ASTM D1500-04

(Test Method)Standard Test Method for ASTM Color of Petroleum Products (ASTM Color Scale)

Standard Test Method for ASTM Color of Petroleum Products (ASTM Color Scale)

SCOPE

1.1 This test method covers the visual determination of the color of a wide variety of petroleum products, such as lubricating oils, heating oils, diesel fuel oils, and petroleum waxes.

Note 1—Test Method D 156 is applicable to refined products that have an ASTM color lighter than 0.5. IP Method 17 includes a procedure for measuring the color of undyed, refined products such as gasoline, white spirit, and kerosine by comparison with a series of IP Standard glasses. It also includes a procedure by which petroleum products, except black oils and bitumens, may be measured for tint and depth of color in terms of Lovibond units by a series of red, yellow, and blue glasses.

1.2 This test method reports results specific to the test method and recorded as "ASTM Color."

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D1500–04

Designation: 196/97

Standard Test Method for

1

ASTM Color of Petroleum Products (ASTM Color Scale)

This standard is issued under the fixed designation D 1500; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* Waxes, Including Petrolatum

D 2500 Test Method for Cloud Point of Petroleum Products

1.1 This test method covers the visual determination of the

D 4057 Practice for Manual Sampling of Petroleum and

color of a wide variety of petroleum products, such as

Petroleum Products

lubricating oils, heating oils, diesel fuel oils, and petroleum

4

2.2 Energy Institute Standard:

waxes.

IP 17 Color by the Lovibond Tintometer

NOTE 1—Test Method D 156 is applicable to refined products that have

an ASTM color lighter than 0.5. IP Method 17 includes a procedure for

3. Summary of Test Method

measuring the color of undyed, refined products such as gasoline, white

3.1 Using a standard light source, a liquid sample is placed

spirit, and kerosine by comparison with a series of IP Standard glasses. It

in the test container and compared with colored glass disks

also includes a procedure by which petroleum products, except black oils

ranging in value from 0.5 to 8.0. When an exact match is not

and bitumens, may be measured for tint and depth of color in terms of

Lovibond units by a series of red, yellow, and blue glasses.

found and the sample color falls between two standard colors,

the higher of the two colors is reported.

1.2 This test method reports results specific to the test

method and recorded as “ASTM Color.”

4. Significance and Use

1.3 This standard does not purport to address all of the

4.1 Determinationofthecolorofpetroleumproductsisused

safety concerns, if any, associated with its use. It is the

mainly for manufacturing control purposes and is an important

responsibility of the user of this standard to establish appro-

quality characteristic, since color is readily observed by the

priate safety and health practices and determine the applica-

user of the product. In some cases, the color may serve as an

bility of regulatory limitations prior to use.

indicationofthedegreeofrefinementofthematerial.Whenthe

2. Referenced Documents colorrangeofaparticularproductisknown,avariationoutside

2

theestablishedrangemayindicatepossiblecontaminationwith

2.1 ASTM Standards:

another product. However, color is not always a reliable guide

D 155 Method of Test for Color of Lubricating Oil and

3

to product quality and should not be used indiscriminately in

Petrolatum by Means of ASTM Union Colorimeter

product specifications.

D 156 Test Method for Saybolt Color of Petroleum Prod-

ucts (Saybolt Chromometer Method)

5. Apparatus

D 938 Test Method for Congealing Point of Petroleum

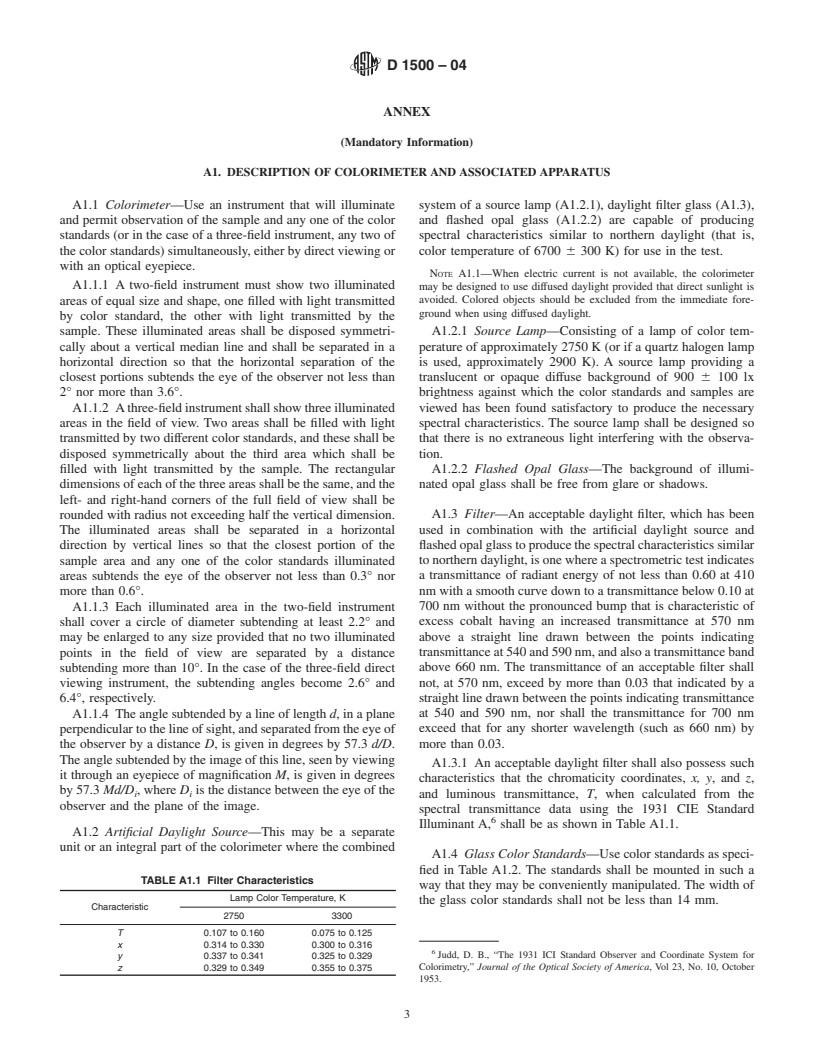

5.1 Colorimeter, consisting of light source, glass color

standards, sample container housing with cover, and viewing

1

piece as listed in Annex A1.

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

5.2 Sample Container—For referee work, use the glass

D02.05 on Properties of Fuels, Petroleum Coke and Carbon Material.

samplejarasshowninFig.1.Forroutinetests,itispermissible

CurrenteditionapprovedJune1,2004.PublishedJuly2004.Originallyapproved

to use a cylindrical, clear glass jar with a flat bottom of 30 to

in 1957. Last previous edition approved in 2003 as D 1500–03.

32.4 mm internal diameter, 115 to 125 mm in external height,

This is also a standard of the Institute of Petroleum issued under the fixed

designation IP 196. The final number indicates the year of last revision. This test

andawallthicknessnogreaterthan1.6mmasspecifiedinTest

methodwasadoptedasajointASTM-IPstandardin1966.IntheIP,thistestmethod

Method D 2500, or an ordinary 125-mL oil sample bottle if it

is under the jurisdiction of the Standardization Committee.

2

meets these requirements.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

4

the ASTM website. “Methods for Analysis and Testing,” available from Energy Institute, 61 New

3

Withdrawn. Cavendish St., London, WIG 7AR, U.K.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.