ASTM D6507-19

(Practice)Standard Practice for Fiber Reinforcement Orientation Codes for Composite Materials

Standard Practice for Fiber Reinforcement Orientation Codes for Composite Materials

SIGNIFICANCE AND USE

4.1 The purpose of a laminate orientation code is to provide a simple, easily understood method of describing the lay-up of a laminate. The laminate orientation code is based largely on a combination of industry practice and the codes used in the NASA/DOD Advanced Composites Design Guide,5 CMH-17-2G, and ISO 1268-1.

4.2 The braiding orientation code provides similar information for a two-dimensional braid, based largely on Standard Test Methods for Textile Composites.6

SCOPE

1.1 This practice establishes orientation codes for continuous-fiber-reinforced composite materials. Orientation codes are explicitly provided for two-dimensional laminates and braids. The laminate code may also be used for filament-wound materials. A method is included for presenting subscript information in computerized formats that do not permit subscript notation.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6507 − 19

Standard Practice for

Fiber Reinforcement Orientation Codes for Composite

1

Materials

This standard is issued under the fixed designation D6507; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

4

1. Scope Stacking Designation Systems

1.1 This practice establishes orientation codes for

3. Terminology

continuous-fiber-reinforced composite materials. Orientation

codes are explicitly provided for two-dimensional laminates 3.1 Definitions—Definitions in accordance with Terminol-

ogy D3878 shall be used where applicable.

and braids. The laminate code may also be used for filament-

wound materials.Amethod is included for presenting subscript

4. Significance and Use

information in computerized formats that do not permit sub-

script notation.

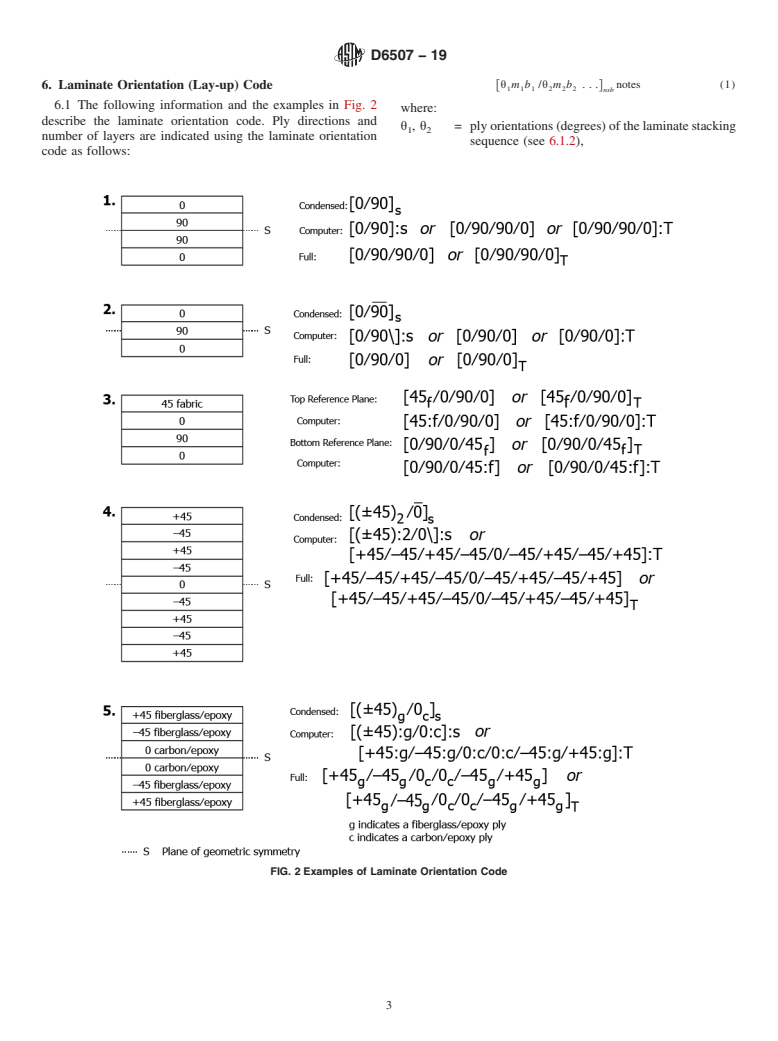

4.1 The purpose of a laminate orientation code is to provide

a simple, easily understood method of describing the lay-up of

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the a laminate. The laminate orientation code is based largely on a

combination of industry practice and the codes used in the

responsibility of the user of this standard to establish appro-

5

priate safety, health, and environmental practices and deter- NASA/DOD Advanced Composites Design Guide, CMH-17-

2G, and ISO 1268-1.

mine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accor-

4.2 The braiding orientation code provides similar informa-

dance with internationally recognized principles on standard-

tion for a two-dimensional braid, based largely on Standard

6

ization established in the Decision on Principles for the

Test Methods for Textile Composites.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

5. Reference Systems

Barriers to Trade (TBT) Committee.

5.1 A set of reference coordinate axes and associated

reference plane and direction are selected before writing the

2. Referenced Documents

orientation code.

2

2.1 ASTM Standards:

5.1.1 The reference plane is selected as the bottom or top

D3518/D3518M Test Method for In-Plane Shear Response

layer for the laminate orientation code. The orientation code is

of Polymer Matrix Composite Materials byTensileTest of

thendeterminedbyprogressingthroughthelaminatethickness.

a 645° Laminate

For a laminate symmetric about its midplane, the orientation

D3878 Terminology for Composite Materials

code using the top layer as the reference plane is identical to

2.2 Other Documents:

the orientation code using the bottom layer as the reference

CMH-17-2G, Polymer Matrix Composites, Volume 2 Ma-

plane.

3

terials Properties, Section 1.6.1

5.1.2 The reference direction, from which ply orientation is

ISO 1268-1 Fibre-reinforced Plastics—Methods of Produc-

measured,issomewhatarbitrarilyselectedforconvenienceand

ing Test Plates—Part 1: General Conditions, Annex

relevance to the application. Often, a dominant fiber direction,

such as that aligned with the laminate principal axis, is defined

1

to be 0°. An example in which relevance to testing determines

This practice is under the jurisdiction ofASTM Committee D30 on Composite

Materials and is the direct responsibility of Subcommittee D30.01 on Editorial and

the reference direction is the Test Method D3518/D3518M

Resource Standards.

Current edition approved Oct. 15, 2019. Published November 2019. Originally

approved in 2000. Last previous edition approved in 2016 as D6507 – 16. DOI:

4

10.1520/D6507-19. Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 4th Floor, New York, NY 10036, http://www.ansi.org.

5

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM NASA/DOD Advanced Composites Design Guide, Vol. 4, Section 4.0.5, Air

Standards volume information, refer to the standard’s Document Summary page on Force Wright Aeronautical Laboratories, Day, OH, prepared by Rockwell Interna-

the ASTM website. tional Corp., 1983 (distribution limited).

3 6

Available from SAE International (SAE), 400 Commonwealth Dr., Warrendale, Masters, J. E., and Portanova, M. A., Standard Test Methods for Textile

PA 15096, http://www.sae.org. Composites, NASA CR-4751, NASA Langley Research Center, 1996.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, W

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6507 − 16 D6507 − 19

Standard Practice for

Fiber Reinforcement Orientation Codes for Composite

1

Materials

This standard is issued under the fixed designation D6507; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice establishes orientation codes for continuous-fiber-reinforced composite materials. Orientation codes are

explicitly provided for two-dimensional laminates and braids. The laminate code may also be used for filament-wound materials.

A method is included for presenting subscript information in computerized formats that do not permit subscript notation.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D3518/D3518M Test Method for In-Plane Shear Response of Polymer Matrix Composite Materials by Tensile Test of a 645°

Laminate

D3878 Terminology for Composite Materials

2.2 Other Documents:

3

CMH-17-2G, Polymer Matrix Composites, Volume 2 Materials Properties, Section 1.6.1

ISO 1268-1 Fibre-reinforced Plastics—Methods of Producing Test Plates—Part 1: General Conditions, Annex Stacking

4

Designation Systems

3. Terminology

3.1 Definitions—Definitions in accordance with Terminology D3878 shall be used where applicable.

4. Significance and Use

4.1 The purpose of a laminate orientation code is to provide a simple, easily understood method of describing the lay-up of a

laminate. The laminate orientation code is based largely on a combination of industry practice and the codes used in the

5

NASA/DOD Advanced Composites Design Guide, CMH-17-2G, and ISO 1268-1.

4.2 The braiding orientation code provides similar information for a two-dimensional braid, based largely on Standard Test

6

Methods for Textile Composites.

1

This practice is under the jurisdiction of ASTM Committee D30 on Composite Materials and is the direct responsibility of Subcommittee D30.01 on Editorial and

Resource Standards.

Current edition approved July 1, 2016Oct. 15, 2019. Published July 2016November 2019. Originally approved in 2000. Last previous edition approved in 20112016 as

D6507 – 11.D6507 – 16. DOI: 10.1520/D6507-16.10.1520/D6507-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from SAE International (SAE), 400 Commonwealth Dr., Warrendale, PA 15096, http://www.sae.org.

4

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

5

NASA/DOD Advanced Composites Design Guide, Vol. 4, Section 4.0.5, Air Force Wright Aeronautical Laboratories, Day, OH, prepared by Rockwell International Corp.,

1983 (distribution limited).

6

Masters, J. E., and Portanova, M. A., Standard Test Methods for Textile Composites, Standard Test Methods for Textile Composites, NASA CR-4751, NASA Langley

Research Center, 19961996.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6507 − 19

5. Reference SystemSystems

5.1 A reference set of reference coordinate axes and associated reference plane and direction are selected before writing the

orientation code. The reference plane is selected as the bottom or top layer for the laminate orientation code. For laminates

symmetric about their midplane, the orientation code using the top layer as the reference plane is identical to the orientation code

using the bottom layer as the reference plane; selection of the reference plane effectively determines the positive z- or three-axis

of the lamin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.