ASTM D5010-01

(Guide)Standard Guide for Testing Printing Inks and Related Materials

Standard Guide for Testing Printing Inks and Related Materials

SCOPE

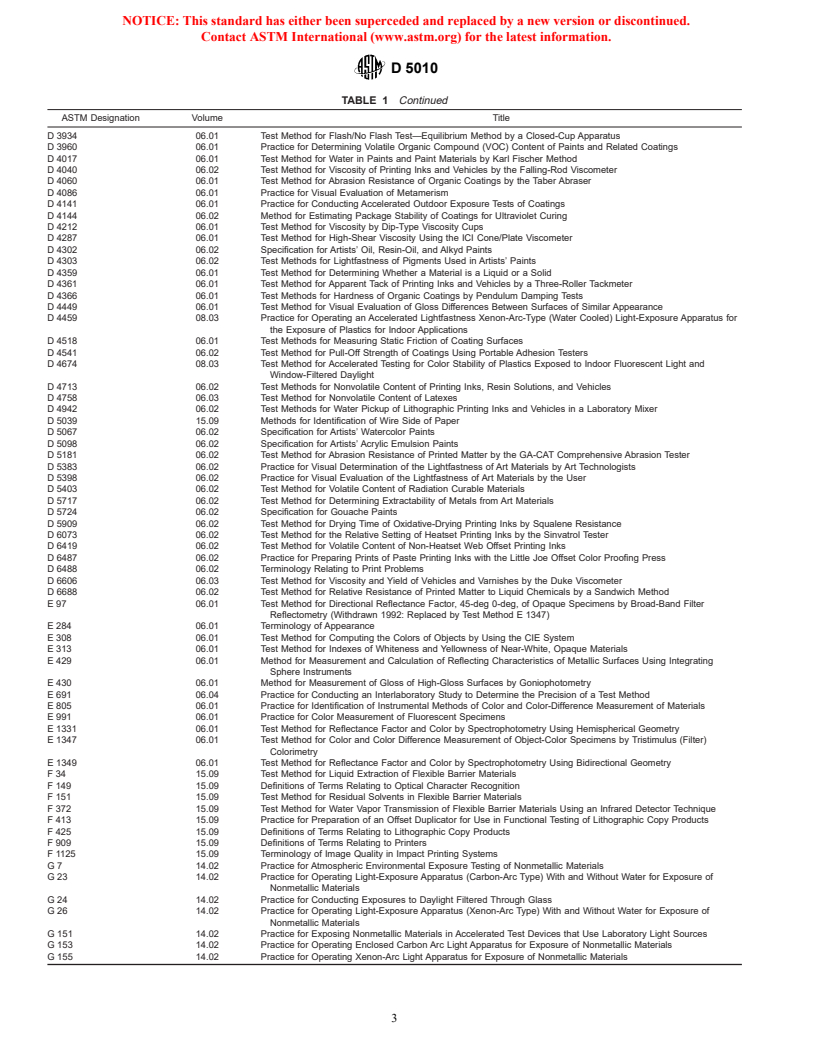

1.1 This guide covers a list of test methods, practices, and specifications that can be used for the testing and evaluation of printing inks, printed ink films, and substrates used in their production (see Table 1).

1.2 This guide includes methods that were developed to test paints, paint films, and substrates, but may be adapted for use in testing printing inks and printed matter. Tests on raw materials and analytical methods in general have not been included.

Note 1—For the purpose of this guide, clear coatings such as overprint varnishes are classed as printing inks.

1.3 Other ASTM standards not specified here may also be applicable.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5010 – 01

Standard Guide for

1

Testing Printing Inks and Related Materials

This standard is issued under the fixed designation D 5010; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope ited in the production of printed matter. Printing substrates

include paper, paperboard, plastic film, glass, and metallic

1.1 This guide covers a list of test methods, practices, and

surfaces. In this guide, standards relating to substrates are

specifications that can be used for the testing and evaluation of

largely restricted to properties associated with appearance and

printing inks, printed ink films, and substrates used in their

printability.

production (see Table 1).

1.2 This guide includes methods that were developed to test

3. Test Categories

paints, paint films, and substrates, but may be adapted for use

3.1 For convenience in selection, the test methods, prac-

in testing printing inks and printed matter. Tests on raw

tices, and specifications, listed in this guide are classified into

materials and analytical methods in general have not been

three groups by type of printing process and in subgroups

included.

indicating whether the test is conducted on a bulk ink, a printed

NOTE 1—For the purpose of this guide, clear coatings such as overprint

ink film, or a substrate (see Table 2). The group is given in the

varnishes are classed as printing inks.

left column preceding the test method reference. The classifi-

1.3 Other ASTM standards not specified here may also be

cation are a follows:

applicable.

3.1.1 Group 1—Applicable in General:

Class A—Bulk inks.

2. Terminology

Class B—Printed ink films.

2.1 Definitions:

Class C—Substrates.

2.1.1 printing ink—a colored or pigmented liquid or paste

3.1.2 Group 2—Applicable to Low Viscosity or Liquid Inks

composition that dries to a solid film after application as a thin

Associated With Flexography or Gravure:

layer by printing machinery.

Class A—Bulk inks.

2.1.1.1 Discussion—Printing inks may contain vehicles,

Class B—Printed ink films.

colorants, waxes, solvents, and other additives. Bulk inks are

Class C—Substrates.

tested for dispersion, tinting strength, density, heat and storage

3.1.3 Group 3—Applicable to High Viscosity or Paste Inks

stability, rheology, and printing properties.

Associated With Letterpress, Lithography, or Silk Screen:

2.1.2 printed ink film—thin layer of a printing ink deposited

Class A—Bulk inks.

onto a substrate by means of a laboratory or production

Class B—Printed ink films.

printing press, occasionally by a drawdown or roll-out tech-

Class C—Substrates.

nique. Printed matter is the usual medium by which inks are

4. Precision and Bias

tested for appearance properties, drying, and resistance to

various agents.

4.1 If available, precision for each test method listed can be

2.1.3 printing substrate—material onto which ink is depos-

found in the latest revision of that test method.

5. Keywords

1

This guide is under the jurisdiction of the ASTM Committee D01 on Paint and

5.1 printed matter; printing inks; printing substrates; test

Related Coatings, Materials, and Applications and is the direct responsibility of

methods and practices (tabulation of)

Subcommittee D01.56 on Printing Inks.

Current edition approved Dec. 10, 2001. Published February 2002. Originally

published as D 5010 – 91. Last previous edition D 5010 – 00a.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5010

TABLE 1 Numerical Listing of Ink-Related Standards

ASTM Designation Volume Title

D 16 06.01 Terminology Relating to Paint, Varnish, Lacquer, and Related Products

D 56 05.03 Test Method for Flash Point by Tag Closed Tester

06.04

D 93 04.09 Test Method for Flash Point by Pensky-Martin Closed Tester

05.01

06.04

D 185 06.03 Test Methods for Coarse Particles in Pigments, Pastes, and Paints

D 344 06.01 Test Method for Relative Dry Hiding Power of Paints by the Visual Evaluation of Brushouts

D 523 06.01 Test Method for Specular Gloss

D 528 15.09 Test Method for Machine Direction of Paper and Paperboard

D 562 06.01 Test Method for Consistency of Paints Using the Stormer Viscometer

D 644 15.09 Test Method for Moisture Content of Paper and Paperboard by Oven Drying

D 685 15.09 Method for Conditioning Paper and Paperboard Products for Testing

D 724 15.09 Test Method for Surface Wetta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.