ASTM A789/A789M-01

(Specification)Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service

Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service

SCOPE

1.1 This specification covers grades of nominal wall thickness, stainless steel tubing for services requiring general corrosion resistance, with particular emphasis on resistance to stress corrosion cracking. These steels are susceptible to embrittlement if used for prolonged periods at elevated temperatures.

Note 1—For tubing smaller than ½ in. [12.7 mm] in outside diameter, the elongation values given for strip specimens in Table 1 shall apply. Mechanical property requirements do not apply to tubing smaller than 1/8 in. [3.2 mm] in outside diameter or with walls thinner than 0.015 in. [0.4 mm].

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the Mdesignation of this specification is specified in the order.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 789/A 789M – 01 An American National Standard

Standard Specification for

Seamless and Welded Ferritic/Austenitic Stainless Steel

1

Tubing for General Service

This standard is issued under the fixed designation A 789/A 789M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

TABLE 1 Tensile and Hardness Requirements

1. Scope

2

Tensile Yield Elongation

Hardness, max

1.1 This specification covers grades of nominal wall thick-

Strength, Strength, in 2 in. or

UNS Designation

ness, stainless steel tubing for services requiring general

Rock-

min, ksi min, ksi 50 mm,

Brinell

well C

corrosion resistance, with particular emphasis on resistance to [MPa] [MPa] min, %

stress corrosion cracking. These steels are susceptible to

S31803 90 [620] 65 [450] 25 290 30.5

S32205 95 [655] 70 [485] 25 290 30.5

embrittlement if used for prolonged periods at elevated tem-

S31500 92 [630] 64 [440] 30 290 30.5

peratures.

S32550 110 [760] 80 [550] 15 297 31.5

S31200 100 [690] 65 [450] 25 280 . . .

1

NOTE 1—For tubing smaller than ⁄2in. [12.7 mm] in outside diameter,

A

S31260 100 [690] 65 [450] 25 290 30.5

the elongation values given for strip specimens in Table 1 shall apply.

S32304

Mechanical property requirements do not apply to tubing smaller than

OD 1 in. [25 mm] and

1

⁄8in. [3.2 mm] in outside diameter or with walls thinner than 0.015 in. [0.4 Under 100 [690] 65 [450] 25 . . . . . .

OD over 1 in. [25 mm] 87 [600] 58 [400] 25 290 30.5

mm].

S39274 116 [800] 80 [550] 15 310 . . .

1.2 The values stated in either inch-pound units or SI units

S32750 116 [800] 80 [550] 15 310 32

S32760 109 [750] 80 [550] 25 300 . . .

are to be regarded separately as standard. Within the text, the

SI units are shown in brackets. The values stated in each

S32900 90 [620] 70 [485] 20 271 28

B

system are not exact equivalents; therefore, each system must

S32950 100 [690] 70 [480] 20 290 30.5

S39277 120 [825] 90 [620] 25 290 30

be used independently of the other. Combining values from the

S32520 112 [770] 80 [550] 25 310 . . .

two systems may result in nonconformance with the specifi-

S32906

cation. The inch-pound units shall apply unless the M desig- Wall below 0.40 in. 116 [800] 94 [650] 25 310 32

(10 mm)

nation of this specification is specified in the order.

Wall 0.40 in. (10 mm) 109 [750] 80 [550] 25 310 32

and above

2. Referenced Documents

A

Prior to A 789/A 789M – 87, the values for S31260 were: 92 ksi tensile

2.1 ASTM Standards:

strength, 54 ksi yield strength, and 30 % elongation.

B

Prior to A 789/A 789M – 89, the tensile strength value was 90 ksi for UNS

A 450/A 450M Specification for General Requirements for

3 S32950.

Carbon, Ferritic Alloy, and Austenitic Alloy Steel Tubes

A 480/A 480M Specification for General Requirements for

3. Terminology

Flat-Rolled Stainless and Heat-Resisting Steel Plate,

4

Sheet, and Strip

3.1 Definitions—For definitions of terms used in this speci-

A 941 Terminology Relating to Steel, Stainless Steel, Re-

fication, refer to Terminology A 941.

3

lated Alloys, and Feroalloys

3

4. Ordering Information

E 527 Practice for Numbering Metals and Alloys (UNS)

5

2.2 SAE Standard:

4.1 Orders for material under this specification should

SAE J 1086

include the following, as required, to describe the desired

material adequately:

4.1.1 Quantity (feet, metres, or number of lengths),

1

4.1.2 Name of material (seamless or welded tubes),

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee 4.1.3 Grade (see Table 2),

A01.10 on Stainless and Alloy Steel Tubular Products.

4.1.4 Size (outside diameter and nominal wall thickness),

Current edition approved Mar. 10, 2001. Published May 2001. Originally

4.1.5 Length (specific or random),

published as A 789 – 81. Last previous edition A 789/A 789M – 00b.

2

4.1.6 Optional requirements (product analysis for welded

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

cation SA–789 in Section II of that Code.

tubes, Section 9; hydrostatic test or nondestructive electric test,

3

Annual Book of ASTM Standards, Vol 01.01.

Section 11),

4

Annual Book of ASTM Standards, Vol 01.03.

5 4.1.7 Test report required (section on inspection of Specifi-

Available from Society of Automotive Engineers, 400 Commonwealth Drive,

Warrendale, PA 15096. cation A 450/A 450M),

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

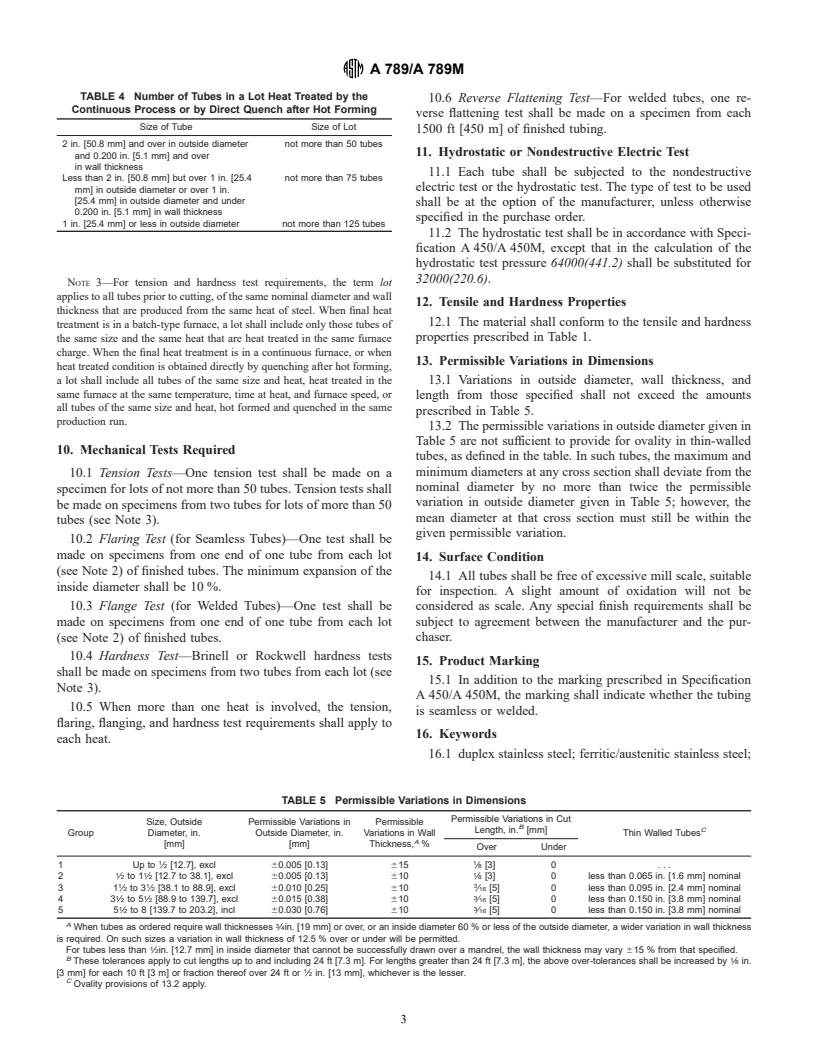

A 789/A 789M

TABLE 2 Chemical Requirements

UNS

C Mn P S Si Ni Cr Mo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.