ASTM D7304-14

(Test Method)Standard Test Method for Determination of Denatonium Ion in Engine Coolant by HPLC

Standard Test Method for Determination of Denatonium Ion in Engine Coolant by HPLC

SIGNIFICANCE AND USE

4.1 This test method provides for the qualitative and quantitative determination of denatonium benzoate in engine coolant in milligrams per litre to low percent range and requires approximately 1 mL per test, with results available in less than 10 min. Denatonium benzoate is a compound composed of a quaternary ammonium cation, denatonium and an inert anion, benzoate. In solution the denatonium benzoate exists in equilibrium between the denatonium benzoate compound, the denatonium cation and benzoate anion. By slightly adjusting the pH of the solution to be more acidic (≈ pH 4.6) the equilibrium will be shifted to the direction of forming more denatonium and benzoate ions in the solution.

SCOPE

1.1 This test method covers the chemical analysis of engine coolant for denatonium benzoate (DNB) by high-performance liquid chromatography (HPLC). DNB is added to potentially render engine coolant unpalatable to animals and humans. This analytical method was designed for the analysis of DNB and is not valid for any other bittering agents such as denatonium saccharide.

1.2 This test method is applicable to both new and used coolants.

1.3 Coelution of other ions may cause interferences in the detection of the denatonium cation. In the case of unfamiliar formulations, identification verification should be performed by either or both fortification and dilution of the sample matrix with denatonium ion.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7304 − 14

StandardTest Method for

Determination of Denatonium Ion in Engine Coolant by

1

HPLC

This standard is issued under the fixed designation D7304; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope an auto-sampler vial and mixed with a known volume of

de-ionized water. The auto-sampler vial is placed in a HPLC

1.1 This test method covers the chemical analysis of engine

autosampler and the measurement of denatonium benzoate is

coolant for denatonium benzoate (DNB) by high-performance

performed using a C-18 reverse phase column attached to an

liquid chromatography (HPLC). DNB is added to potentially

ultraviolet detector. The ultraviolet detector is used to measure

render engine coolant unpalatable to animals and humans.This

the response of the DNB active ingredients (denatonium and

analytical method was designed for the analysis of DNB and is

benzoate) in the engine coolant after they have been separated

not valid for any other bittering agents such as denatonium

in the reverse phase column. The denatonium and benzoate

saccharide.

responses are compared to responses of known concentrations

1.2 This test method is applicable to both new and used

and the HPLC’s computer calculates the amount of DNB

coolants.

present in the coolant.

1.3 Coelution of other ions may cause interferences in the

4. Significance and Use

detection of the denatonium cation. In the case of unfamiliar

formulations, identification verification should be performed

4.1 This test method provides for the qualitative and quan-

by either or both fortification and dilution of the sample matrix titative determination of denatonium benzoate in engine cool-

with denatonium ion.

ant in milligrams per litre to low percent range and requires

approximately 1 mLper test, with results available in less than

1.4 The values stated in SI units are to be regarded as the

10 min. Denatonium benzoate is a compound composed of a

standard. The values given in parentheses are for information

quaternary ammonium cation, denatonium and an inert anion,

only.

benzoate. In solution the denatonium benzoate exists in equi-

1.5 This standard does not purport to address all of the

librium between the denatonium benzoate compound, the

safety concerns, if any, associated with its use. It is the

denatonium cation and benzoate anion. By slightly adjusting

responsibility of the user of this standard to establish appro-

the pH of the solution to be more acidic (≈ pH 4.6) the

priate safety and health practices and determine the applica-

equilibrium will be shifted to the direction of forming more

bility of regulatory limitations prior to use.

denatonium and benzoate ions in the solution.

2. Referenced Documents

5. Interferences

2

2.1 ASTM Standards:

5.1 Interferences can be caused by substances with similar

D1193 Specification for Reagent Water

retention times, especially if they are in high concentration

D1176 Practice for Sampling and Preparing Aqueous Solu-

compared to the analyte of interest, denatonium ion. Known

tions of Engine Coolants orAntirusts forTesting Purposes

chromatographic interferences have been determined and the

3. Summary of Test Method

analysis modified to minimize any co-elution of interfering

peaks. The eluent strength and flow rate can be used to reduce

3.1 The denatonium benzoate analysis is achieved by an

or solve most interference problems.

HPLC method, where a weight of engine coolant is placed in

5.2 Method interferences can also be caused by the con-

1

This test method is under the jurisdiction ofASTM Committee D15 on Engine

tamination of glassware, eluant, reagents, etc. Great care must

Coolants and Related Fluids and is the direct responsibility of Subcommittee

be taken to ensure that contamination is kept at the lowest

D15.04 on Chemical Properties.

possible level.

Current edition approved March 15, 2014. Published May 2014. Originally

approved in 2006. Last previous edition approved in 2006 as D7304–06. DOI:

6. Apparatus

10.1520/D7304-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1 HPLC System—High Performance Liquid Chromato-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

graph system equipped with appropriate computer and soft-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ware.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

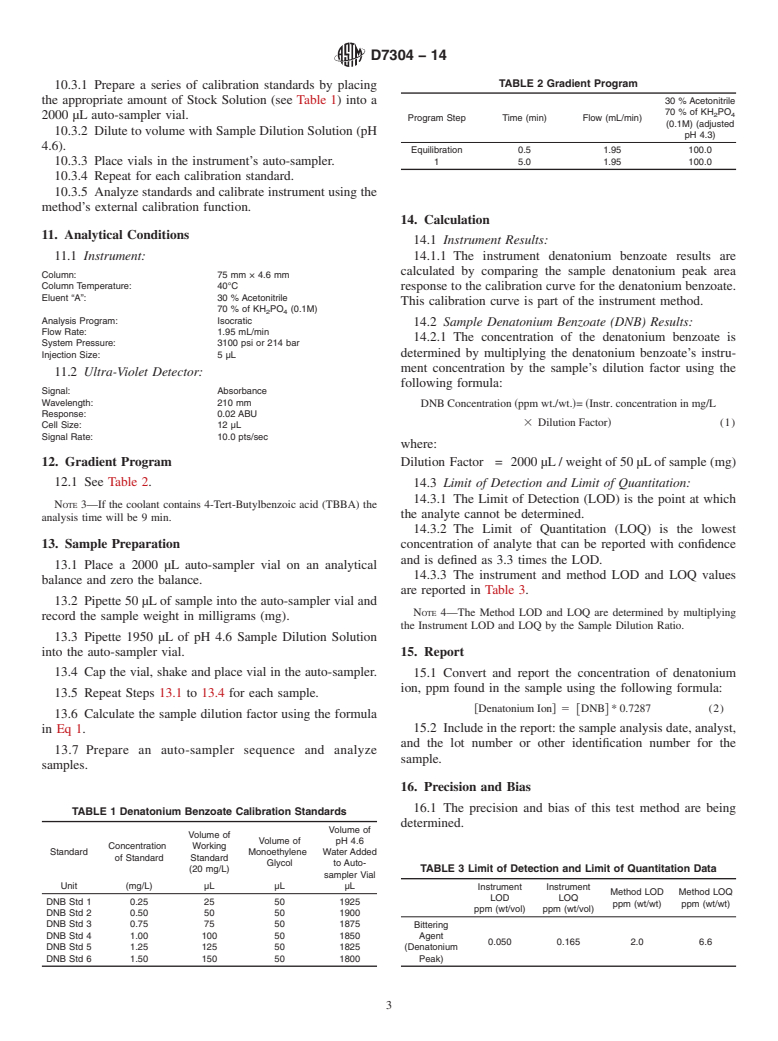

D7304 − 14

6.1.1 Gradient Pump. 7.10.3 Measure the pH o

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7304 − 06 D7304 − 14

Standard Test Method for

Determination of Denatonium Ion in Engine Coolant by

1

HPLC

This standard is issued under the fixed designation D7304; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

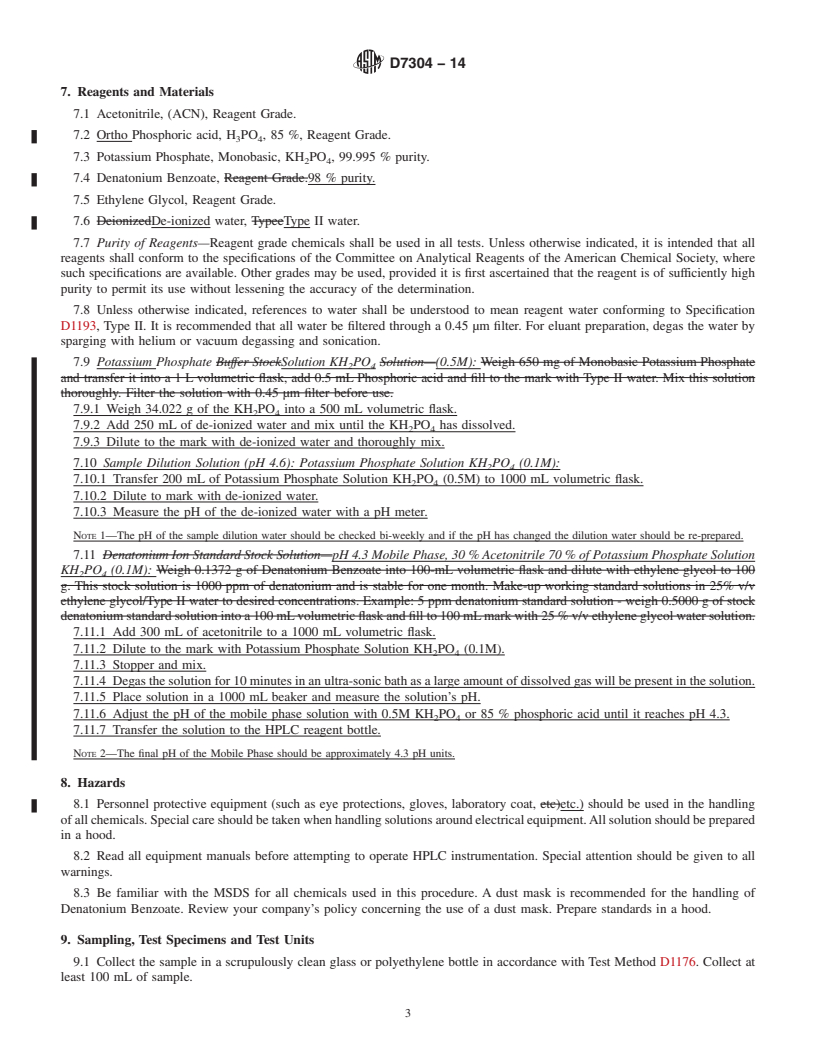

1.1 This test method covers the chemical analysis of engine coolant for denatonium ion benzoate (DNB) by high-performance

liquid chromatography (HPLC). DNB is added to potentially render engine coolant unpalatable to animals and humans. This

analytical method was designed for the analysis of DNB and is not valid for any other bittering agents such as denatonium

saccharide.

1.2 This test method is applicable to both new and used coolants.

1.3 Coelution of other ions may cause interferences in the detection of the denatonium cation. In the case of unfamiliar

formulations, identification verification should be performed by either or both fortification and dilution of the sample matrix with

denatonium ion.ion.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D1176 Practice for Sampling and Preparing Aqueous Solutions of Engine Coolants or Antirusts for Testing Purposes

3. Summary of Test Method

3.1 A sample volume of working sample is prepared by dilution of the sample with water. A high-pressure pump forces the

mobile phase, eluant, through the HPLC columns (a guard and analytical column) at typical flow rates of 0.1- 2 mL/min. A sample

to be separated is introduced in the mobile phase by an injection device prior to the column. The analytes are separated as they

pass through the column. An optical sensor detects the changes in characteristics of the eluant stream and converts the signal into

an absorbance spectrum. The data system compares this response with an external calibration curve and the results of the

concentration of analyte reported as ppm or milligrams per litre (mg/L). Refer to The denatonium benzoate analysis is achieved

by an HPLC method, where a weight of engine coolant is placed in an auto-sampler vial and mixed with a known volume of

de-ionized water. The auto-sampler vial is placed in a HPLC autosampler and the measurement of denatonium benzoate is

performed using a C-18 reverse phase column attached to an ultraviolet detector. The ultraviolet detector is used to measure the

response of the DNB active ingredients (denatonium and benzoate) in the engine coolant after they have been separated in the

reverse phase column. The denatonium and benzoate responses are compared to responses of known concentrations and the

HPLC’s computer calculates the amount of DNB present in the coolant.Appendix X1 for a HPLC flow diagram.

4. Significance and Use

4.1 This test method provides for the qualitative and quantitative determination of denatonium ionbenzoate in engine coolant

in milligrams per literlitre to low percent range and requires approximately 1001 mL per test, with results available in less than

1

This test method is under the jurisdiction of ASTM Committee D15 on Engine Coolants and Related Fluids and is the direct responsibility of Subcommittee D15.04 on

Chemical Properties.

Current edition approved Nov. 1, 2006March 15, 2014. Published January 2007May 2014. Originally approved in 2006. Last previous edition approved in 2006 as

D7304–06. DOI: 10.1520/D7304-06.10.1520/D7304-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7304 − 14

30 min. Acceptable levels of denatonium vary with manufacturer’s blending specifications and applicable minimum or maximum

industry and state spec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.