ASTM C157/C157M-08(2014)e1

(Test Method)Standard Test Method for Length Change of Hardened Hydraulic-Cement Mortar and Concrete

Standard Test Method for Length Change of Hardened Hydraulic-Cement Mortar and Concrete

SIGNIFICANCE AND USE

4.1 Measurement of length change permits assessment of the potential for volumetric expansion or contraction of mortar or concrete due to various causes other than applied force or temperature change. This test method is particularly useful for comparative evaluation of this potential in different hydraulic-cement mortar or concrete mixtures.

4.2 This test method provides useful information for experimental purposes or for products that require testing under nonstandard mixing, placing, handling, or curing conditions, such as high product workability or different demolding times. Standard conditions are described in 5.4.1.

4.3 If conditions for mixing, curing, sampling, and storage other than specified in this test method are required, they shall be reported but are not to be considered as standard conditions of this test method. Nonstandard conditions and the reasons for departure from standard conditions shall be reported clearly and prominently with comparator values.

SCOPE

1.1 This test method covers the determination of the length changes that are produced by causes other than externally applied forces and temperature changes in hardened hydraulic-cement mortar and concrete specimens made in the laboratory and exposed to controlled conditions of temperature and moisture.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. An exception is with regard to sieve sizes and nominal size of aggregate, in which the SI values are the standard as stated in Specification E11. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: C157/C157M − 08 (Reapproved 2014)

Standard Test Method for

Length Change of Hardened Hydraulic-Cement Mortar and

Concrete

This standard is issued under the fixed designation C157/C157M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Editorial corrections were made in November 2014.

1. Scope* C192/C192M Practice for Making and Curing Concrete Test

Specimens in the Laboratory

1.1 This test method covers the determination of the length

C305 Practice for Mechanical Mixing of Hydraulic Cement

changes that are produced by causes other than externally

Pastes and Mortars of Plastic Consistency

applied forces and temperature changes in hardened hydraulic-

C490 Practice for Use ofApparatus for the Determination of

cement mortar and concrete specimens made in the laboratory

Length Change of Hardened Cement Paste, Mortar, and

and exposed to controlled conditions of temperature and

Concrete

moisture.

C511 Specification for Mixing Rooms, Moist Cabinets,

1.2 The values stated in either SI units or inch-pound units

Moist Rooms, and Water Storage Tanks Used in the

are to be regarded separately as standard.An exception is with

Testing of Hydraulic Cements and Concretes

regard to sieve sizes and nominal size of aggregate, in which

C596 Test Method for Drying Shrinkage of Mortar Contain-

the SI values are the standard as stated in Specification E11.

ing Hydraulic Cement

Within the text, the SI units are shown in brackets. The values

C1437 Test Method for Flow of Hydraulic Cement Mortar

stated in each system may not be exact equivalents; therefore,

E11 Specification for Woven Wire Test Sieve Cloth and Test

each system shall be used independently of the other. Combin-

Sieves

ing values from the two systems may result in non-

E337 Test Method for Measuring Humidity with a Psy-

conformance with the standard.

chrometer (the Measurement of Wet- and Dry-Bulb Tem-

1.3 This standard does not purport to address all of the

peratures)

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety and health practices and determine the applica-

3.1 Definitions—The terms used in this test method are

bility of regulatory limitations prior to use.

defined in Terminology C125.

3.2 Definitions of Terms Specific to This Standard:

2. Referenced Documents

2 3.2.1 length change, n—an increase or decrease in the

2.1 ASTM Standards:

lengthofatestspecimenthathasbeencausedtochangebyany

C125 Terminology Relating to Concrete and Concrete Ag-

factor other than externally applied forces and temperature

gregates

changes.

C143/C143M Test Method for Slump of Hydraulic-Cement

Concrete

4. Significance and Use

C172 Practice for Sampling Freshly Mixed Concrete

4.1 Measurement of length change permits assessment of

the potential for volumetric expansion or contraction of mortar

This test method is under the jurisdiction of ASTM Committee C09 on

or concrete due to various causes other than applied force or

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

C09.68 on Volume Change. temperature change. This test method is particularly useful for

Current edition approved Oct. 1, 2014. Published November 2014. Originally

comparative evaluation of this potential in different hydraulic-

ε1

approved in 1940. Last previous edition approved in 2008 as C157/C157M – 08 .

cement mortar or concrete mixtures.

DOI: 10.1520/C0157_C0157M-08R14E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.2 This test method provides useful information for experi-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

mental purposes or for products that require testing under

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. nonstandard mixing, placing, handling, or curing conditions,

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

C157/C157M − 08 (2014)

FIG. 1 Atmometer

´1

C157/C157M − 08 (2014)

such as high product workability or different demolding times. 5.5.1 Mounting—Fig. 2 shows a suggested arrangement for

Standard conditions are described in 5.4.1. operating the atmometer. Punch a central hole ⁄2 in. [13 mm]

in diameter in a filter paper, place it on the atmometer, and

4.3 If conditions for mixing, curing, sampling, and storage

secure it in place while dry, by turning the torque handle only,

other than specified in this test method are required, they shall

until it just starts to slip. Mount the atmometer on a stand with

be reported but are not to be considered as standard conditions

the filter paper in a horizontal position. Mount a 100-mL glass

of this test method. Nonstandard conditions and the reasons for

graduate so that the 100-mL mark is from 1 to 3 in. [25 to 75

departure from standard conditions shall be reported clearly

mm] below the level of the filter paper. Stopper the graduate so

and prominently with comparator values.

that entrance is provided for two short glass tubes not extend-

ing to the water level and one long tube extending to the

5. Apparatus

bottom of the graduate. Connect the glass tubing leading from

5.1 Molds and Length Comparator—The molds for casting

the bottom of the graduate to the inlet of the atmometer by

test specimens and the length comparator for measuring length

means of clear plastic tubing.

change shall conform to the requirements of Practice C490.

5.5.2 Operation—Use clear plastic tubing to connect a

5.2 Tamper—The tamper shall be made of a nonabsorptive,

squeeze bottle containing distilled or deionized water to one of

nonabrasive material such as medium-hard rubber or seasoned

the short glass tubes into the graduate. Force water into the

oak wood rendered nonabsorptive by immersion for 15 min in

graduate until it is about half full and then close the remaining

paraffin at approximately 392 °F [200 °C], and shall have a

glass tube into the graduate. Continue to force water through

cross section of ⁄2 by 1.0 in. [13 by 25 mm] and a convenient

the graduate into the atmometer until the filter paper is

length of about 6 in. [150 mm].The tamping face of the tamper

saturated and there are no air bubbles in the system. Open the

shall be flat and at right angles to the length of the tamper.

glasstubeintothegraduateandreleasepressureonthesqueeze

bottle gradually to avoid trapping air in the tube leading to the

5.3 Tamping Rod—The tamping rod shall be a straight steel

atmometer. Adjust the level of water in the graduate to

rod ⁄8 in. [10 mm] in diameter and not less than 10 in. [250

approximatelythe100-mLmark.Iftheatmometeristobeused

mm] in length, having at least the tamping end rounded to a

under variable temperature conditions, disconnect the squeeze

hemispherical tip of the same diameter.

bottle after filling the graduate to avoid the possibility of

5.4 Drying Room and Controls—A drying room with suit-

additional water being forced into the graduate. Permit evapo-

able racks shall be provided when storing specimens in air.The

rationofwaterfromthefilterpaperfor1hbeforerecordingthe

racks shall be designed for free circulation of air around

time and initial reading of the graduate. It is not permitted to

specimens, except for necessary supports, and shall be so

omit the waiting period during subsequent use of the atmom-

situated with respect to the nearest wall or other obstruction

eter provided the filter paper does not become dry. Change the

that air circulation is not restricted in the intervening space.

filter paper whenever it shows signs of contamination but not

The supports shall be horizontal and shall consist of two

less frequently than once every two weeks.

nonabsorptive members not deeper than 1 in. [25 mm] and

5.6 Filter Paper—The filter paper to be used with the

having a bearing area of not more than ⁄4 in. [6 mm] in width.

atmometershallbewhitewithasmoothsurfacetexture.Itshall

Conditioned air shall be circulated into and out of the room in

be 6 in. [152 mm] in diameter and 0.050 6 0.003 in. [1.27 6

a uniform manner so that the specified rate of evaporation is

0.08 mm] thick and shall have a cotton fiber content of not less

attained adjacent to all specimens.

than 75 weight %. The density shall be between 0.400 and

5.4.1 The air in the room shall be maintained at a tempera-

0.425 g/cm . The Mullen bursting strength shall not be less

ture of 73 63°F[23 6 2 °C] and a relative humidity of 50 6

than 50 psi [345 kPa].

4 %. The air movement past all specimens shall be such that

the rate of evaporation is 77 6 30-mL/24 h from an atmometer 3

NOTE 1—E and D filter paper No. 625 has been found suitable.

or 13 6 5-mL/24 h from a 400-mL Griffin low-form beaker

filled to ⁄4 in. [20 mm] from the top. The temperature and

relative humidity of the air in the room shall be measured with

either a sling or Assmann psychrometer at least twice each

The sole source of supply of the apparatus known to the committee at this time

workingday.ThepsychrometershallcomplywithTestMethod

is Ahlstrom Filtration Co., Mt. Holly Springs, PA 17065. If you are aware of

E337, except that thermometers having an overall length of 10

alternative suppliers, please provide this information to ASTM International

in. [250 mm] and marked in subdivisions of 0.5 °F [0.25 °C] Headquarters.Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend.

are permitted. The room shall be equipped with a means of

measuring and recording wet- and dry-bulb temperatures

continuously. Correction factors as indicated by the sling or

Assmann psychrometer shall be applied to the recorded data.

The rate of evaporation within the room shall be determined

daily by the use of the atmometer or by the loss of mass of

water from a 400-mLGriffin low-form beaker filled initially to

⁄4 in. [20 mm] from the top.

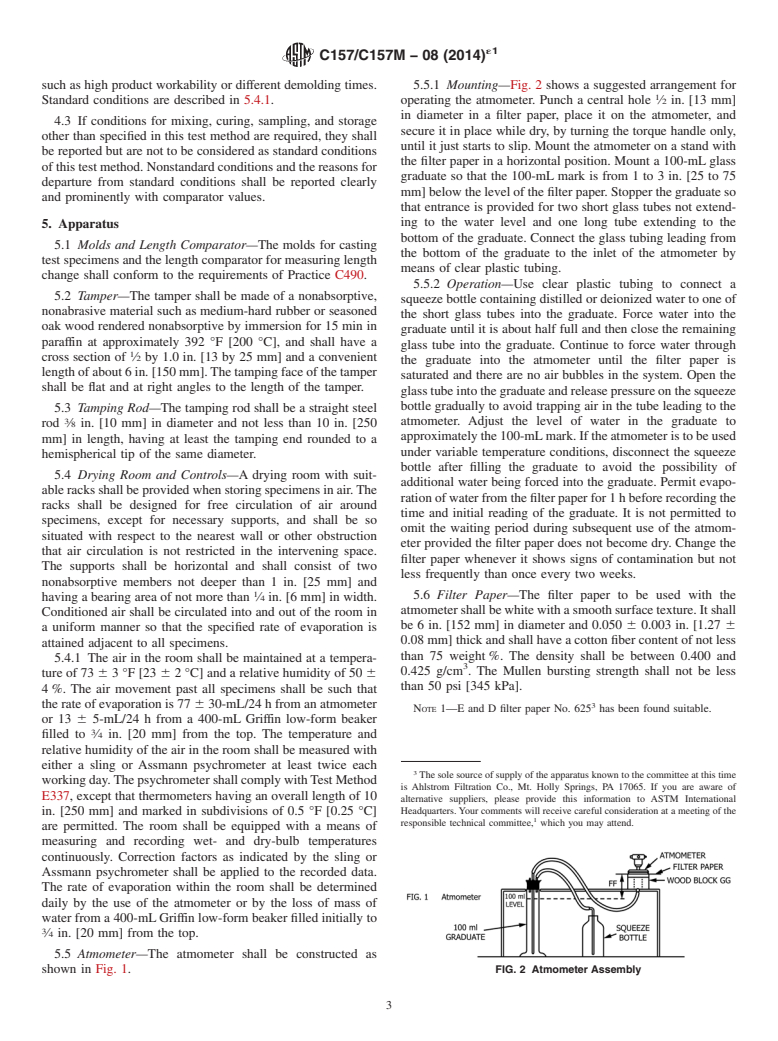

5.5 Atmometer—The atmometer shall be constructed as

shown in Fig. 1. FIG. 2 Atmometer Assembly

´1

C157/C157M − 08 (2014)

ASTM C157 FIGURES

Figure Di- SI Units Inch-Pound Units

mensions

A Adjustable torque handle Adjustable torque handle

1.4–1.7 Nm 12–15 in.lb

B Jam nut Jam nut

10–15 IMC ⁄8-in.–16 NC

C 10-mm diameter 1.5 IMC Thd. ⁄8-in. dia–16 NC Thd.

D 12-mm diameter 1.5 IMC Thd. ⁄2-in. dia–20 NC Thd.

E 64-mm diameter 2.50-in. diameter

F 64-mm diameter 2.50-in. diameter

G 57-mm diameter 2.25-in. diameter

H 52-mm diameter 2.06-in. diameter

I 51-mm diameter 2.00-in. diameter

J 14mm 0.56in.

K 8 mm 0.31 in.

L 13mm 0.50in.

M 3 mm 0.125 in.

N 8 mm 0.31 in.

O 19mm 0.75in.

P 32mm 1.25in.

Q 53mm 2.06in.

1 29

R 1.5-mm drill through 11.5-mm C’ ⁄16-in. drill through ⁄64-in. C’ drill

drill

1 1

32-mm deep tap 12-mm 1.5-mm 1 ⁄4-in. deep tap ⁄2-in.–20 Thd

IMF Thd

3 5 1

S 19 mm deep 16 mm C’ bore 6 ⁄4-in. deep ⁄8-in. C’ bore ⁄4 in.

mm deep deep

3 1

T 5-mm drill 3-mm deep C’ drill ⁄16-in. drill ⁄8-in. deep C’ drill

at 60° as shown at 60° as shown

through to center tapped hole through to center tapped hole

Instructions for Use—Remove the end and the outer side plates leaving the

U 3 mm 0.12 in. diameter

base, center side plate, and gage stud holders in place. Engage the machine

V 2 mm 0.09 in.

screw in the drilled and tapped end of the center side plate. Turn the thumbscrew

W 10mm 0.40in.

to loosen the bars.

X 60mm 2.36in.

FIG. 3 Device for Detaching 1-in. [25-mm] Square by 11 ⁄4-in.

Y 35mm 1.37in.

[285-mm] Bars from Center Side Plate of Double Molds

Z 6 mm 0.25 in.

AA 6mm 0.25in.

BB 4mm 0.15in.

CC 6mm 0.25in.

DD 23 mm 0.87 in.

EE 38 mm 1.50 in.

FF 25 to 75 mm 1 to 3 in.

GG 35 mm high 1.37 in. high

HH 100 mm 4 in.

II 130 mm 5 in.

JJ 8 cm–6.1 kg/m channel 3 in.–4.1 lb/ft channel

KK 20 mm ⁄4 in.

LL 330 mm 13 in.

MM 14–2.0 IMC Thd. ⁄2 in.–12 Thd.

NN 20 mm ⁄4 in.

OO 50 mm 2 in.

PP 20 mm ⁄4 in.

QQ 60 mm ⁄4 in.

RR 10 mm ⁄8 in.

SS Drill Cl. hole for Drill Cl. hole for

4.5–0.75 IMC machine screw 8–32 in. machine screw

TT 13 mm ⁄2 in.

NOTE 1—Dimensions shown are appropriate for one design of mold for

UU 25 mm 1 in.

3-in. [75-mm] square specimens. Change dimensions as required for other 3

VV 30 mm 1- ⁄16 in.

molds. 3

WW 60 mm 2- ⁄8 in.

FIG. 4 Device for Demolding Specimens from Single Molds XX 12.5 mm ⁄2 in.

YY 6-mm diameter steel rod ⁄4-in. diameter steel rod

ZZ 4.5–0.75 IMC × 16-mm machine 8–32 × ⁄8-in. machine screw

screw

5.7 Apparatus for Demolding Specimens—It is useful to

construct an apparatus for demolding specimens molded in

6. Sampling

double molds as detailed in Fig. 3 or to a different design that

6.1 Take samples according to the applicable provisions of

serves the same purpose. When this device is to be used, the

Practice C192/C192M from batches of hydraulic-cement mor-

center side plate of the double mold must be appropriately

tar or concrete made in the laboratory (Note 2).

drilled and tapped to receive the 8-32 by ⁄8 in. [4.5-0.74 IMC

by 16 mm] machine screw of the demolding thumbscrew. Fig.

NOTE 2—When collecting samples in nonstandard conditions, such as

4 shows the details of a suitable apparatus for demolding

field concrete, it is suggested that Practice C172 be followed. Field cast

specimens molded in single molds. specimens can show up to twice as much drying shrinkage as laboratory

´1

C157/C157M − 08 (2014)

cast specimens from the same materials and proportions.

a homogeneous specimen is obtained. After the top layer has

been compacted, strike off the mortar flush with the top of the

7. Test Specimens

mold, and smooth the surface with a few strokes of a trowel.

7.1 Mortar—The test specimen for mortar shall be a prism Immediately after completion of molding, loosen the device by

of 1-in. [25-mm] square cross-section and approximately 11 ⁄4 holding the gage studs in position at each end of the mold in

in. [285 mm] in length. Three specimens shall be prepared for order to prevent any restraint of the gage studs during initial

each test condition. shrinkage of the specimen.

7.2 Concrete—The test specimen for concrete, in which all

9.2 Concrete Specimens—Place the concrete in the mold in

of the aggregate passes a 2-in. [50-mm] sieve,

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1 ´1

Designation: C157/C157M − 08 C157/C157M − 08 (Reapproved 2014)

Standard Test Method for

Length Change of Hardened Hydraulic-Cement Mortar and

Concrete

This standard is issued under the fixed designation C157/C157M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Editorial corrections were made to Section 2 in Junein November 2014.

1. Scope*

1.1 This test method covers the determination of the length changes that are produced by causes other than externally applied

forces and temperature changes in hardened hydraulic-cement mortar and concrete specimens made in the laboratory and exposed

to controlled conditions of temperature and moisture.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. An exception is with regard

to sieve sizes and nominal size of aggregate, in which the SI values are the standard as stated in Specification E11. Within the text,

the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall

be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C125 Terminology Relating to Concrete and Concrete Aggregates

C143/C143M Test Method for Slump of Hydraulic-Cement Concrete

C172 Practice for Sampling Freshly Mixed Concrete

C192/C192M Practice for Making and Curing Concrete Test Specimens in the Laboratory

C305 Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency

C490 Practice for Use of Apparatus for the Determination of Length Change of Hardened Cement Paste, Mortar, and Concrete

C511 Specification for Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in the Testing of Hydraulic

Cements and Concretes

C596 Test Method for Drying Shrinkage of Mortar Containing Hydraulic Cement

C1437 Test Method for Flow of Hydraulic Cement Mortar

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

E337 Test Method for Measuring Humidity with a Psychrometer (the Measurement of Wet- and Dry-Bulb Temperatures)

3. Terminology

3.1 Definitions—The terms used in this test method are defined in Terminology C125.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 length change, n—an increase or decrease in the length of a test specimen that has been caused to change by any factor

other than externally applied forces and temperature changes.

This test method is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee C09.68 on

Volume Change.

Current edition approved Oct. 1, 2008Oct. 1, 2014. Published November 2008November 2014. Originally approved in 1940. Last previous edition approved in 20062008

ε1

as C157/C157M – 06.C157/C157M – 08 . DOI: 10.1520/C0157_C0157M-08E01.10.1520/C0157_C0157M-08R14E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

C157/C157M − 08 (2014)

4. Significance and Use

4.1 Measurement of length change permits assessment of the potential for volumetric expansion or contraction of mortar or

concrete due to various causes other than applied force or temperature change. This test method is particularly useful for

comparative evaluation of this potential in different hydraulic-cement mortar or concrete mixtures.

4.2 This test method provides useful information for experimental purposes or for products that require testing under

nonstandard mixing, placing, handling, or curing conditions, such as high product workability or different demolding times.

Standard conditions are described in 5.4.1.

4.3 If conditions for mixing, curing, sampling, and storage other than specified in this test method are required, they shall be

reported but are not to be considered as standard conditions of this test method. Nonstandard conditions and the reasons for

departure from standard conditions shall be reported clearly and prominently with comparator values.

5. Apparatus

5.1 Molds and Length Comparator—The molds for casting test specimens and the length comparator for measuring length

change shall conform to the requirements of Practice C490.

5.2 Tamper—The tamper shall be made of a nonabsorptive, nonabrasive material such as medium-hard rubber or seasoned oak

wood rendered nonabsorptive by immersion for 15 min in paraffin at approximately 392 °F [200 °C], and shall have a cross section

of ⁄2 by 1.0 in. [13 by 25 mm] and a convenient length of about 6 in. [150 mm]. The tamping face of the tamper shall be flat and

at right angles to the length of the tamper.

5.3 Tamping Rod—The tamping rod shall be a straight steel rod ⁄8 in. [10 mm] in diameter and not less than 10 in. [250 mm]

in length, having at least the tamping end rounded to a hemispherical tip of the same diameter.

5.4 Drying Room and Controls—A drying room with suitable racks shall be provided when storing specimens in air. The racks

shall be designed for free circulation of air around specimens, except for necessary supports, and shall be so situated with respect

to the nearest wall or other obstruction that air circulation is not restricted in the intervening space. The supports shall be horizontal

and shall consist of two nonabsorptive members not deeper than 1 in. [25 mm] and having a bearing area of not more than ⁄4 in.

[6 mm] in width. Conditioned air shall be circulated into and out of the room in a uniform manner so that the specified rate of

evaporation is attained adjacent to all specimens.

5.4.1 The air in the room shall be maintained at a temperature of 73 6 3 °F [23 6 2 °C] and a relative humidity of 50 6 4 %.

The air movement past all specimens shall be such that the rate of evaporation is 77 6 30-mL/24 h from an atmometer or 13 6

5-mL/24 h from a 400-mL Griffin low-form beaker filled to ⁄4 in. [20 mm] from the top. The temperature and relative humidity

of the air in the room shall be measured with either a sling or Assmann psychrometer at least twice each working day. The

psychrometer shall comply with Test Method E337, except that thermometers having an overall length of 10 in. [250 mm] and

marked in subdivisions of 0.5 °F [0.25 °C] are permitted. The room shall be equipped with a means of measuring and recording

wet- and dry-bulb temperatures continuously. Correction factors as indicated by the sling or Assmann psychrometer shall be

applied to the recorded data. The rate of evaporation within the room shall be determined daily by the use of the atmometer or

by the loss of mass of water from a 400-mL Griffin low-form beaker filled initially to ⁄4 in. [20 mm] from the top.

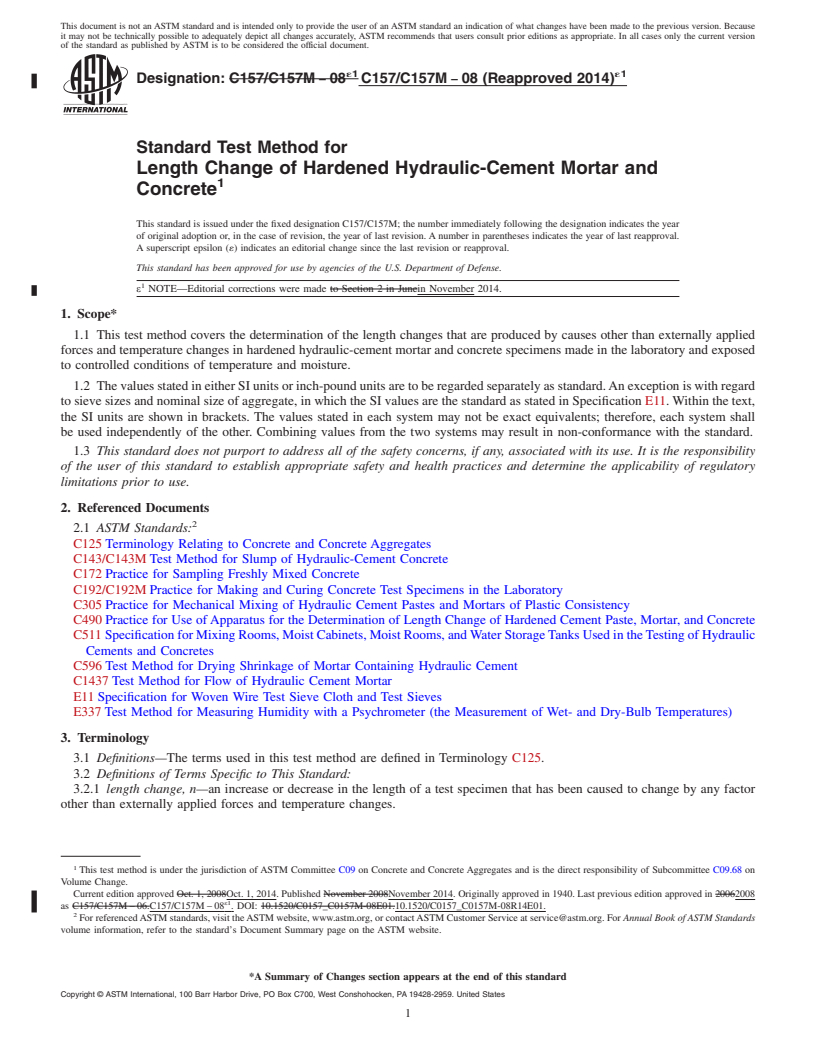

5.5 Atmometer—The atmometer shall be constructed as shown in Fig. 1.

5.5.1 Mounting—Fig. 2 shows a suggested arrangement for operating the atmometer. Punch a central hole ⁄2 in. [13 mm] in

diameter in a filter paper, place it on the atmometer, and secure it in place while dry, by turning the torque handle only, until it

just starts to slip. Mount the atmometer on a stand with the filter paper in a horizontal position. Mount a 100-mL glass graduate

so that the 100-mL mark is from 1 to 3 in. [25 to 75 mm] below the level of the filter paper. Stopper the graduate so that entrance

is provided for two short glass tubes not extending to the water level and one long tube extending to the bottom of the graduate.

Connect the glass tubing leading from the bottom of the graduate to the inlet of the atmometer by means of clear plastic tubing.

5.5.2 Operation—Use clear plastic tubing to connect a squeeze bottle containing distilled or deionized water to one of the short

glass tubes into the graduate. Force water into the graduate until it is about half full and then close the remaining glass tube into

the graduate. Continue to force water through the graduate into the atmometer until the filter paper is saturated and there are no

air bubbles in the system. Open the glass tube into the graduate and release pressure on the squeeze bottle gradually to avoid

trapping air in the tube leading to the atmometer. Adjust the level of water in the graduate to approximately the 100-mL mark. If

the atmometer is to be used under variable temperature conditions, disconnect the squeeze bottle after filling the graduate to avoid

the possibility of additional water being forced into the graduate. Permit evaporation of water from the filter paper for 1 h before

recording the time and initial reading of the graduate. It is not permitted to omit the waiting period during subsequent use of the

atmometer provided the filter paper does not become dry. Change the filter paper whenever it shows signs of contamination but

not less frequently than once every two weeks.

5.6 Filter Paper—The filter paper to be used with the atmometer shall be white with a smooth surface texture. It shall be 6 in.

[152 mm] in diameter and 0.050 6 0.003 in. [1.27 6 0.08 mm] thick and shall have a cotton fiber content of not less than 75

weight %. The density shall be between 0.400 and 0.425 g/cm . The Mullen bursting strength shall not be less than 50 psi [345

kPa].

´1

C157/C157M − 08 (2014)

FIG. 1 Atmometer

´1

C157/C157M − 08 (2014)

FIG. 2 Atmometer Assembly

Instructions for Use—Remove the end and the outer side plates leaving the base, center side plate, and gage stud holders in place. Engage the machine screw in the

drilled and tapped end of the center side plate. Turn the thumbscrew to loosen the bars.

FIG. 3 Device for Detaching 1-in. [25-mm] Square by 11 ⁄4-in. [285-mm] Bars from Center Side Plate of Double Molds

NOTE 1—Dimensions shown are appropriate for one design of mold for 3-in. [75-mm] square specimens. Change dimensions as required for other

molds.

FIG. 4 Device for Demolding Specimens from Single Molds

´1

C157/C157M − 08 (2014)

NOTE 1—E and D filter paper No. 625 has been found suitable.

5.7 Apparatus for Demolding Specimens—It is useful to construct an apparatus for demolding specimens molded in double

molds as detailed in Fig. 3 or to a different design that serves the same purpose. When this device is to be used, the center side

plate of the double mold must be appropriately drilled and tapped to receive the 8-32 by ⁄8 in. [4.5-0.74 IMC by 16 mm] machine

screw of the demolding thumbscrew. Fig. 4 shows the details of a suitable apparatus for demolding specimens molded in single

molds.

The sole source of supply of the apparatus known to the committee at this time is Ahlstrom Filtration Co., Mt. Holly Springs, PA 17065. If you are aware of alternative

suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical

committee, which you may attend.

´1

C157/C157M − 08 (2014)

ASTM C157 FIGURES

Figure Di- SI Units Inch-Pound Units

mensions

A Adjustable torque handle Adjustable torque handle

1.4–1.7 Nm 12–15 in.lb

B Jam nut Jam nut

10–15 IMC ⁄8-in.–16 NC

C 10-mm diameter 1.5 IMC Thd. ⁄8-in. dia–16 NC Thd.

D 12-mm diameter 1.5 IMC Thd. ⁄2-in. dia–20 NC Thd.

E 64-mm diameter 2.50-in. diameter

F 64-mm diameter 2.50-in. diameter

G 57-mm diameter 2.25-in. diameter

H 52-mm diameter 2.06-in. diameter

I 51-mm diameter 2.00-in. diameter

J 14 mm 0.56 in.

K 8 mm 0.31 in.

L 13 mm 0.50 in.

M 3 mm 0.125 in.

N 8 mm 0.31 in.

O 19 mm 0.75 in.

P 32 mm 1.25 in.

Q 53 mm 2.06 in.

1 29

R 1.5-mm drill through 11.5-mm C’ ⁄16-in. drill through ⁄64-in. C’ drill

drill

1 1

32-mm deep tap 12-mm 1.5-mm 1 ⁄4-in. deep tap ⁄2-in.–20 Thd

IMF Thd

3 5 1

S 19 mm deep 16 mm C’ bore 6 ⁄4-in. deep ⁄8-in. C’ bore ⁄4 in.

mm deep deep

3 1

T 5-mm drill 3-mm deep C’ drill ⁄16-in. drill ⁄8-in. deep C’ drill

at 60° as shown at 60° as shown

through to center tapped hole through to center tapped hole

U 3 mm 0.12 in. diameter

V 2 mm 0.09 in.

W 10 mm 0.40 in.

X 60 mm 2.36 in.

Y 35 mm 1.37 in.

Z 6 mm 0.25 in.

AA 6 mm 0.25 in.

BB 4 mm 0.15 in.

CC 6 mm 0.25 in.

DD 23 mm 0.87 in.

EE 38 mm 1.50 in.

FF 25 to 75 mm 1 to 3 in.

GG 35 mm high 1.37 in. high

HH 100 mm 4 in.

II 130 mm 5 in.

JJ 8 cm–6.1 kg/m channel 3 in.–4.1 lb/ft channel

KK 20 mm ⁄4 in.

LL 330 mm 13 in.

MM 14–2.0 IMC Thd. ⁄2 in.–12 Thd.

NN 20 mm ⁄4 in.

OO 50 mm 2 in.

PP 20 mm ⁄4 in.

QQ 60 mm ⁄4 in.

RR 10 mm ⁄8 in.

SS Drill Cl. hole for Drill Cl. hole for

4.5–0.75 IMC machine screw 8–32 in. machine screw

TT 13 mm ⁄2 in.

UU 25 mm 1 in.

VV 30 mm 1- ⁄16 in.

WW 60 mm 2- ⁄8 in.

XX 12.5 mm ⁄2 in.

YY 6-mm diameter steel rod ⁄4-in. diameter steel rod

ZZ 4.5–0.75 IMC × 16-mm machine 8–32 × ⁄8-in. machine screw

screw

6. Sampling

6.1 Take samples according to the applicable provisions of Practice C192/C192M from batches of hydraulic-cement mortar or

concrete made in the laboratory (Note 2).

NOTE 2—When collecting samples in nonstandard conditions, such as field concrete, it is suggested that Practice C172 be followed. Field cast

specimens can show up to twice as much drying shrinkage as laboratory cast specimens from the same materials and proportions.

7. Test Specimens

7.1 Mortar—The test specimen for mortar shall be a prism of 1-in. [25-mm] square cross-section and approximately 11 ⁄4 in.

[285 mm] in length. Three specimens shall be prepared for each test condition.

-----------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.