ASTM A126-95(2001)

(Specification)Standard Specification for Gray Iron Castings for Valves, Flanges, and Pipe Fittings

Standard Specification for Gray Iron Castings for Valves, Flanges, and Pipe Fittings

SCOPE

1.1 This specification covers three classes of gray iron for castings intended for use as valve pressure retaining parts, pipe fittings, and flanges.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

Note 1--The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 126 – 95 (Reapproved 2001)

Standard Specification for

Gray Iron Castings for Valves, Flanges, and Pipe Fittings

This standard is issued under the fixed designation A 126; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

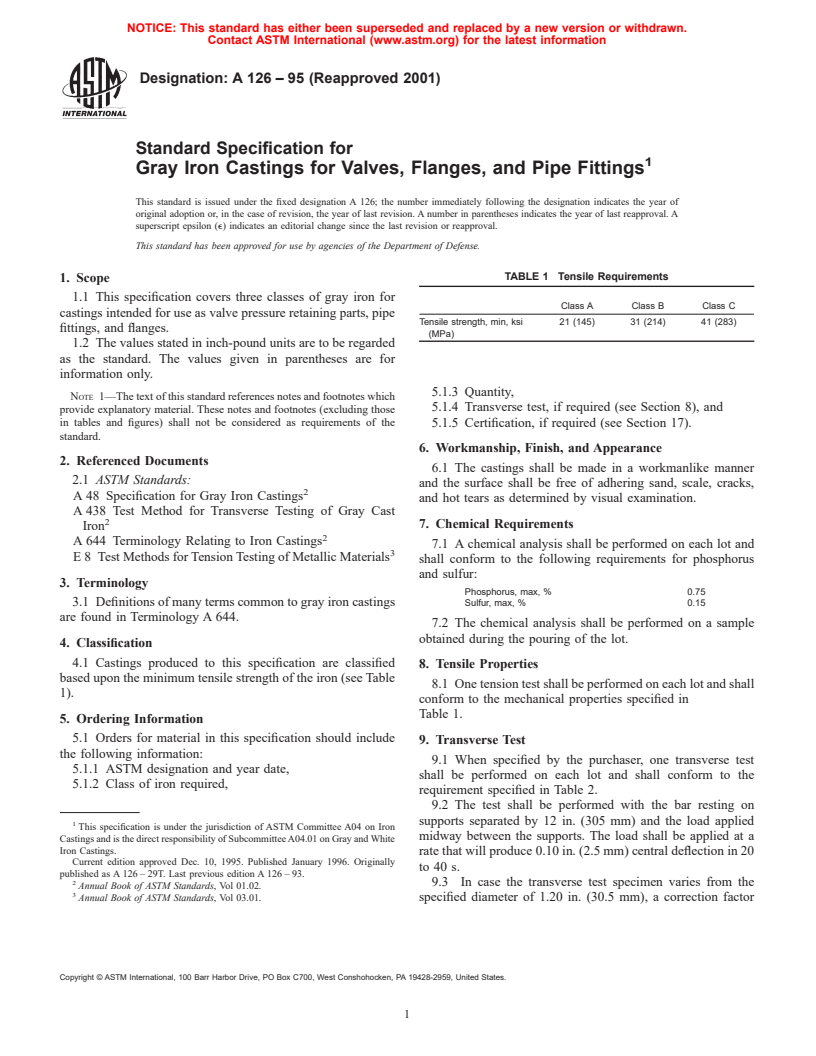

TABLE 1 Tensile Requirements

1. Scope

1.1 This specification covers three classes of gray iron for

Class A Class B Class C

castings intended for use as valve pressure retaining parts, pipe

Tensile strength, min, ksi 21 (145) 31 (214) 41 (283)

fittings, and flanges.

(MPa)

1.2 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are for

information only.

5.1.3 Quantity,

NOTE 1—The text of this standard references notes and footnotes which

5.1.4 Transverse test, if required (see Section 8), and

provide explanatory material. These notes and footnotes (excluding those

in tables and figures) shall not be considered as requirements of the 5.1.5 Certification, if required (see Section 17).

standard.

6. Workmanship, Finish, and Appearance

2. Referenced Documents

6.1 The castings shall be made in a workmanlike manner

2.1 ASTM Standards:

and the surface shall be free of adhering sand, scale, cracks,

A 48 Specification for Gray Iron Castings

and hot tears as determined by visual examination.

A 438 Test Method for Transverse Testing of Gray Cast

7. Chemical Requirements

Iron

A 644 Terminology Relating to Iron Castings

7.1 A chemical analysis shall be performed on each lot and

E 8 Test Methods for Tension Testing of Metallic Materials

shall conform to the following requirements for phosphorus

and sulfur:

3. Terminology

Phosphorus, max, % 0.75

3.1 Definitions of many terms common to gray iron castings Sulfur, max, % 0.15

are found in Terminology A 644.

7.2 The chemical analysis shall be performed on a sample

obtained during the pouring of the lot.

4. Classification

4.1 Castings produced to this specification are classified

8. Tensile Properties

based upon the minimum tensile strength of the iron (see Table

8.1 One tension test shall be performed on each lot and shall

1).

conform to the mechanical properties specified in

Table 1.

5. Ordering Information

5.1 Orders for material in this specification should include

9. Transverse Test

the following information:

9.1 When specified by the purchaser, one transverse test

5.1.1 ASTM designation and year date,

shall be performed on each lot and shall conform to the

5.1.2 Class of iron required,

requirement specified in Table 2.

9.2 The test shall be performed with the bar resting on

supports separated by 12 in. (305 mm) and the load applied

This specification is under the jurisdiction of ASTM Committee A04 on Iron

midway between the supports. The load shall be applied at a

Castings and is the direct responsibility of Subcommittee A04.01 on Gray and White

Iron Castings.

rate that will produce 0.10 in. (2.5 mm) central deflection in 20

Current edition approved Dec. 10, 1995. Published January 1996. Originally

to 40 s.

published as A 126 – 29T. Last previous edition A 126 – 93.

2 9.3 In case the transverse test specimen varies from the

Annual Book of ASTM Standards, Vol 01.02.

specified diameter of 1.20 in. (30.5 mm), a correction factor

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 126

TABLE 2 Transverse Test Requirements NOTE 3—Suitable socket specimens holders and spherical-seated bear-

ing device are shown in Fig. 4 and described in 5.2.3 of Test Methods E 8.

Class A Class B Class C

11.2 After reaching a stress of 15 000 psi (103 MPa), the

Force at center, min, lb (kN) 2200 3300 4000

speed of the crosshead of the testing machine shall not exceed

(9.75) (14.65) (17.75)

⁄8 in. (3.2 mm)/min.

Deflection at center, min, in. 0.10 0.12 0.12

(mm) (2.5) (3.0) (3.0)

12. Sampling

12.1 A lot shall consist of one of the following:

12.1.1 All the metal poured from a single heating in a batch

conforming to the requirements for Test Bar B in Table 1 of

type melting furnace,

Test Method A 438 shall apply.

12.1.2 All the metal from two or more batch type melting

10. Cast Test Bars

furnaces poured into a single ladle or single casting, or

1 12.1.3 All the metal poured from a continuous melting

10.1 Separately cast 1 ⁄8 in. (28.6 mm) diameter test bars

furnace for a given period of time between changes in charge,

shown in Fig. 1 shall be poured in sand molds from the same

processing conditions, or aim-for chemistry or 4 h, whichever

lot as the castings represented.

is the shorter period.

NOTE 2—The numbering on the test specimens shown in Fig. 1 and Fig.

12.1.3.1 The purchaser may agree to extend the 4-h time

2 is intended simply to illustrate a method of designation. In the particular

period to8hifthe manufacturer can demonstrate sufficient

method shown refers to December 8, B

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.