ASTM E778-87(2004)

(Test Method)Standard Test Methods for Nitrogen in the Analysis Sample of Refuse-Derived Fuel

Standard Test Methods for Nitrogen in the Analysis Sample of Refuse-Derived Fuel

SIGNIFICANCE AND USE

The standard sample is available to producers and users of RDF as a method for determining the weight percent of nitrogen in the analysis sample.

Nitrogen is part of the ultimate analysis and can be used for calculation of combustion parameters.

A = electric heater

B = Kjeldahl digestion flask

C = Kjeldahl connecting bulb

D = condenser

E = connecting tube

F = receiving flaskFIG. 1 Kjeldahl Distillation Apparatus

SCOPE

1.1 These test methods cover the determination of total Kjeldahl nitrogen in (prepared analysis) samples of (solid forms) of refuse-derived fuel (RDF). The procedures measure free ammonia or ammonia formed from the conversion of organic nitrogenous compounds such as amino acids and proteins. However, the procedures may not convert the nitrogenous compounds of some wastes to ammonia. Examples of such compounds that may not be measured are nitro compounds, hydrozones, oxines, nitrates, semicarbazones, pyridines, and some refractory tertiary amines.

1.2 Two alternatives are described for the final determination of the ammonia, the Kjeldahl-Gunning Test Method and the Acid-Titration Test Method.

1.3 The analytical data from these test methods are to be reported as part of the ultimate analysis where ultimate analysis is requested.

1.4 These test methods may be applicable to any waste material from which a laboratory analysis sample can be prepared.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements see 8.4.1 and 9 Section .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E778–87(Reapproved2004)

Standard Test Methods for

Nitrogen in the Analysis Sample of Refuse-Derived Fuel

This standard is issued under the fixed designation E 778; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Methods for Analysis and Testing of Industrial Chemicals

E 200 Practice for Preparation, Standardization, and Stor-

1.1 These test methods cover the determination of total

age of Standard and Reagent Solutions for Chemical

Kjeldahl nitrogen in (prepared analysis) samples of (solid

Analysis

forms) of refuse-derived fuel (RDF). The procedures measure

E 790 Test Method for Residual Moisture in Refuse-

free ammonia or ammonia formed from the conversion of

Derived Fuel Analysis Sample

organic nitrogenous compounds such as amino acids and

E 791 Test Method for Calculating Refuse-Derived Fuel

proteins. However, the procedures may not convert the nitrog-

Analysis Data from As-Determined to Different Bases

enous compounds of some wastes to ammonia. Examples of

E 829 Practice for Preparing Refuse-Derived Fuel (RDF)

such compounds that may not be measured are nitro com-

Laboratory Samples for Analysis

pounds, hydrozones, oxines, nitrates, semicarbazones, py-

ridines, and some refractory tertiary amines.

3. Terminology

1.2 Two alternatives are described for the final determina-

3.1 Definitions of Terms Specific to This Standard:

tion of the ammonia, the Kjeldahl-Gunning Test Method and

3.1.1 refuse-derived fuel—solid forms of refuse-derived

the Acid-Titration Test Method.

fuels from which appropriate analytical samples may be

1.3 The analytical data from these test methods are to be

prepared are defined as follows in ASTM STP 832:

reportedaspartoftheultimateanalysiswhereultimateanalysis

RDF-1—Wastes used as a fuel in as-discarded form with

is requested.

only bulky wastes removed.

1.4 These test methods may be applicable to any waste

RDF-2—Wastes processed to coarse particle size with or

material from which a laboratory analysis sample can be

without ferrous metal separation.

prepared.

RDF-3—Combustible waste fraction processed to particle

1.5 This standard does not purport to address all of the

sizes, 95 % passing 2-in. square screening.

safety concerns, if any, associated with its use. It is the

RDF-4—Combustible waste fraction processed into powder

responsibility of the user of this standard to establish appro-

form, 95 % passing 10-mesh screening.

priate safety and health practices and determine the applica-

RDF-5—Combustible waste fraction densified (compressed)

bility of regulatory limitations prior to use. For specific

into the form of pellets, slugs, cubettes, or briquettes.

precautionary statements see 8.4.1 and Section 9.

4. Summary of Test Methods

2. Referenced Documents

2 4.1 The determination of nitrogen is made by either the

2.1 ASTM Standards:

Kjeldahl-Gunning Test Method (Section 11) or the Acid-

D 1193 Specification for Reagent Water

Titration Test Method (Section 12). In both these methods the

E 180 Practice for Determining the Precision of ASTM

nitrogen in the sample is converted into ammonium salts by

destructive digestion of the sample with a hot, catalyzed

These test methods are under the jurisdiction of ASTM Committee D34 on

mixture of concentrated sulfuric acid and potassium sulfate.

Waste Management and are the direct responsibility of Subcommittee D34.03.02 on

The salts are subsequently decomposed in a hot alkaline

Municipal Recovery and Reuse.

solution from which the ammonia is recovered by distillation,

Current edition approved Aug. 28, 1987. Published October 1987. Originally

and finally determined by alkalimetric or acidimetric titration.

published as E 778 – 81. Last previous edition E 778 – 81.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Thesaurus on Resource Recovery Terminology, ASTM STP 832, ASTM, 1983,

the ASTM website. p. 72.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E778–87 (2004)

5. Significance and Use 7.3 Condenser, glass, water-cooled, having a minimum

jacket length of 500 mm.

5.1 The standard sample is available to producers and users

7.4 Kjeldahl Digestion Flask, of heat-resistant glass, having

of RDF as a method for determining the weight percent of

a capacity of 500 or 800 mL. Borosilicate glass has been found

nitrogen in the analysis sample.

satisfactory for this purpose.

5.2 Nitrogen is part of the ultimate analysis and can be used

7.5 Kjeldahl Connecting Bulb, cylindrical type, 45 mm in

for calculation of combustion parameters.

diameter by 100 mm long, or larger, with curved inlet and

outlet tubes.

7.6 Receiving Flasks—Erlenmeyer flask having a capacity

of 250 or 300 mL.

7.7 Connecting Tube—Glass tubing approximately 10 mm

in outside diameter by 200 mm in length.

7.8 Pure Gum Rubber Tubing.

8. Reagents

8.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

all reagents shall conform to the specifications of the Commit-

tee onAnalytical Reagents of theAmerican Chemical Society,

where such specifications are available. Other grades may be

used, provided it is first ascertained that the reagent is of

sufficiently high purity to permit its use without lessening the

accuracy of the determination.

8.2 Purity of Water—Unless otherwise indicated, reference

to water shall be understood to mean reagent water, Type II,

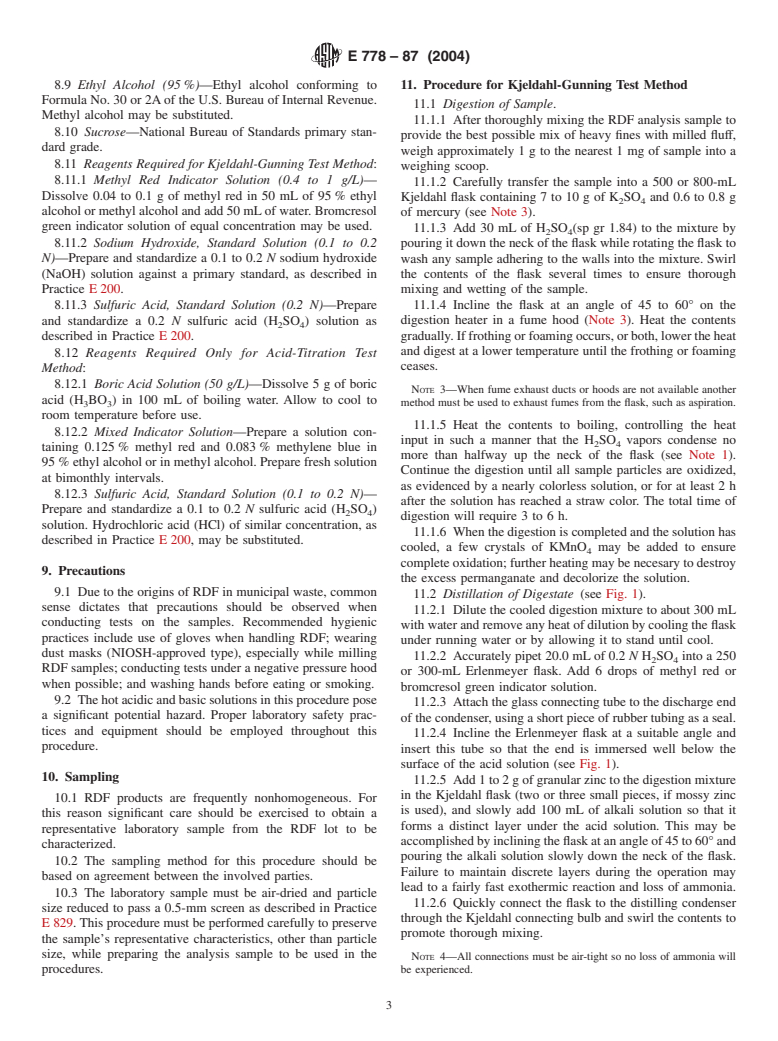

A = electric heater

B = Kjeldahl digestion flask

conforming to Specification D 1193, prepared by the passage

C = Kjeldahl connecting bulb

through an ion-exchange column containing a strongly acid

D = condenser

cation resin in the hydrogen form.

E = connecting tube

F = receiving flask

8.3 Potassium Sulfate (K SO ), crystals.

2 4

FIG. 1 Kjeldahl Distillation Apparatus

NOTE 2—Other satisfactory and permissible catalysts for the digestion,

together with the quantities of K SO required in their use, are as follows:

2 4

6. Interferences and Limitations

(1) Five grams of a mixture containing 32 parts by weight of K SO ,5

2 4

parts by weight of mercuric sulfate (HgSO ), and 1 part by weight of

6.1 Because of the nature of RDF, nitrogenous compounds

selenium.

maybepresentwhichwillnotreadilybeconvertedtoammonia

(2) Three-tenths gram of mercuric selenite (HgSeO )with7to10gof

by this test method (1.1). Modifications to the digestion of the 3

K SO .

2 4

waste may enhance the conversion of these nitrogenous com-

(3) Three-tenths gram of cupric selenite dihydrate (CuSeO ·2H O)

2 2

pounds to the ammonium salts.

with7to10gofK SO . When this mixture is used, the addition of a

2 4

sulfide to the alkali solution is not necessary.

7. Apparatus

8.4 Mercury, metal (see Note 2).

7.1 Digestion Unit—An electrical heater of approximately

8.4.1 Warning—Appropriate safety precautions should be

500-Wminimumratingoragasburnerofcomparablecapacity.

Either type of heater shall be provided with adequate means of used when handling and disposing of mercury and selenium

compounds.

control to maintain digestion rates as described in 11.1 (Note

1).Commerciallymade,multiple-unitdigestionracksprovided 8.5 Sulfuric Acid (sp gr 1.84)—Concentrated sulfuric acid

(H SO ).

with fume exhaust ducts may be used.

2 4

8.6 Potassium Permanganate (KMnO ), crystals.

NOTE 1—If commercially made electrical heaters are used, auxiliary

8.7 Zinc, mossy or granular.

voltage control equipment, such as an autotransformer, may be needed to

8.8 Alkali Solution—Dissolve 8.0 g of potassium sulfide

maintain the specified rates of digestion and distillation.

(K S) and 500 g of sodium hydroxide (NaOH) in water and

7.2 Distillation Unit (Fig. 1)—An electrical heater or gas

dilute to 1 L.The use of appropriate amounts of sodium sulfide

burner as described in 7.1. Either type shall be provided with

(Na S) or potassium hydroxide (KOH) may be substituted for

adequate means of control to maintain rates as described in

the above, if desired (Note 2 (c)).

11.2. Commercially made, multiple-unit distillation racks pro-

vided with water-cooled glass or block tin condensers may be

used.

“Reagent Chemicals,American Chemical Society Specifications,”Am. Chemi-

cal Soc., Washington, DC. For suggestions on the testing of reagents not listed by

Kolthoff, I. M., and Stenger, V. A., Volumetric Analysis II, Intersciences the American Chemical Society, see “Analar Standards for Laboratory U.K.

Publishers, Inc., New York, NY, pp. 173–176. Chemicals,” BDH Ltd., Poole, Dorset, and the “United States Pharmacopoeia”.

E778–87 (2004)

8.9 Ethyl Alcohol (95 %)—Ethyl alcohol conforming to 11. Procedure for Kjeldahl-Gunning Test Method

Formula No. 30 or 2Aof the U.S. Bureau of Internal Revenue.

11.1 Digestion of Sample.

Methyl alcohol may be substituted.

11.1.1 After thoroughly mixing the RDF analysis sample to

8.10 Sucrose—National Bureau of Standards primary stan-

provide the best possible mix of heavy fines with milled fluff,

dard grade.

weigh approximately1gtothe nearest 1 mg of sample into a

8.11 Reagents Required for Kjeldahl-Gunning Test Method:

weighing scoop.

8.11.1 Methyl Red Indicator Solution (0.4 to 1 g/L)—

11.1.2 Carefully transfer the sample into a 500 or 800-mL

Dissolve 0.04 to 0.1 g of methyl red in 50 mL of 95 % ethyl

Kjeldahl flask containing 7 to 10 g of K SO and 0.6 to 0.8 g

2 4

alcohol or methyl alcohol and add 50 mLof water. Bromcresol

of mercury (see Note 3).

green indicator solution of equal concentration may be used.

11.1.3 Add 30 mL o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.