ASTM G42-96

(Test Method)Standard Test Method for Cathodic Disbonding of Pipeline Coatings Subjected to Elevated Temperatures

Standard Test Method for Cathodic Disbonding of Pipeline Coatings Subjected to Elevated Temperatures

SCOPE

1.1 This test method describes an accelerated procedure for determining comparative characteristics of insulating coating systems applied to steel pipe exterior for the purpose of preventing or mitigating corrosion that may occur in underground service where the pipe will be exposed to high temperatures and is under cathodic protection. This test method is intended for use with samples of coated pipe taken from commercial production and is applicable to such samples when the coating is characterized by function as an electrical barrier.

1.2 This test method is intended for testing coatings submerged or immersed in the test solution at elevated temperature. When it is impractical to submerge or immerse the test specimen, Test Method G95 may be considered where the test cell is cemented to the surface of the coated pipe specimen. If room temperatures are required, see Test Method G 8. If a specific test method is required with no options, see Test Method G 80.

1.3 The values stated in SI units to three significant decimals are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: G 42 – 96

Standard Test Method for

Cathodic Disbonding of Pipeline Coatings Subjected to

Elevated Temperatures

ThisstandardisissuedunderthefixeddesignationG42;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope G95 Test Method for Cathodic Disbondment Test of Pipe-

line Coatings (Attached Cell Method)

1.1 This test method describes an accelerated procedure for

determining comparative characteristics of insulating coating

3. Summary of Test Method

systems applied to steel pipe exterior for the purpose of

3.1 This test method subjects the coating on the test speci-

preventing or mitigating corrosion that may occur in under-

men to electrical stress in a highly conductive electrolyte. The

ground service where the pipe will be exposed to high

coating is artificially perforated before starting the test. The

temperaturesandisundercathodicprotection.Thistestmethod

electrical stress is produced by connecting the test specimen to

is intended for use with samples of coated pipe taken from

the negative terminal of a source of direct current and by

commercialproductionandisapplicabletosuchsampleswhen

connecting an anode to the positive terminal. Electrical instru-

the coating is characterized by function as an electrical barrier.

mentation is provided for measuring the current flowing in the

1.2 This test method is intended for testing coatings sub-

cell.Theelectricalpotentialisalsomeasuredandthespecimen

merged or immersed in the test solution at elevated tempera-

is physically examined at intervals during the test period and

ture. When it is impractical to submerge or immerse the test

upon conclusion of the test.

specimen,Test Method G95 may be considered where the test

3.1.1 The cathodic stress is applied under conditions of a

cell is cemented to the surface of the coated pipe specimen. If

constant-elevated temperature.

room temperatures are required, see Test Method G8. If a

specific test method is required with no options, see Test

4. Significance and Use

Method G80.

4.1 Damage to pipe coating is almost unavoidable during

1.3 The values stated in SI units to three significant deci-

transportation and construction. Breaks or holidays in pipe

mals are to be regarded as the standard. The values given in

coatings may expose the pipe to possible corrosion since, after

parentheses are for information only.

a pipe has been installed underground, the surrounding earth

1.4 This standard does not purport to address all of the

will be moisture-bearing and will constitute an effective

safety concerns, if any, associated with its use. It is the

electrolyte. Applied cathodic protection potentials may cause

responsibility of the user of this standard to establish appro-

loosening of the coating, beginning at holiday edges. Sponta-

priate safety and health practices and determine the applica-

neousholidaysmayalsobecausedbysuchpotentials.Thistest

bility of regulatory limitations prior to use.

method provides accelerated conditions for cathodic disbond-

2. Referenced Documents ment to occur and provides a measure of resistance of coatings

to this type of action.

2.1 ASTM Standards:

4.2 The effects of the test are to be evaluated by physical

G8 Test Methods for Cathodic Disbonding of Pipeline

2 examinations and monitoring the current drawn by the test

Coatings

specimen. Usually there is no correlation between the two

G12 TestMethodforNondestructiveMeasurementofFilm

2 methods of evaluation, but both methods are significant.

Thickness of Pipeline Coatings on Steel

Physicalexaminationconsistsofassessingtheeffectivecontact

G80 Test Method for Specific Cathodic Disbonding of

2 of the coating with the metal surface in terms of observed

Pipeline Coatings

differences in the relative adhesive bond. It is usually found

that the cathodically disbonded area propagates from an area

This method is under the jurisdiction of ASTM Committee D01 on Paint and where adhesion is zero to an area where adhesion reaches the

Related Coatings, Materials, and Applications and is the direct responsibility of

originallevel.Anintermediatezoneofdecreasedadhesionmay

Subcommittee D01.48 on Durability of Pipeline Coatings and Linings.

also be present.

Current edition approved May 10, 1996. Published July 1996. Originally

4.3 Assumptions associated with test results include:

published as G42–75T. Last previous edition G42–90.

Annual Book of ASTM Standards, Vols 06.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

G42–96

4.3.1 Maximum adhesion, or bond, is found in the coating 5.1.5 The reference electrode may be placed anywhere in

that was not immersed in the test liquid, and thevessel,provideditisseparatedfromthespecimenandfrom

the anode by not less than 38 mm (1 ⁄2 in.).

4.3.2 Decreased adhesion in the immersed test area is the

5.2 Anode—The anode shall be provided with a factory-

result of cathodic disbondment.

sealed, insulated copper wire lead.

4.4 Ability to resist disbondment is a desired quality on a

5.3 Connectors—Wiring from anode to test specimen shall

comparative basis, but disbondment in this test method is not

be 4107 cmil (14-gage Awg), minimum, insulated copper.

necessarily an adverse indication of coating performance. The

Attachment to the test specimen shall be by soldering or

virtueofthistestmethodisthatalldielectric-typecoatingsnow

brazing to the nonimmersed end, and the place of attachment

in common use will disbond to some degree, thus providing a

shall be coated with an insulating material. A junction in the

means of comparing one coating to another.

connectingwireispermitted,providedthatitismadebymeans

4.5 The current density appearing in this test method is

of a bolted pair of terminal lugs soldered or mechanically

much greater than that usually required for cathodic protection

crimped to clean wire ends.

in natural environments.

5.4 Holiday Tools—Holidays shall be made with conven-

4.6 That any relatively lesser bonded area was caused by

tional drills of the required diameter. For use in preparing

electrical stressing in combination with the elevated and or

small-diameterpipespecimenssuchas19-mm( ⁄4-in.)nominal

depressed temperature and was not attributable to an anomaly

diameter pipe, the use of a drill modified by substantially

in the application process. Ability to resist disbondment is a

grinding away the sharp cone point has been found effective in

desired quality on a comparative basis, but most insulating

preventing perforation of the metal wall of the pipe. A

materials will disbond to some extent under the accelerated

sharp-pointed knife with a safe handle is required for use in

conditions of this test. Bond strength is more important for

making physical examinations.

proper functioning of some coatings than others and the same

5.5 Multimeters:

measured disbondment for two different coating systems may

5.5.1 Multimeter, for direct current, having an internal

not represent equivalent loss of corrosion protection.

resistanceofnotlessthan10MVandhavingarangefrom0.01

4.6.1 The amount of current flowing in the test cell may be

to 5 V for measuring potential to the reference electrode.

a relative indicator of the extent of areas requiring protection

5.5.2 Multimeter, for direct current, having an internal

against corrosion; however, the current density appearing in

resistance of not less than 11 MV and capable of measuring as

this test is much greater than that usually required for cathodic

low as 10 µV potential drop across a shunt in the test cell

protection in natural, inland soil environments.

circuit.

4.6.2 Test voltages higher than those recommended may

5.5.3 Multimeter, for initial testing of apparent coating

result in the formation of chlorine gas. The subsequent chemi-

resistance.

cal effects on the coating could cast doubt on the interpretation

5.6 Reference Electrode—Saturated Cu CuSO electrode

of the test results.

having a potential of−0.316 V with respect to the standard

hydrogen electrode shall be the standard of reference in these

5. Apparatus

test methods. Other electrodes may be used but measurements

thusobtainedshallbeconvertedtotheCuCuSO referencefor

5.1 TestVessel—Asuitablenonreactivevesselshallbeused,

reporting by making the proper correction.

capable of withstanding internal heating at not less than 60°C

and suitable for continuous circulation of the electrolyte.

NOTE 1—A saturated Cu CuSO electrode reading−1.50 V at 25°C

A19-L(5-gal) cylindrical glass vessel has been found suitable,

will read−1.53 V at 60°C, a scale increase of 0.03 V.

having an approximate diameter of 300 mm (12 in.) and a

5.6.1 Asaturated calomel electrode at 25°C is converted to

depth of 300 mm. A flat bottom is required for operation of a

Cu CuSO by adding−0.07 V to the observed reading. If the

magnetic stirring rod. An alternate means of heating the test

saturated calomel electrode reads−1.43 V at 25°C, it will

sample can be provided by internally heating.The pipe sample

read−1.46Vat60°C,ascaleincreaseof0.03V.Itfollowsthat

may be filled with a suitable heat transfer material (oil, steel

a saturated calomel electrode reading of−1.46 V at 60°C is

shot, etc). A thermocouple or thermometer and heater can be

equal to a saturated Cu CuSO reading of−1.50 V at 25°C.

immersedintheheattransfermediumtoeffectivelycontrolthe

5.6.2 A0.1normalcalomelelectrodeat25°Cisconvertedto

temperature of the sample. Dimensions of the vessel shall

Cu CuSO by subtracting−0.02 V from the observed reading.

permit the following requirements:

Since the potential change due to an increase from 25°C to

5.1.1 Test specimens shall be suspended vertically in the

60°C is negligible, it follows that a 0.1 normal calomel

vessel with at least 25 mm (1 in.) clearance from the bottom.

electrode reading−1.52 V at 60°C is equal to a saturated Cu

5.1.2 Test specimens shall be separated by not less than 38

CuSO reading of−1.50 V at 25°C.

mm (1 ⁄2 in.), and a vertically suspended anode can be placed

5.7 Thermometers, two, mercury-filled type, accurate to

at an equal distance from each specimen not less than the

61°C. One shall be of the full-immersion type for measuring

separation distance. temperature near the bottom of the vessel, and a second

5.1.3 Testspecimensshallbeseparatedfromanywallofthe

vessel by not less than 13 mm ( ⁄2 in.).

5.1.4 Depth of electrolyte shall permit the test length of the

Duriron, a material found suitable for this purpose is available from Duriron

specimen to be immersed as required in 7.4. Co., Inc., Dayton, OH.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

G42–96

thermometer shall be of the partial-immersion type for mea- materials, including molded elastomeric or plastic end caps,

suring temperature near the top of the vessel. capable of withstanding the test temperature.

5.8 Combination Heater Plate, with built-in magnetic stir- 6.3 Plywood has been found suitable for the construction of

rer, or equivalent, shall be used for heating and stirring the nonconductive test vessel covers and for the support through

electrolyte. The heater shall be adjustable to produce and apertures of test specimens and electrodes. Wood dowels

control a temperature of 60 6 1°C in the test vessel. introducedthroughholesinthetopendsoftestspecimenshave

5.9 Direct-Current Rectifier, capable of supplying constant been found suitable for suspending test specimens from the

currentatavoltageof1.50 60.01V,asmeasuredbetweenthe vessel cover.

specimen and reference cell.

7. Test Specimen

5.10 Thickness Gage, for measuring coating thickness in

accordance with Test Method G12. 7.1 The test specimen shall be a representative piece of

production-coated pipe. One end shall be plugged, sealed, or

5.11 PrecisionResistor,1V61%,1W(min),tobeusedin

the test cell circuit as a shunt for current. capped.

7.2 One holiday shall be made in the middle of the im-

5.12 Carbon or Stainless Steel Electrode, used temporarily

mersed length by drilling a radial hole through the coating so

with the volt-ohm-meter to determine apparent initial holiday

status of the test specimen. that the angular cone point of the drill will fully enter the steel

where the cylindrical portion of the drill meets the steel

5.13 Additional Connecting Wires, 4107 cmil (14-gage

Awg), minimum, insulated copper. surface.Thedrilldiametershallbenotlessthanthreetimesthe

coating thickness, but it shall never be less than 6 mm ( ⁄4 in.)

5.14 Brass Studs, used at a terminal board, together with

alligator clips or knife switches, for making and breaking in diameter. The steel wall of the pipe shall not be perforated.

Withsmall-diameterpipes,wherethereisdangerofperforating

circuits. Alligator clips shall not be used to connect the

electrodes or specimens at the top location of test cells. the pipe, the holiday shall be started with a standard 60° cone

pointandfinishedwithadrillthathashadasubstantialportion

6. Reagents and Materials

of the cone point ground away.

6.1 The electrolyte shall consist of potable tap water or

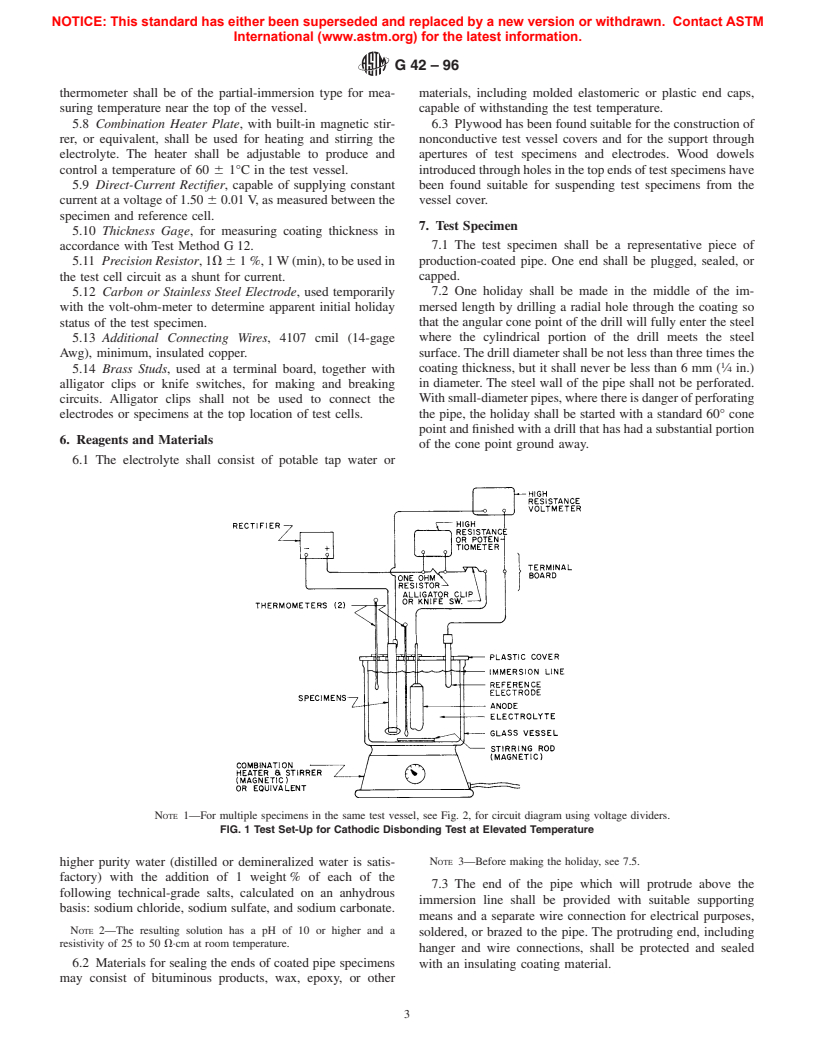

NOTE 1—For multiple specimens in the same test vessel, see Fig. 2, for circuit diagram using voltage dividers.

FIG. 1 Test Set-Up for Cathodic Disbonding Test at Elevated Temperature

NOTE 3—Before making the holiday, see 7.5.

higher purity water (distilled or demineralized water is satis-

factory) with the addition of 1 weight% of each of the

7.3 The end of the pipe which will protrude above the

following technical-grade salts, calculated on an anhydrous

immersion line shall be provided with suitable supporting

basis: sodium chloride, sodium sulfate, and sodium carbonate.

means and a separate wire connection for electrical purposes,

NOTE 2—The resulting solution has a pH of 10 or higher and a

soldered, or brazed to the pipe. The protruding end, including

resistivity of 25 to 50 V·cm at room temperature.

hanger and wire connections, shall be protected and sealed

6.2 Materials for sealing the ends of coated pipe specimens with an insulating coating material.

may consist of bituminous products, wax, epoxy, or other

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.