ASTM D5458-95

(Test Method)Standard Test Method for Peel Cling of Stretch Wrap Film

Standard Test Method for Peel Cling of Stretch Wrap Film

SCOPE

1.1 This test method measures cling between two layers of film, in both a stretched and unstretched condition.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5458 – 95

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

1

Peel Cling of Stretch Wrap Film

This standard is issued under the fixed designation D 5458; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope wrap after a load is stretch wrapped.

1.1 This test method measures cling between two layers of

6. Equipment and Preparation

film, in both a stretched and unstretched condition.

6.1 Apparatus—A universal testing machine with a constant

1.2 This standard does not purport to address all of the

rate of grip separation equipped, as follows:

safety concerns, if any, associated with its use. It is the

6.1.1 One lightweight jaw equipped with 1 by 1.5 in. (25 by

responsibility of the user of this standard to establish appro-

38 mm) flat rubber-faced grips,

priate safety and health practices and determine the applica-

6.1.2 Cling attachment (see Figs. 1-5),

bility of regulatory limitations prior to use.

6.1.3 Cling clamp (see Fig. 6),

2. Referenced Documents

6.1.4 Load cell, 500-g load capacity,

2.1 ASTM Standards:

6.1.5 If using pneumatic grips, air supply, 60 to 70 psi with

D 996 Terminology Relating to Packaging and Distribution

appropriate filter,

2

Environments

6.1.6 Sample template, picture-frame style with inside di-

3

D 1898 Practice for Sampling of Plastics

mensions of 5 by 20 in. (125 by 500 mm),

D 4332 Practice for Conditioning Containers, Packages, or

6.1.7 Precision sample cutter, 1 6 0.001 in. (25.4 mm 6

2

Packaging Components for Testing

0.03 mm) width, with precision of 1 6 0.001 in. (25.4 6 0.03

5

E 122 Practice for Choice of Sample Size to Estimate the

mm),

4

Average Quality of a Lot or Process

6.1.8 Single-edged safety razor blade,

E 691 Practices for Conducting an Interlaboratory Study to

6.1.9 Synthetic bristle paint brush, 2 in. (50 mm) wide,

4

Determine the Precision of a Test Method

6.1.10 Ruler, 12 in. (approximately 300 mm),

6.1.11 Separation paper, 8.5 by 12 in. (approximately 125

3. Terminology

by 280 mm) bond,

3.1 Definitions—General definitions for packaging and dis-

6.1.12 String, 24 in. (approximately 610 mm) nonelastic,

tribution environments are found in Terminology D 996.

such as dental floss or fishing line,

3.2 Definitions of Terms Specific to This Standard:

6.1.13 Steel rod, approximately 0.25 in. (6 mm) in diameter

3.2.1 cling—the property of a material’s ability to adhere to

and 10 in. (255 mm) long.

itself.

6.1.14 Cutting surface, approximately 36 by 36 in. (approxi-

3.2.2 stretch wrap material—a material used for over-

mately 900 by 900 mm) plate glass, 0.25 in. (6 mm) thick.

wrapping which, when applied under tension, elongates, and

6.2 Preparation of Apparatus:

through elastic recovery, conforms to the item(s) packaged.

6.2.1 Install the load cell on the upper set frame and allow

15-min warm-up period.

4. Summary of Test Method

6.2.2 Install the upper lightweight jaw.

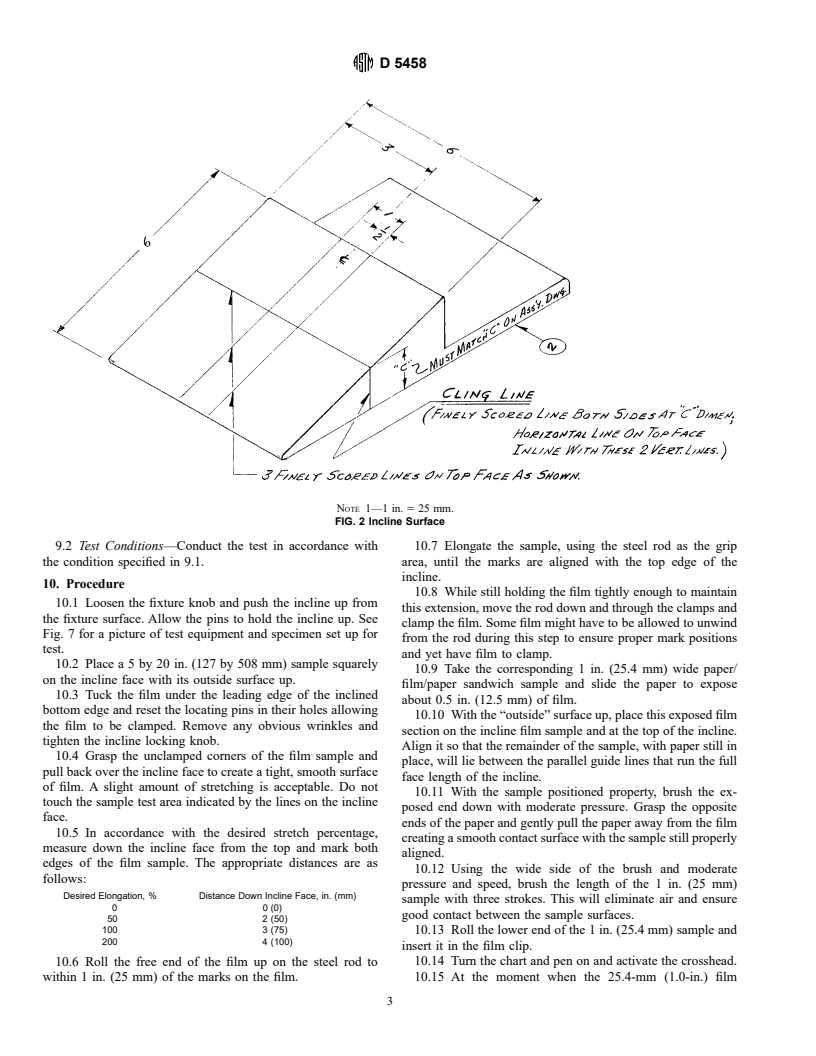

4.1 This test method is a peel cling procedure. A1 in. (25

6.2.3 Remove the lower jaw and install the cling attach-

mm) wide film strip is adhered to a flat film attached to an

ment, using the locking pin to secure.

inclined surface. The force required to remove the film strip

6.2.4 Feed the end of the string not fastened to the clamp

from the flat film is measured.

through the pulley on the cling attachment and place in the

5. Significance and Use

center of the upper jaw.

6.2.5 With the clamp resting at the base of the incline

5.1 Cling is of critical importance in maintaining a tight

(which is in position on the base plate), adjust the crosshead, or

the amount of string pulled through the grips, or both in

1

This test method is under the jurisdiction of ASTM Committee D-10 on

combination, to achieve a distance of 5 by 7 in. (125 by 180

Packaging and is the direct responsibility of Subcommittee D10.25 on Palletizing

and Unitizing of Loads.

mm) between the top of the pulley and the bottom of the grips.

Current edition approved July 15, 1995. Published September 1995. Originally

published as D 5458 – 94. Last previous edition D 5458 – 94.

2

Annual Book of ASTM Standards, Vol 15.09.

3 5

Annual Book of ASTM Standards, Vol 08.02. JDC-1-10 Cutter is available from Thwing-Albert Instrument Co., 10960

4

Annual Book of ASTM Standards, Vol 14.02. Dutton Rd., Philadelphia, PA 19154 or other manufacturers.

1

---------------------- Page: 1 ----------------------

D 5458

NOTE 1—1 in. 5 25 mm.

FIG. 1 Overall Fixture

Tighten the upper jaw. Adjust the crosshead return stop as

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.