ASTM A227/A227M-99

(Specification)Standard Specification for Steel Wire, Cold-Drawn for Mechanical Springs

Standard Specification for Steel Wire, Cold-Drawn for Mechanical Springs

SCOPE

1.1 This specification covers two classes of round cold-drawn steel spring wire having properties and quality for the manufacture of mechanical springs that are not subject to high stress or requiring high fatigue properties and wire forms.

1.2 The values stated in either SI (metric) units or inch-pound units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system must be used independent of the other.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 227/A 227M – 99

Standard Specification for

Steel Wire, Cold-Drawn for Mechanical Springs

This standard is issued under the fixed designationA227/A227M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope MIL-STD-163 Steel Mill Products, Preparation for Ship-

ment and Storage

1.1 This specification covers two classes of round cold-

2.4 Federal Standard:

drawn steel spring wire having properties and quality for the

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

manufacture of mechanical springs that are not subject to high

2.5 AIAG Standard:

stress or requiring high fatigue properties and wire forms.

AIAG B-5 02.00 Primary Metals Identification Tag Appli-

1.2 The values stated in either SI (metric) units or inch-

cation Standard

pound units are to be regarded separately as standard. The

values stated in each system are not exact equivalents; there-

3. Terminology

fore, each system must be used independent of the other.

3.1 Definitions of Terms Specific to This Standard:

2. Referenced Documents 3.1.1 For definition of terms used in this specification, refer

to Terminology A 941.

2.1 ASTM Standards:

A 370 Test Methods and Definitions for MechanicalTesting

4. Ordering Information

of Steel Products

4.1 It shall be the responsibility of the purchaser to specify

A 510 Specification for General Requirements for Wire

2 all requirements that are necessary for material under this

Rods and Coarse Round Wire, Carbon Steel

specification. Such requirement may include, but are not

A 510M Specification for General Requirements for Wire

2 limited to, the following:

Rods and Coarse Round Wire, Carbon Steel [Metric]

4.1.1 Quantity (mass),

A 700 Practices for Packaging, Marking, and Loading

3 4.1.2 Name of material (cold-drawn steel mechanical spring

Methods for Steel Products for Domestic Shipment

wire) and class (Table 1 or Table 2),

A 751 Test Methods, Practices, and Terminology for

2 4.1.3 Wire diameter (Table 1 or Table 2),

Chemical Analysis of Steel Products

4.1.4 Packaging (Section 15),

A 941 Terminology Relating to Steel, Stainless Steel, Re-

2 4.1.5 Cast or heat analysis report, if requested (Section 6),

lated Alloys and Ferroalloys

4.1.6 Certification or test report, or both, if specified (Sec-

E 29 Practice for Using Significant Digits in Test Data to

4 tion 14), and

Determine Conformance with Specifications

4.1.7 ASTM designation and date of issue.

2.2 American National Standard:

B 32.4M Preferred Metric Sizes for Round, Square, Rec-

NOTE 1—A typical ordering description is as follows: 15 000 kg

tangle, and Hexagon Metal Products Cold-Drawn Mechanical Spring Wire, Class I, Size 5.00 mm in 700-kg

coils to ASTM A 227M dated_______ , or for non-SI units, 30 000 lb

2.3 Military Standard:

Cold-Drawn Mechanical Spring Wire, Class I, Size 0.207 in. diameter in

500-lb coils to ASTM A 227 dated_______ .

5. Manufacture

This specification is under the jurisdiction of ASTM committee A-1 on Steel,

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee 5.1 The steel may be made by any commercially accepted

A01.03 on Steel Rod and Wire.

steel-making process. The steel may be either ingot cast or

Current edition approved March 10, 1999. Published May 1999. Originally

strand cast.

published as A 227 – 39 T and A 227M – 80. Last previous edition A 227/

A 227M – 93.

Annual Book of ASTM Standards, Vol 01.03.

3 6

Annual Book of ASTM Standards, Vol 01.05. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Annual Book of ASTM Standards, Vol 14.02. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

5 7

Available from American National Standards Institute, 11 West 42nd Street, Available from the Automotive Industry Action Group, 26200 Lahser, Suite

13th Floor, New York, NY 10036.

200, Southfield, MI 48034.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 227/A 227M – 99

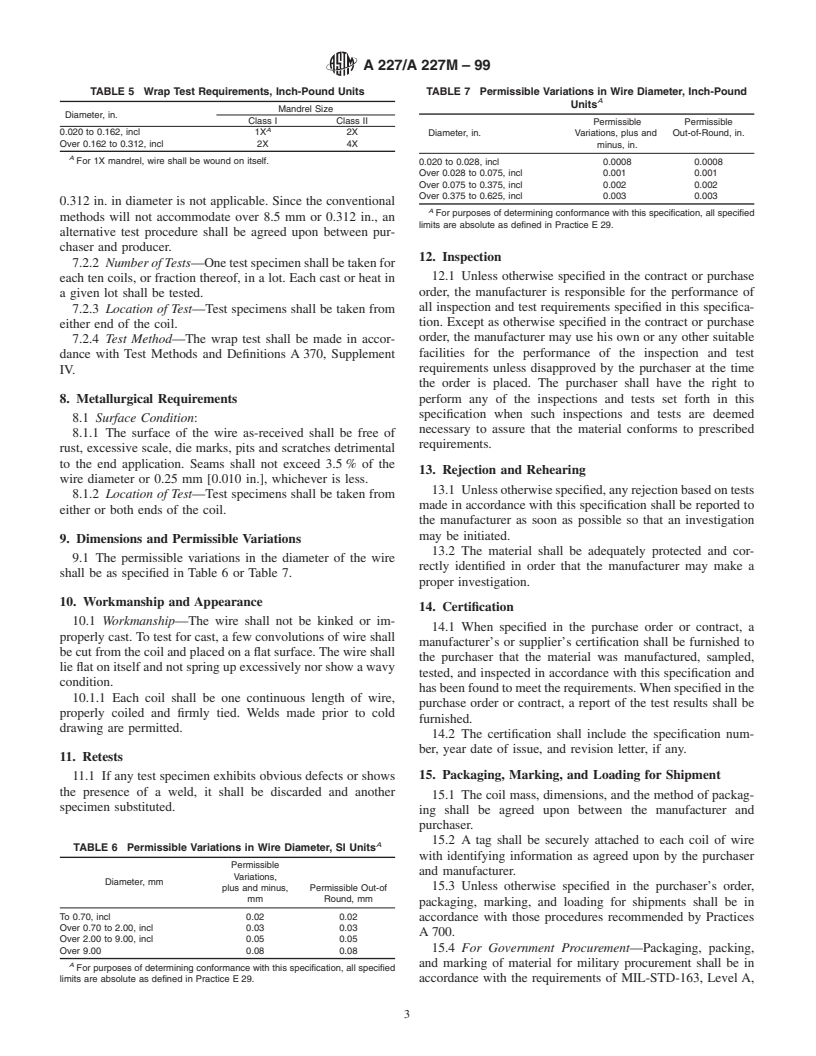

A A

TABLE 1 Tensile Requirements, SI Units TABLE 2 Tensile Requirements, Inch-Pound Units

Class I Class II Class I Class II

B

Diameter,

Tensile Strength, MPa Tensile Strength MPa Diameter, in. Tensile Strength, ksi Tensile Strength, ksi

mm

min max min max min max min max

0.50 1960 2240 2240 2520 0.020 283 323 324 364

0.55 1940 2220 2220 2500 0.023 279 319 320 360

0.60 1920 2200 2200 2480 0.026 275 315 316 356

0.65 1900 2180 2180 2460 0.029 271 311 312 352

0.70 1870 2140 2140 2410 0.032 266 306 307 347

0.80 1830 2100 2100 2370 0.035 261 301 302 342

0.90 1800 2070 2070 2340 0.041 255 293 294 332

1.00 1770 2040 2040 2310 0.048 248 286 287 325

1.10 1740 2000 2000 2260 0.054 243 279 280 316

1.20 1720 1980 1980 2240 0.062 237 272 273 308

1.40 1670 1930 1930 2180 0.072 232 266 267 301

1.60 1640 1880 1880 2120 0.080 227 261 262 296

1.80 1600 1840 1840 2080 0.092 220 253 254 287

2.00 1580 1810 1810 2040 0.106 216 248 249 281

2.20 1550 1780 1780 2010 0.120 210 241 242 273

2.50 1510 1730 1730 1960 0.135 206 237 238 269

2.80 1480 1700 1700 1920 0.148 203 234 235 266

3.00 1460 1680 1680 1900 0.162 200 230 231 261

3.50 1420 1630 1630 1840 0.177 195 225 226 256

4.00 1380 1590 1600 1700 0.192 192 221 222 251

4.50 1350 1550 1550 1750 0.207 190 218 219 247

5.00 1320 1510 1510 1700 0.225 186 214 215 243

5.50 1300 1490 1490 1670 0.250 182 210 211 239

6.00 1280 1470 1470 1650 0.312 174 200 201 227

6.50 1250 1440 1440 1630 0.375 167 193 194 220

7.00 1220 1410 1410 1600 0.438 165 190 191 216

7.50 1200 1390 1390 1580 0.500 156 180 181 205

8.00 1190 1370 1370 1550 0.562 152 176 177 201

9.00 1160 1340 . . . . . . 0.625 147 170 171 294

10.00 1130 1310 . . . . . .

A

Tensile strength values for intermediate diameters shall be interpolated.

11.00 1110 1280 . . . . . .

12.00 1090 1260 . . . . . .

14.00 1050 1210 . . . . . .

TABLE 3 Chemical Requirements

16.00 1010 1170 . . . . . .

Element Composition, %

A

Tensile strength values for intermediate diameters may be interpolated.

A

B

Carbon 0.45–0.85

Preferred sizes. For a complete list, refer to ANSI B32.4M, Preferred Metric

B

Manganese 0.30–1.30

Sizes for Round, Square, Rectangle, and Hexagon Metal Products.

Phosphorus, max 0.040

Sulfur, max 0.050

Silicon 0.15–0.35

5.2 The finished wire shall be free of detrimental pipe and

A

Carbon in any one lot shall not vary more than 0.13 %.

undue segregation.

B

Manganese in any one lot shall not vary more than 0.30 %.

5.3 The wire shall be cold drawn to produce the desired

mechanical properties.

7.1.1 Requirements—Thematerialasrepresentedbytension

6. Chemical Composition

test specimens shall conform to the requirements prescribed in

6.1 Thesteelshallconformtotherequirementsforchemical

Table 1 or Table 2.

composition prescribed in Table 3.

7.1.2 Number of Tests—Onetestspecimenshallbetakenfor

6.2 Cast or Heat Analysis—Each cast or heat of steel shall

each ten coils or fraction thereof, in a lot. Each cast or heat in

beanalyzedbythemanufacturertodeterminethepercentageof

a given lot shall be tested.

elements prescribed in Table 3. This analysis shall be made

7.1.3 Location of Tests—Test specimens shall be taken from

from a test specimen preferably taken during the pouring of the

either end of the coil.

cast or heat. When requested, this shall be reported to the

7.1.4 Test Method—The tension test shall be made in

purchaser and shall

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.