ASTM B830-18

(Specification)Standard Specification for Uniform Test Methods and Frequency

Standard Specification for Uniform Test Methods and Frequency

ABSTRACT

This specification covers a standard basis for uniform testing and frequency to determine physical and electrical compliance for aluminum and copper conductors. Diameter, tensile, resistivity and all other material properties shall be tested per specific level and acceptable quality level (AQL) and must meet the corresponding requirements. Any lot of drawing stock/wire that has been sampled and from which the number of specimens failing to comply with the requirements does not equal or exceed the appropriate reject number of the sampling used, shall be considered as complying with requirements of ASTM. Rejected lots may be screened to remove nonconforming production units by testing one specimen form each production unit in the lot for the failing characteristic. Identify and classify product, process, and service characteristics for which statistical techniques will be used as basis for the assurance and control of quality and acceptance or rejection of lots. The process performance index (CPK) shall meet the requirements of the applicable ASTM standard.

SCOPE

1.1 This specification covers a standard basis for uniform testing and frequency to determine physical and electrical compliance for aluminum and copper drawing stock, and aluminum and copper conductors.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.2.1 Exception—Resistivity is measured in SI units.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B830 −18

Standard Specification for

1

Uniform Test Methods and Frequency

This standard is issued under the fixed designation B830; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Success of an Organization—A Quality Management

5

Approach

1.1 This specification covers a standard basis for uniform

ANSI/ASQC S1-2012 AnAttribute Skip-Lot Sampling Pro-

testing and frequency to determine physical and electrical

gram

compliance for aluminum and copper drawing stock, and

ANSI/ASQ Z1.4-2003 (R2013) Sampling Procedures and

aluminum and copper conductors.

Tables for Inspection by Attributes

1.2 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

3. Terminology

conversions to SI units that are provided for information only

3.1 Definitions of Terms Specific to This Standard:

and are not considered standard.

3.1.1 acceptable quality level (AQL)—the maximum per-

1.2.1 Exception—Resistivity is measured in SI units.

cent nonconforming (or the maximum number of nonconfor-

1.3 This international standard was developed in accor-

mities per hundred units) that, for purposes of sampling

dance with internationally recognized principles on standard-

inspection, can be considered as a process average.

ization established in the Decision on Principles for the

3.1.2 average outgoing quality (AOQ)—the average quality

Development of International Standards, Guides and Recom-

ofoutgoingproduct,includingallacceptedlotsorbatches,plus

mendations issued by the World Trade Organization Technical

all lots or batches not accepted after such lots or batches have

Barriers to Trade (TBT) Committee.

been effectively 100 % inspected and all nonconforming units

replaced by conforming units.

2. Referenced Documents

3.1.3 CPK—Process Performance Index.

2.1 Thefollowingdocuments,ofthedateissued,formapart

Discussion:

of this specification to the extent referenced herein.

Capability in Relation to Spec Mean:

2

2.2 ASTM Standards:

USL = 5.0

E29 Practice for Using Significant Digits in Test Data to

LSL = 1.0

Determine Conformance with Specifications

MEAN = 2.0

3

Standard deviation (σ)=0.5

2.3 National Bureau of Standards:

CPK tells the capability of a process based upon the worst case view

NBS Handbook 100 —Copper Wire Tables

of the data.

4

The equation is:

2.4 ANSI Standards:

CPK = the lesser of:

ANSI/ISO/ASQ 9001-2015 Quality Management

USL 2 MEAN MEAN 2 LSL

~ ! ~ !

Systems—Requirements

or (1)

3σ 3σ

ANSI/ISO/ASQ Q9004-2009 Managing for the Sustained

For example:

~5.0 2 2.0! ~2.0 2 1.0!

CPK 5 or (2)

1.5 1.5

1

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductors and is the direct responsibility of Subcommittee B01.02 on

52.0 or 0.67

Methods of Test and Sampling Procedure.

Current edition approved June 15, 2018. Published January 2019. Originally 50.67

approved in 1993. Last previous edition approved in 2011 as B830 – 11. DOI:

A negative value for CPK indicates that the mean is out-

10.1520/B0830-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

side the specification limits. A CPK of zero indicates that the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

mean is equal to one of the specification limits. A CPK be-

Standards volume information, refer to the standard’s Document Summary page on

tween 0 and 1.0 means that part of the 6 sigma limits falls

the ASTM website.

3

Available from National Technical Information Service (NTIS), 5301 Shawnee

Rd., Alexandria, VA 22312, http://www.ntis.gov.

4 5

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., ThisANSIstandardisanidenticaladoptionofISO9001:2015andthetextdoes

4th Floor, New York, NY 10036, http://www.ansi.org. not differ in any way from ISO 9001:2015.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

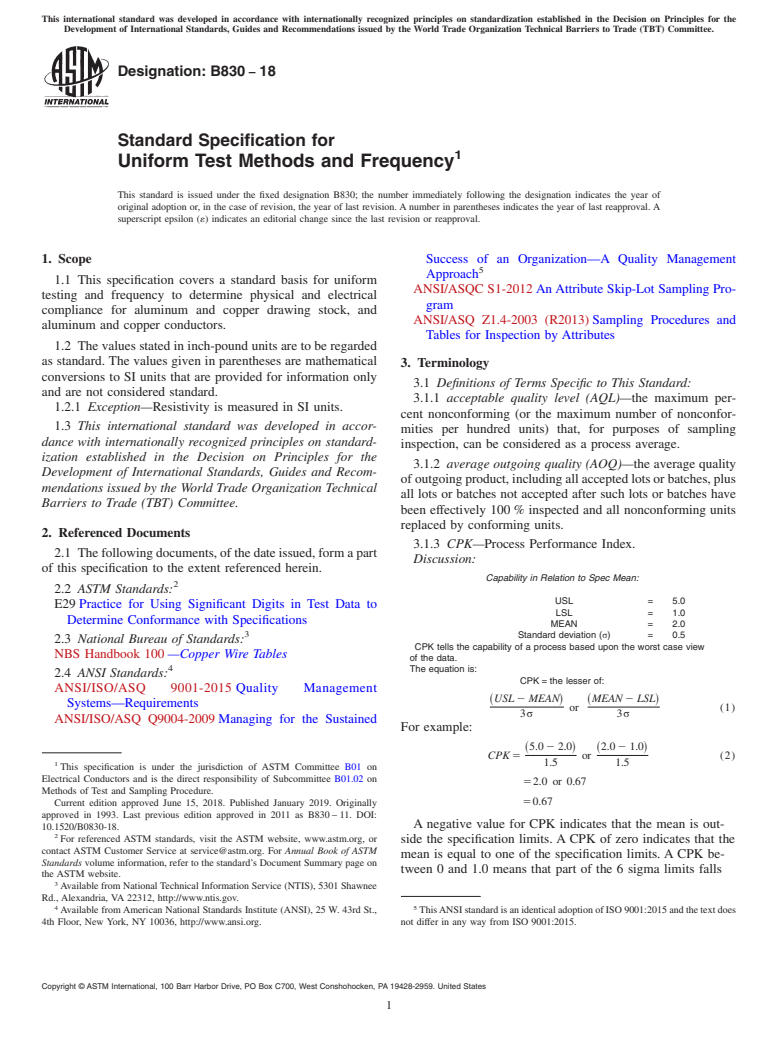

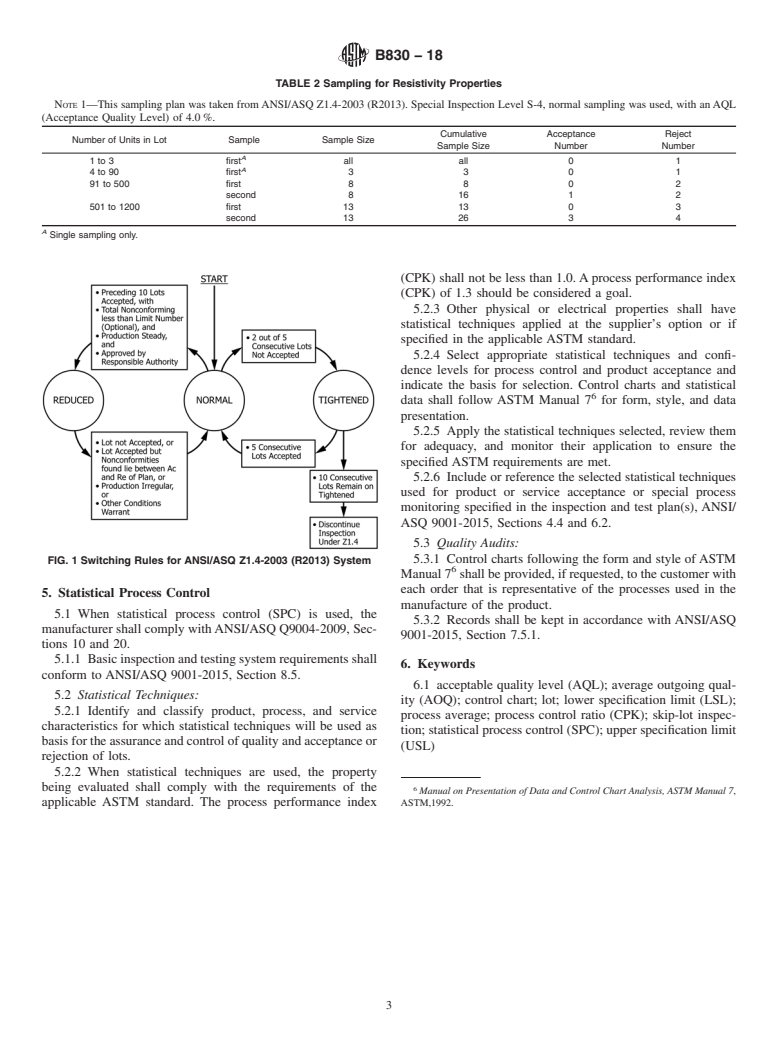

B830−18

outside the specification limits. A CPK of 1.0 means that one 4.1.3 Resistivity shall be tested using Special Inspection

end of the 6 sigma limits falls on a specification limit. A Level S-4 with an AQL of 4.0 %. (See Table 2.)

CPK larger than 1.0 means that the 6 sigma limits fall com-

4.1.4 All other material properties shall be tested per the

pletely within the specification limits. See Explanatory Note

specific level and AQ

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B830 − 11 B830 − 18

Standard Specification for

1

Uniform Test Methods and Frequency

This standard is issued under the fixed designation B830; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers a standard basis for uniform testing and frequency to determine physical and electrical compliance

for aluminum and copper drawing stock, and aluminum and copper conductors.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.2.1 Exception—Resistivity is measured in SI units.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents, of the issue in effect on date of material purchase date issued, form a part of this specification

to the extent referenced herein.

2

2.2 ASTM Standards:

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

3

2.3 National Bureau of Standards:

NBS Handbook 100 Handbook 100, Copper —Copper Wire Tables

4

2.4 Canadian Standards Association:

CAN/CSA-ISO 9001-08 Quality Management Systems – Requirements

CAN/CSA Z299.3-85 (R2006) Quality Assurance Program - Category 3

1

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.02 on Methods of

Test and Sampling Procedure.

Current edition approved Oct. 1, 2011June 15, 2018. Published November 2011January 2019. Originally approved in 1993. Last previous edition approved in 20032011

as B830 – 97B830 – 11. (2003). DOI: 10.1520/B0830-11.10.1520/B0830-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from National Technical Information Service (NTIS), 5301 Shawnee Rd., Alexandria, VA 22312, http://www.ntis.gov.

5

This ANSI standard is an identical adoption of ISO 9001:2015 and the text does not differ in any way from ISO 9001:2015.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B830 − 18

4

2.4 ANSI Standards:

ANSI/ISO/ASQ 9001-2015 3534-1-2006 Statistics-Vocabulary and Symbols Part 1-General Statistical Terms and Terms Used

In Probability Quality Management Systems—Requirements

ANSI/ISO/ASQ 3534-2-2006 Statistics-Vocabulary and Symbols Part 2-Applied Statistics

ANSI/ISO/ASQ Q9001-2008 Quality Management Systems - Requirements

ANSI/ISO/ASQ Q9004-2009 Q9004-1-2009 Managing for the Sustained Success of an Organization – A Organization—A

5

Quality Management Approach

ANSI/ASQC C1-1996 Specification of General Requirements for a Quality Program

ANSI/ASQC S1-1996S1-2012 An Attribute Skip-Lot Sampling Program

ANSI/ASQ Z1.4-2003 (R2013) Z1.4-2008 Sampling Procedures and Tables for Inspection by Attributes

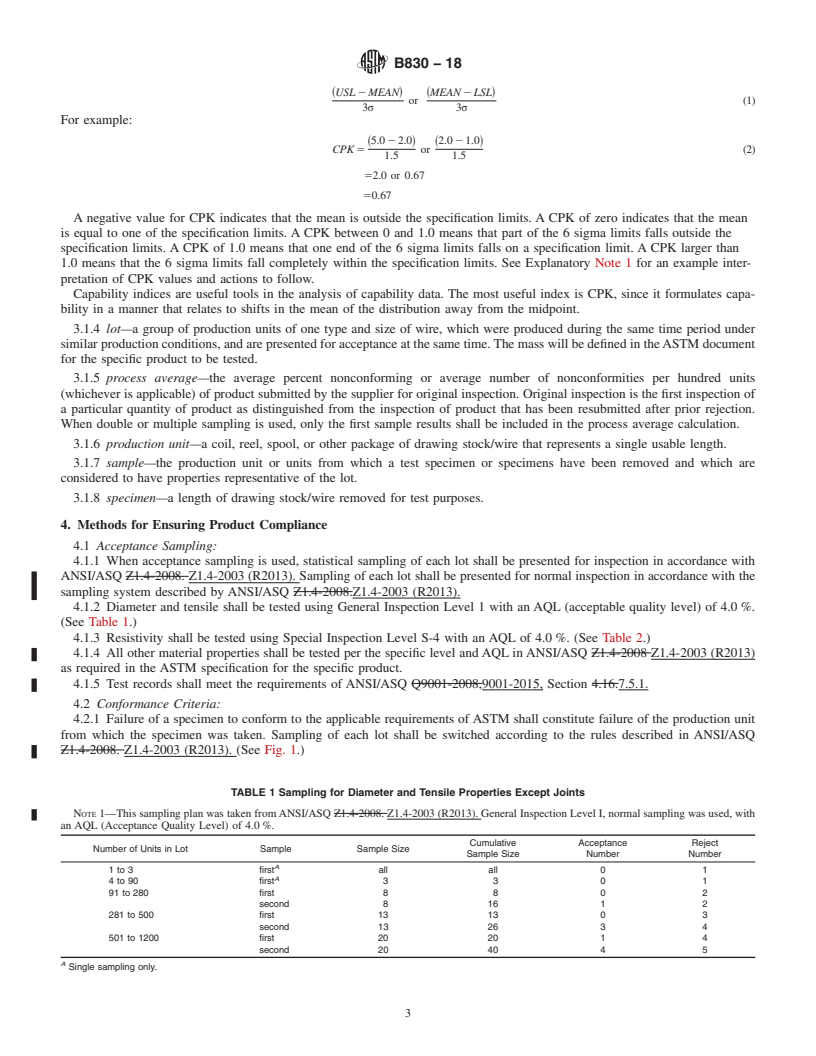

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 acceptable quality level (AQL)—the maximum percent nonconforming (or the maximum number of nonconformities per

hundred units) that, for purposes of sampling inspection, can be considered as a process average.

3.1.2 average outgoing quality (AOQ)—the average quality of outgoing product, including all accepted lots or batches, plus all

lots or batches not accepted after such lots or batches have been effectively 100 % inspected and all nonconforming units replaced

by conforming units.

3.1.3 CPK—Process Performance Index.

Discussion:

Capability in Relation to Spec Mean:

USL = 5.0

LSL = 1.0

MEAN = 2.0

Standard deviation (σ) = 0.5

CPK tells the capability of a process based upon the worst case view of the data.

The equation is:

CPK = the lesser of:

4

Available from Canadian Standards Association (CSA), 5060 Spectrum Way, Missis

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.