ASTM F25/F25M-21

(Test Method)Standard Test Method for Sizing and Counting Airborne Particulate Contamination in Cleanrooms and Other Dust-Controlled Areas

Standard Test Method for Sizing and Counting Airborne Particulate Contamination in Cleanrooms and Other Dust-Controlled Areas

ABSTRACT

This test method covers the apparatuses required, sampling methods, standard procedures and calculations, and test reports for counting and sizing airborne microparticulate matter, the sampling areas for which are specifically those with contamination levels typical of cleanrooms and dust-controlled areas. The test method is based on the microscopical examination of particles impinged upon a membrane filter with the aid of a vacuum. Sampling may be done in a cleanroom, clean zone, or other controlle areas, or in a duct or pipe, wherein the number of sampling points is proportional to the floor area of the enclosure to be checked. The apparatus and facilities required are typical of a laboratory for the study of macroparticle contamination. The operator must have adequate basic training in microscopy and the techniques of particle sizing and counting.

SCOPE

1.1 This test method covers counting and sizing airborne particulate matter 5 µm and larger (macroparticles). The sampling areas are specifically those with contamination levels typical of cleanrooms and dust-controlled areas.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F25/F25M − 21

Standard Test Method for

Sizing and Counting Airborne Particulate Contamination in

1

Cleanrooms and Other Dust-Controlled Areas

This standard is issued under the fixed designation F25/F25M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope 2.2 ISO Standard:

ISO 14644-1 Cleanrooms and Associated Controlled

1.1 This test method covers counting and sizing airborne

Environments—Part 1: Classification of Air Cleanliness

particulate matter 5 µm and larger (macroparticles). The

4

2.3 IEST Document:

samplingareasarespecificallythosewithcontaminationlevels

IEST-G-CC1003Measurement of Airborne Macroparticles

typical of cleanrooms and dust-controlled areas.

(1999)

5

1.2 Units—The values stated in either SI units or inch-

2.4 SAE Document:

pound units are to be regarded separately as standard. The

SAEAbstractARP-743, Procedure for the Determination of

values stated in each system are not necessarily exact equiva-

Particulate Contamination of Air in Dust-Controlled

lents; therefore, to ensure conformance with the standard, each

Spaces by Particle Count Method, August 1962

system shall be used independently of the other, and values

from the two systems shall not be combined. 3. Terminology

3.1 Definitions:

1.3 This standard does not purport to address all of the

3.1.1 airflow, n—

safety concerns, if any, associated with its use. It is the

3.1.1.1 unidirectional airflow, n—air flow which has a

responsibility of the user of this standard to establish appro-

singular direction of flow and may or may not contain uniform

priate safety, health, and environmental practices and deter-

velocities of air flow along parallel lines.

mine the applicability of regulatory limitations prior to use.

NOTE 1—Formerly known as laminar airflow.

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard- 3.1.1.2 non-unidirectional airflow, n—airdistributionwhere

the supply air entering the room mixes with the internal air by

ization established in the Decision on Principles for the

means of induction.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

3.1.2 critical pressure, n—for an orifice with a constant

Barriers to Trade (TBT) Committee.

upstream pressure, the downstream pressure at which the flow

will not increase when the downstream pressure decreases.

2. Referenced Documents

3.1.3 critical pressure ratio, n—the ratio of the critical

2

pressure of an orifice to the entrance pressure.

2.1 ASTM Standards:

3.1.4 customer, n—organization, or the agent thereof, re-

F50Practice for Continuous Sizing and Counting of Air-

sponsible for specifying the requirements of a cleanroom or

borne Particles in Dust-Controlled Areas and Clean

clean zone.

Rooms Using Instruments Capable of Detecting Single

Sub-Micrometre and Larger Particles

3.1.5 fiber, n—particle having an aspect (length-to-width)

ratio of 10 or more.

3.1.6 macroparticle, n—particlewithanequivalentdiameter

1

greater than 5 µm.

This test method is under the jurisdiction of ASTM Committee E21 on Space

Simulation andApplications of SpaceTechnology and is the direct responsibility of

Subcommittee E21.05 on Contamination.

Current edition approved April 1, 2021. Published April 2021. Originally

3

approvedin1963.Lastpreviouseditionapprovedin2015asF25/F25M–09(2015). Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

DOI: 10.1520/F0025_F0025M-21. 4th Floor, New York, NY 10036, http://www.ansi.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Institute of Environmental Sciences and Technology (IEST),

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 1827Walden Office Square, Suite 400, Schaumburg, IL60173, http://www.iest.org.

5

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F25/F25M − 21

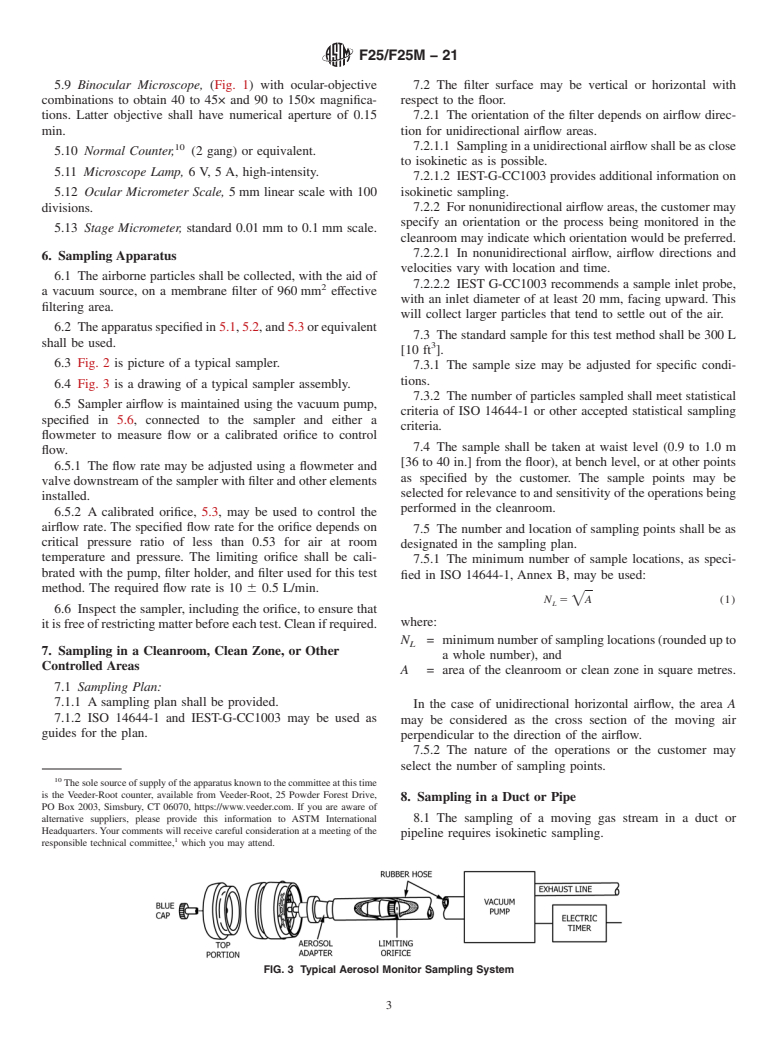

FIG. 2 Typical Air Sampling-Filtration Apparatus

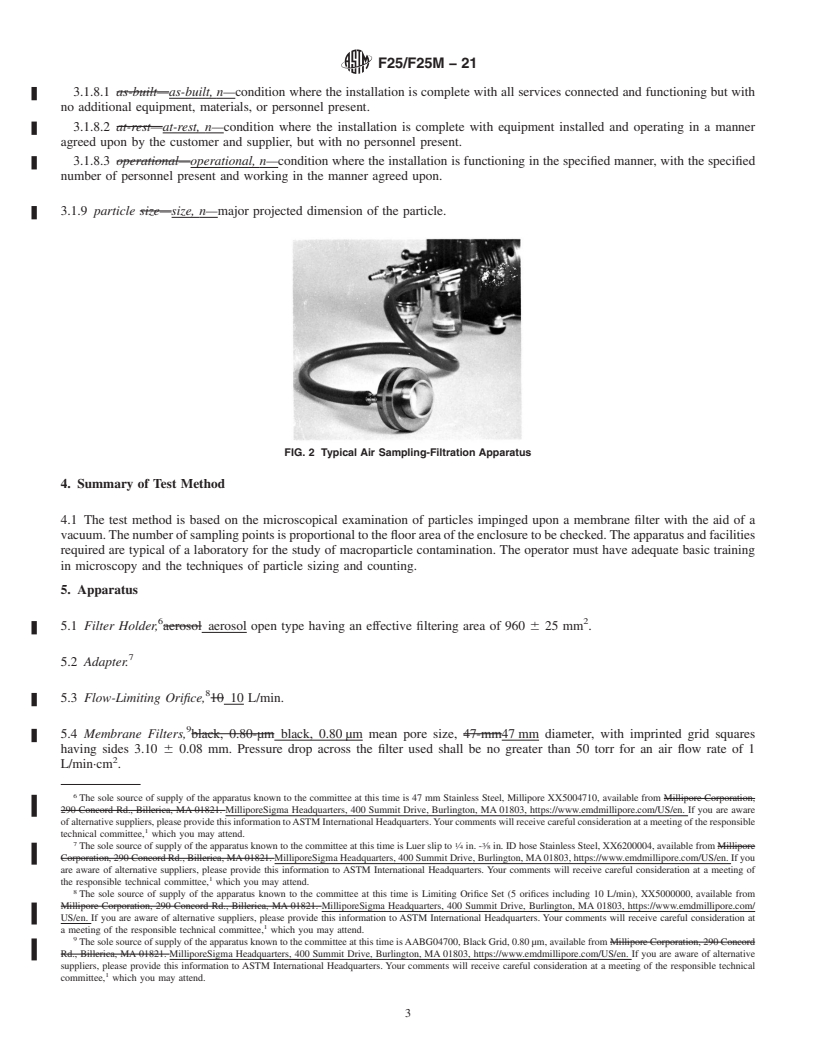

5. Apparatus

6

5.1 Filter Holder, aerosol open type having an effective

2

filtering area of 960 6 25 mm .

FIG. 1 Suitable M

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F25/F25M − 09 (Reapproved 2015) F25/F25M − 21

Standard Test Method for

Sizing and Counting Airborne Particulate Contamination in

1

Cleanrooms and Other Dust-Controlled Areas

This standard is issued under the fixed designation F25/F25M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers counting and sizing airborne particulate matter 5 μm and larger (macroparticles). The sampling areas

are specifically those with contamination levels typical of cleanrooms and dust-controlled areas.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in

each system mayare not benecessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be

used independently of the other. Combiningother, and values from the two systems may result in non-conformance with the

standard.shall not be combined.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory requirementslimitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

F50 Practice for Continuous Sizing and Counting of Airborne Particles in Dust-Controlled Areas and Clean Rooms Using

Instruments Capable of Detecting Single Sub-Micrometre and Larger Particles

3

2.2 ISO Standard:

ISO 14644-1 Cleanrooms and Associated Controlled Environments—Part 1: Classification of Air Cleanliness

4

2.3 IEST Document:

IEST-G-CC1003 Measurement of Airborne Macroparticles (1999)

5

2.4 SAE Document:

SAE Abstract ARP-743, Procedure for the Determination of Particulate Contamination of Air in Dust-Controlled Spaces by

Particle Count Method, August 1962

1

This test method is under the jurisdiction of ASTM Committee E21 on Space Simulation and Applications of Space Technology and is the direct responsibility of

Subcommittee E21.05 on Contamination.

Current edition approved Oct. 1, 2015April 1, 2021. Published November 2015April 2021. Originally approved in 1963. Last previous edition approved in 20092015 as

F25 – 09.F25/F25M – 09(2015). DOI: 10.1520/F0025_F0025M-09R15.10.1520/F0025_F0025M-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Available from Institute of Environmental Sciences and Technology (IEST), Arlington Place One, 2340 S. Arlington Heights Rd., Suite 100, Arlington Heights, IL

60005-4516,1827 Walden Office Square, Suite 400, Schaumburg, IL 60173, http://www.iest.org.

5

Available from Society of Automotive Engineers (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F25/F25M − 21

3. Terminology

3.1 Definitions:

3.1.1 airflow:airflow, n—

3.1.1.1 unidirectional airflow—airflow, n—air flow which has a singular direction of flow and may or may not contain uniform

velocities of air flow along parallel lines.

NOTE 1—Formerly known as laminar airflow.

3.1.1.2 non-unidirectional airflow—airflow, n—air distribution where the supply air entering the room mixes with the internal

air by means of induction.

3.1.2 critical pressure—pressure, n—for an orifice,orifice with a constant upstream pressure, the downstream pressure at which the

flow will not increase when the downstream pressure decreases.

3.1.3 critical pressure ratio—ratio, n—the ratio of the critical pressure of an orifice to the entr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.