ASTM D4617-96

(Specification)Standard Specification for Phenolic Compounds, (PF)

Standard Specification for Phenolic Compounds, (PF)

SCOPE

1.1 This specification covers phenolic compounds suitable for molding.

1.2 This specification is intended to be a means of calling out plastic materials used in the fabrication of end items or parts. It is not intended for the selection of materials. Material selection should be made by those having expertise in the plastics field after careful consideration of the design and the performance required of the part, the environment to which it will be exposed, the fabrication process to be employed, the inherent properties of the material other than those covered by this specification, and the economics.

1.3 The properties included in this specification are those required to identify the compositions covered. There may be other requirements necessary to identify particular characteristics important to specialized applications. These will be agreed upon between the user and the supplier, by using the suffixes specified in Section 5.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use.

1.6 The following precautionary caveat pertains only to the test method portion, Section 13 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1- ISO 800-1977(E) is similar but not equivalent to this specification. Product classification and characterization are not the same.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4617 – 96

Standard Specification for

Phenolic Compounds (PF)

This standard is issued under the fixed designation D 4617; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification covers phenolic compounds suitable 2.1 ASTM Standards:

for molding. D 256 Test Methods for Impact Resistance of Plastics and

1.2 This specification is intended to be a means of calling Electrical Insulating Materials

out plastic materials used in the fabrication of end items or D 570 Test Method for Water Absorption of Plastics

parts. It is not intended for the selection of materials. Material D 618 Practice for Conditioning Plastics and Electrical

selection should be made by those having expertise in the Insulating Materials for Testing

plastics field after careful consideration of the design and the D 638 Test Method for Tensile Properties of Plastics

performance required of the part, the environment to which it D 648 Test Method for Deflection Temperature of Plastics

will be exposed, the fabrication process to be employed, the Under Flexural Load

inherent properties of the material other than those covered by D 695 Test Method for Compressive Properties of Rigid

this specification, and the economics. Plastics

1.3 The properties included in this specification are those D 700 Specification for Phenolic Molding Compounds

required to identify the compositions covered. There may be D 790 Test Methods for Flexural Properties of Unreinforced

other requirements necessary to identify particular character- and Reinforced Plastics and Electrical Insulating Materi-

istics important to specialized applications. These will be als

agreed upon between the user and the supplier, by using the D 792 Test Methods for Specific Gravity (Relative Density)

suffixes specified in Section 5. and Density of Plastics by Displacement

1.4 The values stated in SI units are to be regarded as the D 796 Practice for Compression Molding Test Specimens of

standard. Phenolic Molding Compounds

1.5 This standard should be used to measure and describe D 883 Terminology Relating to Plastics

the properties of materials, products, or assemblies in response D 1600 Terminology for Abbreviated Terms Relating to

to heat and flame under controlled laboratory conditions and Plastics

should not be used to describe or appraise the fire hazard or D 1896 Practice for Transfer Molding Specimens of Ther-

fire risk of materials, products, or assemblies under actual fire mosetting Compounds

conditions. However, results of this test may be used as D 1898 Practice for Sampling of Plastics

elements of a fire risk assessment which takes into account all D 3419 Practice for In-Line Screw-Injection Molding of

of the factors which are pertinent to an assessment of the fire Test Specimens from Thermosetting Compounds

hazard of a particular end use. D 3892 Practice for Packaging/Packing of Plastics

1.6 The following precautionary caveat pertains only to the D 4000 Classification System for Specifying Plastic Mate-

test method portion, Section 13 of this specification: This rials

standard does not purport to address all of the safety concerns, E 29 Practice for Using Significant Digits in Test Data to

if any, associated with its use. It is the responsibility of the user Determine Conformance with Specification

of this standard to establish appropriate safety and health 2.2 Military Standard:

practices and determine the applicability of regulatory limita- MIL-STD-105 Sampling Procedures and Tables for Inspec-

tions prior to use. tion by Attributes

2.3 ISO Standard:

NOTE 1—ISO 800-1977(E) is similar but not equivalent to this speci-

fication. Product classification and characterization are not the same.

Annual Book of ASTM Standards, Vol 08.01.

1 3

This specification is under the jurisdiction of ASTM Committee D-20 on Annual Book of ASTM Standards, Vol 08.02.

Plastics and is the direct responsibility of Subcommittee D20.16 on Thermosetting Annual Book of ASTM Standards, Vol 14.02.

Materials. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Current edition approved March 10, 1996. Published July 1996. Originally Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

published as D 4617 – 86. Last previous edition D 4617 – 91a. Available from American National Standards Institute, 11 West 42nd St., 13th

This edition includes the addition of an ISO equivalency statement. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4617

ISO 8000-1977(E) conform to the requirements specified herein. The color and

form of the material shall be as agreed upon by the supplier and

3. Terminology

the user. Specification changes due to the effects of colorants

3.1 Definitions—For definitions of technical terms pertain- should be noted by both parties and, where necessary, covered

ing to plastics used in this specification see Terminology

by suffixes.

D 883.

8. Detail Requirements

4. Classification

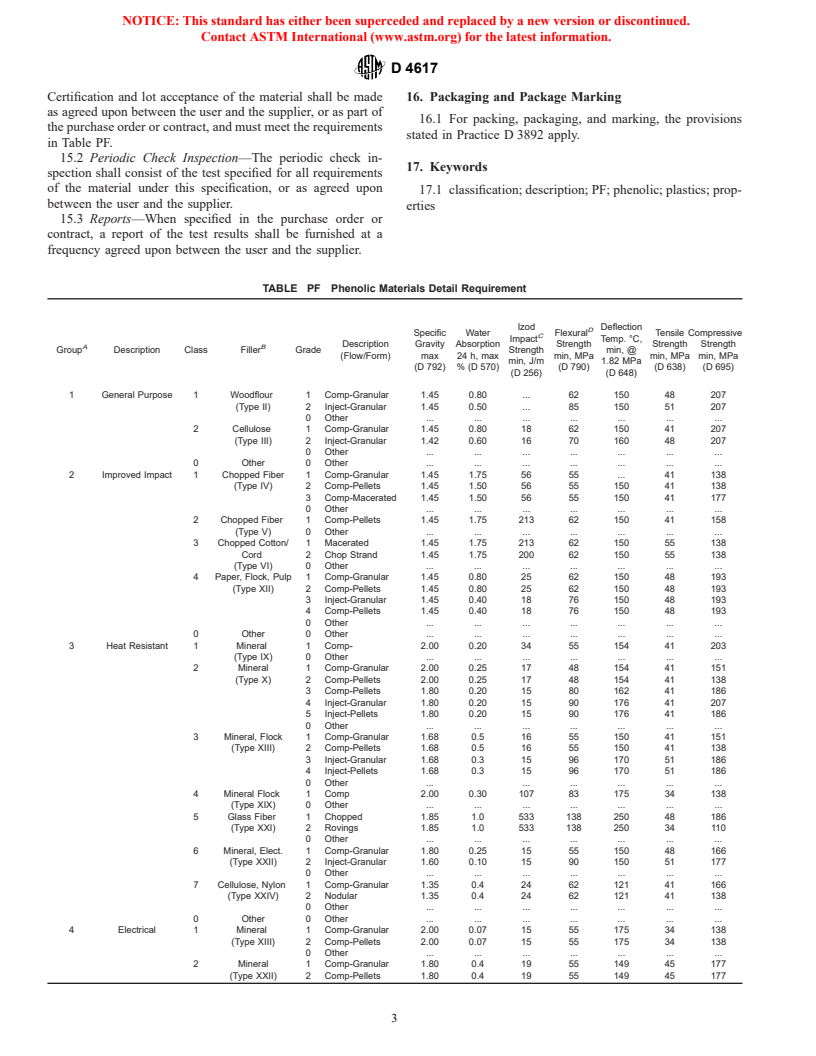

8.1 Test specimens for the various materials shall conform

4.1 Phenolic compounds are classified into groups accord- to the requirements prescribed in Table PF and Table A, and

ing to their application. These groups are subdivided into suffix requirements as they apply.

classes and grades as shown in Table PF. 8.2 Observed or calculated values obtained from analysis,

measurement, or test shall be rounded off to the nearest unit in

NOTE 2—An example of this classification system is as follows:

the last right-hand place of figures used in expressing the

The designation PF 111 indicates:

specified limiting value in accordance with the rounding

PF = Phenol-Formaldehyde (Phenolic) as found in Terminology D 1600

method of Practice E 29. The value obtained is compared

1 = General Purpose (Group)

1 = Cellulose Filled, Type III (Class)

directly with the specified limiting value. Conformance or

1 = Compression Molding Grade with Requirements given in Table PF.

nonconformance with the specification is based on this com-

(Grade)

parison.

4.1.1 To facilitate the incorporation of future or special

materials, the “other unspecified” category (0) for group, class,

9. Sampling

and grade is shown in Table PF. The basic properties can be

9.1 Unless otherwise agreed upon between the user and the

obtained from Table A.

supplier, sample the materials in accordance with the sampling

4.2 Specific requirements for special or new phenolic com-

procedure prescribed in Practice D 1898. Adequate statistical

pounds shall be shown by a six-character designation. The

sampling shall be considered an acceptable alternative. A lot of

designation will consist of the letter A and the five digits

compound shall be considered as a unit of manufacture as

comprising the cell numbers for the property requirements in

prepared for shipment, and may consist of a blend of two or

the order they appear in Table A.

more production runs or batches of material.

4.2.1 Although the values listed are necessary to include the

10. Number of Tests

range of properties available in existing materials, users should

not infer that every possible combination of the properties

10.1 Conduct the number of tests as agreed upon between

exists or can be obtained.

the user and the supplier.

4.3 When the grade of the basic material is not known, or is

11. Specimen Preparation

not important, the use of “0” grade classification shall be used.

11.1 Mold the test specimens by compression in accordance

NOTE 3—An example of this classification system for a special phe-

with Practice D 796, by transfer in accordance with Practice

nolic compound is as follows:

D 1896, by injection in accordance with Practice D 3419, or as

The designation PF110A34130 indicates:

specified by the compound supplier.

PF110 = General-purpose injection molding grade phenolic from Table PF,

A = Table A property requirements,

12. Conditioning

3 = 50 MPa Tensile strength, min,

4 = 75 MPa Flexural modulus, min,

12.1 Condition test specimens in the standard laboratory

1 = 15 J/M Izod impact strength; min,

3 = 150°C Deflection temperature, min, and atmosphere in accordance with Procedure A of Practice D 618

0 = Unspecified.

before performing the required tests.

12.2 Conduct tests in the standard laboratory atmosphere of

NOTE 4—Specific

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.