ASTM E1826-00

(Specification)Standard Specification for Low Volatile Organic Compound (VOC) Corrosion-Inhibiting Adhesive Primer for Aluminum Alloys to Be Adhesively Bonded

Standard Specification for Low Volatile Organic Compound (VOC) Corrosion-Inhibiting Adhesive Primer for Aluminum Alloys to Be Adhesively Bonded

SCOPE

1.1 This specification is for pigmented, sprayable, low volatile organic compound (VOC) corrosion-inhibiting adhesive primers for use on aluminum alloys that are to be adhesively bonded in the fabrication of panels for tactical shelters. When applied to a properly prepared surface of aluminum alloy, the primer imparts corrosion resistance and forms a surface suitable for structural bonding and for coating with shelter paint finishes.

1.2 The values stated in SI units are to be regarded as the standard where only SI units are given or where SI units are given first followed by inch-pound units; where inch-pound units are given first followed by SI units, the inch-pound units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: E 1826 – 00

Standard Specification for

Low Volatile Organic Compound (VOC) Corrosion-Inhibiting

Adhesive Primer for Aluminum Alloys to Be Adhesively

Bonded

This standard is issued under the fixed designation E1826; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope eycomb Sandwich Panels

E874 Practice forAdhesive Bonding ofAluminum Facings

1.1 This specification is for pigmented, sprayable, low

to Nonmetallic Honeycomb Core for Shelter Panels

volatile organic compound (VOC) corrosion-inhibiting adhe-

2.2 Federal Specifications:

sive primers for use on aluminum alloys that are to be

QQ-A-250/8d AluminumAlloy 5052 H34 Plate and Sheet

adhesively bonded in the fabrication of panels for tactical

QQ-A-250/11d Aluminum Alloy 6061 T6 Plate and Sheet

shelters. When applied to a properly prepared surface of

2.3 Government Document:

aluminum alloy, the primer imparts corrosion resistance and

Rule1124 Aerospace Assembly and Component Manufac-

forms a surface suitable for structural bonding and for coating

turing Operations, South Coast Air Quality Management

with shelter paint finishes.

District

1.2 The values stated in SI units are to be regarded as the

standard where only SI units are given or where SI units are

3. Materials and Manufacturer

given first followed by inch-pound units; where inch-pound

3.1 The primer shall be a pigmented liquid composed of a

units are given first followed by SI units, the inch-pound units

modified epoxy phenolic or other resin system compounded to

are to be regarded as the standard.

be spray-applied to produce a continuous, uniform coating

1.3 This standard does not purport to address all of the

without dilution.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Physical Properties

priate safety and health practices and determine the applica-

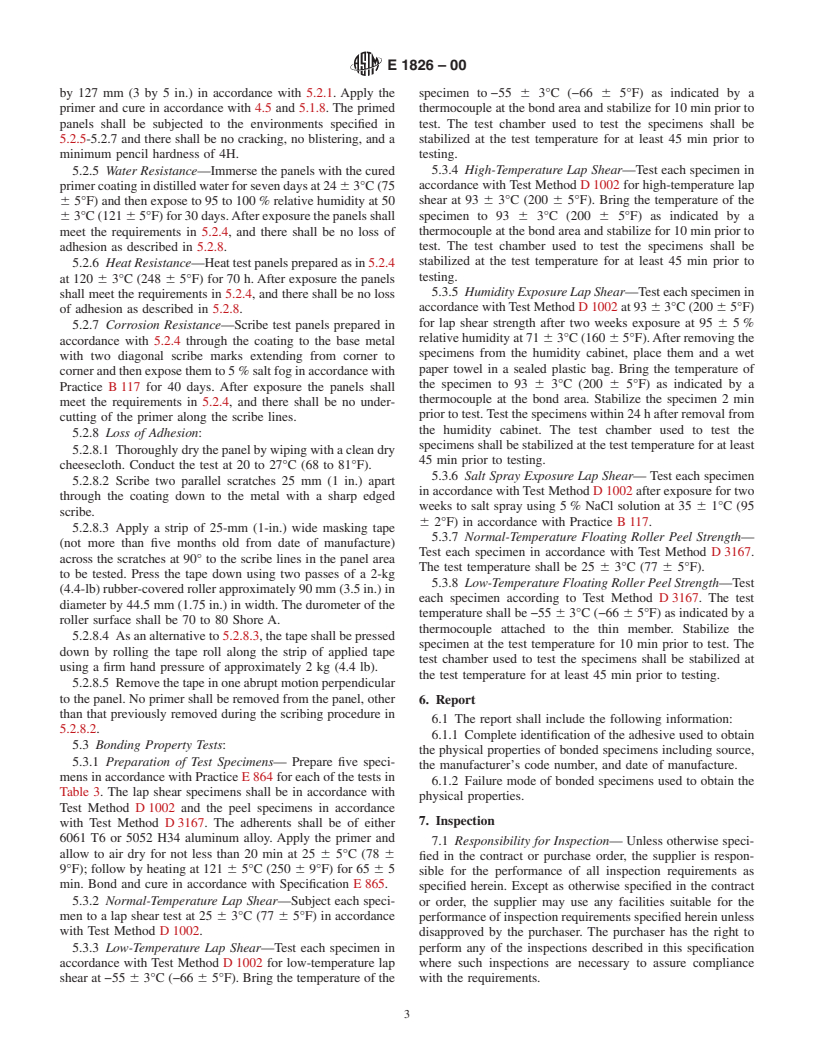

4.1 The uncured primer shall be tested as specified in 5.1

bility of regulatory limitations prior to use.

and meet the requirement of Table 1.

4.2 Properties of Cured Film—When applied and cured in

2. Referenced Documents

accordance with 5.1.8, the cured film shall meet the require-

2.1 ASTM Standards:

2 mentsofTables2and3whentestedasspecifiedin5.2and5.3.

B117 Practice for Operating Salt Spray (Fog) Apparatus

4.3 Storage Stability—Primer stored in accordance with

D1002 TestMethodforApparentShearStrengthofSingle-

5.1.3 shall meet the requirements for normal- and low-

Lap-Joint Adhesively Bonded Metal Specimens by Ten-

3 temperature floating roller peel in Table 3 when cured in

sion Loading (Metal-to-Metal)

accordancewith5.1.8andtestedasspecifiedin5.3.7and5.3.8.

D3167 Test Method for Floating Roller Peel Resistance of

3 4.4 Shelf Life—The shelf life of the primer at 25 6 7°C (77

Adhesives

612°F)shallbeatleastfourdays.Afterfourdays,whentested

E864 Practice for Surface Preparation ofAluminumAlloys

according to 5.1.4, the primer shall meet the requirements for

to be Adhesively Bonded in Honeycomb Shelter Panels

normal- and low-temperature floating roller peel in Table 3

E865 Specification for Structural FilmAdhesives for Hon-

when cured in accordance with 5.1.8 and tested as specified in

5.3.7 and 5.3.8.

1 4.5 FilmThickness—Theaverage,minimum,andmaximum

This specification is under the jurisdiction of ASTM Committee E06 on

film thicknesses shall be between 0.0025 and 0.010 mm

Performance of Buildings and is the direct responsibility of Subcommittee E06.53

on Materials and Processes for Durable Rigidwall Relocatable Structures.

Current edition approved Oct. 10, 2000. Published Janurary 2001. Originally

published as E1826–96. Last previous edition E 1826–96. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Annual Book of ASTM Standards, Vol 03.02. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

3 6

Annual Book of ASTM Standards, Vol 15.06. Available from South Coast Air Quality Management District, 9150 Flair Dr.,

Annual Book of ASTM Standards, Vol 04.11. El Monte, CA 91731.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1826–00

TABLE 1 Physical Properties of Uncured Liquid Polymer

meet the requirements for normal- and low-temperature float-

Test Requirement ing roller peel in Table 3 when cured in accordance with 5.1.8

and tested as specified in 5.3.7 and 5.3.8.

Solids content,% Report only

Ash content, % Report only

5.1.4 Shelf Life—Store a sample of the primer for four days

Color Easily visible film

at 25 6 7°C (77 6 13°F). The aged sample shall meet the

VOC content 250 g/L max

requirements for normal- and low-temperature floating roller

peel inTable 3 when cured in accordance with 5.1.8 and tested

as specified in 5.3.7 and 5.3.8.

TABLE 2 Physical Property of Cured Film on Primed Surfaces

5.1.5 Film Thickness—The cured primer film thickness

Test Requirement

Smooth uniform coating 0.0025 to 0.010 mm (0.0001 to 0.0004

shallbedeterminedwithaeddy-currentinstrumentasspecified

in.)6 15 % coefficient of variation

in 5.2.2.

5.1.6 Color—During spray application, there shall be a

discernible color change for the primer thickness specified in

TABLE 3 Physical Properties of Bonded Specimens

4.5.

Requirements

Test

5.1.7 Sprayability—The primer shall be capable of being

(min)

readily applied in accordance with the manufacturer’s instruc-

Normal-temperature lap shear, 24°C (77°F), MPa (psi) 20.0 (2903)

Low-temperature lap shear, −55°C (−67°F), MPa (psi) 20.0 (2903) tionstoalltestpanelsofeither6061T6or5052H34aluminum

High-temperature lap shear, 93°C (200°F), MPa (psi) 13.0 (1890)

alloy (Fed. Spec. QQ-A-250/11d or QQ-A-250/8d, respec-

Humidity exposure lap shear, 93°C (200°F), MPa (psi) 8.0 (1161)

tively) and cleaned in accordance with Practice E864 for each

Salt spray exposure lap shear, 35°C (95°F), MPa (psi) 16.0 (2322)

of the tests described in 5.1.8-5.3.8.

Normal-temperature floating roller peel strength, 24°C (75°F), 4400 (25.1)

N/m (lbf/in.)

5.1.8 Curing Properties—Test the cured film for the ability

Low-temperature floating roller peel strength, −55°C (−67°F), 2625 (15.0)

to meet the requirements listed in Tables 2 and 3. Spray the

N/m (lbf/in.)

primer onto the test panels and air dry at least 20 min at 24 6

5°C (77 6 9°F); then heat in air for 65 6 5 min at 121 6 5°C

(250 6 9°F).

(0.0001 and 0.0004 in.) 615% coefficient of variation. At

5.1.9 VOC Content—The grams ofVOC per litre of primer,

least five thickness readings shall be made with no more than

2 2 less water and exempt compounds per Rule1124, shall be

one in any 645 mm (1 in. ) area.

determinedbytheadhesiveprimermanufacturerinaccordance

4.6 VOC Content—The volatile organic compound (VOC)

with Rule1124 and meet the requirement for VOC content in

is any volatile compound containing the element of carbon,

Table 1.

excluding methane, carbon monoxide, carbon dioxide, car-

5.2 Cured Film:

bonic acid, metallic carbides or carbonates, and ammonium

5.2.1 Test Panels and Panel Preparation—Testpanelsshall

carbonates, as stated in Rule1124. The VOC content shall

be either 6061 T6 or 5052 H34 bare aluminum alloy (Fed.

meet the requirement in Table 1 when determined in accor-

Spec. QQ-A-250/11d or QQ-A-250/8d, respectively) and

dance with 5.1.9.

cleaned in accordance with Practice E864.

5.2.2 Smooth Uniform Coating—Clean a 30 by 30 cm (12

5. Test Methods

by12in.)panel,spraytoaprimerthicknessasspecifiedin4.5,

5.1 Uncured Primer:

and cure as specified in 5.1.8. Determine the primer thickness

5.1.1 Solids Content—Determinethesolidscontentbyheat-

with a Fisher isoscope MP2-T3.3B (or equivalent) calibrated

inga2-gsampleofthoroughlymixedprimerinanignition-loss

with standards between 0.0025 and 0.010 mm (0.0001 and

cruciblewithcoverat121 65°C(250 69°F)fornotlessthan

0.0004 in.). The primer thickness shall meet the requirements

90 min. Cool the crucible to room temperature in a desiccator.

in 4.5 and Table 2.

Weighings before and after heating shall be accurate to 6

5.2.3 Pencil Hardness—Determine the pencil hardness of

0.001g.Calculatethemassofsolidsremainingasapercentage

the cured film using the following procedure:

of the initial sample mass as follows:

5.2.3.1 Preparation of Pencils—Prepare a set of drawing

massofnonvolatileresidue

Percentsolidscontent 5 3100 (1)

pencils ranging in hardness from 6B to 5H by stripping the

initialsamplemass

woodawayfromtheendapproximately10mm( ⁄8in.)without

5.1.2 Ash Content—Place the crucibles containing the sol-

damaging the lead. Square the tip of the lead by holding the

ids content samples in a furnace at 565 6 28°C (1050 6 82°F)

pencilinaverticalpositionandmovingtheleadbackandforth

fornotlessthan60min.Coolthecrucibletoroomtemperature

over 400-grit or finer abrasive paper. Square the tip of the lead

in a desiccator. Weighings before and after heating shall be

after each trial.

accurate to 6 0.001 g. Calculate the ash content remaining as

5.2.3.2 Procedure—Place a test panel with the cured primer

a percentage of the solids content as follows:

applied in a horizontal position. Push pencils of increasing

massofashresidue

hardnessata45°angleintothecoatedsurfaceofthepaneluntil

Percentashcontent 5 3100 (2)

massofnonvolatileresidue

one is found that will cut or scratch the coating. Use the

number of this pencil to express the primer hardness.

5.1.3 Storage Stability—Store a sample of the primer for

three months from the date of manufacture at a temperature 5.2.4 Environmental Resistance Test— Clean three test

recommended by the manufacturer. The stored sample shall panels for each test described in 5.2.5-5.2.7 approximately 76

E1826–00

by 127 mm (3 by 5 in.) in accordance with 5.2.1. Apply the specimen to−55 6 3°C (−66 6 5°F) as indicated by a

primer and cure in accordance with 4.5 and 5.1.8. The primed thermocouple at the bond area and stabilize for 10 min prior to

panels shall be subjected to the environments specified in test. The test chamber used to test the specimens shall be

5.2.5-5.2.7 and there shall be no cracking, no blistering, and a stabilized at the test temperature for at least 45 min prior to

minimum pencil hardness of 4H. testing.

5.2.5 Water Resistance—Immerse the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.