ASTM D3134-97(2003)

(Practice)Standard Practice for Establishing Color and Gloss Tolerances

Standard Practice for Establishing Color and Gloss Tolerances

SIGNIFICANCE AND USE

Color specifications are centered around exact positions in color space. Correspondingly, gloss specifications are centered around an exact position on the gloss scale. Because it is difficult to achieve these exact positions repeatedly, it is necessary to specify tolerances that are acceptable to both the buyer and the seller. This practice details the procedure for accomplishing this goal.

SCOPE

1.1 This practice describes a procedure for establishing tolerances and evaluating the color and gloss of specimens with respect to specified standards. This practice is appropriate for nonfluorescent opaque specimens.

1.2 This practice does not indicate the extent of tolerances, but gives guidance on how they can be set. For product specification, the tolerances between specimens and the specified standard should be agreed upon between the purchaser and the seller.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

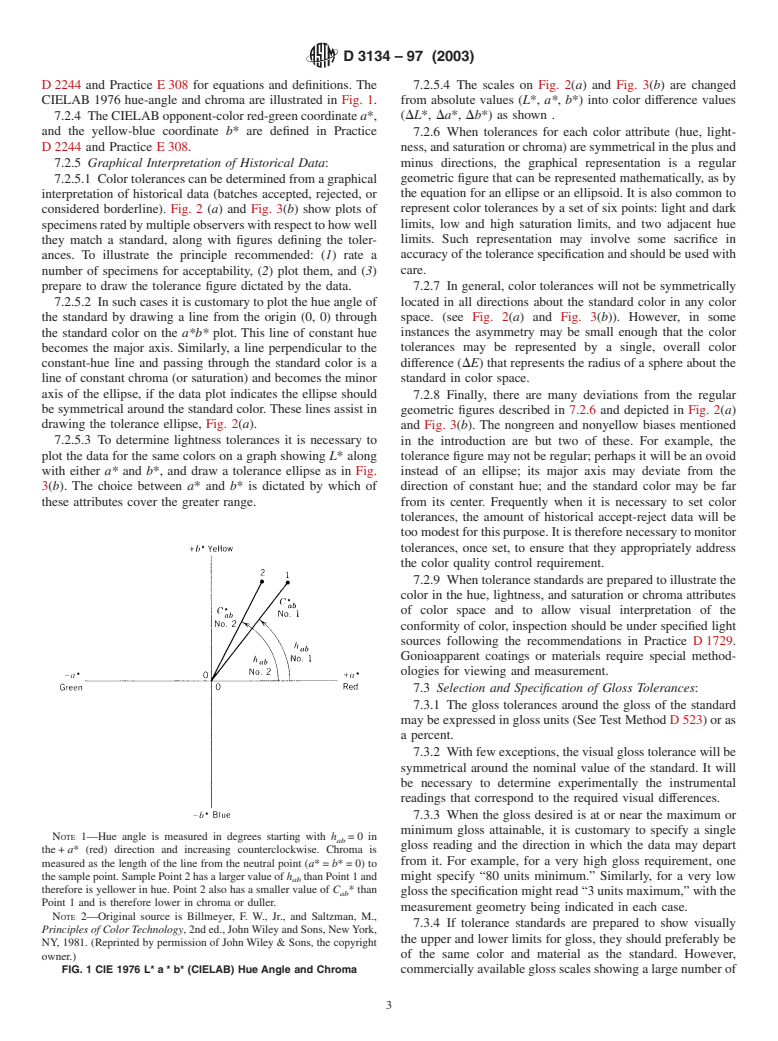

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3134–97(Reapproved2003)

Standard Practice for

1

Establishing Color and Gloss Tolerances

This standard is issued under the fixed designation D 3134; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Permissible color and gloss deviations from a standard are generally dependent upon the color

discrimination of the observer, on the lighting and surround in which the material is viewed, and on

special considerations related to the design, manufacture, and practical usage of the colored material

or object. The tolerances, therefore, may be influenced by economic, technical, psychological, and

practical requirements. In many circumstances, acceptability of color and gloss deviations from a

standard may differ appreciably from the perceptibility of deviations such as on-tone fading

preferences, large tolerances for luminance variation, nongreen bias, or nonyellow bias. With proper

allowances, perceptibility data can be used as an aid to develop permissible tolerances. Finally, the

sum of all these considerations should result in a specification acceptable to both buyer and seller.

1. Scope D 2244 Practice for Calculation of Color Tolerances and

Color Differences from Instrumentally Measured Color

1.1 This practice describes a procedure for establishing

Coordinates

tolerancesandevaluatingthecolorandglossofspecimenswith

D 3964 Practice for Selection of Coating Specimens for

respect to specified standards. This practice is appropriate for

Appearance Measurement

nonfluorescent opaque specimens.

D 4449 Test Method for Visual Evaluation of Gloss Differ-

1.2 This practice does not indicate the extent of tolerances,

ences Between Surfaces of Similar Appearance

but gives guidance on how they can be set. For product

D 5531 Guide for Preparation, Maintenance, and Distribu-

specification, the tolerances between specimens and the speci-

tion of Physical Product Standards for Color and Geomet-

fiedstandardshouldbeagreeduponbetweenthepurchaserand

ric Appearance of Coatings

the seller.

E 284 Terminology of Appearance

1.3 This standard does not purport to address all of the

E 308 Practice for Computing the Colors of Objects by

safety concerns, if any, associated with its use. It is the

Using the CIE System

responsibility of the user of this standard to establish appro-

E 312 Practice for Description and Selection of Conditions

priate safety and health practices and determine the applica-

for Photographing Specimens

bility of regulatory limitations prior to use.

E 805 PracticeforIdentificationofInstrumentalMethodsof

2. Referenced Documents Color or Color-Difference Measurement of Materials

2

E 1164 Practice for Obtaining Spectrophotometric Data for

2.1 ASTM Standards:

Object-Color Evaluation

D 523 Test Method for Specular Gloss

E 1331 Test Method for Reflectance Factor and Color by

D 1535 Practice for Specifying Color by the Munsell Sys-

Spectrophotometry Using Hemispherical Geometry

tem

E 1345 Practice for Reducing the Effect of Variability of

D 1729 Practice for Visual Appraisal of Colors and Color

Color Measurement by Use of Multiple Measurements

Differences of Diffusely Illuminated Opaque Materials

E 1349 Test Method for Reflectance Factor and Color by

Spectrophotometry Using Bidirectional Geometry

E 1360 Practice for Specifying Color by Using the Optical

1

This practice is under the jurisdiction of ASTM Committee E12 on Color and

Society of America Uniform Color Scales System

Appearance and is the direct responsibility of Subcommittee E12.11 on Visual

E 1499 Guide to the Selection, Evaluation, and Training of

Methods.

Observers

Current edition approved Dec. 1, 2003. Published December 2003. Originally

approved in 1972. Last previous edition approved in 1997 as D 3134 – 97.

E 1541 Practice for Specifying and Matching Color Using

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the Colorcurve System

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

E 1708 Practice for Electronic Interchange of Color and

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Appearance Data

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3134–97 (2003)

2.2 CIE Publication: the standard is textured. (If the standard is textured, note the

3

No. 15.2 Colorimetry 2nd ed. texture orientation during measurement.) The variability of the

measurements due to texture may be reduced by following the

3. Terminology

r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.