ASTM D5478-98

(Test Method)Standard Test Methods for Viscosity of Materials by a Falling Needle Viscometer

Standard Test Methods for Viscosity of Materials by a Falling Needle Viscometer

SCOPE

1.1 These test methods cover the measurement of the viscosity of Newtonian and non-Newtonian liquids. These test methods are applicable to liquids having viscosities in the range from 5 X 10 -4 to 10 Pa[dot]s (0.5 to 10 cP). The shear rate range is dependent upon the needle used and viscosity of the liquid and may vary from 10 -4 to 10 s -1 .

1.2 The yield stress of liquids having this property may also be determined.

1.3 These test methods consist of determining liquid viscosities of Newtonian and non-Newtonian fluids (clear or opaque) by measuring the steady-state (constant) or terminal velocities of cylindrical needles as they fall through the test liquid under the influence of gravity. Yield stresses of non-Newtonian liquids may be measured using the same procedure.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: D 5478 – 98

Standard Test Methods for

Viscosity of Materials by a Falling Needle Viscometer

This standard is issued under the fixed designation D5478; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope fluid but a variable depending on the shear rate. The viscosity

of most non-Newtonian fluids fits a power law expression. A

1.1 These test methods cover the measurement of the

power law fluid is defined by the following equation:

viscosity of Newtonian and non-Newtonian liquids. These test

n21

methods are applicable to liquids having viscosities in the

h 5 K~g˙! (1)

a

−4 3 6

rangefrom5 310 to10 Pa·s(0.5to10 cP).Theshearrate

range is dependent upon the needle used and viscosity of the

−4 3 −1

where:

liquid and may vary from 10 to 10 s .

h = apparent viscosity, dyne · s/cm =P=100 cP,

a

1.2 Theyieldstressofliquidshavingthispropertymayalso

n 2

K = fluid consistency, dyne·s /cm ,

be determined.

g˙ = shear rate, 1/s, and

1.3 These test methods consist of determining liquid vis-

n = flow index, dimensionless.

cosities of Newtonian and non-Newtonian fluids (clear or

3.1.3 pseudoplastic fluid (or shear thinning fluid)—one in

opaque) by measuring the steady-state (constant) or terminal

which the apparent viscosity decreases with increasing shear

velocities of cylindrical needles as they fall through the test

rate.

liquid under the influence of gravity. Yield stresses of non-

3.1.4 viscosity—Theratiobetweenanappliedshearstressto

Newtonianliquidsmaybemeasuredusingthesameprocedure.

the resulting shear rate (velocity gradient) is defined as the

1.4 This standard does not purport to address all of the

dynamic viscosity. It is a measure of the resistance to flow of

safety concerns, if any, associated with its use. It is the

a fluid.

responsibility of the user of this standard to establish appro-

3.1.4.1 Discussion—In the SI unit system the units of

priate safety and health practices and determine the applica-

viscosity are Pa·s. One mPa·s is equal to one centipoise (cP).

bility of regulatory limitations prior to use.

3.1.5 yield stress—Some fluids when subjected to a shear

stress behave as deformable solids until a certain critical shear

2. Referenced Documents

stressisreachedafterwhichtheybehaveasfluids.Thiscritical

2.1 ASTM Standards:

shear stress is called the yield stress or yield value.

E1 Specification for ASTM Thermometers

3.1.5.1 Discussion—Examples of such fluids include many

paints and pigment pastes and certain food materials, for

3. Terminology

example, ketchup.

3.1 Definitions:

3.1.1 dilatant fluid (or shear thickening fluid)— one in

4. Summary of Test Methods

which the apparent viscosity increases with increasing shear

4.1 Test Method A consists of determining the viscosity of

rate.

Newtonian liquids.

3.1.2 Newtonian and non-Newtonian fluids—A Newtonian

4.2 Test Method B consists of determining the apparent

fluid is one in which the dynamic viscosity does not vary with

viscosity and shear rate of pseudoplastic and dilatant fluids in

shear rate but only with the temperature and pressure. A

the power law region.

non-Newtonian fluid is one in which the dynamic viscosity

4.3 Test Method C consists of determining the apparent

varies with shear rate over at least some shear rate range.

viscosity and shear rate of pseudoplastic and dilatant fluids

3.1.2.1 Discussion—This viscosity is sometimes referred to

outside of the power law region.

as the “apparent viscosity” since it is not a true property of the

4.4 Test Method D consists of determining the yield stress

of liquids that have such a property.

ThesetestmethodsareunderthejurisdictionofASTMCommitteeD-1onPaint

and Related Coatings, Materials, and Applications and are the direct responsibility

of Subcommittee D01.24 on Physical Properties of Liquid Paints and Paint

Materials.

Current edition approved June 10, 1998. Published September 1998. Originally

published as D5478–93. Last previous edition D5478–93.

Annual Book of ASTM Standards, Vol 14.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D5478–98

5. Significance and Use

5.1 These test methods are applicable for measuring the

rheologicalpropertiesofvarnishesandpaints.Inparticular,the

low to moderate shear rate measurements provide information

related to sag resistance, leveling, etc.

6. Apparatus

6.1 Viscometer, falling-needle-type and associated equip-

ment listed as follows:

3,4,5

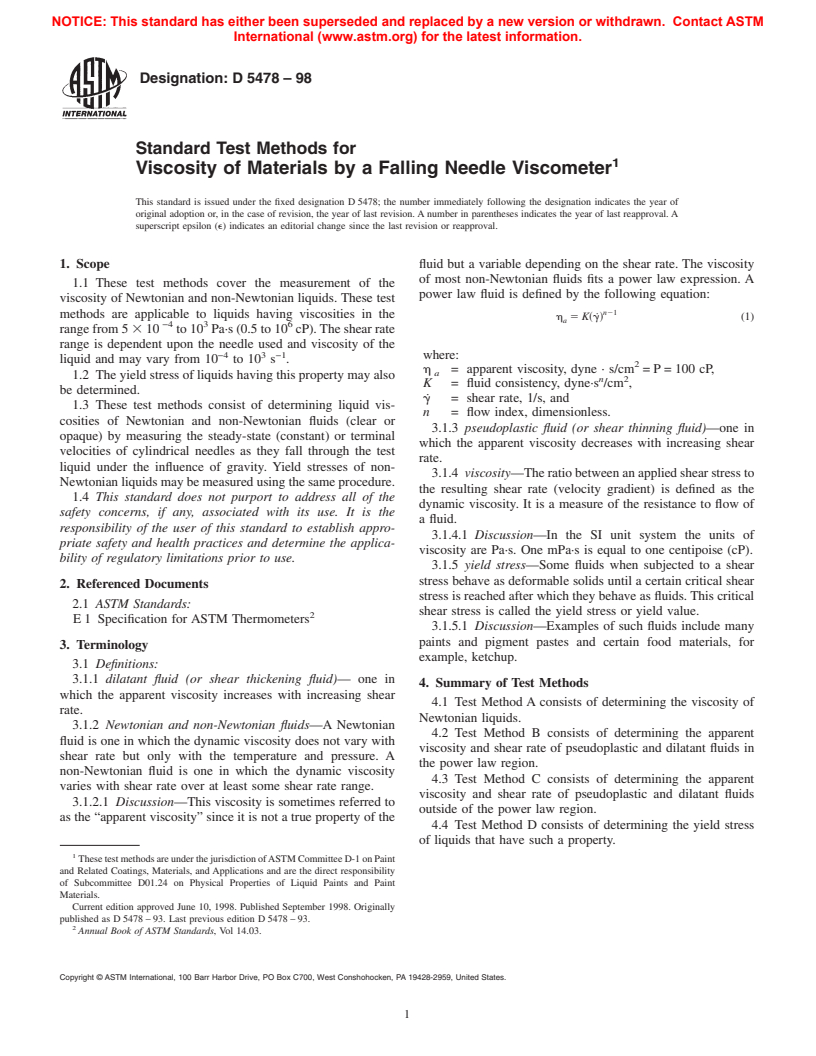

6.1.1 Falling Needle Viscometer —A schematic of the

falling needle viscometer is shown in Fig. 1. The viscometer

consistsofaverticalcylindricaltestsectionofdiameter D.The

liquidspecimenisplacedinthetestsectionandthespecimen’s

temperature is maintained constant by means of a constant

temperature bath that circulates a liquid through another

cylindrical container (water jacket) that is coaxial to the test

section.Athin hollow cylinder of length L with hemispherical

ends and diameter d (the needle) is aligned with the axis of the

test section and allowed to fall under the influence of gravity.

The needle has a small weight in its forward end that may be

varied to change its density. After the needle has attained its

constant terminal velocity, this velocity is measured by deter-

mining the needle transit time between two circumferential

marks a known distance apart on the test section (for opaque

liquids this can be done by an automatic sensing device, such

as a magnetic sensor, etc.). With a knowledge of the terminal

velocity, the liquid and needle densities, the geometric con-

stants of the system (L, D, d), the viscosity of a Newtonian

fluid can be calculated from the instrument theory. For a

non-Newtonian fluid whose viscosity depends upon the shear

rate, a series of needles are dropped. The falling needle is an

absolute method of viscosity measurement that does not need

any instrument calibration. However, it may be checked

through use of known certified viscous fluids such as standard

oils.

6.1.2 Thermometer—A thermometric device calibrated to

0.1°Cwhoseaccuracy,precision,andsensitivityareequaltoor

better than the ASTM thermometer described in Specification

FIG. 1 Schematic of Falling Needle Viscometer

E1.

6.1.3 Circulating Liquid Bath, capable of maintaining the

test specimen temperature to 60.1°C.

6.1.4 Stopwatch or Electronic Device,capableofmeasuring

to 60.01 s or an automatic sensing device with the same

accuracy.

Park, N. A., and Irvine, T. F., Jr., “Measurements of Rheological Fluid

Properties with the Falling Needle Viscometer,” Review of Scientific Instruments,

Vol 59, 1988, pp. 2051–2058.

7. Preparation of Specimen

Park, N. A., and Irvine, T. F., Jr., “The Falling Needle Viscometer, A New

Technique for Viscosity Measurements,” American Laboratory, Vol 20, November 7.1 After opening the specimen container, mix the fluid

1988, pp. 57–63.

gently with a glass rod for 5 min.

“The sole source of supply of the falling needle viscometer known to the

7.2 Pour the specimen carefully into the test section so as to

committee at this time is Stony Brook Scientific, Ltd., P.O. Box 147, 914 Filmore

minimizetheformationofairbubbles.Ifavailable,asyringeis

Rd.,Norristown,PA19403.Ifyouareawareofalternativesuppliers,pleaseprovide

this information to ASTM Headquarters. Your comments will receive careful

useful for this purpose.

consideration at a meeting of the responsible technical committee, which you may

7.3 Remix the specimen in the test container using the

attend.” This instrument may be interfaced with a computer for data collection and

needle retriever rod by pushing it up and down four times at a

analysis.Acomputer program is available for data analysis for instruments that are

not interfaced. velocity of approximately 4 cm/s.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D5478–98

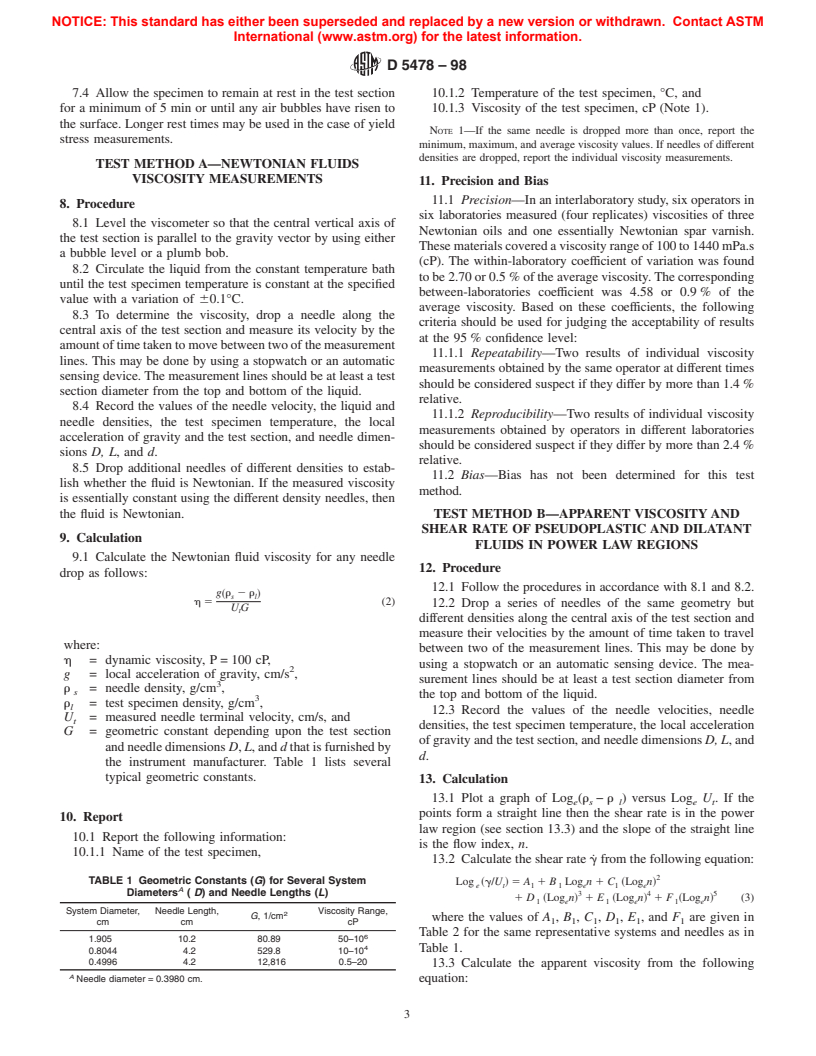

7.4 Allow the specimen to remain at rest in the test section 10.1.2 Temperature of the test specimen, °C, and

for a minimum of 5 min or until any air bubbles have risen to 10.1.3 Viscosity of the test specimen, cP (Note 1).

the surface. Longer rest times may be used in the case of yield

NOTE 1—If the same needle is dropped more than once, report the

stress measurements.

minimum, maximum, and average viscosity values. If needles of different

densities are dropped, report the individual viscosity measurements.

TEST METHOD A—NEWTONIAN FLUIDS

VISCOSITY MEASUREMENTS

11. Precision and Bias

11.1 Precision—Inaninterlaboratorystudy,sixoperatorsin

8. Procedure

six laboratories measured (four replicates) viscosities of three

8.1 Level the viscometer so that the central vertical axis of

Newtonian oils and one essentially Newtonian spar varnish.

the test section is parallel to the gravity vector by using either

Thesematerialscoveredaviscosityrangeof100to1440mPa.s

a bubble level or a plumb bob.

(cP). The within-laboratory coefficient of variation was found

8.2 Circulate the liquid from the constant temperature bath

tobe2.70or0.5%oftheaverageviscosity.Thecorresponding

until the test specimen temperature is constant at the specified

between-laboratories coefficient was 4.58 or 0.9% of the

value with a variation of 60.1°C.

average viscosity. Based on these coefficients, the following

8.3 To determine the viscosity, drop a needle along the

criteria should be used for judging the acceptability of results

central axis of the test section and measure its velocity by the

at the 95% confidence level:

amountoftimetakentomovebetweentwoofthemeasurement

11.1.1 Repeatability—Two results of individual viscosity

lines. This may be done by using a stopwatch or an automatic

measurements obtained by the same operator at different times

sensing device.The measurement lines should be at least a test

should be considered suspect if they differ by more than 1.4%

section diameter from the top and bottom of the liquid.

relative.

8.4 Record the values of the needle velocity, the liquid and

11.1.2 Reproducibility—Two results of individual viscosity

needle densities, the test specimen temperature, the local

measurements obtained by operators in different laboratories

acceleration of g

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.