ASTM D97-09

(Test Method)Standard Test Method for Pour Point of Petroleum Products

Standard Test Method for Pour Point of Petroleum Products

SIGNIFICANCE AND USE

The pour point of a petroleum specimen is an index of the lowest temperature of its utility for certain applications.

SCOPE

1.1 This test method covers and is intended for use on any petroleum product. A procedure suitable for black specimens, cylinder stock, and nondistillate fuel oil is described in 8.8. The cloud point procedure formerly part of this test method now appears as Test Method D 2500.

1.2 Currently there is no ASTM test method for automated Test Method D 97 pour point measurements.

1.3 Several ASTM test methods offering alternative procedures for determining pour points using automatic apparatus are available. None of them share the same designation number as Test Method D 97. When an automatic instrument is used, the ASTM test method designation number specific to the technique shall be reported with the results. A procedure for testing the pour point of crude oils is described in Test Method D 5853.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D97–09

Designation: 15/95

Standard Test Method for

1

Pour Point of Petroleum Products

ThisstandardisissuedunderthefixeddesignationD97;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* D117 GuideforSampling,TestMethods,andSpecifications

for Electrical Insulating Oils of Petroleum Origin

1.1 This test method covers and is intended for use on any

2

D396 Specification for Fuel Oils

petroleum product. Aprocedure suitable for black specimens,

D2500 Test Method for Cloud Point of Petroleum Products

cylinderstock,andnondistillatefueloilisdescribedin8.8.The

D5853 Test Method for Pour Point of Crude Oils

cloud point procedure formerly part of this test method now

D6300 Practice for Determination of Precision and Bias

appears as Test Method D2500.

Data for Use in Test Methods for Petroleum Products and

1.2 Currently there is no ASTM test method for automated

Lubricants

Test Method D97 pour point measurements.

E1 Specification for ASTM Liquid-in-Glass Thermometers

1.3 Several ASTM test methods offering alternative proce-

2.2 Energy Institute Standards:

dures for determining pour points using automatic apparatus

4

Specifications for IP Standard Thermometers

areavailable.Noneofthemsharethesamedesignationnumber

as Test Method D97. When an automatic instrument is used,

3. Terminology

the ASTM test method designation number specific to the

3.1 Definitions:

technique shall be reported with the results. A procedure for

3.1.1 black oil, n—lubricant containing asphaltic materials.

testing the pour point of crude oils is described inTest Method

Blackoilsareusedinheavy-dutyequipmentapplications,such

D5853.

as mining and quarrying, where extra adhesiveness is desired.

1.4 The values stated in SI units are to be regarded as

3.1.2 cylinder stock, n—lubricant for independently lubri-

standard. No other units of measurement are included in this

cated engine cylinders, such as those of steam engines and air

standard.

compressors. Cylinder stock are also used for lubrication of

1.5 This standard does not purport to address all of the

valves and other elements in the cylinder area.

safety concerns, if any, associated with its use. It is the

3.1.3 pour point, n—in petroleum products, the lowest

responsibility of the user of this standard to establish appro-

temperature at which movement of the test specimen is

priate safety and health practices and determine the applica-

observed under prescribed conditions of test.

bility of regulatory limitations prior to use.

3.1.4 residual fuel, n—a liquid fuel containing bottoms

2. Referenced Documents remaining from crude distillation or thermal cracking; some-

3 times referred to as heavy fuel oil.

2.1 ASTM Standards:

3.1.4.1 Discussion—Residual fuels comprise Grades 4, 5,

and 6 fuel oils, as defined in Specification D396.

1

This test method is under the jurisdiction of ASTM Committee D02 on

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee

D02.07 on Flow Properties.

Current edition approved April 15, 2009. Published April 2009. Originally

approved in 1927, replacing D47. Last previous edition approved in 2008 as

D97–08.

In the IP, this test method is under the jurisdiction of the Standardization

Committee. This test method was adopted as a joint ASTM-IP Standard in 1965.

DOI: 10.1520/D0097-09.

2

Statements defining this test and its significance when applied to electrical

insulating oils of mineral origin will be found in Guide D117.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on MethodsforAnalysisandTesting,IPStandardsforPetroleumanditsProducts,

the ASTM website. Part I, Vol 2.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D97–09

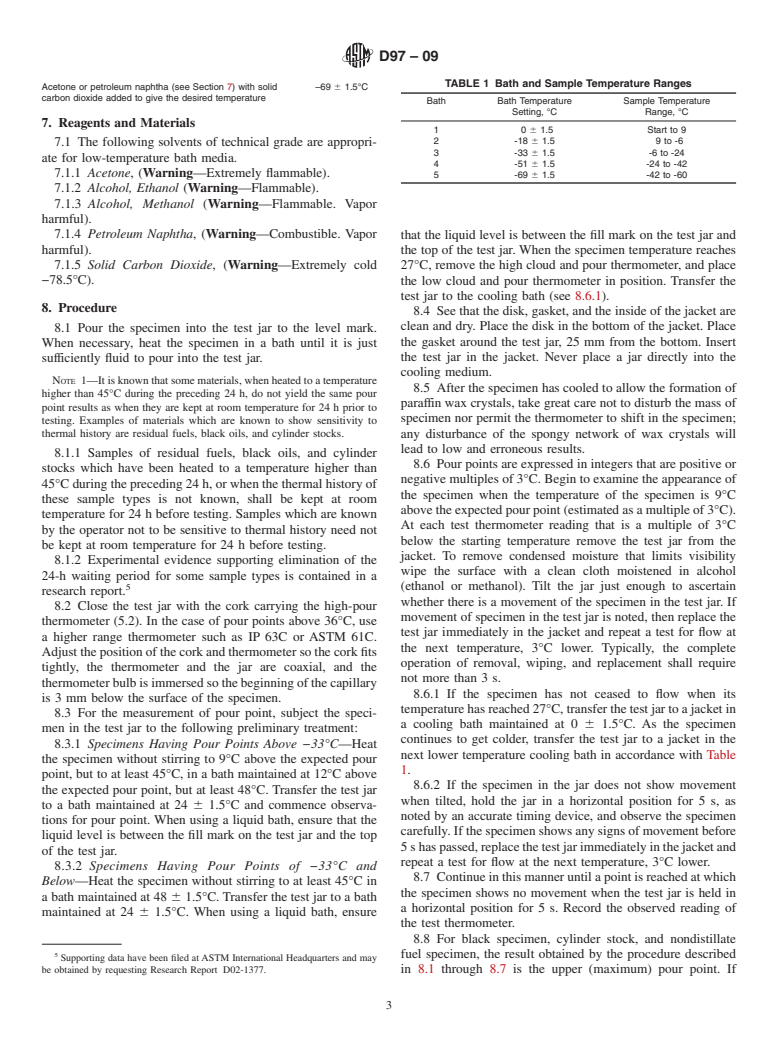

NOTE—Dimensions are in millimetres (not to scale).

FIG. 1 Apparatus for Pour Point Test

4. Summary of Test Method 6.3 Cork, to fit the test jar, bored centrally for the test

thermometer.

4.1 After preliminary heating, the sample is cooled at a

specified rate and examined at intervals of 3°C for flow 6.4 Jacket,watertight,cylindrical,metal,flat-bottomed,115

characteristics. The lowest temperature at which movement of 6 3-mm depth, with inside diameter of 44.2 to 45.8 mm. It

the specimen is observed is recorded as

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D97–08 Designation:D97–09

Designation: 15/95

Standard Test Method for

1

Pour Point of Petroleum Products

ThisstandardisissuedunderthefixeddesignationD97;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

2

1.1 This test method covers and is intended for use on any petroleum product. A procedure suitable for black specimens,

cylinder stock, and nondistillate fuel oil is described in 8.8.Aprocedure for testing the fluidity of a residual fuel oil at a specified

temperatureisdescribedinAppendixX1.ThecloudpointprocedureformerlypartofthistestmethodnowappearsasTestMethod

D2500.

1.2 Currently there is no ASTM test method for automated Test Method D97 pour point measurements.

1.3 Several ASTM test methods offering alternative procedures for determining pour points using automatic apparatus are

available. None of them share the same designation number as Test Method D97. When an automatic instrument is used, the

ASTMtestmethoddesignationnumberspecifictothetechniqueshallbereportedwiththeresults.Aprocedurefortestingthepour

point of crude oils is described in Test Method D5853.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

3

2.1 ASTM Standards:

D117 Guide for Sampling, Test Methods, and Specifications for Electrical Insulating Oils of Petroleum Origin

D396 Specification for Fuel Oils D1659Test Method for Maximum Fluidity Temperature of Residual Fuel Oil

D2500 Test Method for Cloud Point of Petroleum Products D3245Test Method for Pumpability of Industrial Fuel Oils

D5853 Test Method for Pour Point of Crude Oils

D6300 Practice for Determination of Precision and Bias Data for Use in Test Methods for Petroleum Products and Lubricants

E1 Specification for ASTM Liquid-in-Glass Thermometers

2.2 Energy Institute Standards:

4

Specifications for IP Standard Thermometers

3. Terminology

3.1 Definitions:

3.1.1 black oil, n—lubricant containing asphaltic materials. Black oils are used in heavy-duty equipment applications, such as

mining and quarrying, where extra adhesiveness is desired.

3.1.2 cylinder stock, n—lubricant for independently lubricated engine cylinders, such as those of steam engines and air

compressors. Cylinder stock are also used for lubrication of valves and other elements in the cylinder area.

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.07 on

Flow Properties.

CurrenteditionapprovedSept.1,2008.April15,2009.PublishedSeptember2008.April2009.Originallyapprovedin1927,replacingD47.Lastpreviouseditionapproved

in 20072008 as D97–07. D97–08.

In the IP, this test method is under the jurisdiction of the Standardization Committee. This test method was adopted as a joint ASTM-IP Standard in 1965.

2

Statements defining this test and its significance when applied to electrical insulating oils of mineral origin will be found in Guide D117.

3

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Withdrawn.

4

Methods for Analysis and Testing, IP Standards for Petroleum and its Products, Part I, Vol 2.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D97–09

3.1.3 pour point, n—in petroleum products, the lowest temperature at which movement of the test specimen is observed under

prescribed conditions of test.

3.1.4 residual fuel, n—a liquid fuel containing bottoms remaining from crude distillation or thermal cracking; sometimes

referred to as heavy fuel oil.

3.1.4.1 Discussion—Residual fuels comprise Grades 4, 5, an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.