ASTM D70-97

(Test Method)Standard Test Method for Specific Gravity and Density of Semi-Solid Bituminous Materials (Pycnometer Method)

Standard Test Method for Specific Gravity and Density of Semi-Solid Bituminous Materials (Pycnometer Method)

SCOPE

1.1 This test method covers the determination of the specific gravity and density of semi-solid bituminous materials, asphalt cements, and soft tar pitches by use of a pycnometer.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 70 – 97

Standard Test Method for

Density of Semi-Solid Bituminous Materials (Pycnometer

Method)

This standard is issued under the fixed designation D 70; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.2 relative density—the ratio of the mass of a given

volume of a material to the mass of the same volume of water

1.1 This test method covers the determination of the specific

at the same temperature (see Note 2).

gravity and density of semi-solid bituminous materials, asphalt

cements, and soft tar pitches by use of a pycnometer.

NOTE 2—Relative density is also described as specific gravity.

NOTE 1—An alternate method for determining the density of semi-solid

4. Summary of Test Method

and solid bituminous materials is Test Method D 3289. For materials

4.1 The sample is placed in a calibrated pycnometer. The

which are too fluid for use of this test method, use Test Method D 3142.

pycnometer and sample are weighed, then the remaining

1.2 The values in SI units are to be regarded as the standard.

volume is filled with water. The filled pycnometer is brought to

1.3 This standard does not purport to address the safety

the test temperature, and weighed. The density of the sample is

concerns, if any, associated with its use. It is the responsibility

calculated from its mass and the mass of water displaced by the

of the user of this standard to establish appropriate safety and

sample in the filled pycnometer.

health practices and determine the applicability of regulatory

limitations prior to use.

5. Significance and Use

5.1 Values of density are used for converting volumes to

2. Referenced Documents

units of mass, and for correcting measured volumes from the

2.1 ASTM Standards:

temperature of measurement to a standard temperature using

C 670 Practice for Preparing Precision and Bias Statements

Practice D 4311.

for Test Methods for Construction Materials

D 140 Practice for Sampling Bituminous Materials

6. Apparatus

D 3142 Test Method for Density of Liquid Asphalts (Hy-

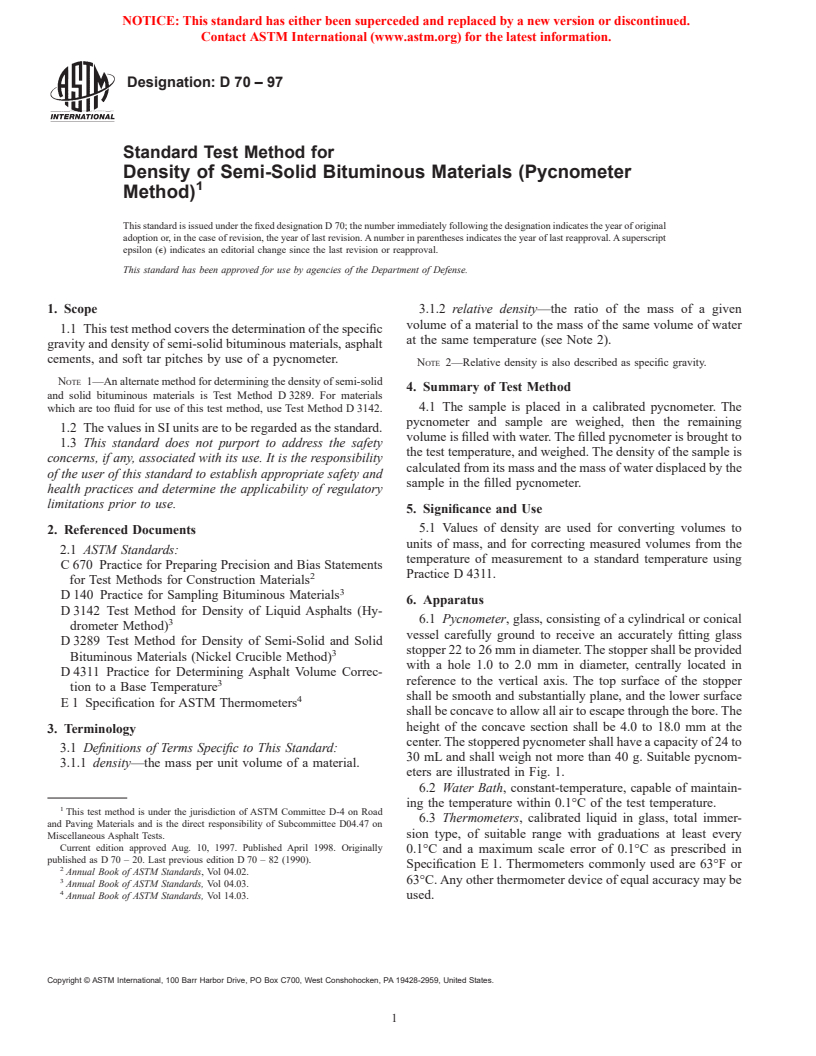

6.1 Pycnometer, glass, consisting of a cylindrical or conical

drometer Method)

vessel carefully ground to receive an accurately fitting glass

D 3289 Test Method for Density of Semi-Solid and Solid

stopper 22 to 26 mm in diameter. The stopper shall be provided

Bituminous Materials (Nickel Crucible Method)

with a hole 1.0 to 2.0 mm in diameter, centrally located in

D 4311 Practice for Determining Asphalt Volume Correc-

reference to the vertical axis. The top surface of the stopper

tion to a Base Temperature

shall be smooth and substantially plane, and the lower surface

E 1 Specification for ASTM Thermometers

shall be concave to allow all air to escape through the bore. The

height of the concave section shall be 4.0 to 18.0 mm at the

3. Terminology

center. The stoppered pycnometer shall have a capacity of 24 to

3.1 Definitions of Terms Specific to This Standard:

30 mL and shall weigh not more than 40 g. Suitable pycnom-

3.1.1 density—the mass per unit volume of a material.

eters are illustrated in Fig. 1.

6.2 Water Bath, constant-temperature, capable of maintain-

ing the temperature within 0.1°C of the test temperature.

This test method is under the jurisdiction of ASTM Committee D-4 on Road

6.3 Thermometers, calibrated liquid in glass, total immer-

and Paving Materials and is the direct responsibility of Subcommittee D04.47 on

sion type, of suitable range with graduations at least every

Miscellaneous Asphalt Tests.

Current edition approved Aug. 10, 1997. Published April 1998. Originally

0.1°C and a maximum scale error of 0.1°C as prescribed in

published as D 70 – 20. Last previous edition D 70 – 82 (1990).

Specification E 1. Thermometers commonly used are 63°F or

Annual Book of ASTM Standards, Vol 04.02.

3 63°C. Any other thermometer device of equal accuracy may be

Annual Book of ASTM Standards, Vol 04.03.

Annual Book of ASTM Standards, Vol 14.03. used.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D70–97

FIG. 1 Suitable Pycnometers and Stopper

the pycnometer during weighing, quickly redry the outside of the

7. Materials

pycnometer (excluding the top) before recording the mass.

7.1 Water—Freshly boiled and cooled distilled or deionized

water.

11. Procedure

11.1 Preparation of Sample—Heat the sample with care,

8. Sampling

stirring to prevent local overheating, until the sample has

8.1 Take samples in accordance with Practice D 140. The

become sufficiently fluid to pour. In no case should the

sample shall be free of foreign substances.

temperature be raised to more than 56°C above the expected

8.2 Thoroughly mix the sample before removing a repre-

softening point for tar, or to more than 110°C above the

sentative portion for testing.

expected softening point for asphalt. Do not heat for more than

30 min, and avoid incorporating air bubbles into the sample.

9. Preparation of Apparatus

11.2 Pour enough sample into the clean, dry, warmed

9.1 Partially fill a 600-mL Griffin low-form beaker with

pycnometer to fill it about three fourths of its capacity. Take

freshly boiled and cooled distilled or deionized water to a level

precautions to keep the material from touching the sides of the

that will allow the top of the pycnometer to be immersed to a

pycnometer above the final level and prevent the inclusion of

depth of not less than 40 mm.

air bubbles (Note 5). Allow the pycnometer and its contents to

9.2 Partially immerse the beaker in the water bath to a depth

cool to ambient temperature for a period of not less than 40 min

sufficient to allow the bottom of the beake

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.