ASTM D1666-11

(Test Method)Standard Test Methods for Conducting Machining Tests of Wood and Wood-Base Materials

Standard Test Methods for Conducting Machining Tests of Wood and Wood-Base Materials

SIGNIFICANCE AND USE

Machining tests are made to determine the working qualities and characteristics of different species of wood and of different wood-base panel materials under a variety of machine operations such as are encountered in commercial manufacturing practice. The tests provide a systematic basis for comparing the behavior of different products with respect to woodworking machine operations and of evaluating their potential suitability for certain uses where these properties are of prime importance.

SCOPE

1.1 These test methods cover procedures for planing, routing/shaping, turning, mortising, boring, and sanding, all of which are common wood-working operations used in the manufacture of wood products. These tests apply, in different degrees, to two general classes of materials:

1.1.1 Wood in the form of lumber, and

1.1.2 Wood-base panel materials such as plywood and wood-base fiber and particle panels.

1.2 Because of the importance of planing, some of the variables that affect the results of this operation are explored with a view to determining optimum conditions. In most of the other tests, however, it is necessary to limit the work to one set of fairly typical commercial conditions in which all the different woods are treated alike.

1.3 Several factors enter into any complete appraisal of the machining properties of a given wood or wood-base panel. Quality of finished surface is recommended as the basis for evaluation of machining properties. Rate of dulling of cutting tools and power consumed in cutting are also important considerations but are beyond the scope of these test methods.

1.4 Although the methods presented include the results of progressive developments in the evaluation of machining properties, further improvements may be anticipated. For example, by present procedures, quality of the finished surface is evaluated by visual inspection, but as new mechanical or physical techniques become available that will afford improved precision of evaluation, they should be employed.

1.5 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units may be approximate.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1666 − 11

Standard Test Methods for

Conducting Machining Tests of Wood and Wood-Base Panel

1

Materials

This standard is issued under the fixed designation D1666; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

One of the significant characteristics of wood and wood-base panels is the facility with which they

can be machined and fabricated. Different species and products, however, vary greatly in their

behavior under cutting tools, so that some systematic method is needed for determining their

suitability for uses where the character of the machined surface is of prime importance. Such uses

include cabinetwork, millwork, and other applications where favorable machining properties are

essential to good finish. For such products as common boards, on the other hand, good machining

properties are secondary, although still an asset.

The machining test procedures presented in these test methods cover such common operations as

planing, routing/shaping, turning, boring, mortising, and sanding. They are the result of many years

of extensive research and development and include practical methods for qualitatively evaluating and

interpreting the results. Because of their satisfactory use with a wide range of materials, it is believed

thatthemethodsareequallyapplicabletospecies,hardwoodsandsoftwoods,andtowood-basepanel

materials, such as plywood, particleboard, fiberboard, and hardboard.

1. Scope tools and power consumed in cutting are also important

considerations but are beyond the scope of these test methods.

1.1 These test methods cover procedures for planing,

routing/shaping, turning, mortising, boring, and sanding, all of

1.4 Although the methods presented include the results of

which are common wood-working operations used in the

progressive developments in the evaluation of machining

manufacture of wood products. These tests apply, in different

properties, further improvements may be anticipated. For

degrees, to two general classes of materials:

example, by present procedures, quality of the finished surface

1.1.1 Wood in the form of lumber, and

is evaluated by visual inspection, but as new mechanical or

1.1.2 Wood-base panel materials such as plywood and

physicaltechniquesbecomeavailablethatwillaffordimproved

wood-base fiber and particle panels.

precision of evaluation, they should be employed.

1.2 Because of the importance of planing, some of the

1.5 The values stated in inch-pound units are to be regarded

variables that affect the results of this operation are explored

as the standard. The metric equivalents of inch-pound units

withaviewtodeterminingoptimumconditions.Inmostofthe

may be approximate.

othertests,however,itisnecessarytolimittheworktooneset

1.6 This standard does not purport to address all of the

of fairly typical commercial conditions in which all the

safety concerns, if any, associated with its use. It is the

different woods are treated alike.

responsibility of the user of this standard to establish appro-

1.3 Several factors enter into any complete appraisal of the

priate safety and health practices and determine the applica-

machining properties of a given wood or wood-base panel.

bility of regulatory limitations prior to use.

Quality of finished surface is recommended as the basis for

evaluation of machining properties. Rate of dulling of cutting

2. Referenced Documents

2.1 ASTM Standards:

1

D9Terminology Relating to Wood and Wood-Based Prod-

These test methods are under the jurisdiction of ASTM Committee D07 on

Wood and are the direct responsibility of Subcommittee D07.01 on Fundamental

ucts

Test Methods and Properties.

D1038Terminology Relating to Veneer and Plywood

Current edition approved May 1, 2011. Published June 2011. Originally

D1554Terminology Relating to Wood-Base Fiber and Par-

approved in 1959. Last previous edition approved in 2004 as D1666–87 (2004).

DOI: 10.1520/D1666-11. ticle Panel Materials

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

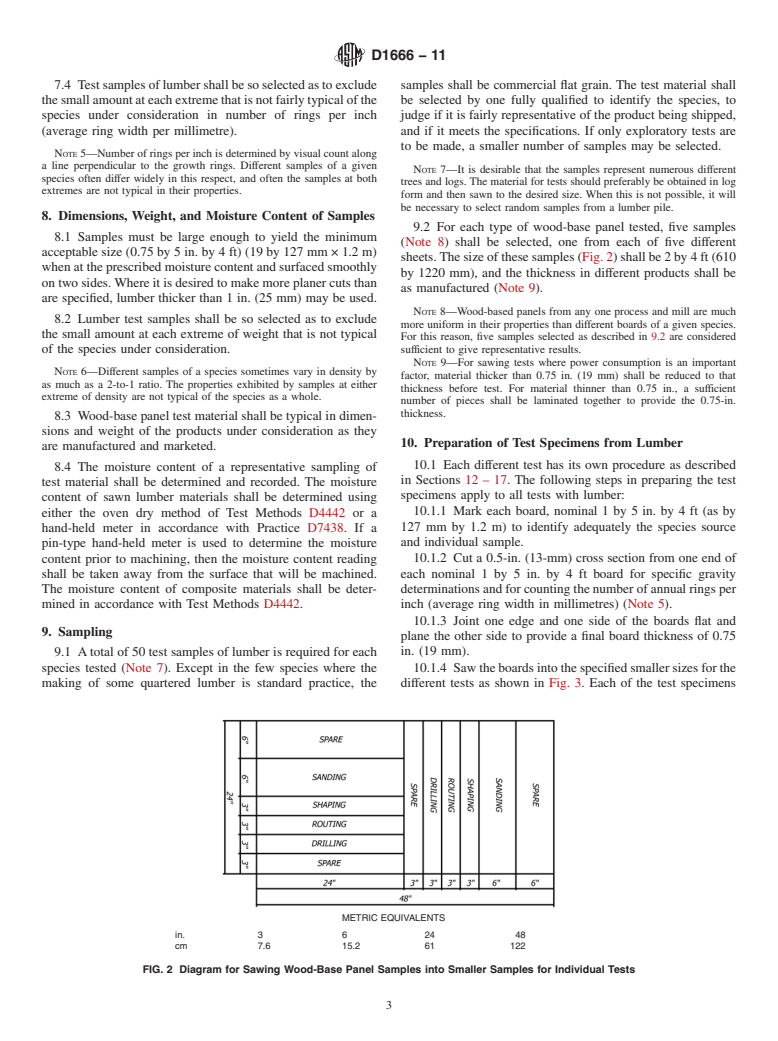

---------------------- Page: 1 ----------------------

D1666 − 11

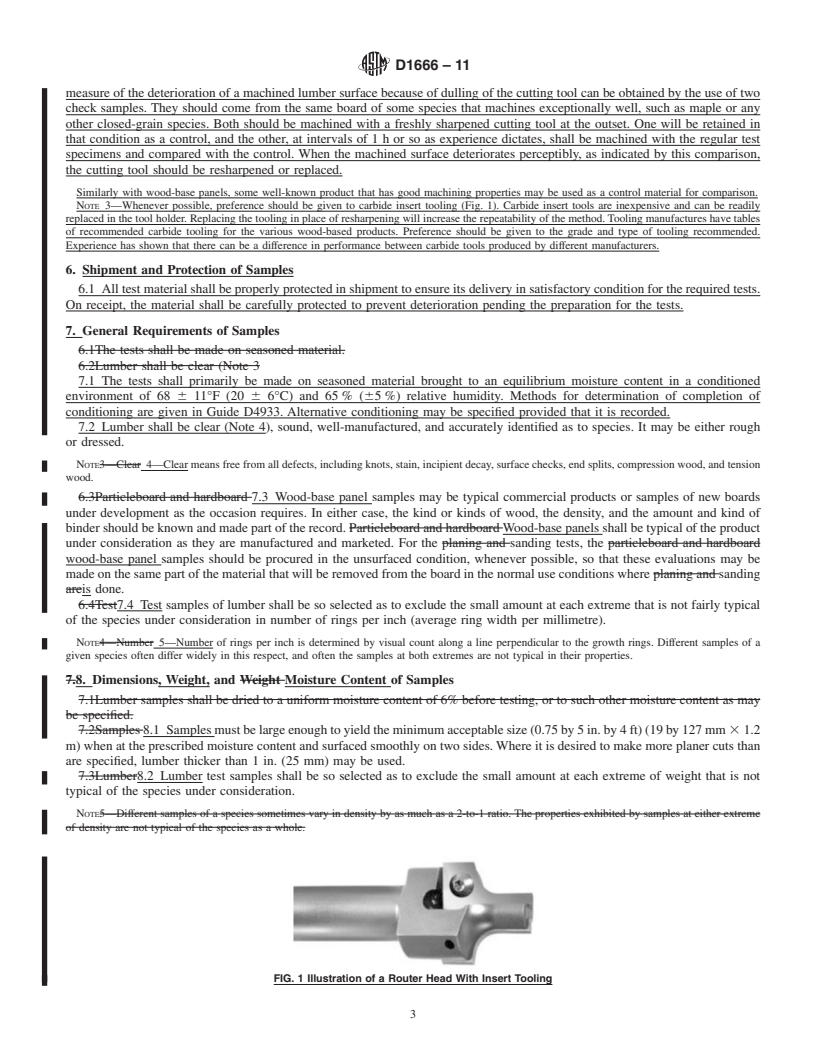

species that machines exceptionally well, such as maple or any other

D4442Test Methods for Direct Moisture Content Measure-

closed-grain species. Both should be machined with a freshly sharpened

ment of Wood and Wood-Based Materials

cutting tool at the outset. One will be retained in that condition as a

D4933Guide for Moisture Conditioning of Wood and

control,andtheother,atintervalsof1horsoasexperiencedictates,shall

Wood-Based Materials

be machined with the regular test specime

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D1666– 87(Reapproved 2004) Designation:D1666–11

Standard Test Methods for

Conducting Machining Tests of Wood and Wood-Base Panel

1

Materials

This standard is issued under the fixed designation D1666; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

One of the significant characteristics of wood and wood-base panels is the facility with which itthey

can be machined and fabricated. Different species and products, however, vary greatly in their

behavior under cutting tools, so that some systematic method is needed for determining their

suitability for uses where the character of the machined surface is of prime importance. Such uses

include cabinetwork, millwork, and other productsapplications where favorable machining properties

are essential to good finish. For such products as common boards, on the other hand, good machining

properties are secondary, although still an asset.

The machining test procedures presented in these test methods cover such common operations as

planing, routing/shaping, turning, boring, mortising, and sanding. They are the result of many years

of extensive research and development and include practical methods for qualitatively evaluating and

interpreting the results. Because of their satisfactory use with a wide range of materials, it is believed

that the methods are equally applicable to species, hardwoods and softwoods, and to wood-base panel

materials, such as plywood, particleboard, fiberboard, and hardboard.

1. Scope

1.1 These test methods cover procedures for planing, routing/shaping, turning, mortising, boring, and sanding, all of which are

common wood-working operations used in the manufacture of wood products. These tests apply, in different degrees, to two

general classes of materials:

1.1.1 Wood in the form of lumber, and

1.1.2Wood-base panel materials.

1.1.2 Wood-base panel materials such as plywood and wood-base fiber and particle panels.

1.2 Because of the importance of planing, some of the variables that affect the results of this operation are explored with a view

to determining optimum conditions. In most of the other tests, however, it is necessary to limit the work to one set of fairly typical

commercial conditions in which all the different woods are treated alike.

1.3 Several factors enter into any complete appraisal of the machining properties of a given wood or wood-base panel. Quality

of finished surface is recommended as the basis for evaluation of machining properties. Rate of dulling of cutting tools and power

consumed in cutting are also important considerations but are beyond the scope of these test methods.

1.4 Although the methods presented include the results of progressive developments in the evaluation of machining properties,

furtherimprovementsmaybeanticipated.Forexample,bypresentprocedures,qualityofthefinishedsurfaceisevaluatedbyvisual

inspection, but as new mechanical or physical techniques become available that will afford improved precision of evaluation, they

should be employed.

1.5 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units may

be approximate.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1

ThesetestmethodsareunderthejurisdictionofASTMCommitteeD07onWoodandarethedirectresponsibilityofSubcommitteeD07.01onFundamentalTestMethods

and Properties.

Current edition approved Oct.May 1, 2004.2011. Published October 2004.June 2011. Originally approved in 1959. Last previous edition approved in 19992004 as

D1666 – 87 (1999).(2004). DOI: 10.1520/D1666-87R04.10.1520/D1666-11.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1666–11

2. Referenced Documents

2.1 ASTM Standards:

D9 Terminology Relating to Wood and Wood-Based Products

D1038 Terminology Relating to Veneer and Plywood

D1554 Terminology Relating to Wood-Base Fiber and Particle Panel Materials

D4442 Test Methods for Direct Moisture Content Measurement of Wood and W

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.