ASTM B836-00(2021)

(Specification)Standard Specification for Compact Round Stranded Aluminum Conductors Using Single Input Wire Construction

Standard Specification for Compact Round Stranded Aluminum Conductors Using Single Input Wire Construction

ABSTRACT

This specification covers compact round stranded aluminium conductors using single input wire construction. Joints may be made in any of the wires of any stranding by electric-butt welding, cold-pressure welding, or electric-butt, cold-upset welding. No joint or splice shall be made in a stranded conductor as a whole. The rated-strength and breaking-strength requirements of conductor are presented in details. Tests for the mechanical and electrical properties of wire composing the conductor shall be made before, but not after, stranding unless otherwise agreed upon by the manufacturer and the purchaser as provided by the reference materials.

SCOPE

1.1 This specification covers aluminum/single input wire (SIW) stranded conductors made from round or shaped wires for use in covered or insulated electrical wires or cables. These conductors shall be composed of one or more roller or die compacted layers of helically applied wires (Explanatory Note 1, Explanatory Note 2, and Explanatory Note 3).

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.2.1 For density, resistivity, and temperature, the values stated in SI units are to be regarded as standard.

Note 1: The aluminum and temper designations conform to ANSI H35.1. Aluminum 1350 and Aluminum-Alloy 8XXX correspond to Unified Numbering System A91350 and A98XXX, in accordance with Practice E527.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B836 −00 (Reapproved 2021)

Standard Specification for

Compact Round Stranded Aluminum Conductors Using

Single Input Wire Construction

This standard is issued under the fixed designation B836; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ASTM Standards:

B230/B230M Specification for Aluminum 1350–H19 Wire

1.1 This specification covers aluminum/single input wire

for Electrical Purposes

(SIW) stranded conductors made from round or shaped wires

B263 Test Method for Determination of Cross-Sectional

for use in covered or insulated electrical wires or cables.These

Area of Stranded Conductors

conductors shall be composed of one or more roller or die

B354 Terminology Relating to Uninsulated Metallic Electri-

compacted layers of helically applied wires (Explanatory Note

cal Conductors

1, Explanatory Note 2, and Explanatory Note 3).

B400 Specification for Compact Round Concentric-Lay-

Stranded Aluminum 1350 Conductors

1.2 The values stated in inch-pound units are to be regarded

B609/B609M Specification for Aluminum 1350 Round

as standard. The values given in parentheses are mathematical

Wire, Annealed and Intermediate Tempers, for Electrical

conversions to SI units that are provided for information only

Purposes

and are not considered standard.

B800 Specification for 8000 Series Aluminum Alloy Wire

1.2.1 For density, resistivity, and temperature, the values

for Electrical Purposes—Annealed and IntermediateTem-

stated in SI units are to be regarded as standard.

pers

NOTE 1—The aluminum and temper designations conform to ANSI

B801 SpecificationforConcentric-Lay-StrandedConductors

H35.1. Aluminum 1350 and Aluminum-Alloy 8XXX correspond to

of 8000 SeriesAluminumAlloy for Subsequent Covering

Unified Numbering System A91350 and A98XXX, in accordance with

or Insulation

Practice E527.

B830 Specification for Uniform Test Methods and Fre-

1.3 This standard does not purport to address all of the

quency

safety concerns, if any, associated with its use. It is the

E29 Practice for Using Significant Digits in Test Data to

responsibility of the user of this standard to establish appro-

Determine Conformance with Specifications

priate safety, health, and environmental practices and deter-

E527 Practice for Numbering Metals and Alloys in the

mine the applicability of regulatory limitations prior to use.

Unified Numbering System (UNS)

1.4 This international standard was developed in accor-

2.3 ANSI Standard:

dance with internationally recognized principles on standard-

ANSI H35.1 Alloy and Temper Designation Systems for

ization established in the Decision on Principles for the

Aluminum

Development of International Standards, Guides and Recom-

2.4 NIST Standard:

mendations issued by the World Trade Organization Technical

Handbook 100 Copper Wire Tables NBS

Barriers to Trade (TBT) Committee.

3. Classification

2. Referenced Documents

3.1 The conductors described in this specification are in-

2.1 The following documents of the issue in effect on date tendedforsubsequentinsulationorcovering.Theclassification

of these conductors is SIW Compact.

of material purchase form a part of this specification to the

extent referenced herein.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This specification is under the jurisdiction of ASTM Committee B01 on Standards volume information, refer to the standard’s Document Summary page on

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on the ASTM website.

Conductors of Light Metals. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Current edition approved Feb. 1, 2021. Published February 2021. Originally 4th Floor, New York, NY 10036, http://www.ansi.org.

approved in 1993. Last previous edition approved in 2015 as B836 – 00 (2015). Available from National Institute of Standards and Technology (NIST), 100

DOI: 10.1520/B0836-00R21. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B836 − 00 (2021)

4. Ordering Information 7. Construction

4.1 Orders for material in accordance with this specification 7.1 The construction of the conductors shall be as given in

shall include the following information: Table 1.

4.1.1 Quantity of each size and class (Table 1);

7.2 Wire used in the fabrication of conductors shall be of

4.1.2 Conductor size, circular-mil area orAWG (Section 7);

such dimensions as to produce a finished conductor as pre-

4.1.3 Temper (Section 12);

scribed in Table 1.

4.1.4 Lay direction, if nonstandard (see 6.2 and 6.3);

4.1.5 Special tension test, if required (see 16.2); 8. Rated Strength of Conductor

4.1.6 Place of inspection (Section 17);

8.1 The rated strength of SIW conductors made from any

4.1.7 Packaging and package marking (Section 18), and

and all alloys and tempers covered in this specification shall be

4.1.8 Material for conductor.

taken as the percentage, indicated in Table 2, of the sum of the

strengthsofthecomponentwires,calculatedonthebasisofthe

5. Joints

equivalent diameter of these wires and the specified minimum

5.1 Joints may be made in any of the wires of any stranding

average tensile strengths given in Specifications B230/B230M,

by electric-butt welding, cold-pressure welding, or electric-

B609/B609M, and B800.

butt, cold-upset welding.

8.2 Rated-strength and breaking-strength values shall be

5.1.1 Joints in the individual wires in a finished conductor

rounded to three significant figures, in the final value only, in

shall not be closer together than 1 ft (0.3 m) for conductors of

accordance with the rounding method of Practice E29.

19 wires or less, or closer than 1 ft (0.3 m) in a layer for

8.3 Rated strengths of conductors are given in Table 3 of

conductors of more than 19 wires.

Specification B400 for conductors made ofAluminum 1350 in

5.2 No joint or splice shall be made in a stranded conductor

all tempers.

as a whole.

8.4 Rated strengths of conductors made from any and all

6. Lay tempers of 8000 series aluminum alloys are given in Table 3 of

Specification B801.

6.1 The length of lay of each layer for SIWconductors shall

not be less than 8 or more than 17.5 times the outside diameter

9. Density

of the finished conductor.

9.1 For the purpose of calculating mass, cross-sections, and

6.2 The direction of lay of the outer layer shall be left-hand

so forth, the density ofAluminum 1350 shall be taken as 2705

and may be reversed or unidirectional in successive layers. 3 3

kg/m (0.0975 lb/in. ) at 20°C, and the density of 8000 series

3 3

6.3 Other lay requirements may be furnished upon special aluminum alloys shall be taken as 2710 kg/m (0.098 lb/in. )

agreement between the manufacturer and the purchaser. at 20°C.

TABLE 1 Construction of Compact Round, Concentric-Lay-Stranded Aluminum Conductors

Nominal Compact Conductor

Minimum Nominal

Conductor Size Nominal dc Resistance at 20°C

Nominal

Diameter

Number of Mass/1000

Mass/km, kg

A

Wires ft, lb

Circular, mils AWG mm in. mm Ω/1000 ft Ω/km

1 000 000 . 507 53 1.060 26.9 937 1394 0.0173 0.0563

900 000 . 456 53 0.999 25.4 844 1257 0.0193 0.0632

800 000 . 405 53 0.938 23.8 750 1116 0.0217 0.0712

750 000 . 380 53 0.908 23.1 703 1046 0.0231 0.0759

700 000 . 355 34 0.877 22.3 656 976 0.0248 0.0813

650 000 . 329 34 0.845 21.5 609 906 0.0267 0.0875

600 000 . 304 34 0.813 20.7 563 838 0.0289 0.0948

550 000 . 279 34 0.775 19.7 516 768 0.0315 0.103

500 000 . 253 30 0.736 18.7 468 696 0.0347 0.114

450 000 . 228 30 0.700 17.8 422 628 0.0385 0.126

400 000 . 203 24 0.659 16.7 375 558 0.0434 0.142

350 000 . 177 24 0.616 15.6 328 488 0.0495 0.162

300 000 . 152 18 0.570 14.5 281 418 0.0578 0.190

250 000 . 127 18 0.520 13.2 234 348 0.0694 0.228

211 600 0000 107 17 0.475 12.1 198 295 0.0820 0.269

167 800 000 85.0 15 0.423 10.7 157 234 0.103 0.338

133 100 00 67.4 12 0.376 9.55 125 186 0.130 0.428

105 600 0 53.5 7 0.336 8.53 98.9 147 0.164 0.539

83 690 1 42.4 7 0.299 7.59 78.4 117 0.207 0.680

66 360 2 33.6 6 0.268 6.81 62.2 92.6 0.261 0.857

52 620 3 26.7 6 0.238 6.05 49.3 73.3 0.330 1.08

41 740 4 21.2 6 0.213 5.41 39.1 58.2 0.416 1.36

26 240 6 13.3 6 0.169 4.29 24.6 36.6 0.661 2.17

16 510 8 8.37 6 0.134 3.40 15.5 23.1 1.05 3.44

A 3

Weights are based on Aluminum 1350 with a density of 0.0975 lb/in.

B836 − 00 (2021)

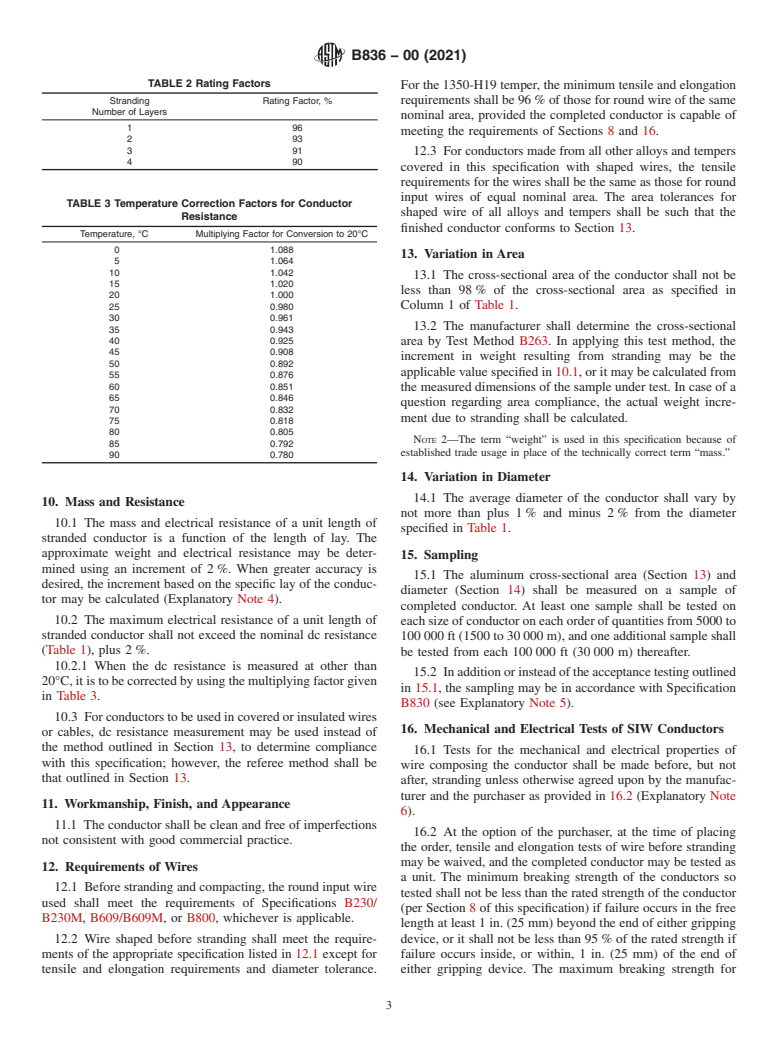

TABLE 2 Rating Factors

For the 1350-H19 temper, the minimum tensile and elongation

Stranding Rating Factor, % requirements shall be 96 % of those for round wire of the same

Number of Layers

nominal area, provided the completed conductor is capable of

meeting the requirements of Sections 8 and 16.

12.3 For conductors made from all other alloys and tempers

covered in this specification with shaped wires, the tensile

requirements for the wires shall be the same as those for round

input wires of equal nominal area. The area tolerances for

TABLE 3 Temperature Correction Factors for Conductor

shaped wire of all alloys and tempers shall be such that the

Resistance

finished conductor conforms to Section 13.

Temperature, °C Multiplying Factor for Conversion to 20°C

0 1.088

13. Variation in Area

5 1.064

10 1.042

13.1 The cross-sectional area of the conductor shall not be

15 1.020

less than 98 % of the cross-sectional area as specified in

20 1.000

25 0.980 Colu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.