ASTM F1407-99a(2006)

(Test Method)Standard Test Method for Resistance of Chemical Protective Clothing Materials to Liquid Permeation-Permeation Cup Method

Standard Test Method for Resistance of Chemical Protective Clothing Materials to Liquid Permeation-Permeation Cup Method

SIGNIFICANCE AND USE

This test method establishes a standard procedure for rapidly (in 1 h or less) determining the chemical resistance of specimens of protective clothing materials. This test method can be used to rank materials as to their suitability for use with liquids of known or unknown composition.

The breakthrough detection time, permeation rate, or cumulative permeation can be used to identify protective clothing materials that are more likely to limit potential exposures to chemicals. Longer breakthrough detection times and lower cumulative amounts permeated and permeation rates are characteristics of materials that are better barriers to the test chemical.

In general this test method is less sensitive than Test Method F 739 coupled with sensitive analytical procedures. In cases where the chemical of concern is highly toxic and contact of even a very small amount with the skin may be detrimental to health, the permeation cup method is not recommended. Use Test Method F 739.

Upon permeating the clothing material, the chemical must evaporate in order for a weight loss to occur and permeation to be detected. Consequently, the test method may not be applicable for chemicals having low volatility (that is, vapor pressure). The vapor pressure below which this test method is not applicable has not been determined.

5.4.1 A procedure for assessing volatility is described in Section 10.

The results of this test method are highly dependent on the test temperature. If the objective is to compare different clothing materials, all tests shall be conducted at the same temperature (±3°C).

SCOPE

1.1 This test method measures the barrier effectiveness of a specimen of protective clothing upon continuous contact with a liquid.

1.1.1 Procedure A For use when a value for the cumulative amount of chemical permeated in 1 h is desired.

1.1.2 Procedure B For use when breakthrough detection time and permeation rate values are desired.

1.2 Although not addressed herein, the effect of the test chemical on the clothing material can be determined by comparing the weight or other physical properties of the specimen before and after the permeation test.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1407–99a (Reapproved 2006)

Standard Test Method for

Resistance of Chemical Protective Clothing Materials to

1

Liquid Permeation—Permeation Cup Method

This standard is issued under the fixed designation F1407; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Workers involved in the production, use, and transportation of chemicals can be exposed to

numerous compounds capable of causing harm upon contact with the human body. The deleterious

effects of these chemicals can range from acute trauma, such as dermatitis or burns, to chronic

degenerative disease, such as cancer or pulmonary fibrosis. Since engineering controls may not

eliminate all possible exposures, attention is often given to reducing the potential for direct skin

contact through the use of protective clothing that resists degradation, penetration, and permeation.

This test method provides a simple, gravimetric means for measuring the resistance of clothing

materialstopermeationbyliquidchemicals.Permeationtestingbyamoresophisticatedprocedureand

penetrationtestingareaddressedbyseparatemethods:TestMethodsF739andF903,respectively.Test

Methods for measuring the effects of chemicals on the physical properties of rubbers, plastics, and

coated fabrics may be found in Test Method D471, Test Method D543, and Test Methods D751,

respectively. Guide F1001 designates 21 chemicals for use with these tests.

1. Scope bility of regulatory limitations prior to use. Specific precau-

tionary statements are given in Section 2.

1.1 This test method measures the barrier effectiveness of a

specimen of protective clothing upon continuous contact with

2. Referenced Documents

a liquid.

2

2.1 ASTM Standards:

1.1.1 Procedure A—For use when a value for the cumula-

D471 Test Method for Rubber Property—Effect of Liquids

tive amount of chemical permeated in1his desired.

D543 Practices for Evaluating the Resistance of Plastics to

1.1.2 Procedure B—For use when breakthrough detection

Chemical Reagents

time and permeation rate values are desired.

D751 Test Methods for Coated Fabrics

1.2 Although not addressed herein, the effect of the test

E105 Practice for Probability Sampling Of Materials

chemical on the clothing material can be determined by

F739 Test Method for Permeation of Liquids and Gases

comparing the weight or other physical properties of the

through Protective Clothing Materials under Conditions of

specimen before and after the permeation test.

Continuous Contact

1.3 This standard does not purport to address all of the

F903 Test Method for Resistance of Materials Used in

safety concerns, if any, associated with its use. It is the

Protective Clothing to Penetration by Liquids

responsibility of the user of this standard to establish appro-

F1001 Guide for Selection of Chemicals to Evaluate Pro-

priate safety and health practices and determine the applica-

tective Clothing Materials

2.2 Federal Standard:

1

This test method is under the jurisdiction of ASTM Committee F23 on

Protective Clothing and is the direct responsibility of Subcommittee F23.30 on

2

Chemicals. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 1, 2006. Published February 2006. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1992. Last previous edition approved in 1999 as F1407 - 99a. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F1407-99AR06. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F1407–99a (2006)

No. 191, Method 5030.2 Measurement of the Thickness of

3

Materials

3. Terminology

3.1 Definitions:

3.1.1 cumulative permeation, n—the total mass of chemical

that permeates during a specified time from when the material

is first contacted.

3.1.2 degradation, n—a deleterious change in one or more

properties of a material.

3.1.3 penetration, n—in a protective clothing material or

item, the process by which a solid, liquid, or gas moves

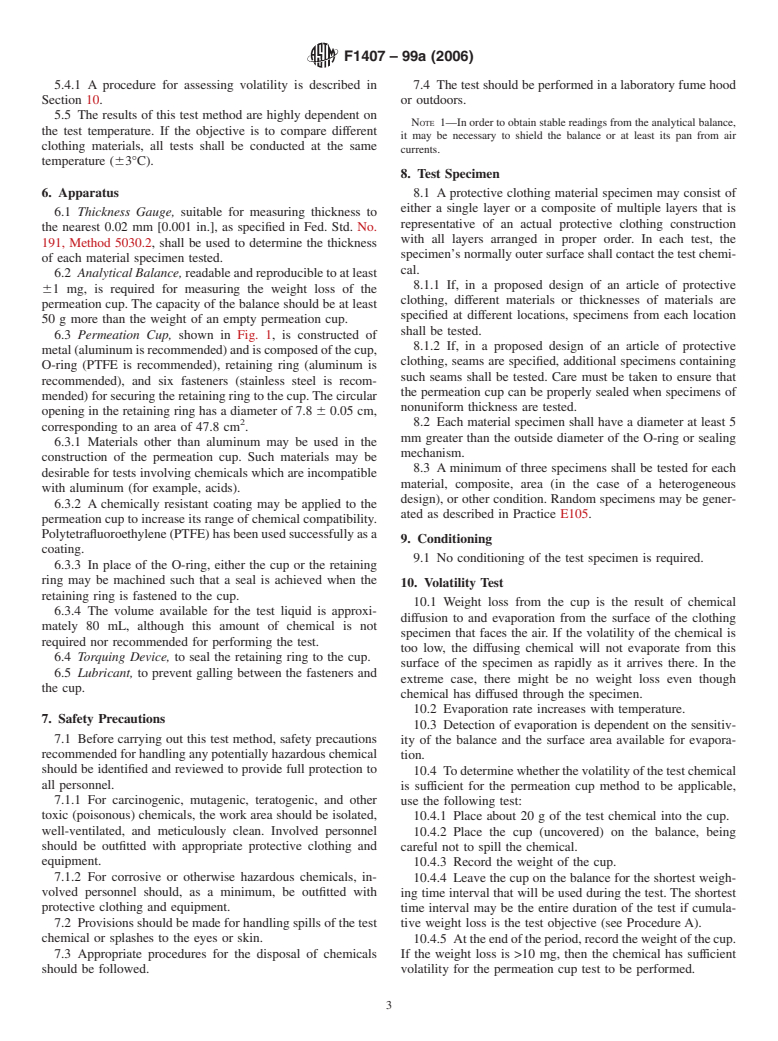

NOTE—Dimensions in centimetres.

through closures, seams, interstices, and pinholes or other

FIG. 1 ASTM Permeation Cup

imperfections on a non-molecular level.

3.1.4 permeation, n—the process by which a chemical

moves through a protective clothing material on a molecular

chemical that permeates the material and subsequently evapo-

level.

rates to the atmosphere.

3.1.4.1 Discussion—Permeation involves the following: (1)

4.4 Based on the amount of chemical lost

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.