ASTM D876-13

(Test Method)Standard Test Methods for Nonrigid Vinyl Chloride Polymer Tubing Used for Electrical Insulation

Standard Test Methods for Nonrigid Vinyl Chloride Polymer Tubing Used for Electrical Insulation

SIGNIFICANCE AND USE

4.1 These test methods include most of the test methods that are considered important to characterize nonrigid vinyl chloride polymer tubing. While they were developed initially for this type of extruded tubing, their use is not limited to this type of tubing.

4.2 Variations in these test methods or alternate contemporary methods are acceptable for use determine the values for the properties in this standard provided such methods ensure quality levels and measurement accuracy equal to or better than those prescribed herein. It is the responsibility of the organizations using alternate test methods to be able to demonstrate this condition. In cases of dispute, the test methods specified herein shall be used.Note 2—Provision for alternate methods is necessary because of (1) the desire to simplify procedures for specific applications without altering the result, and (2) the desire to eliminate redundant testing and use data generated during manufacturing process control, including that generated under Statistical Process Control (SPC) conditions, using equipment and methods other than those specified herein. An example would be the use of laser micrometers or optical comparators to measure dimensions.

SCOPE

1.1 These test methods cover the testing of general-purpose (Grade A), low-temperature (Grade B), and high-temperature (Grade C)2 nonrigid vinyl chloride polymer tubing, or its copolymers with other materials, for use as electrical insulation. For the purpose of these test methods nonrigid tubing shall be tubing having an initial elongation in excess of 100 % at break.Note 1—These test methods are similar but not identical to those in IEC 60684–2.

1.2 The values stated in inch-pound units are to be regarded as standard, except for temperature, which shall be expressed in degrees Celsius. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

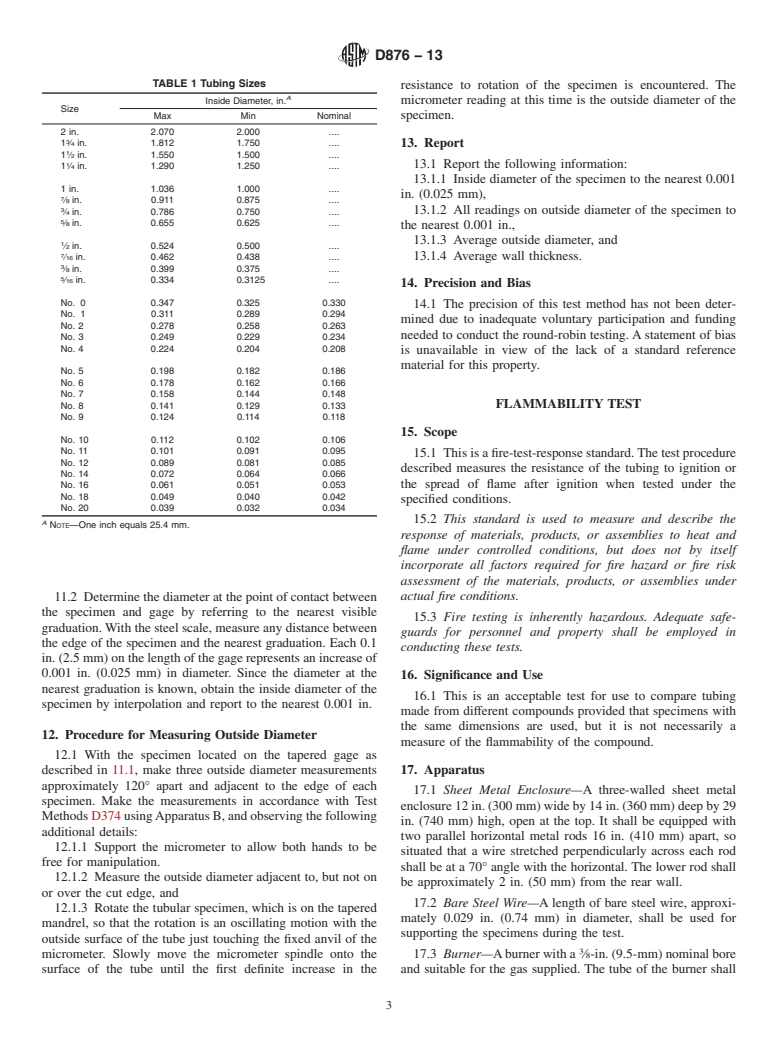

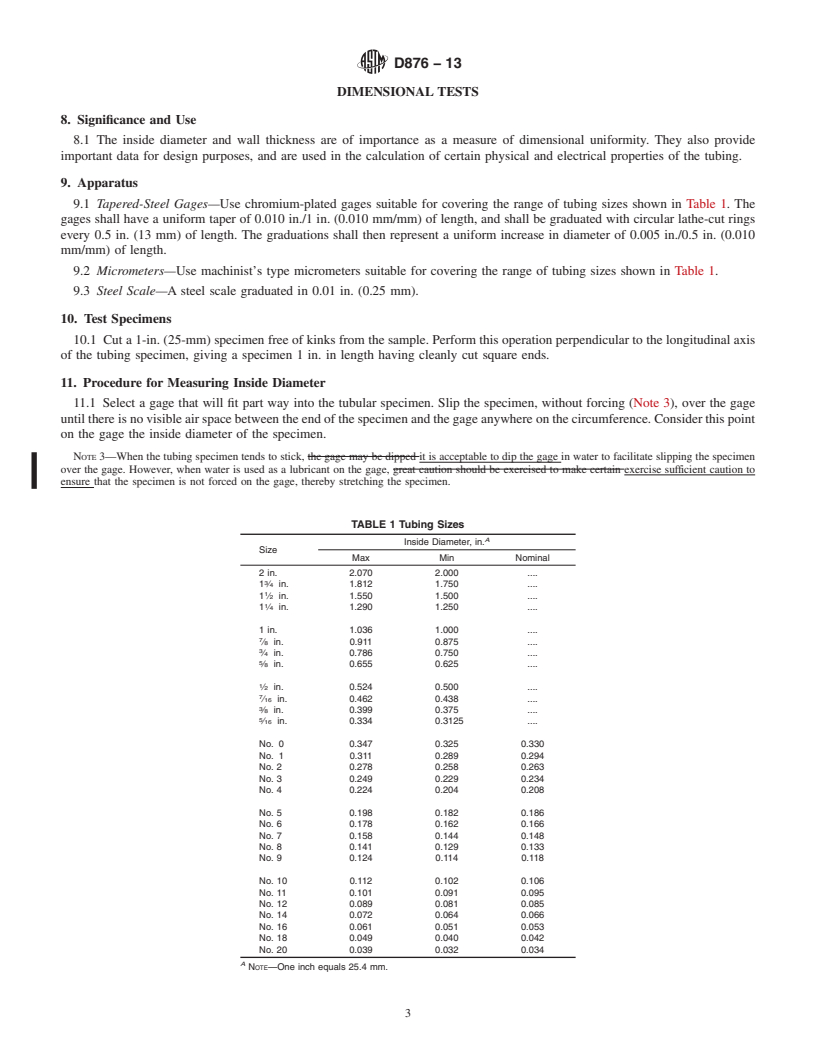

1.3 The procedures appear in the following sections:

Procedure

Section

ASTM Reference Standard

Brittleness Temperature

43 – 45

D746

Corrosion Tests

74 – 85

D1000

Dielectric Breakdown Voltage at High Humidity

65 – 73

E104

Dielectric Breakdown Voltage

58 – 64

D149

Dimensional Tests

8 – 14

D374

Effect of Elevated Temperatures

25 – 36

D412

Flammability Test

15 – 21

Oil Resistance Test

35 – 42

D471

Penetration Test

46 – 51

Sampling

6

Strain Relief Test

68 – 73

Tension Test

22 – 24

D412

Test Conditions

7

Volume Resistivity

52 – 57

D257

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 5.

1.5 For fire test caveats, see Section 15.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D876 − 13

Standard Test Methods for

Nonrigid Vinyl Chloride Polymer Tubing Used for Electrical

1

Insulation

This standard is issued under the fixed designation D876; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* bility of regulatory limitations prior to use. For specific hazard

statements, see Section 5.

1.1 These test methods cover the testing of general-purpose

1.5 For fire test caveats, see Section 15.

(Grade A), low-temperature (Grade B), and high-temperature

2

(Grade C) nonrigid vinyl chloride polymer tubing, or its

2. Referenced Documents

copolymers with other materials, for use as electrical insula-

3

2.1 ASTM Standards:

tion. For the purpose of these test methods nonrigid tubing

D149 Test Method for Dielectric Breakdown Voltage and

shall be tubing having an initial elongation in excess of 100 %

DielectricStrengthofSolidElectricalInsulatingMaterials

at break.

at Commercial Power Frequencies

NOTE 1—These test methods are similar but not identical to those in

D257 Test Methods for DC Resistance or Conductance of

IEC 60684–2.

Insulating Materials

1.2 The values stated in inch-pound units are to be regarded

D374 Test Methods for Thickness of Solid Electrical Insu-

4

as standard, except for temperature, which shall be expressed

lation (Withdrawn 2013)

in degrees Celsius. The values given in parentheses are

D412 Test Methods forVulcanized Rubber andThermoplas-

mathematical conversions to SI units that are provided for

tic Elastomers—Tension

information only and are not considered standard.

D471 Test Method for Rubber Property—Effect of Liquids

D746 Test Method for Brittleness Temperature of Plastics

1.3 The procedures appear in the following sections:

and Elastomers by Impact

ASTM Reference

Procedure Section Standard D1000 Test Methods for Pressure-Sensitive Adhesive-

Brittleness Temperature 43 – 45 D746

Coated Tapes Used for Electrical and Electronic Applica-

Corrosion Tests 74 – 85 D1000

tions

Dielectric Breakdown Voltage at High Humidity 65 – 73 E104

Dielectric Breakdown Voltage 58 – 64 D149

D1711 Terminology Relating to Electrical Insulation

Dimensional Tests 8 – 14 D374

D5032 Practice for Maintaining Constant Relative Humidity

Effect of Elevated Temperatures 25 – 36 D412

by Means of Aqueous Glycerin Solutions

Flammability Test 15–21

Oil Resistance Test 35 – 42 D471 E104 Practice for Maintaining Constant Relative Humidity

Penetration Test 46–51

by Means of Aqueous Solutions

Sampling 6

E176 Terminology of Fire Standards

Strain Relief Test 68–73

Tension Test 22 – 24 D412

2.2 IEC Standards:

Test Conditions 7

60684–2 Flexible insulating sleeving, Part 2, Methods of

Volume Resistivity 52 – 57 D257

5

test

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

3.1 Definitions:

priate safety and health practices and determine the applica-

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

These test methods are under the jurisdiction of ASTM Committee D09 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Electrical and Electronic Insulating Materials and are the direct responsibility of Standards volume information, refer to the standard’s Document Summary page on

Subcommittee D09.07 on Flexible and Rigid Insulating Materials. the ASTM website.

4

Current edition approved Nov. 1, 2013. Published December 2013. Originally The last approved version of this historical standard is referenced on

approved in 1946. Last previous edition approved in 2009 as D876 – 09. DOI: www.astm.org.

5

10.1520/D0876-13. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

2

Test methods applicable to Grade B will be specified at a later date. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D876 − 13

3.1.1 For definitions pertaining to electrical insulation, refer test specimens so as to minimize the possibility of such

to Terminology D1711. occurrences, and to eliminate the possibility of personal injury.

3.1.2 For definitions pertaining to fire standards, refer to If the potential for fire exists, have fire suppression equipment

Terminology E176. available.

3.2 Definit

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D876 − 09 D876 − 13 An American National Standard

Standard Test Methods for

Nonrigid Vinyl Chloride Polymer Tubing Used for Electrical

1

Insulation

This standard is issued under the fixed designation D876; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 These test methods cover the testing of general-purpose (Grade A), low-temperature (Grade B), and high-temperature

2

(Grade C) nonrigid vinyl chloride polymer tubing, or its copolymers with other materials, for use as electrical insulation. For the

purpose of these test methods nonrigid tubing shall be tubing having an initial elongation in excess of 100 % at break.

NOTE 1—These test methods are similar but not identical to those in IEC 60684–2.

1.2 The values stated in inch-pound units are to be regarded as standard, except for temperature, which shall be expressed in

degrees Celsius. The values given in parentheses are mathematical conversions to SI units that are provided for information only

and are not considered standard.

1.3 The procedures appear in the following sections:

ASTM Reference

Procedure Section Standard

Brittleness Temperature 43 – 45 D746

Corrosion Tests 74 – 85 D1000

Dielectric Breakdown Voltage at High Humidity 65 – 73 E104

Dielectric Breakdown Voltage 58 – 64 D149

Dimensional Tests 8 – 14 D374

Effect of Elevated Temperatures 25 – 36 D412

Flammability Test 15 – 21

Oil Resistance Test 35 – 42 D471

Penetration Test 46 – 51

Sampling 6

Strain Relief Test 68 – 73

Tension Test 22 – 24 D412

Test Conditions 7

Volume Resistivity 52 – 57 D257

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, see Section 5.

1.5 For fire test caveats, see Section 15.

2. Referenced Documents

3

2.1 ASTM Standards:

D149 Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at

Commercial Power Frequencies

D257 Test Methods for DC Resistance or Conductance of Insulating Materials

4

D374 Test Methods for Thickness of Solid Electrical Insulation (Withdrawn 2013)

D412 Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension

1

These test methods are under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and are the direct responsibility of Subcommittee

D09.07 on Flexible and Rigid Insulating Materials.

Current edition approved Oct. 1, 2009Nov. 1, 2013. Published November 2009December 2013. Originally approved in 1946. Last previous edition approved in 20072009

ε1

as D876 – 00D876 – 09.(2007) . DOI: 10.1520/D0876-09.10.1520/D0876-13.

2

Test methods applicable to Grade B will be specified at a later date.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D876 − 13

D471 Test Method for Rubber Property—Effect of Liquids

D746 Test Method for Brittleness Temperature of Plastics and Elastomers by Impact

D1000 Test Methods for Pressure-Sensitive Adhesive-Coated Tapes Used for Electrical and Electronic Applications

D1711 Terminology Relating to Electrical Insulation

D5032 Practice for Maintaining Constant Relative Humidity by Means of Aqueous Glycerin Solutions

E104 Practice for Maintaining Constant Relative Humidity by Means of Aqueous Solutions

E176 Terminology of Fire Standards

2.2 IEC Standards:

5

60684–2 Flexible insulating sleeving, Part 2, Methods of test

3. Terminology

3.1 Definitions:

3.1.1 For definitions pertaining to electrical insulation, refer to Terminology D1711.

3.1.2 For definitions pertaini

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.