ASTM A906/A906M-99

(Specification)Standard Specification for Grade 80 and Grade 100 Alloy Steel Chain Slings for Overhead Lifting

Standard Specification for Grade 80 and Grade 100 Alloy Steel Chain Slings for Overhead Lifting

SCOPE

1.1 This specification covers the requirements and method of rating and testing for alloy chain slings. Slings shall be assembled using components manufactured in accordance with Specification A391/A391M for Grade 80 chain, A 973/A973M for Grade 100 chain, and A952/A952M for components. This specification covers welded and mechanically assembled slings.

1.2 This specification does not cover slings used at elevated temperatures (above 400°F [200°C]), in harmful or corrosive environmental conditions or for applications such as nonsymmetrical legs or loading.

1.3 This specification is a performance and assembly specification. Other standards, such as OSHA 1910.184, ASME B30.9, and ASME B30.10, apply to the use of the products in this specification.

1.4 The values stated in either inch-pound units or SI units shall be regarded as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore each system shall be used independently of the other, without combining values in any way.

General Information

Relations

Standards Content (Sample)

STD-ASTM ASOb/ASObM-ENGL I779 m 0759530 Ob117730 7'26 m

Designation: A 906/A 906M - 99 An American National Standard

#Tb

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr. West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Grade 80 and Grade 100 Alloy Steel Chain Slings for

Overhead Lifting'

This standard is issued under the fined designation A MA WM; the number immediately following the designation indicates the year

of original adoption or, in the case. of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. scope ASME B30.9 Slings4

ASME B30.10 Hooks4

1.1 This specification covers the requirements and method

of rating and testing for alloy chain slings. Slings shall be

3. Terminology

assembled using components manufactured in accordance with

3.1 Definitions:

Specification A 3911A 391M for Grade 80 chain, A 9731

3.1.1 chain sling-an assembly consisting of alloy steel

A 973M for Grade 100 chain, and A 952A 952M for compo-

chain or chains joined to suitable upper and lower fittings,

nents. This specification covers welded and mechanically

according to the provisions of this specification, for attaching

assembled slings.

loads to be lifted by a crane or lifting machine.

1.2 This specification does not cover slings used at elevated

3.1.2 coupling link-a link fitted to the end of the chain to

temperatures (above 400°F [200"C]), in harmful or corrosive

connect either directly or through a secondary link to an upper

environmental conditions or for applications such as nonsym-

or lower end fitting. See Fig. 1.

metrical legs or loading.

3.1.3 end Jirting-a link, hook, or other device fitted at the

1.3 This specification is a performance and assembly speci-

end of a leg. See Fig. 1.

fication. Other standards, such as OSHA 1910.184, ASME

3.1.4 master coupling link (secondary or intermediate

B30.9. and ASME B30.10, apply to the use of the products in

linkta link used on three and four leg slings to connect the

this specification.

legs to a master link. See Fig. 1.

1.4 The values stated in either inch-pound units or SI units

3.1.5 master link-a link used as the upper end fitting of a

shall be regarded separately as standard. Within the text, the SI

chain sling and by means of which the sling is attached to a

units are shown in brackets. The values stated in each system

crane or other lifting machine. See Fig. 1.

are not exact equivalents; therefore each system shall be used

3.1.6 overhead lifiing-that process of lifting which would

the other, without combining values in any

independently of

elevate a freely suspended load to such a position that dropping

way.

the load would present a possibility of bodily injury or property

2. Referenced Documents damage.

3.1.7 proof test-a term designating a quality control test

2.1 ASTM Standards:

applied to a welded sling or to components of a welded sling.

A 391/A 391M Specification for Alloy Steel Chain2

It is the minimum force in pounds or newtons which the sling

A 952lA 952M Specification for Forged Grade 80 and

and components have withstood in the condition and at the

Grade 100 Steel Lifting Components and Welded Attach-

in which a constantly

time it left the factory, under a test

ment Links2

increasing force has been applied in direct tension.

A 9731A 973M Specification for Grade 100 Alloy Steel

3.1.8 qualified person-a person who, by possession of a

Chain'

recognized degree or certificate of professional standing, or by

2.2 Other Standards:

extensive knowledge, training, and experience, has success-

OSHA 1910.184

fully demonstrated the ability to solve or resolve problems

relating to the subject matter and work.

3.1.9 reach-the distance from the bearing point of the

upper end fitting to the bearing point of the lower end fitting.

' This specification is under the jurisdiction of ASTM Committee A-1 on Steel.

Stainless Steel. and Related Alloys and is the direct responsibility of Subcommittee

See Fig. 1.

A01.27 on Steel Chain.

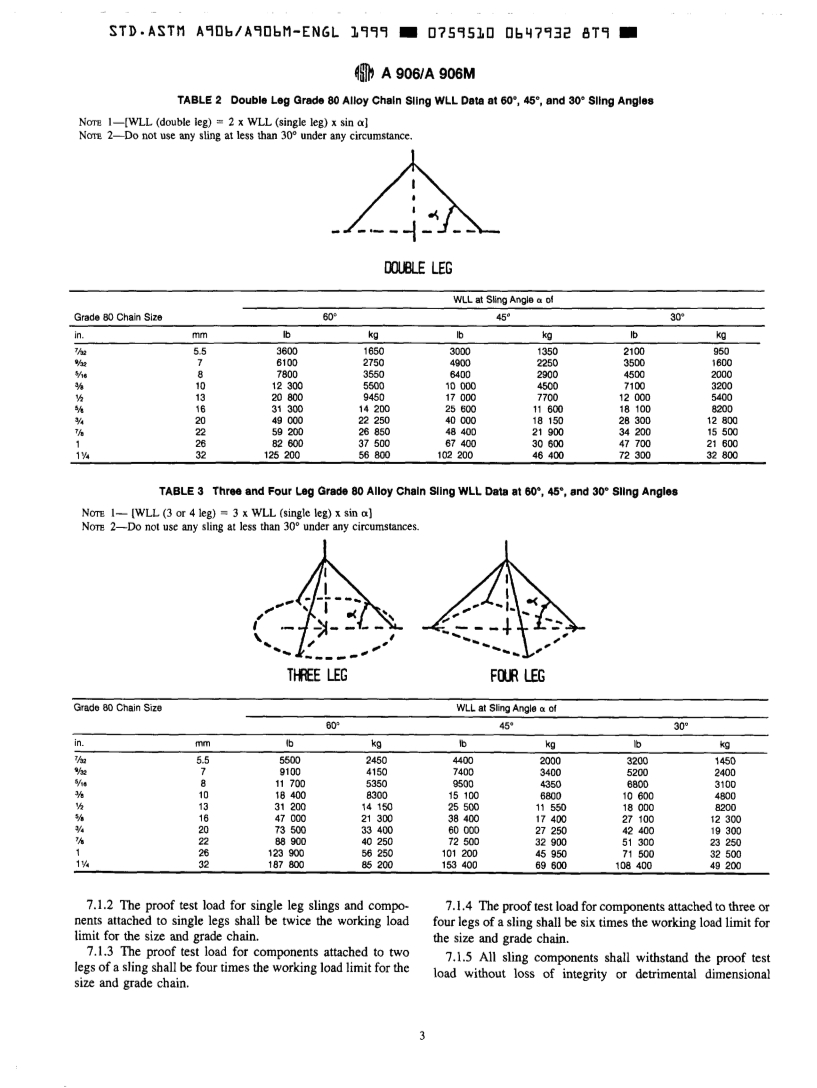

3.1.10 sling angle-that angle measured between the hori-

Current edition approved March 10, 1999. Published July 1999. Originally

zontal plane and the leg (legs) of the sling. See Tables 1-3.

published as A -91. Last previous edition A 906-93.

Annual Book of ASTM Stmahrds. Vol 01.05.

Available from Occupational Safety and Health Administration (OSHA), Office

of the Federal Register National Archives and Records Administration, Washington,

Available from American Society of Mechanical Engineers (ASME), 3 Park

DC.

Ave. New York, NY 10016-5990.

1

---------------------- Page: 1 ----------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.