ASTM G8-96(2019)

(Test Method)Standard Test Methods for Cathodic Disbonding of Pipeline Coatings

Standard Test Methods for Cathodic Disbonding of Pipeline Coatings

SIGNIFICANCE AND USE

4.1 Breaks or holidays in pipe coatings may expose the pipe to possible corrosion, since after a pipe has been installed underground, the surrounding earth will be more or less moisture-bearing and it constitutes an effective electrolyte. Damage to pipe coating is almost unavoidable during transportation and construction. Normal soil potentials as well as applied cathodic protection potentials may cause loosening of the coating, beginning at holiday edges, in some cases increasing the apparent size of the holiday. Holidays may also be caused by such potentials. While apparently loosened coating and cathodic holidays may not result in corrosion, this test provides accelerated conditions for loosening to occur and therefore gives a measure of resistance of coatings to this type of action.

4.2 The effects of the test may be evaluated by either physical examination or monitoring the current drawn by the test specimen and both of these two. Usually there is no correlation between the two methods of evaluation but both methods are significant. Physical examination consists of assessing the effective contact of the coating with the metal surface in terms of observed differences in the relative adhesive bond. It is usually found that the electrically stressed area propagates from the holiday to a boundary where the loosened coating leaves off for the more effective contact or bond attributed to an original condition throughout the specimen before electrical stressing was applied. Assumptions associated with test results include the following:

4.2.1 Attempting to loosen or disbond the coating at a new test hole made in the coating in an area that was not immersed represents maximum adhesion or bond as measured by the lifting technique used, and that the same lifting technique can be used at a test hole that was immersed thereby providing a means of comparing relative resistance to lifting.

4.2.2 Any relatively lesser bonded area at the immersed test holes in the coa...

SCOPE

1.1 These test methods cover accelerated procedures for simultaneously determining comparative characteristics of insulating coating systems applied to steel pipe exterior for the purpose of preventing or mitigating corrosion that may occur in underground service where the pipe will be in contact with inland soils and may or may not receive cathodic protection. They are intended for use with samples of coated pipe taken from commercial production and are applicable to such samples when the coating is characterized by function as an electrical barrier.

1.2 This test method is intended for testing coatings submerged or immersed in the test solution at room temperature. When it is impractical to submerge or immerse the test specimen, Test Method G95 may be considered where the test cell is cemented to the surface of the coated pipe specimen. If higher temperatures are required, see Test Method G42. If a specific test method is required with no options, see Test Method G80.

1.3 The values stated in SI units to 3 significant decimals are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G8 − 96 (Reapproved 2019)

Standard Test Methods for

1

Cathodic Disbonding of Pipeline Coatings

This standard is issued under the fixed designation G8; the number immediately following the designation indicates the year of original

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 These test methods cover accelerated procedures for

G12Test Method for Nondestructive Measurement of Film

simultaneously determining comparative characteristics of in-

Thickness of Pipeline Coatings on Steel (Withdrawn

sulating coating systems applied to steel pipe exterior for the

3

2013)

purposeofpreventingormitigatingcorrosionthatmayoccurin

G42Test Method for Cathodic Disbonding of Pipeline

underground service where the pipe will be in contact with

Coatings Subjected to Elevated Temperatures

inland soils and may or may not receive cathodic protection.

G80Test Method for Specific Cathodic Disbonding of Pipe-

They are intended for use with samples of coated pipe taken

3

line Coatings (Withdrawn 2013)

from commercial production and are applicable to such

G95TestMethodforCathodicDisbondmentTestofPipeline

samples when the coating is characterized by function as an

Coatings (Attached Cell Method)

electrical barrier.

3. Summary of Test Method

1.2 This test method is intended for testing coatings sub-

merged or immersed in the test solution at room temperature.

3.1 Both of the two test methods described subject the

When it is impractical to submerge or immerse the test

coating on the test specimen to electrical stress in a highly

specimen, Test Method G95 may be considered where the test conductive, alkaline electrolyte. Electrical stress is obtained

cell is cemented to the surface of the coated pipe specimen. If either by means of a sacrificial magnesium anode or from an

impressed current system. The coating is perforated before

higher temperatures are required, see Test Method G42.Ifa

starting the test.

specific test method is required with no options, see Test

3.1.1 In Method A, a magnesium anode is used with no

Method G80.

electrical monitoring during the test period. The results are

1.3 ThevaluesstatedinSIunitsto3significantdecimalsare

determined by physical examination after the test period is

toberegardedasthestandard.Thevaluesgiveninparentheses

concluded.

are for information only.

3.1.2 In Method B, either a magnesium anode or an im-

pressedcurrentsystemmaybeused.Electricalinstrumentation

1.4 This standard does not purport to address all of the

is provided for measuring the current in the cell circuit. The

safety concerns, if any, associated with its use. It is the

electrical potential is also measured, and upon conclusion of

responsibility of the user of this standard to establish appro-

the test period, the test specimen is physically examined.

priate safety, health, and environmental practices and deter-

3.1.3 In both test methods physical examination is con-

mine the applicability of regulatory limitations prior to use.

ducted by comparing the extent of loosened or disbonded

1.5 This international standard was developed in accor-

coating at the perforations in the immersed area with extent of

dance with internationally recognized principles on standard-

loosened or disbonded coating at a new test hole in the coating

ization established in the Decision on Principles for the

made in an area that was not immersed.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

4. Significance and Use

Barriers to Trade (TBT) Committee.

4.1 Breaksorholidaysinpipecoatingsmayexposethepipe

to possible corrosion, since after a pipe has been installed

1

These test methods are under the jurisdiction of ASTM Committee D01 on

2

Paint and Related Coatings, Materials, and Applications and are the direct For referenced ASTM standards, visit the ASTM website, www.astm.org, or

responsibility of Subcommittee D01.48 on Durability of Pipeline Coating and contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Linings. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved June 1, 2019. Published June 2019. Originally the ASTM website.

3

approved in 1969. Last previous edition approved in 2010 as G8–96(2010). DOI: The last approved version of this historical standard is referenced on

10.1520/G0008-96R19. www.astm.org.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G8 − 96 (Reapproved 2019)

Standard Test Methods for

1

Cathodic Disbonding of Pipeline Coatings

This standard is issued under the fixed designation G8; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 These test methods cover accelerated procedures for

G12 Test Method for Nondestructive Measurement of Film

simultaneously determining comparative characteristics of in-

Thickness of Pipeline Coatings on Steel (Withdrawn

sulating coating systems applied to steel pipe exterior for the

3

2013)

purpose of preventing or mitigating corrosion that may occur in

G42 Test Method for Cathodic Disbonding of Pipeline

underground service where the pipe will be in contact with

Coatings Subjected to Elevated Temperatures

inland soils and may or may not receive cathodic protection.

G80 Test Method for Specific Cathodic Disbonding of Pipe-

They are intended for use with samples of coated pipe taken

3

line Coatings (Withdrawn 2013)

from commercial production and are applicable to such

G95 Test Method for Cathodic Disbondment Test of Pipeline

samples when the coating is characterized by function as an

Coatings (Attached Cell Method)

electrical barrier.

3. Summary of Test Method

1.2 This test method is intended for testing coatings sub-

merged or immersed in the test solution at room temperature.

3.1 Both of the two test methods described subject the

When it is impractical to submerge or immerse the test coating on the test specimen to electrical stress in a highly

specimen, Test Method G95 may be considered where the test conductive, alkaline electrolyte. Electrical stress is obtained

either by means of a sacrificial magnesium anode or from an

cell is cemented to the surface of the coated pipe specimen. If

impressed current system. The coating is perforated before

higher temperatures are required, see Test Method G42. If a

starting the test.

specific test method is required with no options, see Test

3.1.1 In Method A, a magnesium anode is used with no

Method G80.

electrical monitoring during the test period. The results are

1.3 The values stated in SI units to 3 significant decimals are

determined by physical examination after the test period is

to be regarded as the standard. The values given in parentheses

concluded.

are for information only.

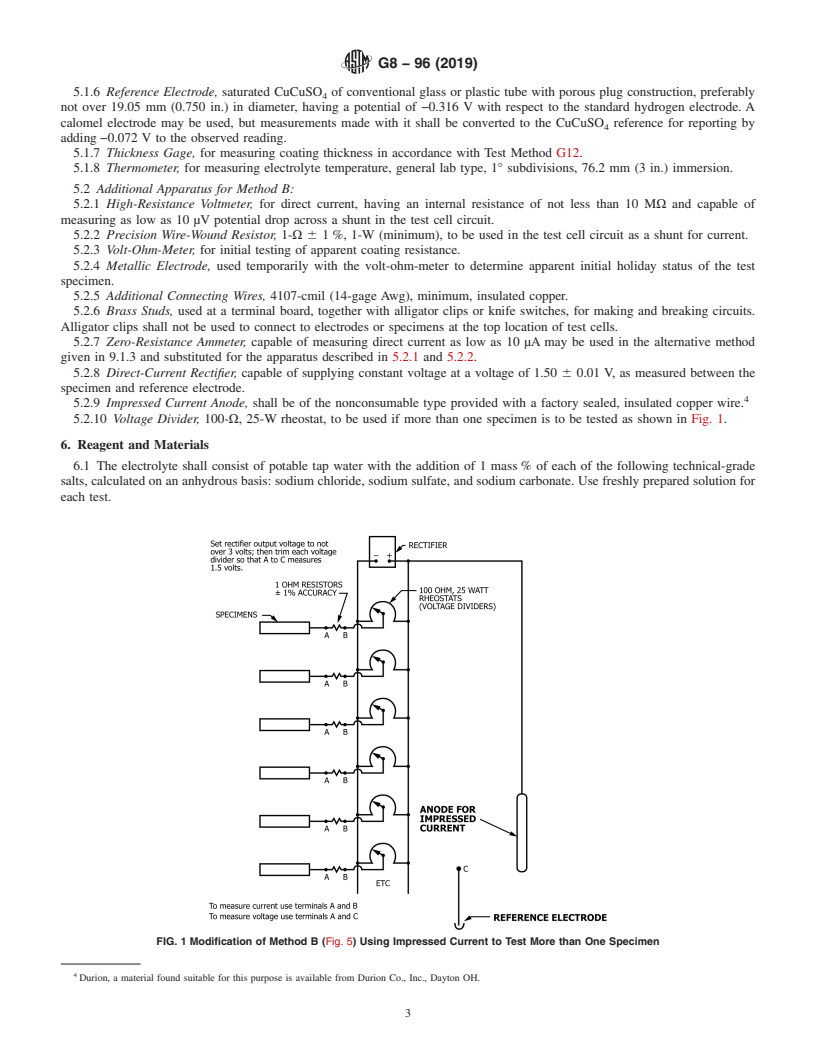

3.1.2 In Method B, either a magnesium anode or an im-

pressed current system may be used. Electrical instrumentation

1.4 This standard does not purport to address all of the

is provided for measuring the current in the cell circuit. The

safety concerns, if any, associated with its use. It is the

electrical potential is also measured, and upon conclusion of

responsibility of the user of this standard to establish appro-

the test period, the test specimen is physically examined.

priate safety, health, and environmental practices and deter-

3.1.3 In both test methods physical examination is con-

mine the applicability of regulatory limitations prior to use.

ducted by comparing the extent of loosened or disbonded

1.5 This international standard was developed in accor-

coating at the perforations in the immersed area with extent of

dance with internationally recognized principles on standard-

loosened or disbonded coating at a new test hole in the coating

ization established in the Decision on Principles for the

made in an area that was not immersed.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

4. Significance and Use

Barriers to Trade (TBT) Committee.

4.1 Breaks or holidays in pipe coatings may expose the pipe

to possible corrosion, since after a pipe has been installed

1

These test methods are under the jurisdiction of ASTM Committee D01 on

2

Paint and Related Coatings, Materials, and Applications and are the direct For referenced ASTM standards, visit the ASTM website, www.astm.org, or

responsibility of Subcommittee D01.48 on Durability of Pipeline Coating and contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Linings. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved June 1, 2019. Published June 2019. Originally the ASTM website.

3

approved in 1969. Last previous edition approved in 2010 as G8 – 96 (2010). DOI: The last approved version of this historical standard is referenced on

10.1520/G0008-96R19. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G8 − 96 (Reapproved 2010) G8 − 96 (Reapproved 2019)

Standard Test Methods for

1

Cathodic Disbonding of Pipeline Coatings

This standard is issued under the fixed designation G8; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods cover accelerated procedures for simultaneously determining comparative characteristics of insulating

coating systems applied to steel pipe exterior for the purpose of preventing or mitigating corrosion that may occur in underground

service where the pipe will be in contact with inland soils and may or may not receive cathodic protection. They are intended for

use with samples of coated pipe taken from commercial production and are applicable to such samples when the coating is

characterized by function as an electrical barrier.

1.2 This test method is intended for testing coatings submerged or immersed in the test solution at room temperature. When it

is impractical to submerge or immerse the test specimen, Test Method G95 may be considered where the test cell is cemented to

the surface of the coated pipe specimen. If higher temperatures are required, see Test Method G42. If a specific test method is

required with no options, see Test Method G80.

1.3 The values stated in SI units to 3 significant decimals are to be regarded as the standard. The values given in parentheses

are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

3

G12 Test Method for Nondestructive Measurement of Film Thickness of Pipeline Coatings on Steel (Withdrawn 2013)

G42 Test Method for Cathodic Disbonding of Pipeline Coatings Subjected to Elevated Temperatures

3

G80 Test Method for Specific Cathodic Disbonding of Pipeline Coatings (Withdrawn 2013)

G95 Test Method for Cathodic Disbondment Test of Pipeline Coatings (Attached Cell Method)

3. Summary of Test Method

3.1 Both of the two test methods described subject the coating on the test specimen to electrical stress in a highly conductive,

alkaline electrolyte. Electrical stress is obtained either by means of a sacrificial magnesium anode or from an impressed current

system. The coating is perforated before starting the test.

3.1.1 In Method A, a magnesium anode is used with no electrical monitoring during the test period. The results are determined

by physical examination after the test period is concluded.

3.1.2 In Method B, either a magnesium anode or an impressed current system may be used. Electrical instrumentation is

provided for measuring the current in the cell circuit. The electrical potential is also measured, and upon conclusion of the test

period, the test specimen is physically examined.

1

These test methods are under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and are the direct responsibility of

Subcommittee D01.48 on Durability of Pipeline Coating and Linings.

Current edition approved Dec. 1, 2010June 1, 2019. Published December 2010June 2019. Originally approved in 1969. Last previous edition approved in 20032010 as

ε1

G8 – 96 (2003)(2010). . DOI: 10.1520/G0008-96R10.10.1520/G0008-96R19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G8 − 96 (2019)

3.1.3 In both test methods ph

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.