ASTM D6595-00(2005)

(Test Method)Standard Test Method for Determination of Wear Metals and Contaminants in Used Lubricating Oils or Used Hydraulic Fluids by Rotating Disc Electrode Atomic Emission Spectrometry

Standard Test Method for Determination of Wear Metals and Contaminants in Used Lubricating Oils or Used Hydraulic Fluids by Rotating Disc Electrode Atomic Emission Spectrometry

SIGNIFICANCE AND USE

Used Lubricating Oil—The determination of debris in used oil is a key diagnostic method practiced in machine condition monitoring programs. The presence or increase in concentration of specific wear metals can be indicative of the early stages of wear if there are baseline concentration data for comparison. A marked increase in contaminant elements can be indicative of foreign materials in the lubricants, such as antifreeze or sand, which may lead to wear or lubricant degradation. The test method identifies the metals and their concentration so that trends relative to time or distance can be established and corrective action can be taken prior to more serious or catastrophic failure.

SCOPE

1.1 This test method covers the determination of wear metals and contaminants in used lubricating oils and used hydraulic fluids by rotating disc electrode atomic emission spectroscopy (RDE-AES).

1.2 This test method provides a quick indication for abnormal wear and the presence of contamination in new or used lubricants and hydraulic fluids.

1.3 This test method uses oil-soluble metals for calibration and does not purport to relate quantitatively the values determined as insoluble particles to the dissolved metals. Analytical results are particle size dependent and low results may be obtained for those elements present in used oil samples as large particles.

1.4 The test method is capable of detecting and quantifying elements resulting from wear and contamination ranging from dissolved materials to particles approximately 10 m in size.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. The preferred units are mg/kg (ppm by mass).

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6595–00 (Reapproved 2005)

Standard Test Method for

Determination of Wear Metals and Contaminants in Used

Lubricating Oils or Used Hydraulic Fluids by Rotating Disc

Electrode Atomic Emission Spectrometry

This standard is issued under the fixed designation D6595; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the determination of wear 3.1 Definitions:

metals and contaminants in used lubricating oils and used 3.1.1 burn, vt—in emission spectroscopy, to vaporize and

hydraulic fluids by rotating disc electrode atomic emission excite a specimen with sufficient energy to generate spectral

spectroscopy (RDE-AES). radiation.

1.2 This test method provides a quick indication for abnor- 3.1.2 calibration, n—the determination of the values of the

mal wear and the presence of contamination in new or used significant parameters by comparison with values indicated by

lubricants and hydraulic fluids. a set of reference standards.

1.3 This test method uses oil-soluble metals for calibration 3.1.3 calibration curve, n—the graphical or mathematical

and does not purport to relate quantitatively the values deter- representation of a relationship between the assigned (known)

mined as insoluble particles to the dissolved metals.Analytical values of standards and the measured responses from the

results are particle size dependent and low results may be measurement system.

obtainedforthoseelementspresentinusedoilsamplesaslarge 3.1.4 calibration standard, n—a standard having an ac-

particles. cepted value (reference value) for use in calibrating a measure-

1.4 The test method is capable of detecting and quantifying ment instrument or system.

elements resulting from wear and contamination ranging from 3.1.5 emission spectroscopy, n—measurement of energy

dissolved materials to particles approximately 10 µm in size. spectrum emitted by or from an object under some form of

1.5 The values stated in SI units are to be regarded as the energetic stimulation; for example, light, electrical discharge,

standard. The values given in parentheses are for information and so forth.

only. The preferred units are mg/kg (ppm by mass). 3.2 Definitions of Terms Specific to This Standard:

1.6 This standard does not purport to address all of the 3.2.1 arc discharge, n—a self-sustaining, high current den-

safety concerns, if any, associated with its use. It is the sity, high temperature discharge, uniquely characterized by a

responsibility of the user of this standard to establish appro- cathode fall nearly equal to the ionization potential of the gas

priate safety and health practices and determine the applica- or vapor in which it exists.

bility of regulatory limitations prior to use. 3.2.2 check sample, n—a reference material usually pre-

pared by a laboratory for its own use as a calibration standard,

2. Referenced Documents

as a measurement control standard, or for the qualification of a

2.1 ASTM Standards:

measurement method.

D4057 Practice for Manual Sampling of Petroleum and 3.2.3 contaminant, n—material in an oil sample that may

Petroleum Products

cause abnormal wear or lubricant degradation.

3.2.4 counterelectrode,n—eitheroftwographiteelectrodes

in an atomic emission spectrometer across which an arc or

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee spark is generated.

D02.03 on Elemental Analysis.

3.2.5 graphite disc electrode, n—a soft form of the element

Current edition approved May 1, 2005. Published June 2005. Originally

carbon manufactured into the shape of a disc for use as a

approved in 2000. Last previous edition approved in 2000 as D6595–00. DOI:

counter electrode in arc/spark spectrometers for oil analysis.

10.1520/D6595-00R05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.2.6 graphite rod electrode, n—a soft form of the element

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

carbon manufactured into the shape of a rod for use as a

Standards volume information, refer to the standard’s Document Summary page on

counter electrode in arc/spark spectrometers for oil analysis.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6595–00 (2005)

TABLE 1 Elements and Recommended Wavelengths

3.2.7 profiling, n—to set the actual position of the entrance

slit to produce optimum measurement intensity. Element Wavelength, nm Element Wavelength, nm

3.2.8 standardization, n—the process of reestablishing and

Aluminum 308.21 Nickel 341.48

Barium 230.48, 455.40 Phosphorus 255.32, 214.91

correcting a calibration curve through the analysis of at least

Boron 249.67 Potassium 766.49

two known oil standards.

Calcium 393.37, 445.48 Silicon 251.60

3.2.9 uptake rate, n—the amount of oil sample that is

Chromium 425.43 Silver 328.07, 243.78

Copper 324.75, 224.26 Sodium 588.89, 589.59

physically carried by the rotating disc electrode into the arc for

Iron 259.94 Tin 317.51

analysis.

Lead 283.31 Titanium 334.94

3.2.10 wear metal, n—material resulting from damage to a

Lithium 670.78 Tungsten 400.87

Manganese 403.07, 294.92 Vanadium 290.88, 437.92

solid surface due to relative motion between that surface and a

Magnesium 280.20, 518.36 Zinc 213.86

contacting substance or substances.

Molybdenum 281.60

4. Summary of Test Method

4.1 Wear metals and contaminants in a used oil test speci-

men are evaporated and excited by a controlled arc discharge will be adversely affected if the sample base stock has a

using the rotating disk technique. The radiant energies of different viscosity from the base line samples.

selected analytical lines and one or more references are 6.3 Particulate—When large particles over 10 µm in size

are detected, the analytical results will be lower than the actual

collected and stored by way of photomultiplier tubes, charge

coupled devices or other suitable detectors. A comparison is concentration they represent. Large particles may not be

effectively transported by the rotating disk electrode sample

made of the emitted intensities of the elements in the used oil

test specimen against those measured with calibration stan- introduction system into the arc, nor will they be fully

dards.The concentrations of the elements present in the oil test vaporized by the spark.

specimen are calculated and displayed. They may also be

entered into a data base for processing.

7. Apparatus

7.1 Electrode Sharpener—An electrode sharpener is neces-

5. Significance and Use

sary to remove the contaminated portion of the rod electrode

5.1 Used Lubricating Oil—The determination of debris in remainingfromthepreviousdetermination.Italsoformsanew

used oil is a key diagnostic method practiced in machine 160° angle on the end of the electrode. Electrode sharpeners

condition monitoring programs. The presence or increase in are not required for instruments using a pre-shaped disc

electrode as the counter electrode.

concentration of specific wear metals can be indicative of the

early stages of wear if there are baseline concentration data for 7.2 Rotating Disc Electrode Atomic Emission Spectrometer,

comparison.Amarkedincreaseincontaminantelementscanbe a simultaneous spectrometer consisting of excitation source,

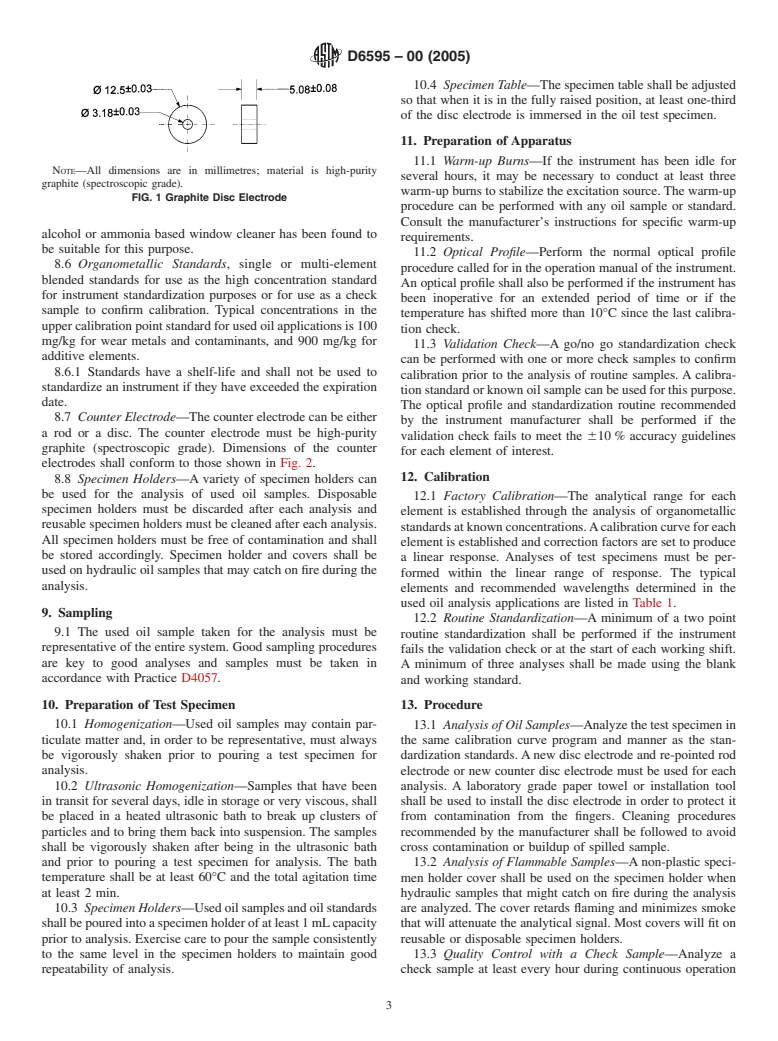

indicative of foreign materials in the lubricants, such as polychromator optics, and a readout system. Suggested ele-

antifreeze or sand, which may lead to wear or lubricant ments and wavelengths are listed in Table 1. When multiple

degradation. The test method identifies the metals and their wavelengths are listed, they are in the order of preference or

concentration so that trends relative to time or distance can be desired analytical range.

established and corrective action can be taken prior to more 7.3 Heated Ultrasonic Bath (Recommended), an ultrasonic

serious or catastrophic failure. bathtoheatandhomogenizeusedoilsamplestobringparticles

into homogeneous suspension. The ultrasonic bath shall be

used on samples containing large amount of debris and those

6. Interferences

that have been in transit or stored for 48 hours or longer.

6.1 Spectral—Mostspectralinterferencescanbeavoidedby

judicious choice of spectral lines. High concentrations of

8. Reagents and Materials

additive elements can have an interfering influence on the

spectral lines used for determining wear metals. Instrument 8.1 Base Oil, a 75 cSt base oil free of analyte to be used as

manufacturers usually compensate for spectral interferences a calibration blank or for blending calibration standards.

during factory calibration. A background correction system, 8.2 Check Samples, An oil standard or sample of known

which subtracts unwanted intensities on either side of the concentration which is periodically analyzed as a go/no go

spectral line, shall also be used for this purpose. When spectral sample to confirm the need for standardization based on an

interferencescannotbeavoidedwithspectrallineselectionand allowable 610 % accuracy limit.

backgroundcorrection,thenecessarycorrectionsshallbemade 8.3 Cleaning Solution, An environmentally safe, non-

using the computer software supplied by the instrument manu- chlorinated,rapidevaporating,andnon-filmproducingsolvent,

facturer. to remove spilled or splashed oil sample in the sample stand.

6.2 Viscosity Effects—Differences in viscosity of used oil 8.4 Disc Electrode, a graphite disc electrode of high-purity

samples will cause differences in uptake rates. Internal refer- graphite (spectroscopic grade). Dimensions of the electrodes

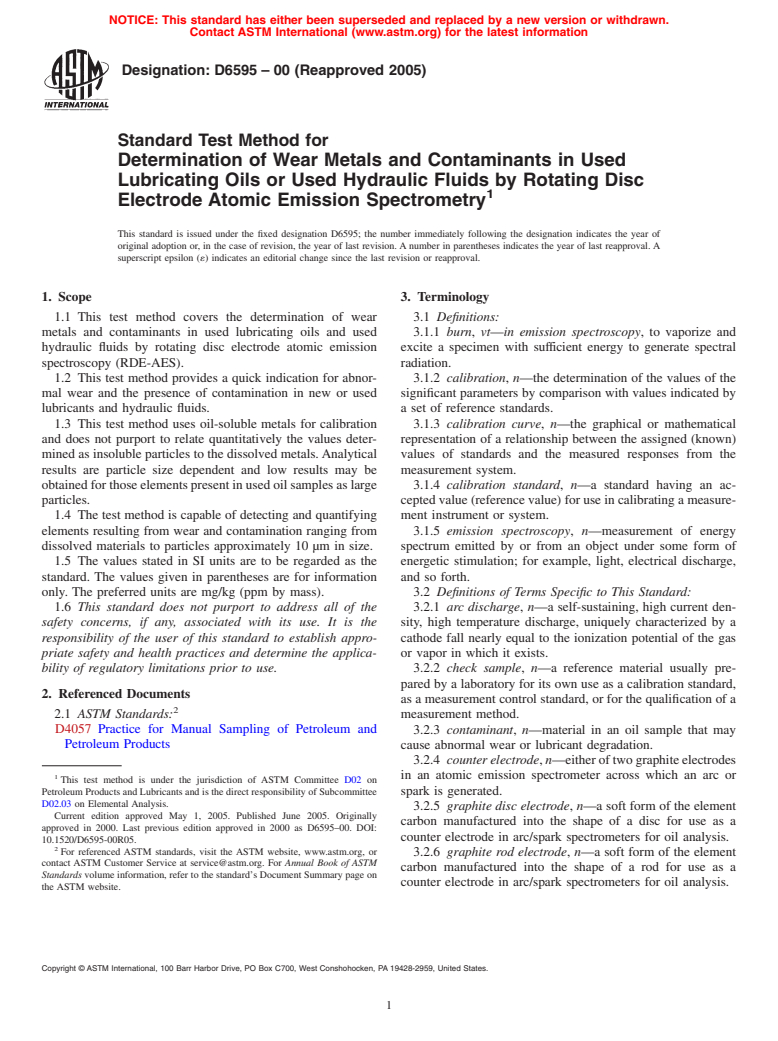

ences of the instrument will compensate for a portion of the shall conform to those shown in Fig. 1.

differences. In used oil applications, the hydrogen 486.10 nm 8.5 Glass Cleaning Solution, capable of cleaning and re-

spectral line has become the industry standard for use as an moving splashed oil sample from the quartz window that

internalreference.Withoutareference,trendeddataonusedoil protects the entrance lens and fiber optic. Isopropyl rubbing

D6595–00 (2005)

10.4 Specimen Table—The specimen table shall be adjusted

so that when it is in the fully raised position, at least one-third

of the disc electrode is immersed in the oil test specimen.

11. Preparation of Apparatus

11.1 Warm-up Burns—If the instrument has been idle for

NOTE—All dimensions are in millimetres; material is high-purity

several hours, it may be necessary to conduct at least three

graphite (spectroscopic grade).

warm-up burns to stabilize the excitation source. The warm-up

FIG. 1 Graphite Disc Electrode

procedure can be performed with any oil sample or standard.

Consult the manufacturer’s instructions for specific warm-up

alcohol or ammonia based window cleaner has been found to

requirements.

be suitable for this purpose.

11.2 Optical Profile—Perform the normal optical profile

8.6 Organometallic Standards, single or multi-element

procedure called for in the operation manual of the instrument.

blended standards for use as the high concentration standard

An optical profile shall also be performed if the instrument has

for instrument standardization purposes or for use as a check

been inoperative for an extended period of time or if the

sample to confirm calibration. Typical concentrations in the

temperature has shifted more than 10°C since the last calibra-

upper calibration point standard for used oil applications is 100

tion check.

mg/kg for wear metals and contaminants, and 900 mg/kg for

11.3 Validation Check—A go/no go standardization check

additive elements.

can be performed with one or more check samples to confirm

8.6.1 Standards have a shelf-life and shall not be used to

calibration prior to the analysis of routine samples. A calibra-

standardize an instrument if they have exceeded the expiration

tion standard or known oil sample can be used for this purpose.

date.

The optical profile and standardization routine recommended

8.7 Counter Electrode—The counter electrode can be either

by the instrument manufacturer shall be performed if the

a rod or a disc. The counter electrode must be high-purity

validation check fails to meet the 610 % accuracy guidelines

graphite (spectroscopic grade). Dimensions of the counter

for each element of interest.

electrodes shall conform to those shown in Fig. 2.

12. Calibration

8.8 Specimen Holders—A variety of specimen holders can

be used for the analysis of used oil samples. Disposable

12.1 Factory Calibration—The analytical range for each

specimen holders must be discarded after each analysis and

element is established through the analysis of organometallic

reusable specimen holders must be cleaned after each analysis.

standardsatknownconcentrations.Acalibrationcurveforeach

All specimen holders must be free of contamination and shall

element is established and correction factors are set to produce

be stored accordingly. Specimen holder and covers shall be

a linear response. Analyses of test specimens must be per-

used on hydraulic oil samples that may catch on fire during the

formed within the linear range of response. The typical

analysis.

elements and recommended wavelengths determined in the

used oil analysis applications are listed in Table 1.

9. Sampling

12.2 Routine Standardization—A minimum of a two point

9.1 The used oil sample taken for the analysis must be

routine standardization shall be performed if the instrument

representative of the entire system. Good sampling procedures

fails the validation check or at the start of each working shift.

are key to good analyses and samples must be taken in

A minimum of three analyses shall be made using the blank

accordance with Practice D4057.

and working standard.

10. Preparation of Test Specimen 13. Procedure

10.1 Homogenization—Used oil samples may contain par-

13.1 Analysis of Oil Samples—Analyze the test specimen in

ticulate matter and, in order to be representative, must always the same calibration curve program and manner as the stan-

be vigorously shaken prior to pouring a test specimen for

dardization standards.Anew disc electrode and re-pointed rod

analysis. electrode or new counter disc electrode must be used for each

10.2 Ultrasonic Homogenization—Samples that have been analysis. A laboratory grade paper towel or installation tool

in transit for several days, idle in storage or very viscous, shall shall be used to install the disc electrode in order to protect it

be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.