ASTM E2860-12

(Test Method)Standard Test Method for Residual Stress Measurement by X-Ray Diffraction for Bearing Steels

Standard Test Method for Residual Stress Measurement by X-Ray Diffraction for Bearing Steels

SIGNIFICANCE AND USE

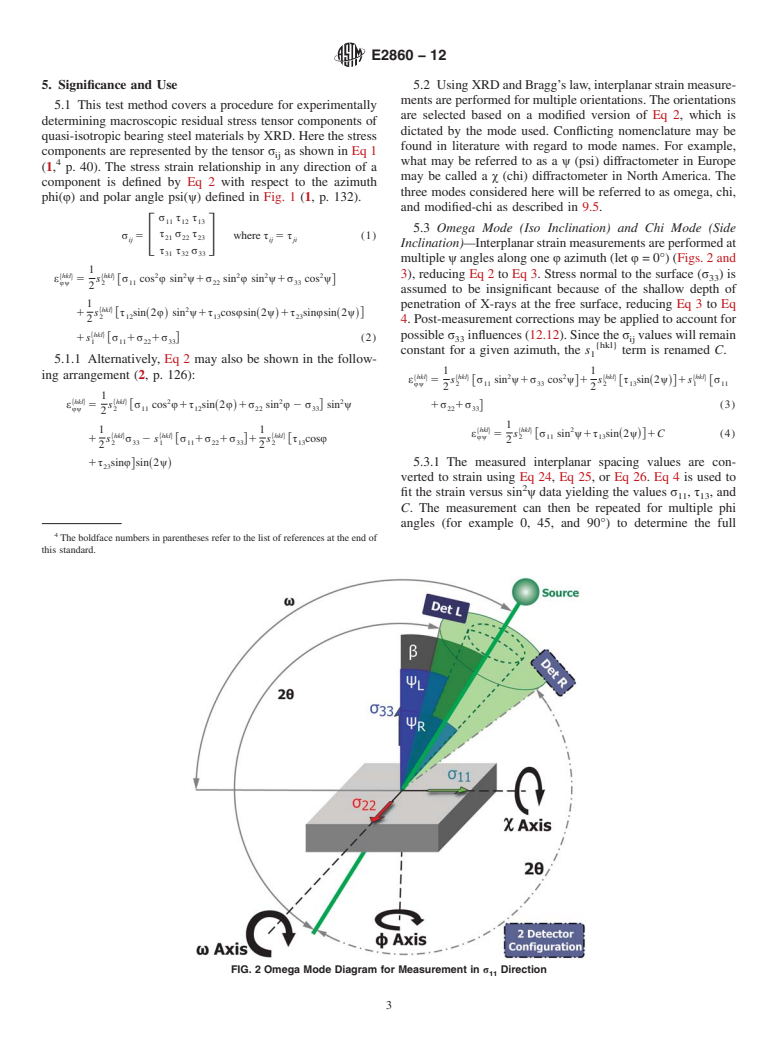

This test method covers a procedure for experimentally determining macroscopic residual stress tensor components of quasi-isotropic bearing steel materials by XRD. Here the stress components are represented by the tensor σij as shown in Eq 1 (1, p. 40). The stress strain relationship in any direction of a component is defined by Eq 2 with respect to the azimuth phi(ϕ) and polar angle psi(ψ) defined in Fig. 1 (1, p. 132).

Alternatively, Eq 2 may also be shown in the following arrangement (2, p. 126):

Using XRD and Bragg’s law, interplanar strain measurements are performed for multiple orientations. The orientations are selected based on a modified version of Eq 2, which is dictated by the mode used. Conflicting nomenclature may be found in literature with regard to mode names. For example, what may be referred to as a ψ (psi) diffractometer in Europe may be called a χ (chi) diffractometer in North America. The three modes considered here will be referred to as omega, chi, and modified-chi as described in 9.5.

Omega Mode (Iso Inclination) and Chi Mode (Side Inclination)—Interplanar strain measurements are performed at multiple ψ angles along one ϕ azimuth (let ϕ = 0°) (Figs. 2 and 3), reducing Eq 2 to Eq 3. Stress normal to the surface (σ33) is assumed to be insignificant because of the shallow depth of penetration of X-rays at the free surface, reducing Eq 3 to Eq 4. Post-measurement corrections may be applied to account for possible σ33 influences (12.12). Since the σij values will remain constant for a given azimuth, the s1{hkl} term is renamed C.

The measured interplanar spacing values are converted to strain using Eq 24, Eq 25, or Eq 26. Eq 4 is used to fit the strain versus sin2ψ data yielding the values σ11, τ13, and C. The measurement can then be repeated for multiple phi angles (for example 0, 45, and 90°) to determine the full stress/strain tensor. The value, σ11, will influence the overall slope of the data, while τ13 is related ...

SCOPE

1.1 This test method covers a procedure for experimentally determining macroscopic residual stress tensor components of quasi-isotropic bearing steel materials by X-ray diffraction (XRD).

1.2 This test method provides a guide for experimentally determining stress values, which play a significant role in bearing life.

1.3 Examples of how tensor values are used are:

1.3.1 Detection of grinding type and abusive grinding;

1.3.2 Determination of tool wear in turning operations;

1.3.3 Monitoring of carburizing and nitriding residual stress effects;

1.3.4 Monitoring effects of surface treatments such as sand blasting, shot peening, and honing;

1.3.5 Tracking of component life and rolling contact fatigue effects;

1.3.6 Failure analysis;

1.3.7 Relaxation of residual stress; and

1.3.8 Other residual-stress-related issues that potentially affect bearings.

1.4 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2860 − 12

Standard Test Method for

Residual Stress Measurement by X-Ray Diffraction for

1

Bearing Steels

This standard is issued under the fixed designation E2860; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The measurement of residual stress using X-ray diffraction (XRD) techniques has gained much

popularityinthematerialstestingfieldoverthepasthalfcenturyandhasbecomeamandatorytestfor

many production and prototype bearing components. However, measurement practices have evolved

over this time period. With each evolutionary step, it was discovered that previous assumptions were

sometimes erroneous, and as such, results obtained were less reliable than those obtained using

state-of-the-art XRD techniques. Equipment and procedures used today often reflect different periods

inthisevolution;forexample,systemsthatstillusethesingle-anddouble-exposuretechniquesaswell

as others that use more advanced multiple exposure techniques can all currently be found in

widespread use. Moreover, many assumptions made, such as negligible shear components and

2

non-oscillatory sin ψ distributions, cannot safely be made for bearing materials in which the demand

for measurement accuracy is high. The use of the most current techniques is, therefore, mandatory to

achievenotonlythemostreliablemeasurementresultsbutalsotoenableidentificationandevaluation

of potential measurement errors, thus paving the way for future developments.

1. Scope 1.3.8 Other residual-stress-related issues that potentially

affect bearings.

1.1 This test method covers a procedure for experimentally

determining macroscopic residual stress tensor components of 1.4 Units—The values stated in SI units are to be regarded

asstandard.Nootherunitsofmeasurementareincludedinthis

quasi-isotropic bearing steel materials by X-ray diffraction

(XRD). standard.

1.5 This standard does not purport to address all of the

1.2 This test method provides a guide for experimentally

safety concerns, if any, associated with its use. It is the

determining stress values, which play a significant role in

responsibility of the user of this standard to establish appro-

bearing life.

priate safety and health practices and determine the applica-

1.3 Examples of how tensor values are used are:

bility of regulatory limitations prior to use.

1.3.1 Detection of grinding type and abusive grinding;

1.3.2 Determination of tool wear in turning operations;

2. Referenced Documents

1.3.3 Monitoringofcarburizingandnitridingresidualstress

2

2.1 ASTM Standards:

effects;

E6Terminology Relating to Methods of Mechanical Testing

1.3.4 Monitoring effects of surface treatments such as sand

E7Terminology Relating to Metallography

blasting, shot peening, and honing;

E915Test Method for Verifying the Alignment of X-Ray

1.3.5 Tracking of component life and rolling contact fatigue

Diffraction Instrumentation for Residual Stress Measure-

effects;

ment

1.3.6 Failure analysis;

E1426Test Method for Determining the Effective Elastic

1.3.7 Relaxation of residual stress; and

Parameter for X-Ray Diffraction Measurements of Re-

sidual Stress

1

This test method is under the jurisdiction of ASTM Committee E28 on

2

Mechanical Testing and is the direct responsibility of Subcommittee E28.13 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Residual Stress Measurement. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved April 1, 2012. Published May 2012. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

E2860–12. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2860 − 12

3 {hkl}

2.2 ANSI Standards: E =Effective elastic modulus for X-ray measurements

eff

N43.2Radiation Safety for X-ray Diffraction and Fluores- µ=Attenuation coefficient

cence Analysis Equipment η=Rotation of the sample around the measuring direction

N43.3For General Radiation Safety—Installations Using given by φ and ψ or χ and β

Non-Medical X-Ray and Sealed Gamma-Ray Sources, ω or Ω=Angle between the specimen surface and incident

Energies Up to 10 MeV beam when χ=0°

φ=Angle between the σ direction and measurement di-

11

3. Terminology

rection azimuth, see Fig. 1

“hkl”=Miller indices

3.1 Definitions—Many of the terms used in this test method

σ =Normal stress component i, j

are defined in Terminologies E6 and E7.

ij

{hkl}

s =X-ray elastic constant of quasi-isotropic material

1

3.2 Defi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.