ASTM D5628-96

(Test Method)Standard Test Method for Impact Resistance of Flat, Rigid Plastic Specimens by Means of a Falling Dart (Tup or Falling Mass)

Standard Test Method for Impact Resistance of Flat, Rigid Plastic Specimens by Means of a Falling Dart (Tup or Falling Mass)

SCOPE

1.1 This test method covers the determination of the relative ranking of materials according to the energy required to crack or break flat, rigid plastic specimens under various specified conditions of impact of a free-falling dart (tup).

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 8.

Note 1—This test method and ISO 6603-1-1985 are technically equivalent only when the test conditions and specimen geometry required for Geometry FE and the Bruceton Staircase method of calculation are used.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5628 – 96 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Impact Resistance of Flat, Rigid Plastic Specimens by

Means of a Falling Dart (Tup or Falling Mass)

This standard is issued under the fixed designation D 5628; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 3763 Test Method for High-Speed Puncture Properties of

Plastics Using Load and Displacement Sensors

1.1 This test method covers the determination of the relative

D 4066 Specification for Nylon Injection and Extrusion

ranking of materials according to the energy required to crack

Materials

or break flat, rigid plastic specimens under various specified

E 171 Specification for Standard Atmospheres for Condi-

conditions of impact of a free-falling dart (tup).

tioning and Testing Materials

1.2 The values stated in SI units are to be regarded as the

E 177 Practice for Use of the Terms Precision and Bias in

standard. The values in parentheses are for information only.

ASTM Test Methods

1.3 This standard does not purport to address all of the

E 691 Practice for Conducting an Interlaboratory Study to

safety concerns, if any, associated with its use. It is the

Determine the Precision of a Test Method

responsibility of the user of this standard to establish appro-

2.2 ISO Standards:

priate safety and health practices and determine the applica-

ISO 291 Standard Atmospheres for Conditioning and Test-

bility of regulatory limitations prior to use. Specific hazard

ing

statements are given in Section 8.

ISO 6603-1 Plastics-Determination of Multiaxial Impact

NOTE 1—This test method and ISO 6603-1-1985 are technically 9

Behavior of Rigid Plastics—Part 1: Falling Dart Method

equivalent only when the test conditions and specimen geometry required

for Geometry FE and the Bruceton Staircase method of calculation are

3. Terminology

used.

3.1 Definitions:

2. Referenced Documents 3.1.1 For definitions of plastic terms used in this test

method, see Terminologies D 883 and D 1600.

2.1 ASTM Standards:

3.2 Definitions of Terms Specific to This Standard:

D 374 Test Methods for Thickness of Solid Electrical Insu-

3.2.1 failure (of test specimen)—the presence of any crack

lation

or split, created by the impact of the falling tup, that can be

D 618 Practice for Conditioning Plastics and Electrical

seen by the naked eye under normal laboratory lighting

Insulating Materials for Testing

conditions.

D 638 Test Method for Tensile Properties of Plastics

3.2.2 mean-failure energy (mean-impact resistance)—the

D 883 Terminology Relating to Plastics

energy required to produce 50 % failures, equal to the product

D 1600 Terminology for Abbreviated Terms Relating to

of the drop height and the mean-failure mass or the product of

Plastics

the constant mass and mean-failure height.

D 1709 Test Method for Impact Resistance of Plastic Film

2 3.2.3 mean-failure height (impact-failure height)—the

by the Free Falling Dart Method

height at which a standard mass when dropped on test

D 1898 Practice for Sampling of Plastics

specimens, will cause 50 % failures.

D 2188 Practice for Statistical Design in Interlaboratory

Testing of Plastics

NOTE 2—Cracks usually start at the surface opposite the one that is

D 2444 Test Method for Impact Resistance of Thermo-

struck. Occasionally incipient cracking in glass-reinforced products, for

example, may be difficult to differentiate from the reinforcing fibers. In

plastic Pipe and Fittings by Means of a Tup (Falling

such cases, a penetrating dye may be used to confirm the onset of crack

Weight)

formation.

3.2.4 mean-failure mass (impact-failure mass)—the mass of

This test method is under the jurisdiction of ASTM Committee D-20 on Plastics

the dart (tup) that, when dropped on the test specimens from a

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

Current edition approved March 10, 1996. Published July 1996. Originally

published as D 5628 – 94. Last previous edition D 5628 – 95. Annual Book of ASTM Standards, Vol 08.02.

2 7

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 08.03.

3 8

Annual Book of ASTM Standards, Vol 10.01. Annual Book of ASTM Standards, Vol 14.02.

4 9

Discontinued; see 1982 Annual Book of ASTM Standards, Vol 08.02. Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 08.04. Floor, New York, NY 10036.

D 5628

standard height, will cause 50 % of them to fail. been used in specifications for extruded sheeting. A limitation

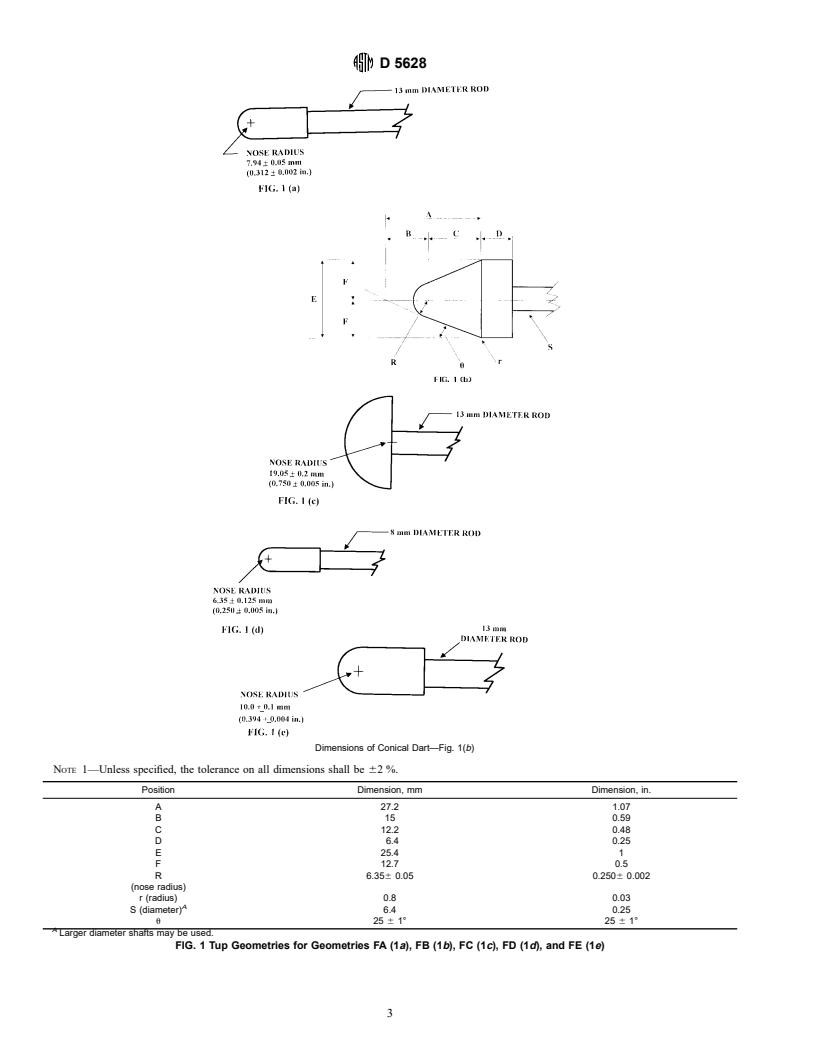

3.2.5 tup—a dart with a hemispherical nose. See 7.2 and of this geometry is that considerable material is required.

Fig. 1. 5.5 The test conditions of Geometry FD are the same as for

Test Method D 3763.

4. Summary of Test Method

5.6 The test conditions of Geometry FE are the same as for

4.1 A free-falling dart (tup) is allowed to strike a supported ISO 6603-1.

5.7 Because of the nature of impact testing, the selection of

specimen directly. Either a dart having a fixed mass may be

dropped from various heights, or a dart having an adjustable a test method and tup must be somewhat arbitrary. While any

one of the tup geometries may be selected, knowledge of the

mass may be dropped from a fixed height. (See Fig. 2).

4.2 The procedure determines the energy (mass 3 height) final or intended end-use application should be considered.

5.8 Clamping of the test specimen will improve the preci-

that will cause 50 % of the specimens tested to fail (mean

failure energy). sion of the data. Therefore, clamping is recommended. How-

ever, with rigid specimens, valid determinations can be made

4.3 The technique used to determine mean failure energy is

commonly called the Bruceton Staircase Method or the Up- without clamping. Unclamped specimens tend to exhibit some-

what greater impact resistance.

and-Down Method (1). Testing is concentrated near the

mean, reducing the number of specimens required to obtain a

6. Interferences

reasonably precise estimate of the impact resistance.

6.1 Falling-mass-impact-test results are dependent on the

4.4 Each test method permits the use of different tup and test

geometry of both the falling mass and the support. Thus,

specimen geometries to obtain different modes of failure,

impact tests should be used only to obtain relative rankings of

permit easier sampling, or test limited amounts of material.

materials. Impact values cannot be considered absolute unless

There is no known means for correlating the results of tests

the geometry of the test equipment and specimen conform to

made by different methods or procedures.

the end-use requirement. Data obtained by different procedures

5. Significance and Use

within this test method, or with different geometries, cannot, in

general, be compared directly with each other. However, the

5.1 Plastics are viscoelastic and therefore may be sensitive

relative ranking of materials may be expected to be the same

to changes in velocity of the mass falling on their surfaces.

between two test methods if the mode of failure and the impact

However, the velocity of a free-falling object is a function of

velocities are the same.

the square root of the drop height. A change of a factor of two

6.1.1 Falling-mass-impact types of tests are not suitable for

in the drop height will cause a change of only 1.4 in velocity.

predicting the relative ranking of materials at impact velocities

Hagan et al (2) found that the mean-failure energy of sheeting

differing greatly from those imposed by these test methods.

was constant at drop heights between 0.30 and 1.4 m. This

6.2 As cracks usually start at the surface opposite the one

suggests that a constant mass-variable height method will give

that is struck, the results can be greatly influenced by the

the same results as the constant height-variable mass tech-

quality of the surface of test specimens. Therefore, the com-

nique. On the other hand, different materials respond differ-

position of this surface layer, its smoothness or texture, levels

ently to changes in the velocity of impact. Equivalence of these

of and type of texture, and the degree of orientation introduced

methods should not be taken for granted. While both constant-

during the formation of the specimen (such as may occur

mass and constant-height techniques are permitted by these

during injection molding) are very important variables. Flaws

methods, the constant-height method should be used for those

in this surface will also affect results.

materials that are found to be rate-sensitive in the range of

6.3 Impact properties of plastic materials can be very

velocities encountered in falling-weight types of impact tests.

sensitive to temperature. This test can be carried out at any

5.2 The test geometry FA causes a moderate level of stress

reasonable temperature and humidity, thus representing actual

concentration and can be used for most plastics.

use environments. However, this test method is intended

5.3 Geometry FB causes a greater stress concentration and

primarily for rating materials under specific impact conditions.

results in failure of tough or thick specimens that do not fail

with Geometry FA (3). This approach may produce a punch

7. Apparatus

shear failure on thick sheet. If that type of failure is undesir-

7.1 Testing Machine—The apparatus shall be constructed

able, Geometry FC may be used. Geometry FB is suitable for

essentially as is shown in Fig. 2. The apparatus is similar in

research and development because of the smaller test area

design to that used in Test Method D 1709 and Test Method

required.

D 2444. The geometry of the specimen clamp and tup shall

5.3.1 The conical configuration of the 12.7-mm diameter

conform to the dimensions given in 7.1.1 and 7.2.

tup used in Geometry FB minimizes problems with tup

7.1.1 Specimen Clamp—For flat specimens, a two-piece

penetration and sticking in failed specimens of some ductile

annular specimen clamp similar to that shown in Fig. 3 is

materials.

recommended. For Geometries FA and FD, the inside diameter

5.4 The test conditions of Geometry FC are the same as

should be 76.06 3.0 mm (3.00 6 0.12 in.). For Geometry FB,

those of Test Method A of Test Method D 1709. They have

the inside diameter should be 38.1 6 0.80 mm (1.5 6 0.03 in.).

For Geometry FC, the inside diameter should be 127.0 6 2.5

mm (5.00 6 0.10 in.). For Geometry FE an annular specimen

The boldface numbers in parentheses refer to a list of references at the end of

the text. clamp similar to that shown in Fig. 4 is required. The inside

D 5628

Dimensions of Conical Dart—Fig. 1(b)

NOTE 1—Unless specified, the tolerance on all dimensions shall be 62%.

Position Dimension, mm Dimension, in.

A 27.2 1.07

B 15 0.59

C 12.2 0.48

D 6.4 0.25

E 25.4 1

F 12.7 0.5

R 6.356 0.05 0.2506 0.002

(nose radius)

r (radius) 0.8 0.03

A

S (diameter) 6.4 0.25

u 25 6 1° 25 6 1°

A

Larger diameter shafts may be used.

FIG. 1 Tup Geometries for Geometries FA (1a), FB (1b), FC (1c), FD (1d), and FE (1e)

D 5628

FIG. 2 One Type of Falling Mass Impact Tester

FIG. 3 Support Plate/Specimen/Clamp Configuration for Geometries FA, FB, FC, and FD

diameter should be 40 6 2 mm (1.57 6 0.08 in.) (see Table 1). 7.1.1.1 Contoured specimens shall be firmly held in a jig so

For Geometries FA, FB, FC, and FD, the inside edge of the

that the point of impact will be the same for each specimen.

upper or supporting surface of the lower clamp should be

7.1.2 Tup Support, capable of supporting a 13.5-kg (30-lb)

rounded slightly; a radius of 0.8 mm (0.03 in.) has been found

mass, with a release mechanism and a centering device to

to be satisfactory. For Geometry FE this radius should be 1 mm

ensure uniform, reproducible drops.

(0.04 in.).

D 5628

FIG. 4 Test-Specimen Support for Geometry FE

TABLE 1 Tup and Support Ring Dimensions

enough to accommodate the maximum mass (see Fig. 1(c) and

Dimensions, mm (in.) Table 1).

Geometry

7.2.4 The tup used in Geometry FD shall have a 12.706

Tup Diameter Inside Diameter Support Ring

0.25-mm (0.500 6 0.010-in.) diameter hemispherical head of

FA 15.86 6 0.10 76.0 6 3.0

(0.625 6 0.004) (3.00 6 0.12) tool steel hardened to 54 HRC or harder. A steel shaft about 8

FB 12.7 6 0.1 38.1 6 0.8

mm (0.31 in.) in diameter shall be attached to the center of the

(0.500 6 0.003) (1.5 6 0.03)

flat surface of the head with its longitudinal axis at 90° to the

FC 38.1 6 0.4 127.0 6 2.5

(1.5 6 0.010) (5.00 6 0.10) surface. The length of the shaft shall be great enough to

FD 12.70 6 0.25 76.0 6 3.0

accommodate the maximum mass required (see Fig. 1(d) and

(0.500 6 0.010) (3.00 6 0.12)

Table 1).

FE 20.0 6 0.2 40.0 6 2.0

(0.787 6 0.008) (1.57 6 0.08) 7.2.5 The tup used in Geometry FE shall have a 20.0 6

0.2-mm (0.787 6 0.008-in.) diameter hemispherical head of

NOTE 3—Reproducible drops may be ensured through the use of a tube tool steel hardened to 54 HRC or harder. A steel shaft about 13

or cage within which the tup falls. In this event, care should be exercised

mm (0.5 in.) in diameter shall be attached to the center of the

so that any friction that develops will not reduce the velocity of the tup

flat surface of the head with its longitudinal axis at 90° to the

appreciably.

surface. The length of the shaft shall be great enough to

7.1.3 Positioning Device—Means shall be provided for

accommodate the maximum mass required (see Fig. 1(e) and

positioning the tup so that the distance from the impinging Table 1).

surface of the tup head to the test specimen is as specified. 7.2.6 The tup head shall be free of nicks, scratches, or other

7.2 Tup: surface irregularities.

7.2.1 The tup used in Geometry FA shall have a 15.866 7.3 Masses—Cylindrical steel masses are required that have

0.10-mm (0.625 6 0.004-in.) diameter hemispherical head of a center hole into which the tup shaft will fit. A variety of

tool steel hardened to 54 HRC or harder. A steel shaft about 13 masses are needed if different materials or thicknesses are to be

mm (0.5 in.) in diameter shall be attached to the center of the tested. For a material of low impact resistance, the tup mass

flat surface of the head with its longitudinal axis at 90° to that may need to be adjusted by increments of 10

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.