ASTM A313/A313M-18

(Specification)Standard Specification for Stainless Steel Spring Wire

Standard Specification for Stainless Steel Spring Wire

ABSTRACT

This guide covers standard specification for austenitic and age-hardenable stainless steel round spring wire intended especially for the manufacture of springs. The steel shall conform to the required chemical composition for carbon, manganese, phosphorus, sulfur, silicon, chromium, nickel, molybdenum, nitrogen, and other elements. The material shall conform to the required tensile strengths following the prescribed heat treatment. Tensile strength requirements for hardened wires and stress-relieved materials shall be given. Mechanical tests such as wrap test, uniformity (coil test), and bend test hall be performed on the steel material.

SCOPE

1.1 This specification covers austenitic, austenitic-ferritic, and age-hardenable stainless steel round spring wire intended especially for the manufacture of springs.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 Unless the order specifies an “M” designation, the material shall be furnished to inch-pound units.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A313/A313M −18

Standard Specification for

1

Stainless Steel Spring Wire

This standard is issued under the fixed designationA313/A313M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 3. Ordering Information

1.1 This specification covers austenitic, austenitic-ferritic, 3.1 It is the responsibility of the purchaser to specify all

and age-hardenable stainless steel round spring wire intended requirements that are necessary for material ordered under this

especially for the manufacture of springs. specification. Such requirements may include, but are not

limited to the following:

1.2 The values stated in either SI units or inch-pound units

3.1.1 Quantity (weight),

are to be regarded separately as standard. The values stated in

3.1.2 Name of material (stainless steel spring wire),

each system may not be exact equivalents; therefore, each

3.1.3 Finish (see 8.1),

system shall be used independently of the other. Combining

3.1.4 Dimension (diameter),

values from the two systems may result in non-conformance

3.1.5 Type designation (Table 1),

with the standard.

3.1.6 ASTM designation and date of issue,

1.3 Unless the order specifies an “M” designation, the

3.1.7 Tensile strength level, when applicable (Table 11 and

material shall be furnished to inch-pound units.

Table 12),

1.4 This international standard was developed in accor- 3.1.8 Supplementary requirements for government

dance with internationally recognized principles on standard-

procurement, and

ization established in the Decision on Principles for the 3.1.9 Special requirements.

Development of International Standards, Guides and Recom-

NOTE 1—A typical ordering description is as follows:

mendations issued by the World Trade Organization Technical

2000 lb (1000 kg) Stainless Steel Spring Wire, cold-drawn Class 1,

Barriers to Trade (TBT) Committee.

bright finish, 0.032-in. (0.82 mm) diameter, in 100-lb (50 kg) 16-in. (0.4

m) coils, Type 302 to ASTM A313, dated ____.

2. Referenced Documents

4. General Requirements for Delivery

2

2.1 ASTM Standards:

4.1 In addition to the requirements of this specification, all

A555/A555M Specification for General Requirements for

requirements of the current edition of Specification A555/

Stainless Steel Wire and Wire Rods

A555M shall apply. Failure to comply with the general

A751 Test Methods, Practices, and Terminology for Chemi-

requirements of Specification A555/A555M constitutes non-

cal Analysis of Steel Products

conformance with this specification.

E527 Practice for Numbering Metals and Alloys in the

Unified Numbering System (UNS)

5. Manufacture

3

2.2 Society of Automotive Engineers Standard:

5.1 Types 302 Class 1, 304, 305, 316, 321, 347, UNS

J 1086 Numbering Metals and Alloys

S20230, and Grades S20430 and XM-28 shall be cold drawn to

produce the required mechanical properties.

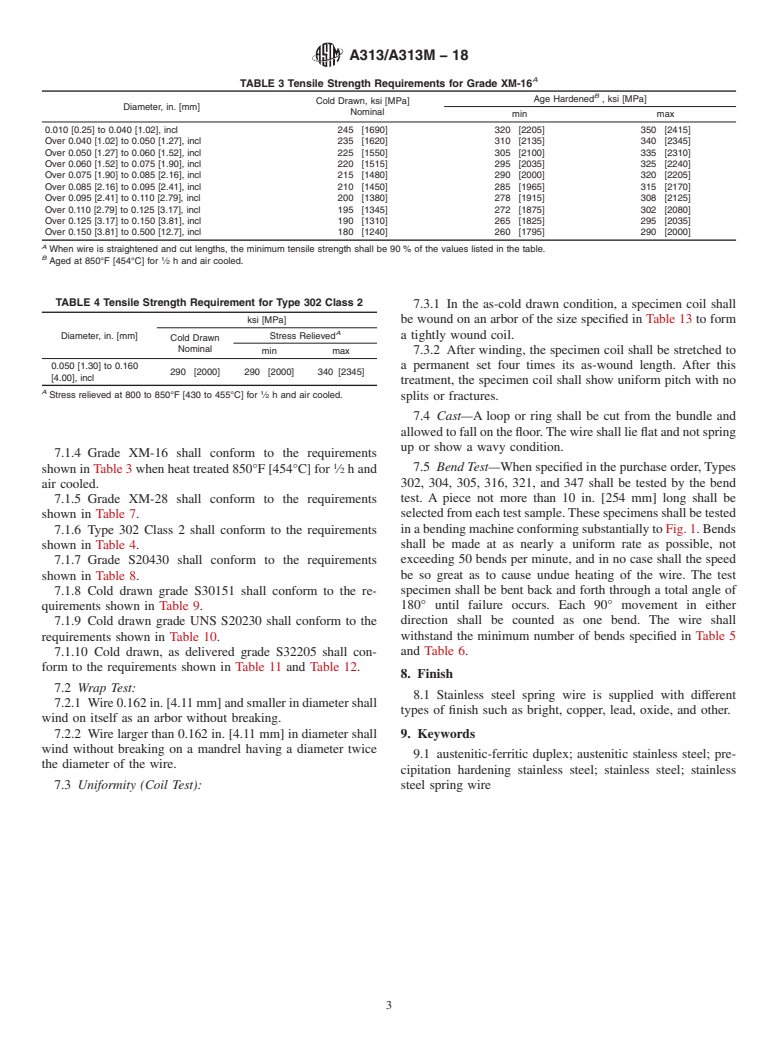

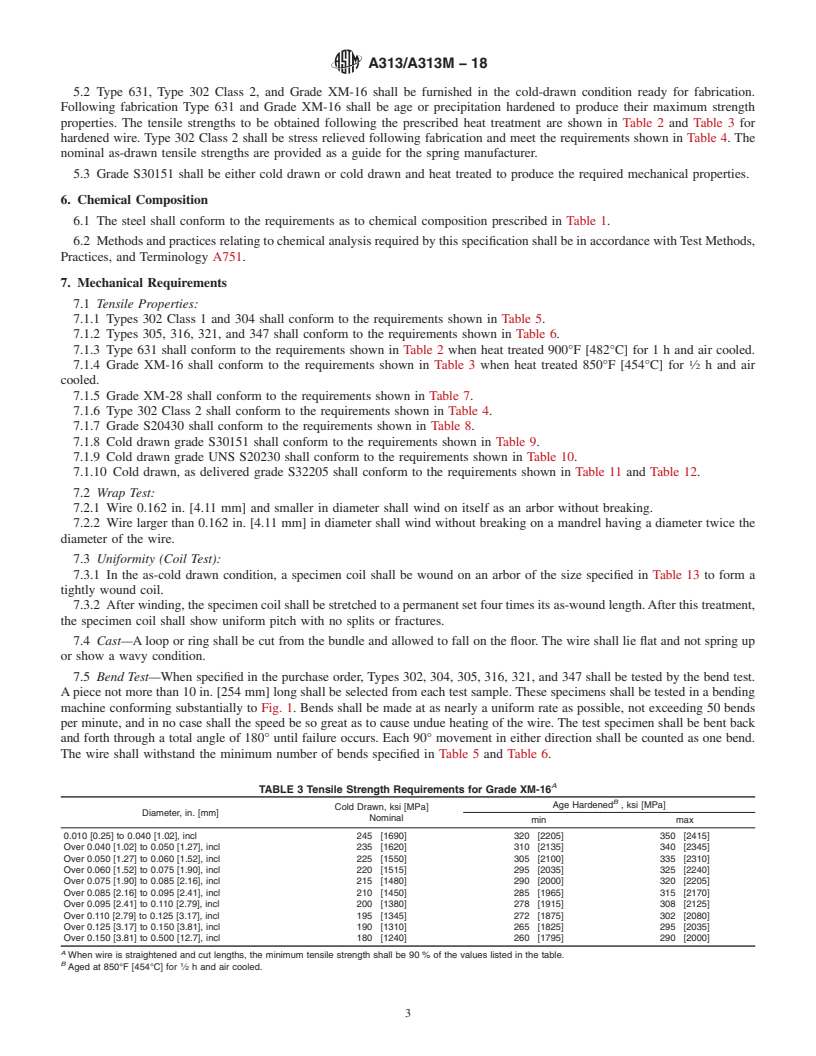

5.2 Type 631, Type 302 Class 2, and Grade XM-16 shall be

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

furnished in the cold-drawn condition ready for fabrication.

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.17 on Flat-Rolled and Wrought Stainless Steel.

Following fabricationType 631 and Grade XM-16 shall be age

Current edition approved Sept. 1, 2018. Published September 2018. Originally

or precipitation hardened to produce their maximum strength

approved in 1947. Last previous edition approved in 2017 as A313/A313M – 17.

properties. The tensile strengths to be obtained following the

DOI: 10.1520/A0313_A0313M-18.

2

prescribed heat treatment are shown in Table 2 and Table 3 for

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

hardened wire. Type 302 Class 2 shall be stress relieved

Standards volume information, refer to the standard’s Document Summary page on

following fabrication and meet the requirements shown in

the ASTM website.

3

Table 4. The nominal as-drawn tensile strengths are provided

Available from Society of Automotive Engineers (SAE), 400 Commonwealth

Dr., Warrendale, PA 15096-0001, http://www.sae.org. as a guide for the spring manufacturer.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A313/A313M − 17 A313/A313M − 18

Standard Specification for

1

Stainless Steel Spring Wire

This standard is issued under the fixed designation A313/A313M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers austenitic, austenitic-ferritic, and age-hardenable stainless steel round spring wire intended

especially for the manufacture of springs.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 Unless the order specifies an “M” designation, the material shall be furnished to inch-pound units.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A555/A555M Specification for General Requirements for Stainless Steel Wire and Wire Rods

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

3

2.2 Society of Automotive Engineers Standard:

J 1086 Numbering Metals and Alloys

3. Ordering Information

3.1 It is the responsibility of the purchaser to specify all requirements that are necessary for material ordered under this

specification. Such requirements may include, but are not limited to the following:

3.1.1 Quantity (weight),

3.1.2 Name of material (stainless steel spring wire),

3.1.3 Finish (see 8.1),

3.1.4 Dimension (diameter),

3.1.5 Type designation (Table 1),

3.1.6 ASTM designation and date of issue,

3.1.7 Tensile strength level, when applicable (Table 11 and Table 12),

3.1.8 Supplementary requirements for government procurement, and

3.1.9 Special requirements.

NOTE 1—A typical ordering description is as follows:

2000 lb (1000 kg) Stainless Steel Spring Wire, cold-drawn Class 1, bright finish, 0.032-in. (0.82 mm) diameter, in 100-lb (50 kg) 16-in. (0.4 m) coils,

Type 302 to ASTM A313, dated ____.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.17

on Flat-Rolled and Wrought Stainless Steel.

Current edition approved Nov. 1, 2017Sept. 1, 2018. Published November 2017September 2018. Originally approved in 1947. Last previous edition approved in 20132017

as A313/A313M – 13.A313/A313M – 17. DOI: 10.1520/A0313_A0313M-17.10.1520/A0313_A0313M-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Society of Automotive Engineers (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001, http://www.sae.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A313/A313M − 18

TABLE 1 Chemical Requirements

B

Composition, %

UNS

Type

A

Designation

Carbon Manganese Phosphorus Sulfur Silicon Chromium Nickel Molybdenum Nitrogen Other Elements

Austenitic Grades

S 20230 . . . 0.02–0.06 2.0–6.0 0.045 0.030 1.00 17.0–19.0 2.0–4.5 1.0 0.13–0.25 Cu 2.0–4.0

S 20430 . . . 0.15 6.5–9.0 0.060 0.030 1.00 15.5–17.5 1.5–3.5 . . . 0.05–0.25 Cu 2.0–4.0

S 24100 XM-28 0.15 11.0–14.0 0.060 0.030 1.00 16.5–19.0 0.50–2.50 . . . 0.20–0.45 . . .

S 30151 . . . 0.07–0.09 1.50–2.00 0.025 0.010 1.20–1.80 16.0–18.0 7.0–9.0 0.50–1.00 0.07–0.11 Cu 0.40

S 30200 302 0.12 2.00 0.045 0.030 1.00 17.0–19.0 8.0–10.0 . . . 0.10 . . .

S 30400 304 0.08 2.00 0.045 0.030 1.00 18.0–20.0 8.0–10.5 . . . 0.10 . . .

S 30500 305 0.12 2.00 0.045 0.030 1.00 17.0–19.0 10.5–13

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.