ASTM C1479-00e1

(Practice)Standard Practice for Installation of Precast Concrete Sewer, Storm Drain, and Culvert Pipe Using Standard Installations

Standard Practice for Installation of Precast Concrete Sewer, Storm Drain, and Culvert Pipe Using Standard Installations

SCOPE

1.1 This practice covers the installation of precast concrete pipe intended to be used for the conveyance of sewage, industrial wastes, and storm water and for the construction of culverts.

1.2 This practice does not have a metric companion, therefore see IEEE/ASTM SI 10 for conversion purposed.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: C 1479 – 00

Standard Practice for

Installation of Precast Concrete Sewer, Storm Drain, and

Culvert Pipe Using Standard Installations

This standard is issued under the fixed designation C 1479; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Corrected title, scope, 8.3, 15.2, and figure captions editorially in January 2001.

1. Scope (2.5 kg) Rammer and a 12-in. (305 mm) Drop

T 180 The Moisture-Density Relations of Soils Using a 10

1.1 This practice covers the installation of precast concrete

lb (4.54 kg) Rammer and an 18-in. (457 mm) Drop

pipe intended to be used for the conveyance of sewage,

2.3 ASCE Standards:

industrial wastes, and storm water and for the construction of

ASCE 15 Standard Practice for the Direct Design of Buried

culverts.

Precast Reinforced Concrete Pipe Using Standard Instal-

1.2 This standard does not purport to address all of the

lations (SIDD)

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety and health practices and determine the applica-

3.1 For definitions of terms relating to concrete pipe, see

bility of regulatory limitations prior to use.

Terminology C 822.

2. Referenced Documents 3.2 For terminology related to soil classifications, see Prac-

tice D 2487 and Practice D 2488.

2.1 ASTM Standards:

3.3 For terminology and definitions of terms relating to

C 822 Terminology Relating to Concrete Pipe and Related

2 structural design, see ASCE 15.

Products

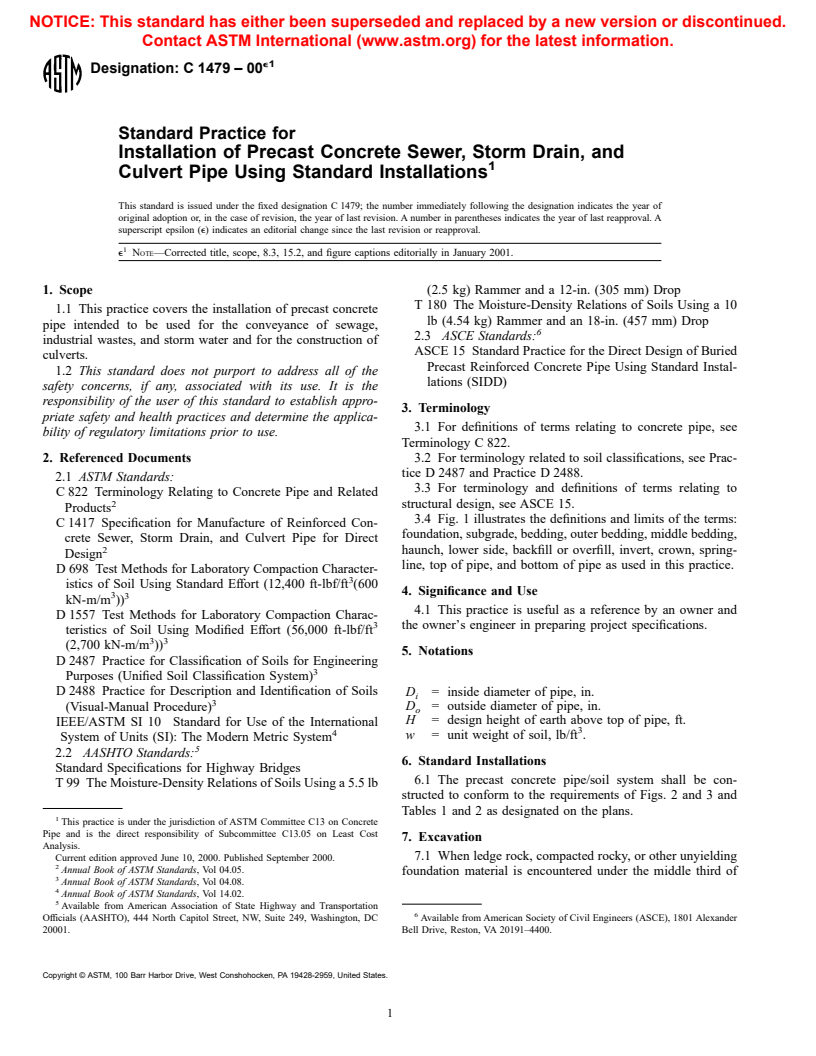

3.4 Fig. 1 illustrates the definitions and limits of the terms:

C 1417 Specification for Manufacture of Reinforced Con-

foundation, subgrade, bedding, outer bedding, middle bedding,

crete Sewer, Storm Drain, and Culvert Pipe for Direct

haunch, lower side, backfill or overfill, invert, crown, spring-

Design

line, top of pipe, and bottom of pipe as used in this practice.

D 698 Test Methods for Laboratory Compaction Character-

istics of Soil Using Standard Effort (12,400 ft-lbf/ft (600

4. Significance and Use

3 3

kN-m/m ))

4.1 This practice is useful as a reference by an owner and

D 1557 Test Methods for Laboratory Compaction Charac-

the owner’s engineer in preparing project specifications.

teristics of Soil Using Modified Effort (56,000 ft-lbf/ft

(2,700 kN-m/m ))

5. Notations

D 2487 Practice for Classification of Soils for Engineering

Purposes (Unified Soil Classification System)

D 2488 Practice for Description and Identification of Soils D = inside diameter of pipe, in.

i

(Visual-Manual Procedure) D = outside diameter of pipe, in.

o

H = design height of earth above top of pipe, ft.

IEEE/ASTM SI 10 Standard for Use of the International

w = unit weight of soil, lb/ft .

System of Units (SI): The Modern Metric System

2.2 AASHTO Standards:

6. Standard Installations

Standard Specifications for Highway Bridges

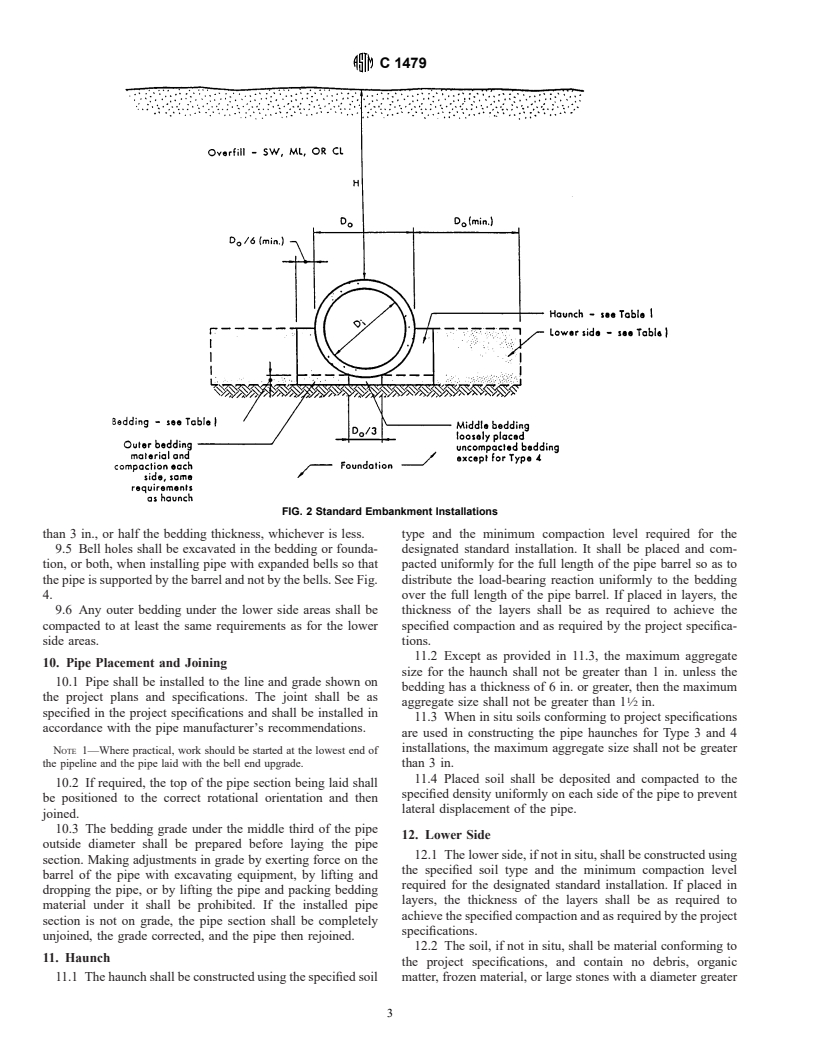

6.1 The precast concrete pipe/soil system shall be con-

T 99 The Moisture-Density Relations of Soils Using a 5.5 lb

structed to conform to the requirements of Figs. 2 and 3 and

Tables 1 and 2 as designated on the plans.

This practice is under the jurisdiction of ASTM Committee C13 on Concrete

Pipe and is the direct responsibility of Subcommittee C13.05 on Least Cost

7. Excavation

Analysis.

7.1 When ledge rock, compacted rocky, or other unyielding

Current edition approved June 10, 2000. Published September 2000.

Annual Book of ASTM Standards, Vol 04.05.

foundation material is encountered under the middle third of

Annual Book of ASTM Standards, Vol 04.08.

Annual Book of ASTM Standards, Vol 14.02.

Available from American Association of State Highway and Transportation

Officials (AASHTO), 444 North Capitol Street, NW, Suite 249, Washington, DC Available from American Society of Civil Engineers (ASCE), 1801 Alexander

20001. Bell Drive, Reston, VA 20191–4400.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

C 1479

FIG. 1 Pipe/Installation Terminology

the pipe outside diameter, it shall be removed at least to the 9. Bedding

requirements shown in Figs. 1 and 2 and Tables 1 and 2.

9.1 The bedding shall be constructed uniformly over the full

Overexcavated areas shall be backfilled with approved mate-

length of the pipe barrel, as required for the designated

rials and compacted to at least the standard proctor density

standard installation, to distribute the loadbearing reaction

specified for the bedding.

uniformly on the pipe barrel over its full length, and to

7.2 Where surface water or groundwater conditions exist,

maintain the required pipe grade. See Fig. 4. If placed in layers,

the site and trench shall be dewatered.

the thickness of the layers shall be as required to achieve the

specified compaction and as required by the project specifica-

8. Foundation

tions.

8.1 The foundation shall be moderately firm to hard in situ

9.2 The bedding layers for standard installation Types 1, 2,

soil, stabilized soil, or compacted fill material.

and 3 shall be placed to be as uniform as possible, but shall be

8.2 When unsuitable or unstable material is encountered,

loosely placed uncompacted material under the middle third of

the foundation shall be stabilized.

the pipe prior to placement of the pipe.

8.3 Methods to prevent migration of soil fines shall be

9.3 Except as provided in 11.4, the maximum aggregate size

provided when groundwater or existing soil conditions are

for beddings shall not be greater than 1 in. except if the

conducive to particle migration. Gravelly soils, with little or no

bedding has a thickness of 6 in. or greater, then the maximum

fines, could migrate under certain conditions, causing lack of

aggregate size shall not be greater than 1 ⁄2 in.

support.

8.4 Pipe installed over an unyielding foundation shall be 9.4 When in situ soils conforming to project specifications

cushioned so as to prevent blasting shock when future blasting are used in constructing the bedding for Type 3 and 4

is anticipated in the area. Installations, the maximum aggregate size shall not be greater

C 1479

FIG. 2 Standard Embankment Installations

than 3 in., or half the bedding thickness, whichever is less. type and the minimum compaction level required for the

9.5 Bell holes shall be excavated in the bedding or founda- designated standard installation. It shall be placed and com-

tion, or both, when installing pipe with expanded bells so that pacted uniformly for the full length of the pipe barrel so as to

the pipe is supported by the barrel and not by the bells. See Fig. distribute the load-bearing reaction uniformly to the bedding

4. over the full length of the pipe barrel. If placed in layers, the

9.6 Any outer bedding under the lower side areas shall be thickness of the layers shall be as required to achieve the

compacted to at least the same requirements as for the lower specified compaction and as required by the project specifica-

side areas. tions.

11.2 Except as provided in 11.3, the maximum aggregate

10. Pipe Placement and Joining

size for the haunch shall not be greater than 1 in. unless the

10.1 Pipe shall be installed to the line and grade shown on

bedding has a thickness of 6 in. or greater, then the maximum

the project plans and specifications. The joint shall be as

aggregate size shall not be greater than 1 ⁄2 in.

specified in the project specifications and shall be installed in

11.3 When in situ soils conforming to project specifications

accordance with the pipe manufacturer’s recommendations.

are used in constructing the pipe haunches for Type 3 and 4

installations, the maximum aggregate size shall not be greater

NOTE 1—Where practical, work should be started at the lowest end of

the pipeline and the pipe laid with the bell end upgrade. than 3 in.

11.4 Placed soil shall be deposited and compacted to the

10.2 If required, the top of the pipe section being laid shall

specified density uniformly on each side of the pipe to prevent

be positioned to the correct rotational orientation and then

lateral displacement of the pipe.

joined.

10.3 The bedding grade under the middle third of the pipe

12. Lower Side

outside diameter shall be prepared before laying the pipe

12.1 The lower side, if not in situ, shall be constructed using

section. Making adjustments in grade by exerting force on the

the specified soil type and the minimum compaction level

barrel of the pipe with excavating equipment, by lifting and

required for the designated standard installation. If placed in

dropping the pipe, or by lifting the pipe and packing bedding

layers, the thickness of the layers shall be as required to

material under it shall be prohibited. If the installed pipe

achieve the specified compaction and as required by the project

section is not on grade, the pipe section shall be completely

specifications.

unjoined, the grade corrected, and the pipe then rejoined.

12.2 The soil, if not in situ, shall be material conforming to

11. Haunch

the project specifications, and contain no debris, organic

11.1 The haunch shall be constructed using the specified soil matter, frozen material, or large stones with a diameter greater

C 1479

NOTE 1—Clearance between pipe and trench wall shall be adequate to enable specified compaction but not less than D /6.

FIG. 3 Standard Trench Installations

than one half the thickness of the compacted layers being of fill material for the full width of the trench.

placed. 14.2 When trench shields or boxes are moved, the previ-

12.3 Placed soil shall be deposited and compacted to the ously placed pipe shall not be disturbed. It may be necessary to

specified density uniformly on each side of the pipe to prevent restrain the installed pipe by use of deadman anchors or other

lateral displacement of the pipe. means. Voids that are created by movement of a shield or box

shall be filled and compacted.

13. Overfill

15. Precast Concrete Appurtenances

13.1 Overfill shall be constructed as specified in the project

specifications. If placed in layers, the thickness of the layers 15.1 Manholes shall be installed in a manner that will

shall be as required to achieve the specified compaction and as minimize differential settlement between the pipe and man-

required by the project specifications. hole.

13.2 The soil shall be material conforming to the project 15.2 Precast concrete fittings, such as tees and wyes, shall

specifications, and contain no debris, organic matter, frozen be bedded, installed, and overfilled with the same material and

material, or large stones with a diameter greater than one half in the same manner as the remainder of the pipeline to reduce

the thickness of the compacted layers being placed. the possibility of differential settlement between pipe and

13.3 Placed soil shall be deposited and compacted to the fittings.

specified density uniformly on each side of the pipe to prevent

16. Minimum Cover for Construction Loads

lateral displacement of the pipe. The overfill placed within one

16.1 If the passage of construction equipment over an

outside diameter of the pipe that is above the springline and

installed pipeline is necessary during project construction,

below the top of the pipe shall be compacted to at least the

compacted overfill in the form of a ramp shall be constructed

same density as the majority of the overfill above the pipe.

to a minimum elevation of 3 ft over the top of the pipe or to a

13.4 When impact or vibratory equipment is used for

height such that the equipment loads on the pipe do not exceed

compaction, care shall be taken to avoid damaging the pipe.

the pipe design strength. To prevent possible lateral displace-

14. Sheathing Removal and Trench Shield Advancement

ment of the pipe when the existing ground is higher or lower

14.1 Unless sheathing is to be left in place, it shall be pulled than the top of this ramp, the overfill shall extend a minimum

out in vertical increments to permit placement and compaction of one pipe diameter width or 3 ft, whichever is greater, beyond

C 1479

TABLE 1 Standard Embankment Installation Soils and Minimum TABLE 2 Standard Trench Installation Soils and Minimum

Compaction Requirements Compaction Requirements

NOTE 1—Compaction and soil symbols, (95% SW), refer to SW soil NOTE 1—Compaction and soil symbols, that is, 95% SW, refer to SW

material with a minimum standard proctor compaction of 95%. See Table soil material with minimum standard proctor compaction of 95%. See

X2.1 for equivalent modified proctor values. Table X2.1 for equivalent modified proctor values.

NOTE 2—Soil in the outer bedding, haunch, and lower side zones, NOTE 2—The trench top elevation shall be no lower than 0.1 H below

except within D /3 from the pipe springline, shall be compacted to at least finished grade or, for roadways, its top shall be no lower than an elevation

the same compaction as the majority of soil in the overfill zone. of 1 ft below the bottom of the pavement base material.

NOTE 3—Required bedding thickness is the thickness of the bedding NOTE 3—Earth loading shall be based on embankment conditions.

after the placement of the pipe on the bedding and prior to the placement NOTE 4—Soil in bedding and haunch zones shall be compacted to at

of the backfill. least the same compaction as specified for the majority of soil in the

NOTE 4—A subtrench is defined as a trench with its top below finished backfill zone.

grade by more than 0.1H or, for roadways, its top is at an elevation lower NOTE 5—The trench width shall be wider than shown if required for

than 1 ft below the bottom of the pavement base material. adequate space to attain the specified compaction in the haunch and

The minimum width of a subtrench shall be 1.33 D , or wider, if bedding zones.

required for adequate space to attain the specified compaction in the NOTE 6—For trench walls that are within 10 degrees of vertical, the

haunch and bedding zones. compaction or firmness of the soil in the trench walls and lower side zone

For subtrenches with walls of natural soil, any portion of the lower side need not be considered. See Note 3.

zone in the subtrench wall shall be at least as firm as an equivalent soil NOTE 7—For trench walls with greater than 10 degree slopes that

placed to the compaction requirements specified for the lower side zone consist of embankment, the lower side shall be compacted to at least the

and as firm as the majority of soil in the overfill zo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.