ASTM B331-95(2002)

(Test Method)Standard Test Method for Compressibility of Metal Powders in Uniaxial Compaction

Standard Test Method for Compressibility of Metal Powders in Uniaxial Compaction

SIGNIFICANCE AND USE

The compressibility obtained is a measure of a material characteristic inherent in the powder. The test method is useful as a quality control test in the evaluation and manufacturing control of metal powder production, and as an acceptance test for shipment of metal powder lots.

Results may be affected by test conditions such as the type amount, and method of lubrication, dwell time, and die material. They may not necessarily agree with results obtained under production conditions.

SCOPE

1.1 This test method covers determination of compressibility of metal powders as measured by the extent to which they can be densified in a specified die under controlled conditions.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI equivalents are in parentheses and may be approximate.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B331–95 (Reapproved 2002)

Standard Test Method for

Compressibility of Metal Powders in Uniaxial Compaction

This standard is issued under the fixed designation B331; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Significance and Use

1.1 This test method covers determination of compressibil- 5.1 The compressibility obtained is a measure of a material

ity of metal powders as measured by the extent to which they characteristic inherent in the powder. The test method is useful

can be densified in a specified die under controlled conditions. as a quality control test in the evaluation and manufacturing

1.2 The values stated in inch-pound units are to be regarded control of metal powder production, and as an acceptance test

as the standard. The SI equivalents are in parentheses and may for shipment of metal powder lots.

be approximate. 5.2 Results may be affected by test conditions such as the

1.3 This standard does not purport to address all of the type amount, and method of lubrication, dwell time, and die

safety concerns, if any, associated with its use. It is the material. They may not necessarily agree with results obtained

responsibility of the user of this standard to establish appro- under production conditions.

priate safety and health practices and determine the applica-

6. Apparatus

bility of regulatory limitations prior to use.

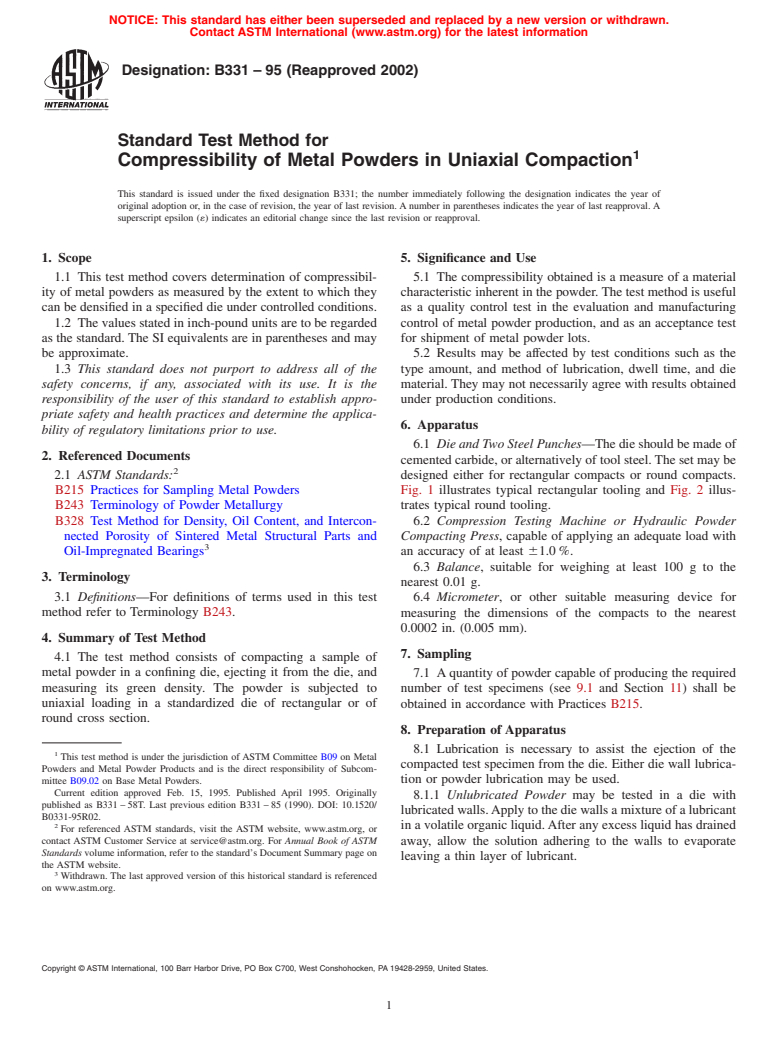

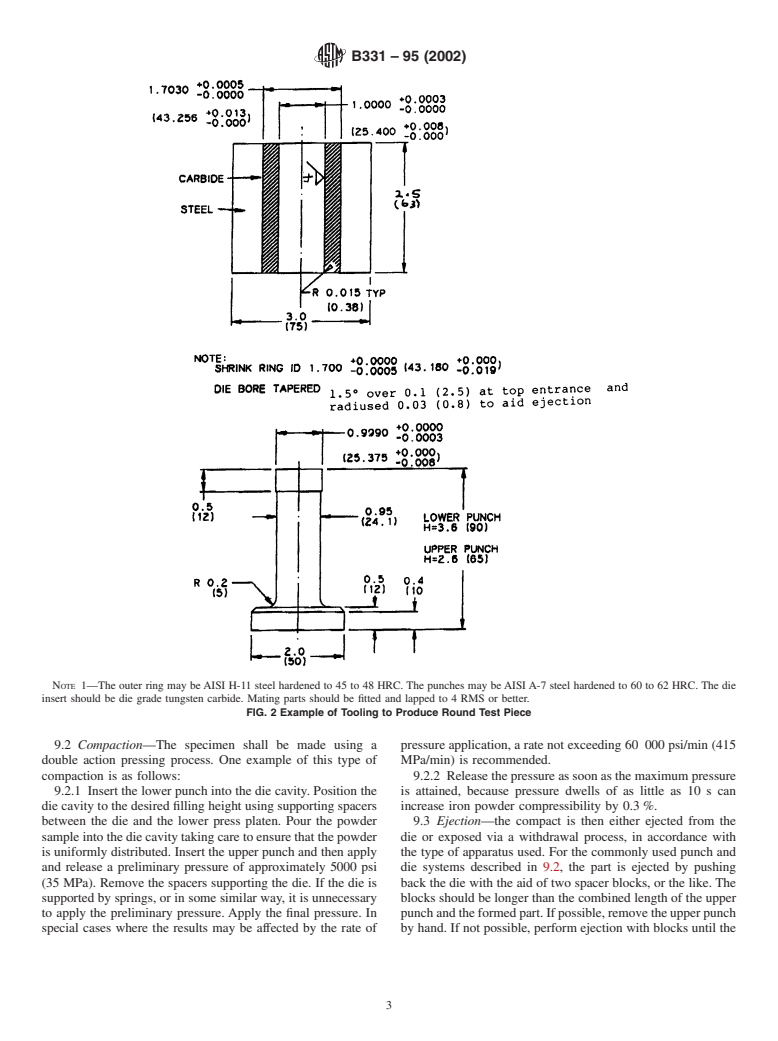

6.1 Die and Two Steel Punches—The die should be made of

2. Referenced Documents

cemented carbide, or alternatively of tool steel. The set may be

2.1 ASTM Standards: designed either for rectangular compacts or round compacts.

B215 Practices for Sampling Metal Powders Fig. 1 illustrates typical rectangular tooling and Fig. 2 illus-

B243 Terminology of Powder Metallurgy trates typical round tooling.

B328 Test Method for Density, Oil Content, and Intercon- 6.2 Compression Testing Machine or Hydraulic Powder

nected Porosity of Sintered Metal Structural Parts and Compacting Press, capable of applying an adequate load with

Oil-Impregnated Bearings an accuracy of at least 61.0 %.

6.3 Balance, suitable for weighing at least 100 g to the

3. Terminology

nearest 0.01 g.

3.1 Definitions—For definitions of terms used in this test

6.4 Micrometer, or other suitable measuring device for

method refer to Terminology B243. measuring the dimensions of the compacts to the nearest

0.0002 in. (0.005 mm).

4. Summary of Test Method

7. Sampling

4.1 The test method consists of compacting a sample of

metal powder in a confining die, ejecting it from the die, and

7.1 Aquantity of powder capable of producing the required

measuring its green density. The powder is subjected to number of test specimens (see 9.1 and Section 11) shall be

uniaxial loading in a standardized die of rectangular or of

obtained in accordance with Practices B215.

round cross section.

8. Preparation of Apparatus

8.1 Lubrication is necessary to assist the ejection of the

This test method is under the jurisdiction of ASTM Committee B09 on Metal

compacted test specimen from the die. Either die wall lubrica-

Powders and Metal Powder Products and is the direct responsibility of Subcom-

mittee B09.02 on Base Metal Powders. tion or powder lubrication may be used.

Current edition approved Feb. 15, 1995. Published April 1995. Originally

8.1.1 Unlubricated Powder may be tested in a die with

published as B331 – 58T. Last previous edition B331 – 85 (1990). DOI: 10.1520/

lubricated walls.Apply to the die walls a mixture of a lubricant

B0331-95R02.

in a volatile organic liquid.After any excess liquid has drained

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

away, allow the solution adhering to the walls to evaporate

Standards volume information, refer to the standard’s Document Summary page on

leaving a thin layer of lubricant.

the ASTM website.

Withdrawn. The last approved version of this historical standard is referenced

on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B331–95 (2002)

NOTE 1—The dimensions for the cavity shall be 0.500 6 0.004 in. wide (12.70 6 0.10 mm) by 1.250 6 0.004 in. long (31.75 6 0.10 mm).The mating

parts shall fit freely and should be finished to 4 RMS, or better, to dimensions of 0.0005 in. (0.013 mm) to 0.001 in. (0.025 mm) smaller than the bottom

of the die cavity, in each dimension.The dimensions given in the drawing typify the die cavity and punch within the stated tolerance, at the nominal width

and length dimensions, permitting die wall to punch clearances of 0.00025 to 0.0005 in. (0.006 mm to 0.013 mm) at each of the four sides of the die,

at the bottom of the die. The outer ring may be AISI H-11 steel hardened to 45 to 48 HRC. The punches may be AISI A-7 steel hardened to 60 to 62

HRC. The die insert should be die grade tungsten carbide.

FIG. 1 Example of Tooling to Produce Rectangular Test Piece

NOTE 1—An example of such a mixture is 100 g of zinc stearate in 1 L

8.3 The parties shall agree on the method, amount, and type

of methyl alcohol.

of lubricant.

8.1.2 An alternative way of testing powder not containing a

lubricant is to use an otherwise unlubricated die after thor-

9. Procedure

oughlymixingintothepowderasufficientamountofasuitable

9.1 Powder Sample Mass—The powder sample mass shall

lubricant.

be such as to result in a rectangular compact 0.240 to 0.260 in.

8.1.3 Lubricated Powder, received already mixed with suf-

thick (6.1 to 6.6 mm) or a round compact 0.27 to 0.29 in. (6.9

ficient lubricant should be tested in an otherwise unlubricated

to 7.4 mm) thick. For a powder whose compressibility is not

die.

known,itmaybenecessarytoadjustthepowdermassbasedon

8.2 Compressibility may vary according to the method of

the specimen thickness obtained in an initial test.

lubrication, type, and amount of lubricant.

B331–95 (2002)

NOTE 1—The outer ring may be AISI H-11 steel hardened to 45 to 48 HRC. The punches may be AISI A-7 steel hardened to 60 to 62 HRC. The die

insert should be die grade tungsten carbide. Mating parts should be fitted and lapped to 4 RMS or better.

FIG. 2 Example of Tooling to Produce Round Test Piece

9.2 Compaction—The specimen shall be made using a pressure application, a rate not exceeding 60 000 psi/min (415

double action pressing process. One example of this type of MPa/min) is recommended.

compaction is as follows: 9.2.2 Release the pressure as soon as the maximum pressure

9.2.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.