ASTM D5497-94c(2000)

(Terminology)Standard Terminology Relating to Buttons

Standard Terminology Relating to Buttons

SCOPE

1.1 This terminology covers special terms or special meanings used in the button industry. These definitions apply only to sew-through flange and shank buttons.

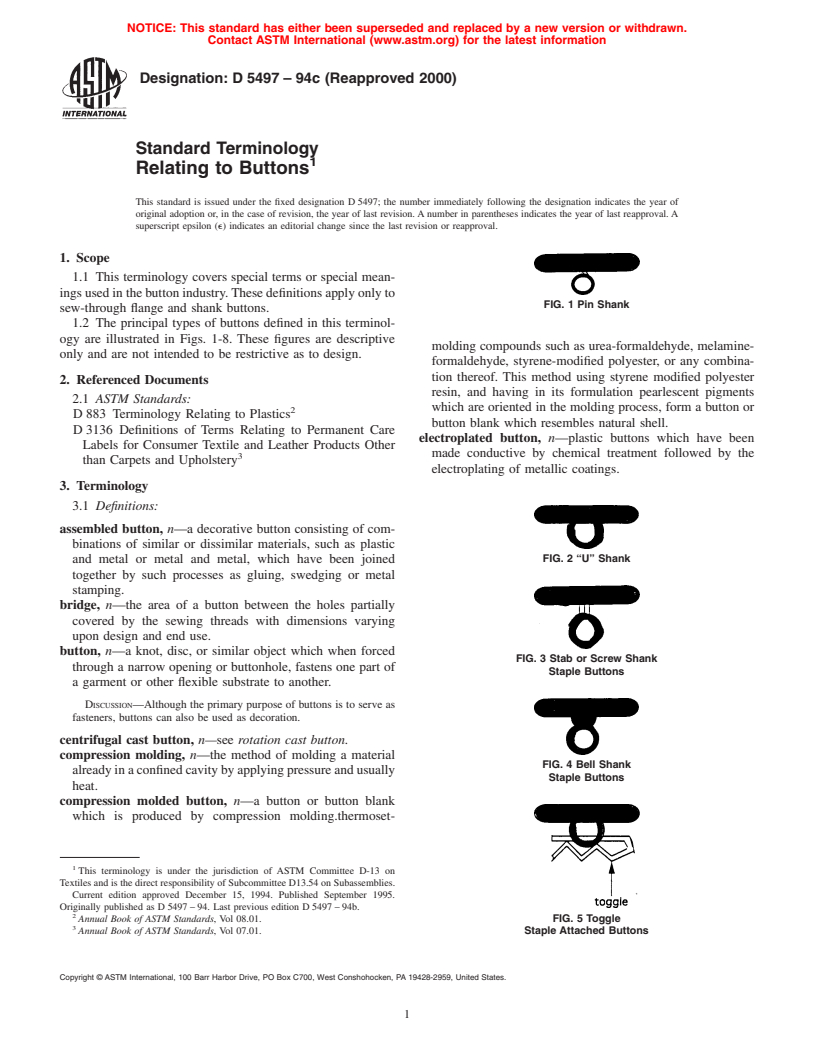

1.2 The principal types of buttons defined in this terminology are illustrated in Figs. 1 - 8. These figures are descriptive only and are not intended to be restrictive as to design.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5497–94c (Reapproved 2000)

Standard Terminology

Relating to Buttons

This standard is issued under the fixed designation D 5497; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This terminology covers special terms or special mean-

ings used in the button industry.These definitions apply only to

FIG. 1 Pin Shank

sew-through flange and shank buttons.

1.2 The principal types of buttons defined in this terminol-

ogy are illustrated in Figs. 1-8. These figures are descriptive

molding compounds such as urea-formaldehyde, melamine-

only and are not intended to be restrictive as to design.

formaldehyde, styrene-modified polyester, or any combina-

tion thereof. This method using styrene modified polyester

2. Referenced Documents

resin, and having in its formulation pearlescent pigments

2.1 ASTM Standards:

which are oriented in the molding process, form a button or

D 883 Terminology Relating to Plastics

button blank which resembles natural shell.

D 3136 Definitions of Terms Relating to Permanent Care

electroplated button, n—plastic buttons which have been

Labels for Consumer Textile and Leather Products Other

made conductive by chemical treatment followed by the

than Carpets and Upholstery

electroplating of metallic coatings.

3. Terminology

3.1 Definitions:

assembled button, n—a decorative button consisting of com-

binations of similar or dissimilar materials, such as plastic

FIG. 2 “U” Shank

and metal or metal and metal, which have been joined

together by such processes as gluing, swedging or metal

stamping.

bridge, n—the area of a button between the holes partially

covered by the sewing threads with dimensions varying

upon design and end use.

button, n—a knot, disc, or similar object which when forced

FIG. 3 Stab or Screw Shank

through a narrow opening or buttonhole, fastens one part of

Staple Buttons

a garment or other flexible substrate to another.

DISCUSSION—Although the primary purpose of buttons is to serve as

fasteners, buttons can also be used as decoration.

centrifugal cast button, n—see rotation cast button.

compression molding, n—the method of molding a material

FIG. 4 Bell Shank

alreadyinaconfinedcavitybyapplyingpressureandusually

Staple Buttons

heat.

compression molded button, n—a button or button blank

which is produced by compression molding.thermoset-

This terminology is under the jurisdiction of ASTM Committee D-13 on

Textiles and is the direct responsibility of Subcommittee D13.54 on Subassemblies.

Current edition approved December 15, 1994. Published September 1995.

Originally published as D 5497 – 94. Last previous edition D 5497 – 94b.

Annual Book of ASTM Standards, Vol 08.01. FIG. 5 Toggle

Annual Book of ASTM Standards, Vol 07.01. Staple Attached Buttons

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5497

laundering, n—a process used to refurbish a textile product or

parts thereof by (1) cleaning it in water containing a cleaning

agent, and possibly bleach, (2) drying it, and (3) usually

ironing or pressing it.

launderability, n—the ability of a button to undergo multiple

cycles of laundering without damage such as cracks or loss

of finish.

FIG. 6 Ring

ligne, n—a unit of measure for buttons; one ligne equals 0.635

Staple Attached Buttons

mm (0.025 in.).

luster, n—in buttons, the degree of brilliance exhibited in

pearlized or pearl buttons.

metal cast button, n—a button produced by the casting of

molten metals and metal alloys into single-cavity or

multiple-cavity molds.

DISCUSSION—Cast metal buttons can be electroplated and treated to

produce other finishes.

orientation, n—in buttons, the degree of order and spatial

alignment of pearlescent pigment crystals internally or in a

coating.

pearlized, n—in buttons, the addition of synthetic or natural

pearlescentpigmentstothebuttonresinformulationortothe

formulation used for coating.

DISCUSSION—Buttons exhibiting a pearl-like luster are made in either

FIG. 7 Sew-Through Flange Button

of two ways: 1) by incorporating pearlescent pigments into the resin

formulation prior to casting or molding the button, or 2) by applying to

thebuttonanexternalcoatingcontainingpearlescentpigmentseitherby

spraying or dipping.

ring, n—in buttons, a split ring used to fasten a staple attached

button to the substrate.

rod cast button, n—a button fabricated from a disk sliced or

sawed from a cast rod of formulated styrene-modified

polyester resin.

DISCUSSION—Formulated styrene-modified polyester resin is cast into

aluminum or glass tubes which are sealed at one end. The flaccid or

rigid rod formed after gelation is removed from the tube and sliced or

sawed into button blanks. The blanks are then fully polymerized

FIG. 8 Sew-Through Shank

(cured) in hot brine solution and fabricated into buttons.This method is

used for buttons which are mottled, and multicolored.

DISCUSSION—in buttons, plastics such as polyester, acetate, ABS,

melamine, and urea formaldehyde are the materials usually electro-

rotation cast button, n

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.