ASTM D6523-00(2009)

(Guide)Standard Guide for Evaluation and Selection of Alternative Daily Covers (ADCs) for Sanitary Landfills

Standard Guide for Evaluation and Selection of Alternative Daily Covers (ADCs) for Sanitary Landfills

SIGNIFICANCE AND USE

This guide provides information which the regulator/permit officials, engineers, waste disposal operators, and others will find helpful to (1) understand and distinguish between the many choices available; (2) understand the performance feature considerations for living up to EPA regulations for landfill daily covers, and (3) understand the various requirements and differences for putting these covers into practice at landfills.

SCOPE

1.1 This guide is intended to assist specifiers and end users in assessing the different options available for sanitary landfill daily cover materials described as alternative (non-soil) daily covers (ADCs). Traditional daily cover consists of at least 6 in. of soil spread over the working faces of sanitary landfills. Alternative systems are attractive to landfill operations in order to conserve landfill disposal space, among other reasons.

1.2 This guide assists in understanding different performance features of broad classifications of ADCs, and determining the extent and degree to which different ADCs are able to “control disease vectors, fires, odors, blowing litter, and scavenging, without presenting a threat to human health and the environment,” as intended by United States Environmental Protection Agency (USEPA) regulations.

1.3 This guide is not intended to provide cost information regarding the various ADCs as a standard guide, it does not dictate a protocol for the practice and testing of ADCs, but rather provides valuable information, guidance, and recommendations to interested parties concerning the many options available.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6523 −00(Reapproved 2009)

Standard Guide for

Evaluation and Selection of Alternative Daily Covers (ADCs)

for Sanitary Landfills

This standard is issued under the fixed designation D6523; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Requirements, 40 CFR 258 21, Nov 1993

“The Use of Alternative Materials for Daily Cover at

1.1 This guide is intended to assist specifiers and end users

Municipal Solid Waste Landfills” EPA 600/R-93/172 PB

in assessing the different options available for sanitary landfill

92-227197 July 1993

daily cover materials described as alternative (non-soil) daily

Alternative Daily Cover Regulations, California Environ-

covers (ADCs).Traditional daily cover consists of at least 6 in.

mental Protection Agency, Title 27, Division 2, Subdivi-

of soil spread over the working faces of sanitary landfills.

sion 1, Chapter 3, Subchapter 4, Article 2, Section 20680

Alternative systems are attractive to landfill operations in order

CIWMB Daily Cover and Section 20690 CIWMB Alter-

to conserve landfill disposal space, among other reasons.

native Daily Cover

1.2 This guide assists in understanding different perfor-

mance features of broad classifications of ADCs, and deter-

3. Terminology

mining the extent and degree to which differentADCs are able

3.1 alternative daily cover, n—an alternative to the tradi-

to “control disease vectors, fires, odors, blowing litter, and

tional 6-in. (15-cm) soil cover required by the USEPA for

scavenging, without presenting a threat to human health and

landfill working faces to “control disease vectors, fires, odors,

the environment,” as intended by United States Environmental

blowing litter, and scavenging, without presenting a threat to

Protection Agency (USEPA) regulations.

human health and the environment.”

1.3 This guide is not intended to provide cost information

3.2 foam, n—a synthetic material sprayed and combined

regarding the various ADCs as a standard guide, it does not

with air to form closed-cell air pockets.

dictate a protocol for the practice and testing of ADCs, but

3.3 geosynthetic, n—a planar product manufactured from

rather provides valuable information, guidance, and recom-

polymeric material used with soil, rock, earth, or other geo-

mendations to interested parties concerning the many options

technical engineering related material as an integral part of a

available.

man-made project, structure, or system.

2. Referenced Documents

3.4 indigenous, adj—native to a particular region.

2.1 ASTM Standards:

3.5 leachate, n—contaminated water resulting from the

D4982 Test Methods for Flammability Potential Screening

combination of waste with precipitation.

Analysis of Waste

3.6 nonreusable, adj—in geosynthetics, a fabric or film

E96/E96M Test Methods for Water Vapor Transmission of

intended to be placed once and then disposed of, discarded, or

Materials

3 left in place.

2.2 Other Standards

3.7 reusable, adj—in geosynthetics, a fabric or membrane

Solid Waste Disposal Facility Criteria, USEPA, Technical

material intended to be retrieved and installed more than once

Manual EPA 530-R-93-017, Cover Material

to perform the cover function.

This guide is under the jurisdiction ofASTM Committee D35 on Geosynthetics 3.8 sanitary landfill, n—a regulated disposal site for the

and is the direct responsibility of Subcommittee D35.03 on Permeability and

deposition of commercial and household wastes.

Filtration

3.9 working face, n—the area of a landfill in which waste is

Current edition approved Nov. 1, 2009. Published December 2009. Originally

approved in 2000. Last previous edition approved in 2005 as D6523–00(2005).

actively being deposited.

DOI: 10.1520/D6523-00R09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4. Significance and Use

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

4.1 This guide provides information which the regulator/

the ASTM website.

3 permit officials, engineers, waste disposal operators, and others

Available from the Superintendent of Documents, US Government Printing

Office, Washington, DC 20402. will find helpful to (1) understand and distinguish between the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6523−00 (2009)

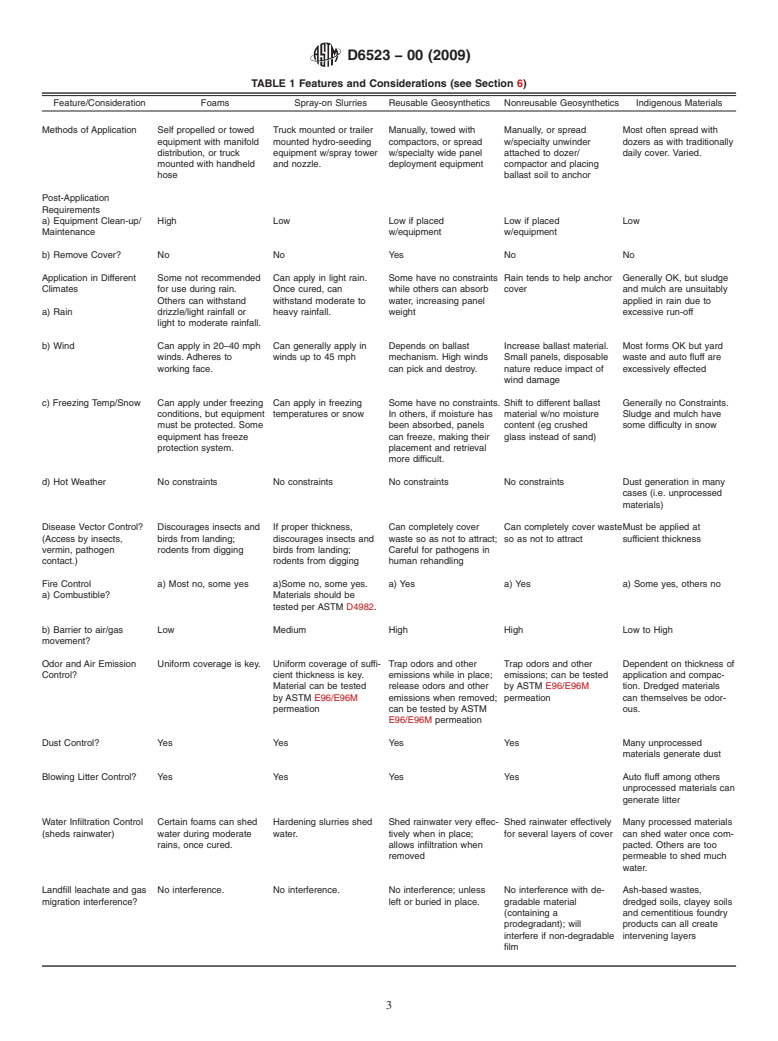

many choices available; (2) understand the performance fea- 6. Features and Considerations (see Table 1)

ture considerations for living up to EPAregulations for landfill

6.1 Summary—See discussion for clarification.

daily covers, and (3) understand the various requirements and

6.2 Discussion:

differences for putting these covers into practice at landfills.

6.2.1 Methods of Application:

5. Classifications of ADCs

6.2.1.1 Manifold-equipped units apply foam as equipment

traverses the working face. Self-propelled units with manifold

5.1 Foams—FoamADCs are applied to the working face of

applicator applies foam as the unit backs down the working

sanitary landfills using foam generation and application equip-

face. Handheld hose-equipped units apply foam as the crew

ment specifically designed for that particular foam. Both

walks next to or across the working face, or both.

hardening and non-hardening foams are currently available.

6.2.1.2 Most slurries use truck-mounted or trailer-mounted

These foam layers are effectively broken-up by the placement

standard hydro-seeding equipment with little or no modifica-

of additional wastes on the next operating day, and therefore

tion. It is applied through the spray tower located on the

does not interfere with fluid movement.

platform of the hydro-seeding equipment using appropriate

5.2 Spray-On Slurries—Most slurries are paper-based. The

nozzles. The use of a hand-held hose may be suitable for

paper-based slurry ADCs are applied to the working face of

certain applications. In at least one case, a specially designed

sanitary landfills using standard hydro-seeding equipment.

storage unit and mobile applicator is required by the manufac-

Certain types of slurries may require some modification of the

turer. Care must be taken to avoid skimping on the thickness of

hydro-seedingequipment.Theslurriesareallowedtohardento

application.

form a crust or shell over the working face. This covering is

6.2.1.3 At some sites, ancillary equipment (for example,

also broken-up by the placement of additional wastes on the

tow bar, lifting bar, reel, or rollers) are used to facilitate

next operating day.

placement of geosynthetic panels (both reusable and nonreus-

5.3 Geosynthetics:

able) and reduce wear and tear. Tires, sandbags, or ballast soil

5.3.1 Reusable—Reusable geosynthetic ADCs consist of

are placed along the edges to anchor the panels.

various types of fabric or plastic membranes that have either

6.2.1.4 The preparation of the working face prior to place-

been developed or adapted for use as a daily cover material.

ment of a geosynthetic panel and the care taken in placement

Panels fabricated from these materials are placed over the

of the panel can have a significant impact on the effective life

working face at the end of the day, and retrieved prior to the

of a panel. Consequently, operators should ensure that the

start of the next operating day. Some landfills use special

working face is properly compacted to provide a smooth

mechanized equipment to facilitate the placement and retrieval

surface, and that protruding objects which could damage

of panels.

panels are eliminated. In addition, during placement of panels,

5.3.2 Nonreusable—Nonreusable geosynthetic ADCs con-

measures should be taken to prevent unnecessary stress on the

sist of less durable disposable films or fabrics, intended to be

material and minimize snagging while dragging the panel

left in place without retrieval. Special equipment also exists to

across the working face.

facilitate the placement and anchoring of these materials to

6.2.1.5 Most indigenous materials may be spread and com-

cover the working face of landfills. The cover may contain

pacted in the same manner as traditional sands and gravels.

pro-degradant additives to accelerate degradation within the

Dozers and front-end loaders are usually used to spread the

waste to cease the interception of fluids.

material. Compaction can be accomplished with single-drum

rollers, dozer tracks, or loader tires, or combination thereof.

5.4 Indigenous Materials—Indigenous ADCs consist of

6.2.2 Post-Application Requirements :

various types of locally available waste products for disposal

6.2.2.1 When equipment is used to apply ADCs there is

(for example, sludges, ash, shredded tires, shredded green

clean-upandmaintenance.Cleanupoftentakesplacebyhosing

waste, pulverized construction and demolition debris, automo-

with water or compressed air, or both.

bile recycling fluff, foundry sand, and so forth) placed onto the

workingfaceoflandfillsinamannersimilartosoilcover.They 6.2.2.2 ManyADCs have no other post-application require-

ments but are simply broken up by the placement of wastes on

often require physical or chemical modification for consistency

subsequent days.

and workability, and evaluation for the presence of potentially

hazardousconstituents.Processedindigenousmaterialssuchas 6.2.2.3 Reusable geosynthetic panels are normally removed

treated sludges and asphalt-stabilized soils are available from from the working face prior to the start of the next operating

manufacturers who are able to provide such products with day. Hence, the necessary personnel and equipment have to be

consistent properties. Manufacturers should have the necessary available, and sufficient time allowed, for this activity to be

supporting data available for review. Unprocessed ADCs can performed prior to the arrival and disposal of waste at the

vary significantly with respect to physical and chemical char- working face. This may require modification of the work

acteristics and composition, depending on the particular schedule for site personnel. Furthermore, depending on the

season of the year and operating hours at the site, panel

source. In addition, suitability and acceptability are dependent

on site-specific climatic and operational conditions and regu- retrieval may have to be performed while it is still dark,

requiring extra precaution against accidents or injury.

latory requirements. Because of the wide variety of processed

and unprocessed indigenous materials, only key factors and 6.2.2.4 Retrieval of geosynthetic panels is accomplished by

considerations related to the use and performance of these reversal of the procedures used to place them. Anchoring

materials can hereby be presented. materials are first removed and stockpiled near the working

D6523−00 (2009)

TABLE 1 Features and Considerations (see Section 6)

Feature/Consideration Foams Spray-on Slurries Reusable Geosynthetics Nonreusable Geosynthetics Indigenous Materials

Methods of Application Self propelled or towed Truck mounted or trailer Manually, towed with Manually, or spread Most often spread with

equipment with manifold mounted hydro-seeding compactors, or spread w/specialty unwinder dozers as with traditionally

distribution, or truck equipment w/spray tower w/specialty wide panel attached to dozer/ daily cover. Varied.

mounted with handheld and nozzle. deployment equipment compactor and placing

hose ballast soil to anchor

Post-Application

Requirements

a) Equipment Clean-up/ High Low Low if placed Low if placed Low

Maintenance w/equipment w/equipment

b) Remove Cover? No No Yes No No

Application in Different Some not recommended Can apply in light rain. Some have no constraints Rain tends to help anchor Generally OK, but sludge

Climates for use during rain. Once cured, can while others can absorb cover and mulch are unsuitably

Others can withstand withstand moderate to water, increasing panel applied in rain due to

a) Rain drizzle/light rainfall or heavy rainfall. weight excessive run-off

light to moderate rainfall.

b) Wind Can apply in 20–40 mph Can generally apply in Depends on ballast Increase ballast material. Most forms OK but yard

winds. Adheres to winds up to 45 mph mechanism. High winds Small panels, disposable waste and auto fluff are

working face. can pick and destroy. nature reduce impact of excessively effected

wind damage

c) Freezing Temp/Snow Can apply under freezing Can apply in freezing Some have no constraints. Shift to different ballast Generally no Constraints.

conditions, but equipment temperatures or snow In others, if moisture has material w/no moisture Sludge and mulch have

must be protected. Some been absorbed, panels content (eg crushed some difficulty in snow

equipment has freeze can freeze, making their glass instead of sand)

protection system. placement and retrieval

more difficult.

d) Hot Weather No constraints No constraints No constraints No constraints Dust generation in many

cases (i.e. unprocessed

materials)

Disease Vector Control? Discourages insects and If proper thickness, Can completely cover Can completely cover wasteMust be applied at

(Access by insects, birds from landing; discourages insects and waste so as not to attract; so as not to attract sufficient thickness

vermin, pathogen rodents from digging birds from landing; Careful for pathogens in

contact.) rodents from digging human rehandling

Fire Control a) Most no, some yes a)Some no, some yes. a) Yes a) Yes a) Some yes, others no

a) Combustible? Materials should be

tested per ASTM D4982.

b) Barrier to air/gas Low Medium High High Low to High

movement?

Odor and Air Emission Uniform coverage is key. Uniform coverage of suffi- Trap odors and other Trap odors and other Dependent on thickness of

Control? cient thickness is key. emissions while in place; emissions; can be tested application and compac-

Material can be tested release odors and other by ASTM E96/E96M tion. Dredged materials

by ASTM E96/E96M emissions when removed; permeation can themselves be odor-

permeation can be tested by ASTM ous.

E96/E96M permeation

Dust Control? Yes Yes Yes Yes Many unprocessed

materials generate dust

Blowing Litter Control? Yes Yes Yes Yes Auto fluff among others

unprocessed materials can

generate litter

Water Infiltration Control Certain foams can shed Hardening slurries shed Shed rainwater very effec- Shed rainwater effectively Many processed materials

(sheds rainwater) water during moderate water. tively when in place; for several layers of cover can

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.