means of a point grid.

1.2 The use of automatic image analysis to determine the volume fraction of constituents is described in Practice E1245.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E562 −19

Standard Test Method for

Determining Volume Fraction by Systematic Manual Point

1

Count

This standard is issued under the fixed designation E562; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method may be used to determine the volume fraction of constituents in an opaque

specimen using a polished, planar cross section by the manual point count procedure. The same

measurements can be achieved using image analysis per Practice E1245.

1. Scope E407Practice for Microetching Metals and Alloys

E691Practice for Conducting an Interlaboratory Study to

1.1 This test method describes a systematic manual point

Determine the Precision of a Test Method

counting procedure for statistically estimating the volume

E1245Practice for Determining the Inclusion or Second-

fraction of an identifiable constituent or phase from sections

Phase Constituent Content of Metals byAutomatic Image

through the microstructure by means of a point grid.

Analysis

1.2 The use of automatic image analysis to determine the

volume fraction of constituents is described in Practice E1245.

3. Terminology

1.3 The values stated in SI units are to be regarded as

3.1 Definitions—For definitions of terms used in this

standard. No other units of measurement are included in this

practice, see Terminology E7.

standard.

3.2 Definitions of Terms Specific to This Standard:

1.4 This standard does not purport to address all of the

3.2.1 point count—the total number of points in a test grid

safety concerns, if any, associated with its use. It is the

that fall within the microstructural feature of interest, or on the

responsibility of the user of this standard to establish appro-

featureboundary;forthelatter,eachtestpointontheboundary

priate safety, health, and environmental practices and deter-

is one half a point.

mine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor-

3.2.2 point fraction—the ratio, usually expressed as a

dance with internationally recognized principles on standard- percentage, of the point count of the phase or constituent of

ization established in the Decision on Principles for the

interest on the two-dimensional image of an opaque specimen

Development of International Standards, Guides and Recom- tothenumberofgridpoints,whichisaveragedover nfieldsto

mendations issued by the World Trade Organization Technical

produce an unbiased estimate of the volume fraction of the

Barriers to Trade (TBT) Committee. phase or constituent.

3.2.3 stereology—themethodsdevelopedtoobtaininforma-

2. Referenced Documents

tion about the three-dimensional characteristics of microstruc-

2

2.1 ASTM Standards:

tures based upon measurements made on two-dimensional

E3Guide for Preparation of Metallographic Specimens

sections through a solid material or their projection on a

E7Terminology Relating to Metallography

surface.

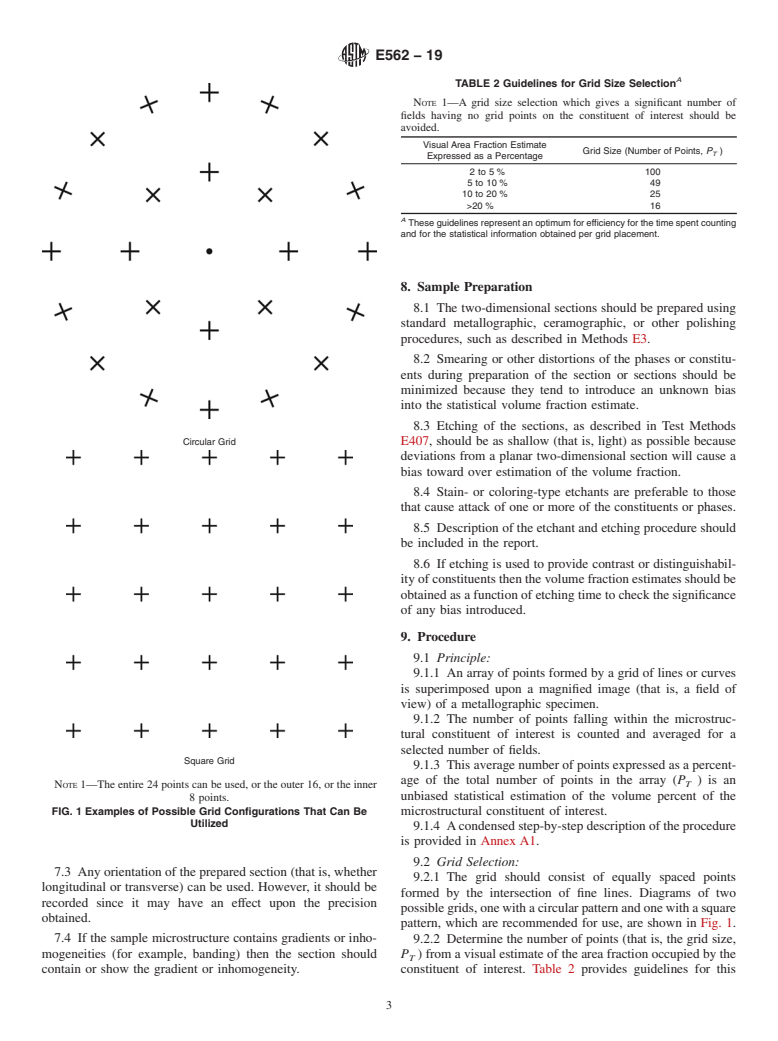

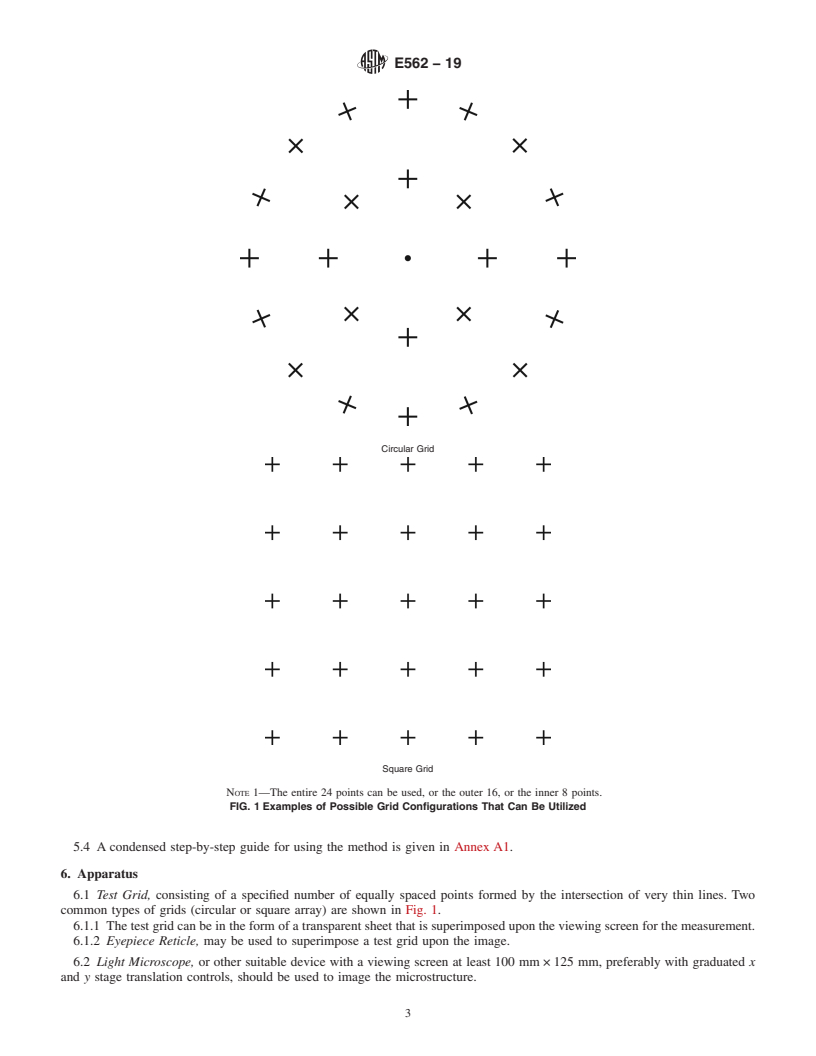

3.2.4 test grid—a transparent sheet or eyepiece reticle with

1

This test method is under the jurisdiction of ASTM Committee E04 on

a regular pattern of lines or crosses that is superimposed over

Metallography and is the direct responsibility of Subcommittee E04.14 on Quanti-

themicrostructuralimageforcountingmicrostructuralfeatures

tative Metallography.

of interest.

Current edition approved Aug. 15, 2019. Published September 2019. Originally

approved in 1976. Last previous edition approved in 2011 as E562–11. DOI:

3.2.5 volume fraction—the total volume of a phase or

10.1520/E0562-19.

2

constituent per unit volume of specimen, generally expressed

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

as a percentage.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 3.3 Symbols:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E562−19

TABLE 1 95% Confidence Interval Multipliers

an unbiased statistical estimation of the volume fraction of an

3

No. of Fields n t No. of Fields n t identifiable constituent or phase (1, 2, 3).

5 2.776 19 2.101

5.2 This test method has been described (4) as being

6 2.571 20 2.093

superior to other manual methods with regard to effort, bias,

7 2.447 21 2.086

8 2.365 22 2.080

and simplicity.

9 2.306 23 2.074

10 2.262 24 2.069 5.3 Any number of clearly distinguishable constituents or

11 2.228 25 2.064

phases within a microstructure (or macrostructure) can be

12 2.201

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E562 − 11 E562 − 19

Standard Test Method for

Determining Volume Fraction by Systematic Manual Point

1

Count

This standard is issued under the fixed designation E562; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method may be used to determine the volume fraction of constituents in an opaque

specimen using a polished, planar cross section by the manual point count procedure. The same

measurements can be achieved using image analysis per Practice E1245.

1. Scope

1.1 This test method describes a systematic manual point counting procedure for statistically estimating the volume fraction of

an identifiable constituent or phase from sections through the microstructure by means of a point grid.

1.2 The use of automatic image analysis to determine the volume fraction of constituents is described in Practice E1245.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E3 Guide for Preparation of Metallographic Specimens

E7 Terminology Relating to Metallography

E407 Practice for Microetching Metals and Alloys

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E1245 Practice for Determining the Inclusion or Second-Phase Constituent Content of Metals by Automatic Image Analysis

3. Terminology

3.1 Definitions—For definitions of terms used in this practice, see Terminology E7.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 point count—the total number of points in a test grid that fall within the microstructural feature of interest, or on the feature

boundary; for the latter, each test point on the boundary is one half a point.

3.2.2 point fraction—the ratio, usually expressed as a percentage, of the point count of the phase or constituent of interest on

the two-dimensional image of an opaque specimen to the number of grid points, which is averaged over n fields to produce an

unbiased estimate of the volume fraction of the phase or constituent.

1

This test method is under the jurisdiction of ASTM Committee E04 on Metallography and is the direct responsibility of Subcommittee E04.14 on Quantitative

Metallography.

Current edition approved Oct. 1, 2011Aug. 15, 2019. Published October 2011September 2019. Originally approved in 1976. Last previous edition approved in 20082011

ε1

as E562 – 08E562 . –11. DOI: 10.1520/E0562-11.10.1520/E0562-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E562 − 19

TABLE 1 95 % Confidence Interval Multipliers

No. of Fields n t No. of Fields n t

5 2.776 19 2.101

6 2.571 20 2.093

7 2.447 21 2.086

8 2.365 22 2.080

9 2.306 23 2.074

10 2.262 24 2.069

11 2.228 25 2.064

12 2.201 26 2.060

13 2.179 27 2.056

14 2.160 28 2.052

15 2.145 29 2.048

16 2.131 30 2.045

17 2.120 40 2.020

18 2.110 60 2.000

` 1.960

3.2.3 stereology—the methods developed to obtain information about the three-dimensional characteristics of microstructures

based upon measurements made on two-dimensional sections through a solid material or their projection on a surface.

3.2.4 test grid—a transparent sheet or eyepiece reticle with a regular pattern of lines or crosses that is superimposed over the

microstructural image for counting microstructural featur

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.