ASTM E750-10

(Practice)Standard Practice for Characterizing Acoustic Emission Instrumentation

Standard Practice for Characterizing Acoustic Emission Instrumentation

ABSTRACT

This practice deals with the testing and measurement of operating characteristics of acoustic emission (AE) electronic components or units. This practice is not intended for routine checks of acoustic emission instrumentation, but rather for periodic evaluation or in the event of a malfunction. The sensor is not addressed in this document other than suggesting methods for standardizing system gains (equalizing them channel to channel) when sensors are present. The test methods and measurement techniques used and their corresponding results should be recorded in documentation, which consists of photographs, charts or graphs, calculations, and tabulations where applicable. This practice does not cover the testing of the computer or computer peripherals used in conjunction with AE systems that use them to control the collection, storage, display, and analysis of data. Instead a manufacturer's specification should be provided for such purpose.

SIGNIFICANCE AND USE

This practice provides information necessary to document the accuracy and performance of an Acoustic Emission system. This information is useful for reference purposes to assure that the instrumentation performance remains consistent with time and use, and provides the information needed to adjust the system to maintain its consistency.

The methods set forth in this practice are not intended to be either exclusive or exhaustive.

Difficult or questionable instrumentation measurements should be referred to electronics engineering personnel.

It is recommended that personnel responsible for carrying out instrument measurements using this practice should be experienced in instrumentation measurements, as well as all the required test equipment being used to make the measurements.

SCOPE

1.1 This practice is recommended for use in testing and measuring operating characteristics of acoustic emission electronic components or units. (See Appendix X1 for a description of components and units.) It is not intended that this practice be used for routine checks of acoustic emission instrumentation, but rather for periodic evaluation or in the event of a malfunction. The sensor is not addressed in this document other than suggesting methods for standardizing system gains (equalizing them channel to channel) when sensors are present.

1.2 Where the manufacturer provides testing and measuring details in an operating and maintenance manual, the manufacturer's methods should be used in conjunction with the methods described in this practice.

1.3 The methods (techniques) used for testing and measuring the components or units of acoustic emission instrumentation, and the results of such testing and measuring should be documented. Documentation should consist of photographs, screenshots, charts or graphs, calculations, and tabulations where applicable.

1.4 AE systems that use computers to control the collection, storage, display, and data analysis, might include waveform collection as well as a wide selection of measurement parameters (features) relating to the AE signal. The manufacturer provides a specification for each system that specifies the operating range and conditions for the system. All calibration and acceptance testing of computer-based AE systems must use the manufacturer's specification as a guide. This practice does not cover testing of the computer or computer peripherals.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E750 −10

StandardPractice for

1

Characterizing Acoustic Emission Instrumentation

This standard is issued under the fixed designation E750; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This practice is recommended for use in testing and

measuring operating characteristics of acoustic emission elec-

2. Referenced Documents

troniccomponentsorunits.(SeeAppendixX1foradescription

2

ofcomponentsandunits.)Itisnotintendedthatthispracticebe 2.1 ASTM Standards:

used for routine checks of acoustic emission instrumentation, E1316 Terminology for Nondestructive Examinations

but rather for periodic evaluation or in the event of a malfunc-

2.2 ANSI Standard:

tion. The sensor is not addressed in this document other than

ANSI/IEEE 100-1984 Dictionary of Electrical and Elec-

3

suggesting methods for standardizing system gains (equalizing

tronic Terms

them channel to channel) when sensors are present.

2.3 Other Documents:

1.2 Where the manufacturer provides testing and measuring

Manufacturer’s Operating and Maintenance Manuals perti-

details in an operating and maintenance manual, the manufac-

nent to the specific instrumentation or component

turer’s methods should be used in conjunction with the

methods described in this practice.

3. Terminology

1.3 The methods (techniques) used for testing and measur-

3.1 Definitions—For definitions of additional terms relating

ing the components or units of acoustic emission

to acoustic emission, refer to Terminology E1316.

instrumentation, and the results of such testing and measuring

should be documented. Documentation should consist of

4. Summary of Practice

photographs, screenshots, charts or graphs, calculations, and

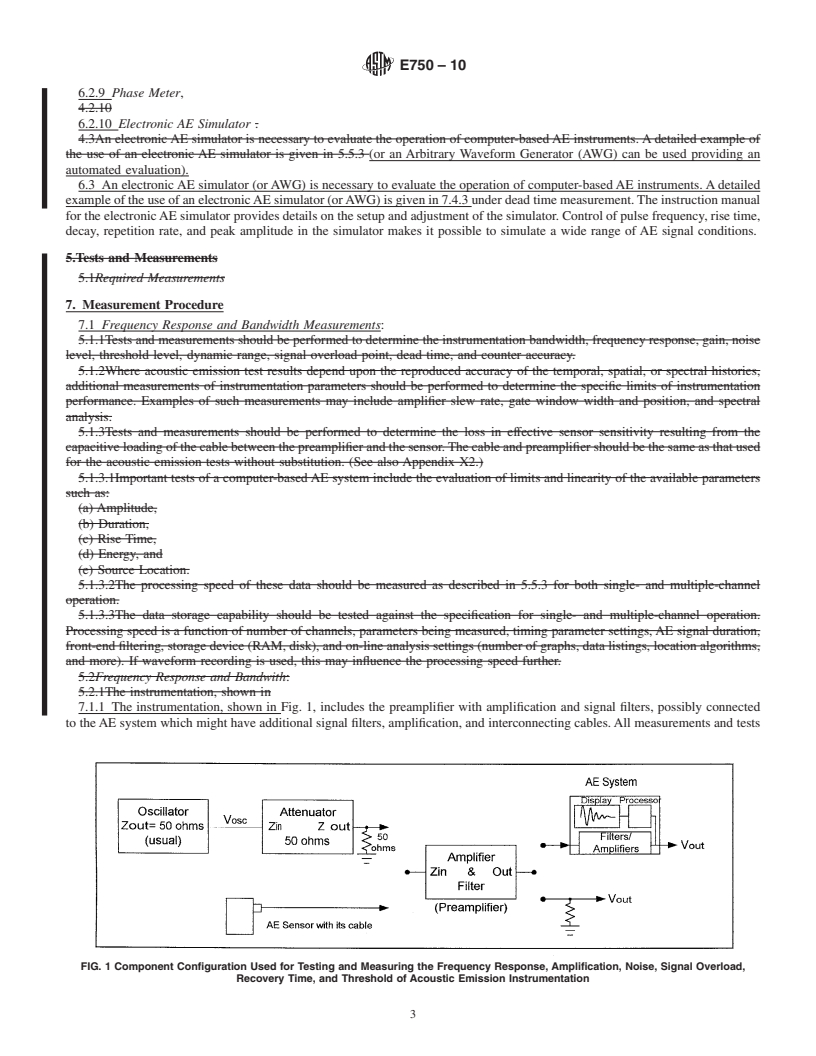

4.1 Tests and measurements should be performed to deter-

tabulations where applicable.

mine the instrumentation bandwidth, frequency response, gain,

1.4 AE systems that use computers to control the collection,

noise level, threshold level, dynamic range, signal overload

storage, display, and data analysis, might include waveform

point, dead time, and counter accuracy.

collection as well as a wide selection of measurement param-

4.2 Where acoustic emission test results depend upon the

eters (features) relating to the AE signal. The manufacturer

reproduced accuracy of the temporal, spatial, or spectral

provides a specification for each system that specifies the

histories, additional measurements of instrumentation param-

operating range and conditions for the system. All calibration

eters should be performed to determine the specific limits of

andacceptancetestingofcomputer-basedAEsystemsmustuse

instrumentation performance. Examples of such measurements

the manufacturer’s specification as a guide. This practice does

may include amplifier slew rate, gate window width and

not cover testing of the computer or computer peripherals.

position, and spectral analysis.

1.5 The values stated in SI units are to be regarded as

4.3 Tests and measurements should be performed to deter-

standard. No other units of measurement are included in this

mine the loss in effective sensor sensitivity resulting from the

standard.

capacitive loading of the cable between the preamplifier and

1.6 This standard does not purport to address all of the

the sensor. The cable and preamplifier should be the same as

safety concerns, if any, associated with its use. It is the

that used for the acoustic emission tests without substitution.

responsibility of the user of this standard to establish appro-

(See also Appendix Appendix X2.)

1 2

This practice is under the jurisdiction of ASTM Committee E07 on Nonde- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

structive Testing and is the direct responsibility of Subcommittee E07.04 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Acoustic Emission Method. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Jan. 1, 2010. Published February 2010. Originally the ASTM website.

3

approved in 1980. Last previous edition approved in 2004 as E750 - 04. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/E0750-10. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E750−10

4.3.1 Important tests of a computer-based AE system in- 6.1.2 True RMS Voltmet

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E750–04 Designation: E750 – 10

Standard Practice for

1

Characterizing Acoustic Emission Instrumentation

This standard is issued under the fixed designation E750; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice is recommended for use in testing and measuring operating characteristics of acoustic emission electronic

components or units. (See Appendix X1 for a description of components and units.) It is not intended that this practice be used

for routine checks of acoustic emission instrumentation, but rather for periodic evaluation or in the event of a malfunction. The

sensor is not addressed in this document other than suggesting methods for standardizing system gains (equalizing them channel

to channel) when sensors are present.

1.2 Wherethemanufacturerprovidestestingandmeasuringdetailsinanoperatingandmaintenancemanual,themanufacturer’s

methods should be used in conjunction with the methods described in this practice.

1.3Difficult or questionable instrumentation measurements should be referred to electronics engineering personnel.

1.4The 1.3 The methods set forth in this practice are not intended to be either exclusive or exhaustive.

1.5The methods (techniques) used for testing and measuring the components or units of acoustic emission instrumentation, and

theresultsofsuchtestingandmeasuringshouldbedocumented.Documentationshouldconsistofphotographs,screenshots,charts

or graphs, calculations, and tabulations where applicable.

1.6AE1.4 AE systems that use computers to control the collection, storage, display, and data analysis are in common use.

Features of the computer-based systems analysis, might include waveform collection as well as a wide selection of measurement

parameters (features) relating to the AE signal. The manufacturer provides a specification for each system that specifies the

operating range and conditions for the system.All calibration and acceptance testing of computer-basedAE systems must use the

manufacturer’s specification as a guide. This practice does not cover testing of the computer or computer peripherals.

1.71.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E1316 Terminology for Nondestructive Examinations

2.2 ANSI Standard:

3

ANSI/IEEE 100-1984 Dictionary of Electrical and Electronic Terms

2.3 Other Documents:

Manufacturer’s Operating and Maintenance Manuals pertinent to the specific instrumentation or component

3. Terminology

3.1 Definitions—For definitions of additional terms relating to acoustic emission, refer to Terminology E1316.

4. Summary of Practice

4.1 Tests and measurements should be performed to determine the instrumentation bandwidth, frequency response, gain, noise

level, threshold level, dynamic range, signal overload point, dead time, and counter accuracy.

4.2 Where acoustic emission test results depend upon the reproduced accuracy of the temporal, spatial, or spectral histories,

1

ThispracticeisunderthejurisdictionofASTMCommitteeE07onNondestructiveTestingandisthedirectresponsibilityofSubcommitteeE07.04onAcousticEmission.

Current edition approved May 1, 2004. Published June 2004. Originally approved in 1980. Last previous edition approved in 1998 as E750-98. DOI: 10.1520/E0750-04.on

Acoustic Emission Method.

Current edition approved Jan. 1, 2010. Published February 2010. Originally approved in 1980. Last previous edition approved in 2004 as E750 - 04. DOI:

10.1520/E0750-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

-----------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.