ASTM D1673-94(1998)

(Test Method)Standard Test Methods for Relative Permittivity And Dissipation Factor of Expanded Cellular Polymers Used For Electrical Insulation

Standard Test Methods for Relative Permittivity And Dissipation Factor of Expanded Cellular Polymers Used For Electrical Insulation

SCOPE

1.1 These test methods cover procedures for determining the relative permittivities and dissipation factor of flat sheets or slabs of expanded cellular polymers of both the rigid and flexible types, at frequencies from 60 Hz to 100 MHz. Provision is made for measurements on specimens up to 50 mm (2 in.) in thickness, but it is recommended that specimens greater than 25 mm (1 in.) in thickness shall be tested at frequencies up to a maximum of only about 1 MHz.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 1673 – 94 (Reapproved 1998)

Standard Test Methods for

Relative Permittivity And Dissipation Factor of Expanded

Cellular Polymers Used For Electrical Insulation

This standard is issued under the fixed designation D 1673; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Although fundamentally similar to test methods used for solid electrical insulating materials in sheet

or plate form, certain modifications in the procedures and measurement techniques are necessary for

the proper determination of the relative permittivities and dissipation factors of foamed or expanded

cellular polymers. This is occasioned by the fact that in many, if not most, instances expanded cellular

materials have surfaces that preclude the use of conventional electrodes such as metal foil attached by

petrolatum and similar adhesives, or conducting silver paint applied by brushing or spraying.

Furthermore, it is generally true that slabs or plates of expanded cellular materials are available only

in substantially greater thicknesses than those commonly used for test specimens of solid insulation.

1. Scope Sponge or Expanded Rubber

D 1711 Terminology Relating to Electrical Insulating Ma-

1.1 These test methods cover procedures for determining

terials

the relative permittivities and dissipation factor of flat sheets or

slabs of expanded cellular polymers of both the rigid and

3. Terminology

flexible types, at frequencies from 60 Hz to 100 MHz.

3.1 For definitions of relative permittivity, dissipation fac-

Provision is made for measurements on specimens up to 50

tor, and loss index, refer to Test Methods D 150 or Terminol-

mm (2 in.) in thickness, but it is recommended that specimens

ogy D 1711.

greater than 25 mm (1 in.) in thickness shall be tested at

frequencies up to a maximum of only about 1 MHz.

4. Significance and Use

1.2 This standard does not purport to address all of the

4.1 Relative Permittivity:

safety concerns, if any, associated with its use. It is the

4.1.1 Because a relatively large proportion of their volumes

responsibility of the user of this standard to establish appro-

are composed of more or less uniformly distributed, isolated or

priate safety and health practices and determine the applica-

interconnected gas-filled cells, foamed or expanded cellular

bility of regulatory limitations prior to use.

polymers always have lower relative permittivities, at a given

2. Referenced Documents frequency and temperature, than the solid base resins from

which they are prepared.

2.1 ASTM Standards:

4.1.2 The relative permittivities of expanded cellular poly-

D 150 Test Methods for AC Loss Characteristics and Per-

mers are important because they determine the increase in

mittivity (Dielectric Constant) of Solid Electrical Insulat-

2 capacitance between conductors, or between conductors and

ing Materials

ground, that will result when a circuit or component is

D 374 Test Methods for Thickness of Solid Electrical Insu-

2 encapsulated in such a material, over their corresponding

lation

values before encapsulation (when air is the surrounding

D 1056 Specification for Flexible Cellular Materials

medium). Likewise, the relative permittivities of an expanded

cellular polymer may serve as a measure of the decrease of

such capacitances caused by substitution of the expanded

These test methods are under the jurisdiction of ASTM Committee D-9 on material for a solid encapsulating compound or resin of known

Electrical and Electronic Insulating Materials and are the direct responsibility of

relative permittivity.

Subcommittee D 09.12 on Electrical Tests.

Current edition approved Jan. 15, 1994. Published March 1994. Originally

e1

published as D 1673 – 59 T. Last previous edition D 1673 – 79 (1989) .

2 3

Annual Book of ASTM Standards, Vol 10.01. Annual Book of ASTM Standards, Vol 09.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 1673 – 94 (1998)

4.1.3 In transmission lines, such as coaxial cable, television 5. Apparatus

lead-in cables, etc., the reduction of relative permittivity of an

5.1 Electrical Measurement Apparatus, consisting of suit-

expanded material from its value in the original solid state has

able bridge and resonant-circuit equipment having character-

significant usefulness in design, since the capacitance per foot

istics as prescribed in Test Methods D 150. Provision shall be

of cable, and such cable characteristics as velocity of propa-

made for the performance of relative permittivity and dissipa-

gation and characteristic impedance are all dependent upon the

tion factor tests at any desired frequency in the range between

relative permittivity of the insulating material.

60 Hz and 100 MHz.

4.1.4 In wave guides, radomes, dielectric lenses, etc., for

6. Electrodes

use at radio frequencies, if the cellular polymer is nonmagnetic,

the relative permittivity (usually in combination with the

6.1 Expanded cellular polymers, in general, do not have

dissipation factor) determines such transmission characteristics

surfaces suitable for attachment of conventional metal foil or

as velocity of propagation, attenuation distance, decibel loss

conducting paint electrodes, so that prefabricated rigid metal

per meter, phase factor, complex index of refraction, index of plate electrodes must usually be employed for relative permit-

absorption, and dielectric conductivity.

tivity and dissipation factor tests. Such electrode systems may

be of either the direct contact type or the noncontacting type.

4.1.5 The relative permittivity determination may serve as a

6.2 Direct-Contact Electrode Systems— Direct-contact type

production control test for batch-to-batch uniformity of a given

electrodes may be one of the following:

expanded cellular polymer. For expanded cellular nonpolar

6.2.1 A calibrated micrometer electrode system of the

polymers (polyethylene, polystyrene, etc.), the relative permit-

Hartshorn-Ward type, shown in Fig. 1 (Fig. 10 of Test Methods

tivity measurement may constitute a useful control test on the

D 150), is particularly useful for samples 50 mm (2 in.) in

density of the product.

diameter and up to about 6.35 mm (0.25 in.) thick. This system

NOTE 1—For useful information concerning the relationship of the

may be used at any frequency up to 100 MHz. Specimens are

relative permittivity of an expanded cellular material to its density and to

lightly clamped and in contact with both electrodes. Care must

the relative permittivity of the solid constituent, see Appendix X1.

be observed to avoid compressing or crushing the material.

4.2 Dissipation Factor and Loss Index: 6.2.2 Two rigid plate electrodes with a single sheet speci-

men between and in contact with them may be used with the

4.2.1 The loss index of an expanded cellular polymer is a

specimen the same size as the electrodes (see Table 1). It may

measure of the ac power loss in the material. When two

be desirable to enclose this system in a metal box for shielding.

materials have the same relative permittivities, their relative

A wide range of specimen sizes and thicknesses may be

dielectric losses per unit volume at a given frequency and

handled by various modifications of this system. However, the

applied voltage gradient are directly indicated by their respec-

upper frequency limit is relatively low for larger thick speci-

tive dissipation factors.

mens.

4.2.2 Since the dielectric loss in an insulating material

6.2.3 A three-plate electrode system with a double specimen

results in the generation of heat, with a subsequent rise in

arranged in a sandwich form may be used and is recommended

temperature of the material, it is desirable in most cases that

for large sheets of thick materials for tests at relatively low

these losses be as low as possible. This is important not only

frequencies. The two specimens should be of nearly the same

from the standpoint of the overall efficiency of an electrical

thickness. The two outer plates are connected together and to

system but also because the increased temperature generally

ground or to the low side of the measuring apparatus. The third

causes significant changes in both the relative permittivity and

(middle) electrode serves as the high side. The system has the

loss and thereby may contribute to instability of operation,

advantage of being practically self-shielding.

particularly in radio-frequency circuits.

6.3 Noncontacting Electrode Systems (“Air Gap” Methods):

4.2.3 The dielectric loss, as measured by the dissipation

6.3.1 A calibrated micrometer electrode system of the

factor and loss index, may serve as a quality control criterion

Hartshorn-Ward type, shown in Fig. 1 may be used, with the

and as a means of determining batch-to-batch uniformity of a

product. It is also an excellent means of measuring the effects

of weathering, aging, and absorption of moisture by the

expanded cellular polymer, these influences generally resulting

in substantial increases in the dielectric loss index.

4.2.4 The dissipation factor (usually in combination with

the relative permittivity) is useful in estimating the contribution

of the dielectric loss to the total attenuation in coaxial cables,

and in calculations of the transmission characteristics of

radomes, dielectric lenses, and related devices, as indicated in

4.1.4.

For details see von Hippel, A. R., Dielectrics and Waves, Part I, John Wiley &

Sons, Inc., New York, NY 1954, Ch. 9, pp. 26–37. FIG. 1 Micrometer Electrode System

D 1673 – 94 (1998)

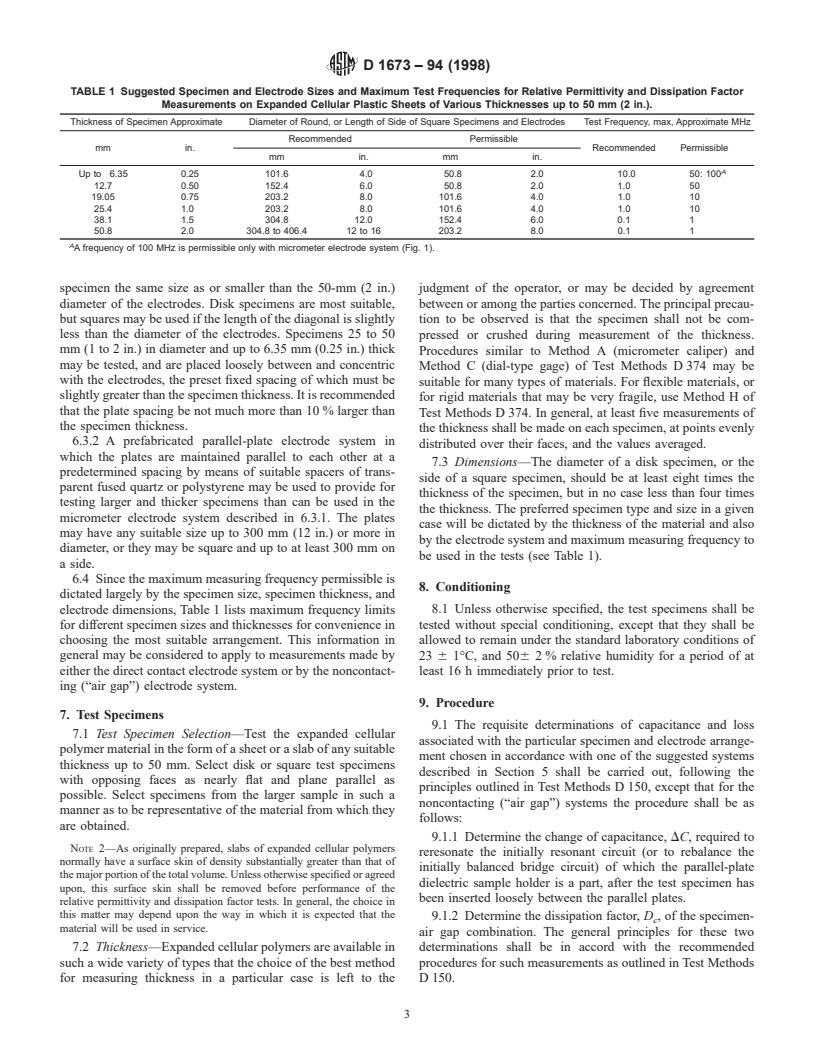

TABLE 1 Suggested Specimen and Electrode Sizes and Maximum Test Frequencies for Relative Permittivity and Dissipation Factor

Measurements on Expanded Cellular Plastic Sheets of Various Thicknesses up to 50 mm (2 in.).

Thickness of Specimen Approximate Diameter of Round, or Length of Side of Square Specimens and Electrodes Test Frequency, max, Approximate MHz

Recommended Permissible

mm in. Recommended Permissible

mm in. mm in.

A

Up to 6.35 0.25 101.6 4.0 50.8 2.0 10.0 50: 100

12.7 0.50 152.4 6.0 50.8 2.0 1.0 50

19.05 0.75 203.2 8.0 101.6 4.0 1.0 10

25.4 1.0 203.2 8.0 101.6 4.0 1.0 10

38.1 1.5 304.8 12.0 152.4 6.0 0.1 1

50.8 2.0 304.8 to 406.4 12 to 16 203.2 8.0 0.1 1

A

A frequency of 100 MHz is permissible only with micrometer electrode system (Fig. 1).

specimen t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.