ASTM D6328-98

(Guide)Standard Guide for Quality Assurance Protocols for Chemical Analysis of Atmospheric Wet Deposition

Standard Guide for Quality Assurance Protocols for Chemical Analysis of Atmospheric Wet Deposition

SCOPE

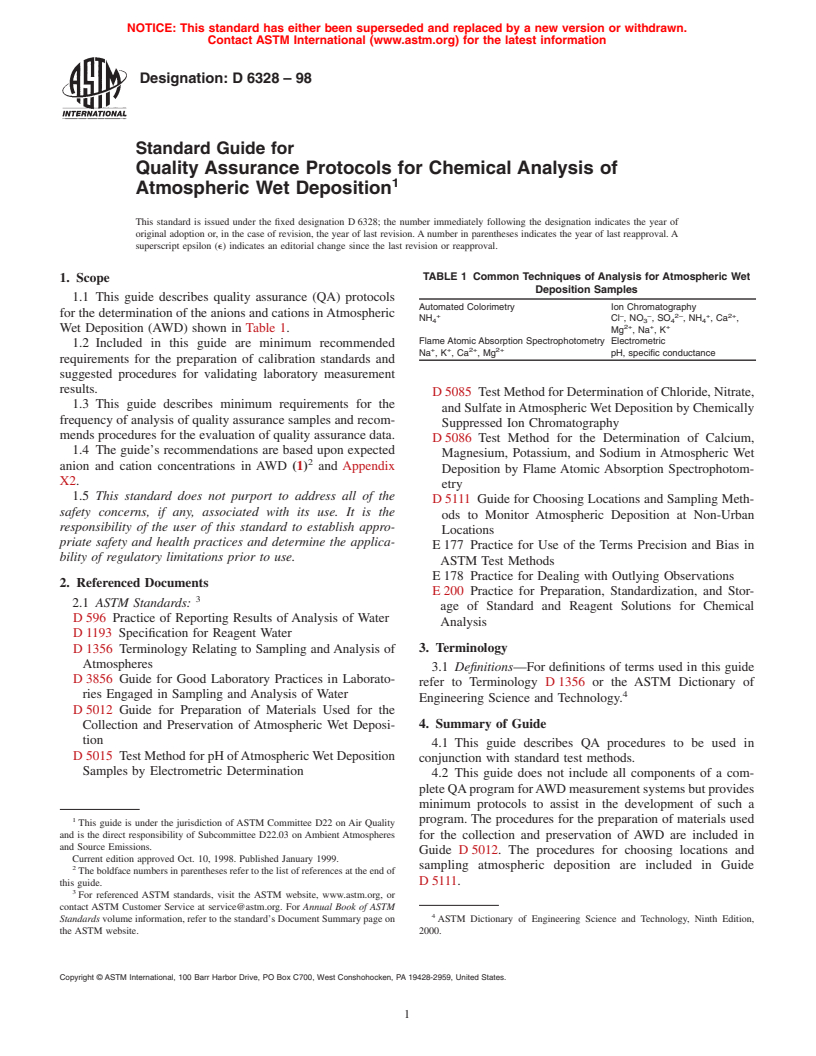

1.1 This guide describes quality assurance (QA) protocols for the determination of the anions and cations in Atmospheric Wet Deposition (AWD) shown in Table 1.

1.2 Included in this guide are minimum recommended requirements for the preparation of calibration standards and suggested procedures for validating laboratory measurement results.

1.3 This guide describes minimum requirements for the frequency of analysis of quality assurance samples and recommends procedures for the evaluation of quality assurance data.

1.4 The guide's recommendations are based upon expected anion and cation concentrations in AWD (1) and Appendix X2.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6328–98

Standard Guide for

Quality Assurance Protocols for Chemical Analysis of

Atmospheric Wet Deposition

This standard is issued under the fixed designation D 6328; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

TABLE 1 Common Techniques of Analysis for Atmospheric Wet

1. Scope

Deposition Samples

1.1 This guide describes quality assurance (QA) protocols

Automated Colorimetry Ion Chromatography

for the determination of the anions and cations inAtmospheric

+ – – 2– + 2+

NH Cl ,NO ,SO ,NH ,Ca ,

4 3 4 4

2+ + +

Wet Deposition (AWD) shown in Table 1.

Mg ,Na ,K

Flame Atomic Absorption Spectrophotometry Electrometric

1.2 Included in this guide are minimum recommended

+ + 2+ 2+

Na ,K ,Ca ,Mg pH, specific conductance

requirements for the preparation of calibration standards and

suggested procedures for validating laboratory measurement

results.

D 5085 TestMethodforDeterminationofChloride,Nitrate,

1.3 This guide describes minimum requirements for the

and Sulfate inAtmosphericWet Deposition by Chemically

frequency of analysis of quality assurance samples and recom-

Suppressed Ion Chromatography

mends procedures for the evaluation of quality assurance data.

D 5086 Test Method for the Determination of Calcium,

1.4 The guide’s recommendations are based upon expected

Magnesium, Potassium, and Sodium in Atmospheric Wet

anion and cation concentrations in AWD (1) and Appendix

Deposition by Flame Atomic Absorption Spectrophotom-

X2.

etry

1.5 This standard does not purport to address all of the

D 5111 Guide for Choosing Locations and Sampling Meth-

safety concerns, if any, associated with its use. It is the

ods to Monitor Atmospheric Deposition at Non-Urban

responsibility of the user of this standard to establish appro-

Locations

priate safety and health practices and determine the applica-

E 177 Practice for Use of the Terms Precision and Bias in

bility of regulatory limitations prior to use.

ASTM Test Methods

E 178 Practice for Dealing with Outlying Observations

2. Referenced Documents

E 200 Practice for Preparation, Standardization, and Stor-

2.1 ASTM Standards:

age of Standard and Reagent Solutions for Chemical

D 596 Practice of Reporting Results of Analysis of Water

Analysis

D 1193 Specification for Reagent Water

3. Terminology

D 1356 Terminology Relating to Sampling and Analysis of

Atmospheres

3.1 Definitions—For definitions of terms used in this guide

D 3856 Guide for Good Laboratory Practices in Laborato-

refer to Terminology D 1356 or the ASTM Dictionary of

ries Engaged in Sampling and Analysis of Water

Engineering Science and Technology.

D 5012 Guide for Preparation of Materials Used for the

4. Summary of Guide

Collection and Preservation of Atmospheric Wet Deposi-

tion

4.1 This guide describes QA procedures to be used in

D 5015 TestMethodforpHofAtmosphericWetDeposition

conjunction with standard test methods.

Samples by Electrometric Determination

4.2 This guide does not include all components of a com-

pleteQAprogramforAWDmeasurementsystemsbutprovides

minimum protocols to assist in the development of such a

program. The procedures for the preparation of materials used

This guide is under the jurisdiction of ASTM Committee D22 on Air Quality

and is the direct responsibility of Subcommittee D22.03 on Ambient Atmospheres for the collection and preservation of AWD are included in

and Source Emissions.

Guide D 5012. The procedures for choosing locations and

Current edition approved Oct. 10, 1998. Published January 1999.

sampling atmospheric deposition are included in Guide

The boldface numbers in parentheses refer to the list of references at the end of

D 5111.

this guide.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on ASTM Dictionary of Engineering Science and Technology, Ninth Edition,

the ASTM website. 2000.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6328–98

5. Reagents dards were correctly prepared and that no degradation or

contamination of the standards has occurred. The frequency of

5.1 Purity of Reagents—Reagent grade chemicals shall be

RM analysis is specified in the test method but must be at least

used in all tests. Unless otherwise indicated, it is intended that

one per analytical run.

all reagents shall conform to the specifications of the commit-

8.3 Evaluation of RM Data—Compare the measured RM

tee on Analytical Reagents of the American Chemical Society

concentration to the certified value immediately after measure-

(ACS),wheresuchspecificationsareavailable. Otherreagents

ment. The analyst must ensure that the concentration value

may be used provided it can be demonstrated that they are of

falls within the limits previously established from the repeated

sufficiently high purity to permit their use without decreasing

analysis of solutions at that concentration level. The measure-

the accuracy of the determination.

ment of samples must be suspended whenever the RM mea-

5.2 Purity of Water—Unless otherwise indicated, reference

surement system is out of control.

towatershallbeunderstoodtomeanreagentwaterconforming

to Specification D 1193, Type II.

NOTE 1—If the confidence interval of the measurement intersects the

5.3 Standard Solutions—Unless otherwise indicated, refer-

confidence or tolerance interval of the RM, there is agreement. If not, then

ence to standard solutions shall be understood to mean solu- a discrepancy exists that needs to be investigated (2).

tions conforming to Practice E 200. Standard Solutions are

8.3.1 When the concentration of the RM differs from the

prepared from primary standards orACS reagent grade salts or

certified value by greater than the established acceptance

may be purchased as secondary standards from commercial

limits, reanalyze the RM immediately to determine if the

laboratory suppliers.

current measurement is reproducible. If this second measure-

ment also differs from the acceptance limits about the certified

6. Storage of Standard Solutions

value, cease analyzing samples.

6.1 TFE-fluorocarbon, polyethylene, and polypropylene

8.3.2 WheneverRMvaluesindicatethatthesystemisoutof

containers are recommended for the storage of standard solu-

control, determine the reason and correct the condition. Reana-

tions. Glass containers are not suitable for storage of most

lyze all samples measured after the last RM value that was in

standard solutions needed to analyze AWD.

control.

7. Verification of Standard Solutions

9. Blanks

7.1 Use two or more of the following procedures to ensure

that the standard solutions are correctly formulated. 9.1 Preparation and Frequency of Analysis:

7.1.1 Confirmation of standard solution analyte concentra-

9.1.1 Prepare reagent blanks according to the procedures

tion by an independent laboratory determination;

recommended in the appropriate test method. Use water

7.1.2 Confirmation of standard solution analyte concentra-

conforming to Specification D 1193, Type I.

tion by an independent analytical procedure within the labora-

9.1.2 Measure reagent blanks each day determinations are

tory.

performed or whenever new reagents are used to check for

7.1.3 Comparison of the standard solution analyte concen-

contamination in sample preparation or analysis.

trations of the same standard solution prepared by different

9.1.3 Use field blanks for analytes whose expected concen-

analysts from the same laboratory or comparison of the analyte

trations are less than 1 mg/L. Field blanks are Type I water

concentration of the new standard solution with the analyte

samples subjected to all aspects of sample collection, field

concentration of a prior standard solution; or

processing, preservation, transportation, and laboratory han-

7.1.4 Comparison of the analyte concentration from the

dling as an environmental sample.

standardsolutionwiththeconcentrationofastandardreference

9.1.4 Other types of blanks may be necessary to determine

material (SRM) or certified reference material (CRM) (2).

the cleanliness of collection vessels, sample storage bottles,

7.2 The results of the confirmation analyses must be within

and membrane filters. Refer to Guide D 5012 for specific

the confidence limits of each measurement. New standard

procedures.

solution(s) must be prepared if the results are not in statistical

9.2 Evaluation of Blank Data:

agreement.

9.2.1 Reagent blank contamination can be highly variable

depending on the source of contamination. When variable

8. Reference Materials (RM)

concentrations of analytes are found in reagent blanks, the

8.1 The RM should be a SRM or a commercially available

source(s) of contamination should be determined and mini-

CRM.

mized.

8.2 Immediately following calibration (Test Methods

9.2.2 Subtracttheconcentrationoftheanalyteinthereagent

D 5015, D 5085, D 5086), at least one RM is to be analyzed to

blank from the concentration of the analyte in the sample only

ensure that the system is functioning properly and that stan-

whentheanalyteconcentrationintheblankislow,forexample

<1 %, in relation to the samples being measured and its value

is constant. When the analyte concentration in the blank is

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

highlyvariable,reanalyzesamplessuspectedofcontamination.

listed by the American Chemical Society, see Analar Standards for Laboratory

9.2.3 Field blank contamination is often more variable than

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

reagent blanks. The field blank concentrations should be used

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

MD. todetermineiftheAWDsampleanalyteconcentrationsarereal

D6328–98

or artifacts. Field blank concentrations of analytes are not to be 11.1.2 Samples used to determine bias include SRM, CRM,

routinely subtracted fromAWD sample analyte concentrations. blind and double blind, and laboratory spike samples.

NOTE 3—Use percent recoveries (calculated from spike samples) cau-

10. Method Detection Limit Definition

tiously when assessing bias (4). They should be used only when matrix

10.1 To improve the comparability of AWD data, it is

interferences are present or suspected in the sample or when a RM is not

strongly recommended that the following definition of method available for either the sample matrix being analyzed or the concentration

level of interest.

detection limit be adopted and implemented.

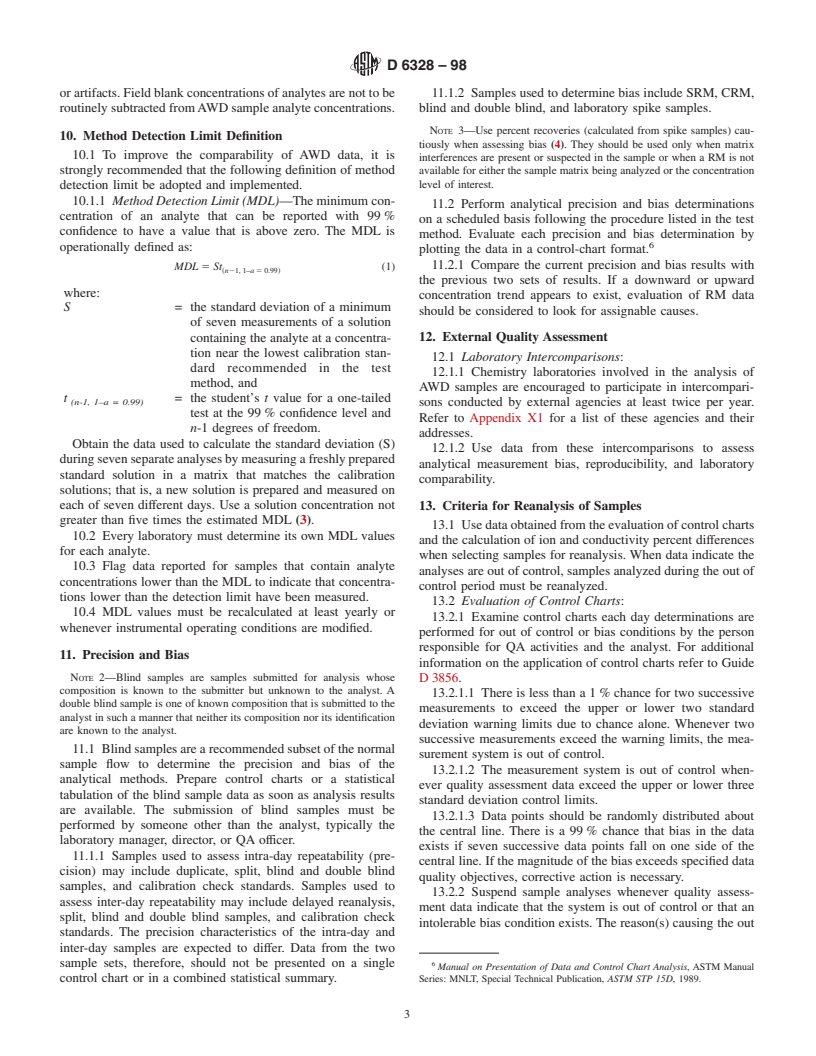

10.1.1 Method Detection Limit (MDL)—Theminimumcon-

11.2 Perform analytical precision and bias determinations

centration of an analyte that can be reported with 99 %

on a scheduled basis following the procedure listed in the test

confidence to have a value that is above zero. The MDL is

method. Evaluate each precision and bias determination by

operationally defined as:

plotting the data in a control-chart format.

11.2.1 Compare the current precision and bias results with

MDL 5 St (1)

~n21, 1–a 5 0.99!

the previous two sets of results. If a downward or upward

where:

concentration trend appears to exist, evaluation of RM data

S = the standard deviation of a minimum

should be considered to look for assignable causes.

of seven measurements of a solution

12. External Quality Assessment

containing the analyte at a concentra-

tion near the lowest calibration stan-

12.1 Laboratory Intercomparisons:

dard recommended in the test

12.1.1 Chemistry laboratories involved in the analysis of

method, and

AWD samples are encouraged to participate in intercompari-

t = the student’s t value for a one-tailed

(n-1, 1–a = 0.99)

sons conducted by external agencies at least twice per year.

test at the 99 % confidence level and

Refer to Appendix X1 for a list of these agencies and their

n-1 degrees of freedom.

addresses.

Obtain the data used to calculate the standard deviation (S)

12.1.2 Use data from these intercomparisons to assess

duringsevenseparateanalysesbymeasuringafreshlyprepared

analytical measurement bias, reproducibility, and laboratory

standard solution in a matrix that matches the calibration

comparability.

solutions; that is, a new solution is prepared and measured on

each of seven different days. Use a solution concentration not

13. Criteria for Reanalysis of Samples

greater than five times the estimated MDL (3).

13.1 Use data obtained from the evaluation of control charts

10.2 Every laboratory must determine its own MDL values

and the calculation of ion and conductivity percent differences

for each analyte.

when selecting samples for reanalysis. When data indicate the

10.3 Flag data reported for samples that contain analyte

analyses are out of control, samples analyzed during the out of

concentrations lower than the MDL to indicate that concentra-

control period must be reanalyzed.

tions lower than the detection limit have been measured.

13.2 Evaluation of Control Charts:

10.4 MDL values must be recalculated at least yearly or

13.2.1 Examine control charts each day determinations are

whenever instrumental operating conditions are modified.

performed for out of control or bias conditions by the person

responsible for QA activities and the analyst. For additional

11. Precision and Bias

information on the application of control charts refer to Guide

NOTE 2—Blind samples are samples submitted for analysis whose

D 3856.

composition is known to the submitter but unknown to the analyst. A

13.2.1.1 There is less than a 1 % chance for two successive

double blind sample is one of known composition that is submitted to the

measurements to exceed the upper or lower two standard

analyst in such a manner that neither its composition nor its identification

deviation warning limits due to chance alone. Whenever two

are known to the analyst.

successive measurements exceed the warning limits, the mea-

11.1 Blindsamplesarearecommendedsubsetofthenormal

surement system is out of control.

sample flow to determine the precision and bias of the

13.2.1.2 The measurement system is out of control when-

analytical methods. Prepare control charts or a statistical

ever quality assessment data exceed the upper or lower three

tabulation of the blind sample data as soon as analysis results

standard deviation control limits.

are available. The submission of blind samples must be

13.2.1.3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.