ASTM E1501-99e1

(Specification)Standard Specification for Nighttime Photometric Performance of Retroreflective Pedestrian Markings for Visibility Enhancement

Standard Specification for Nighttime Photometric Performance of Retroreflective Pedestrian Markings for Visibility Enhancement

SCOPE

1.1 This specification covers the performance of retroreflective markings to be used on objects worn by pedestrians for the purpose of enhanced conspicuity. It addresses conspicuity from viewpoints around the entire object, and it allows for freedom of design of the markings so long as the minimum requirements are achieved. Objects include but are not limited to jackets, shirts, vests, trousers, socks, backpacks, hats, and footwear. An adjustment for the brightness/luminance ratio as a function of color is also made.

1.2 This specification applies only to nighttime viewing conditions in which the observer is positioned near a source of illumination. The most common example is that of a motor vehicle operator seeing by means of the light from the headlamps of the vehicle.

1.3 This specification describes the minimum retroreflective performance required for a reasonable level of nighttime conspicuity. It does not address potentially diminished performance of retroreflective markings that may be experienced with general storage, use, wear, and care.

1.4 SI (metric) units shall be used in referee decisions under this specification.

1.5 The following safety hazards caveat pertains to specifying materials by this standard specification. Although the markings described in this specification are intended to significantly enhance safety through increased conspicuity under most conditions of illumination and viewing of the type described in 1.2 above, they do not guarantee significantly enhanced conspicuity under all such conditions. Individuals exposed to adverse weather conditions or associated with high levels of vehicular or hazards exposure may require other types or amounts of retroreflective markings. This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: E 1501 – 99

Standard Specification for

Nighttime Photometric Performance of Retroreflective

Pedestrian Markings for Visibility Enhancement

This standard is issued under the fixed designation E 1501; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial changes made throughout in September 2000.

INTRODUCTION

The use of appropriate retroreflective markings can significantly enhance the night visibility and

safety of the user. As the first in a series addressing overall visibility for individual safety, this standard

is intended to establish minimum retroreflective performance requirements and test methods for

retroreflective pedestrian markings.

1. Scope exposed to adverse weather conditions or associated with high

levels of vehicular or hazards exposure may require other types

1.1 This specification covers the performance of retroreflec-

or amounts of retroreflective markings. This standard does not

tive markings to be used on objects worn by pedestrians for the

purport to address all of the safety concerns, if any, associated

purpose of enhanced conspicuity. It addresses conspicuity from

with its use. It is the responsibility of the user of this standard

viewpoints around the entire object, and it allows for freedom

to establish appropriate safety and health practices and

of design of the markings so long as the minimum require-

determine the applicability of regulatory limitations prior to

ments are achieved. Objects include but are not limited to

use.

jackets, shirts, vests, trousers, socks, backpacks, hats, and

footwear. An adjustment for the brightness/luminance ratio as

2. Referenced Documents

a function of color is also made.

2.1 ASTM Standards:

1.2 This specification applies only to nighttime viewing

E 284 Terminology of Appearance

conditions in which the observer is positioned near a source of

E 808 Practice for Describing Retroreflection

illumination. The most common example is that of a motor

E 809 Practice for Measuring Photometric Characteristics

vehicle operator seeing by means of the light from the

of Retroreflectors

headlamps of the vehicle.

E 811 Practice for Measuring Colorimetric Characteristics

1.3 This specification describes the minimum retroreflective

of Retroreflectors Under Nighttime Conditions

performance required for a reasonable level of nighttime

F 923 Guide Properties of High Visibility Materials Used to

conspicuity. It does not address potentially diminished perfor-

Improve Individual Safety

mance of retroreflective markings that may be experienced

2.2 Other Standards:

with general storage, use, wear, and care.

Publication CIE No. 54, Retroreflection—Definitions and

1.4 SI (metric) units shall be used in referee decisions under

Measurements, Central Bureau of the CIE, Vienna, 1982

this specification.

1.5 The following safety hazards caveat pertains to speci-

3. Terminology

fying materials by this standard specification. Although the

3.1 Definitions—Definitions of terms relating to retroreflec-

markings described in this specification are intended to signifi-

tion in Terminology E 284, Practice E 808, and Guide F 923

cantly enhance safety through increased conspicuity under

are applicable to this specification.

most conditions of illumination and viewing of the type

3.1.1 coeffıcient of luminous intensity, R , n—of a retrore-

I

described in 1.2 above, they do not guarantee significantly

flector, ratio of the luminous intensity (I) of the retroreflector in

enhanced conspicuity under all such conditions. Individuals

the direction of observation to the illuminance (E )atthe

’

This specification is under the jurisdiction of ASTM Committee E-12 on Color

and Appearance and is the direct responsibility of Subcommittee E12.08 on High

Visibility Materials for Individual Safety. Annual Book of ASTM Standards, Vol 06.01.

Current edition approved Nov. 10, 1999. Published January 2000. Originally Available from the USNC–CIE Publications Office, c/o Mr. Thomas M.

{1

published as E 1501–92. Last previous edition E 1501–92 . Lemons, TLA-Lighting Consultants, 7 Pond Street, Salem, MA 01970-4819.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

E1501–99

retroreflector on a plane perpendicular to the direction of the 3.2 Definitions of Terms Specific to This Standard:

−1

incident light, expressed in candelas per lux (cd·lx ). R = (I/ 3.2.1 color factor F , n—a chromatic adjustment to coeffi-

I c

E ). cient of luminous intensity R to account for the ratio of

’ I

3.1.2 conspicuity, n—the characteristics of an object that brightness to luminance.

3.2.2 entrance angle component for object inclination, b ,

determine the likelihood that it will come to the attention of an

n—angle from the illumination axis to the plane containing the

observer.

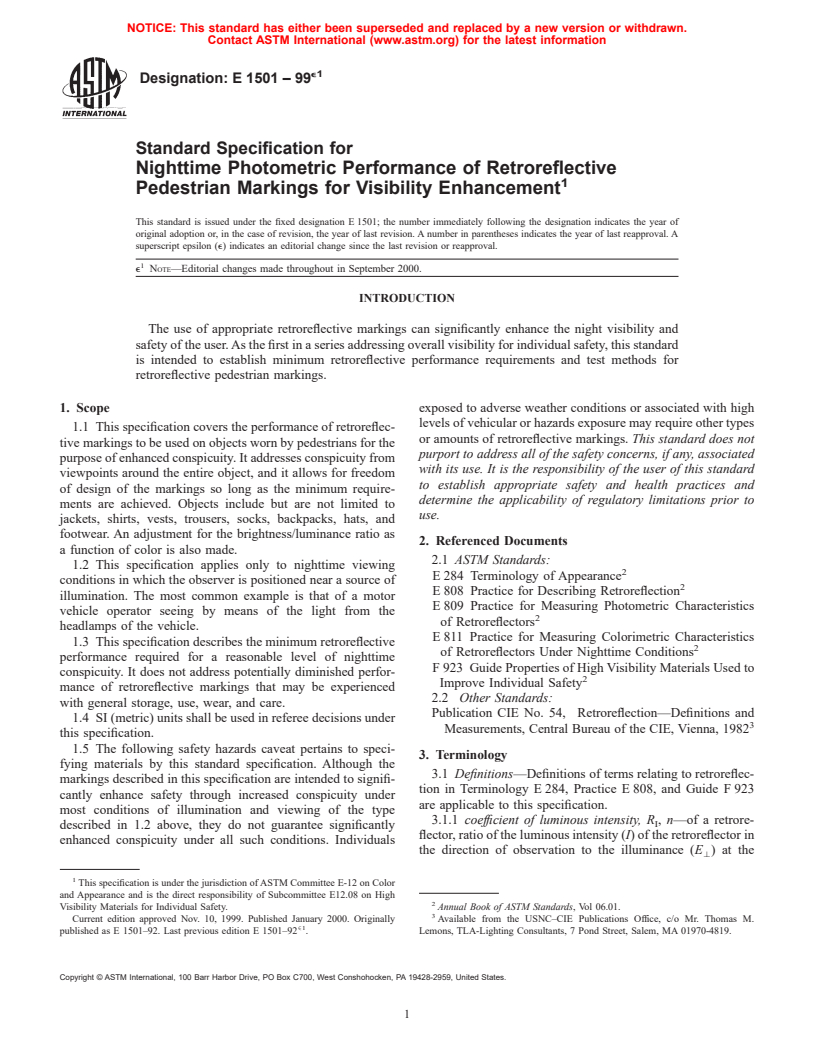

object reference axis and the first axis for the object (see Fig.

3.1.3 observation angle, a, n—in retroreflection, angle be-

1 and Fig. 2). Range: –90°

tween the illumination axis and the observation axis. 1

3.2.3 entrance angle component for object rotation, b ,

3.1.3.1 Discussion—The observation angle is always posi-

n—angle from the plane containing the observation half-plane

tive and is restricted to small acute angles.

to the object reference axis (see Fig. 1 and Fig. 2). Range:

3.1.4 observation half-plane, n—the half-plane that origi-

–180°< b #180°

nates on the line of the illumination axis and contains the 2

3.2.4 first axis for the object,, n—axis through the approxi-

observation axis.

mate center of the object and perpendicular to the observation

3.1.5 pedestrian, n—any person on foot (standing or mov-

half-plane (see Fig. 1 and Fig. 2).

ing) who is located on a highway or street. F 923

3.2.5 marking, n—that portion of an object that retrore-

3.1.6 retroreflection, n—reflection in which the reflected

flects.

rays are preferentially returned in directions close to the

3.2.6 object, n—the item worn by a pedestrian, to be marked

opposite of the direction of the incident rays, this property

for increased conspicuity under this specification.

being maintained over wide variations of the direction of the

3.2.7 object reference axis,, n—a designated line segment

incident rays.

that extends outward from the approximate center of the object

3.1.7 retroreflector axis, n—a designated line segment from

and is horizontial when the object is oriented in its usual

the retroreflector center that is used to describe the angular

upright position (see Fig. 1 and Fig. 2).

position of the retroreflector.

3.2.8 retroreflective return, R , n—the sum of the coeffi-

3.1.7.1 Discussion—This is sometimes called the reference

R

cients of luminous intensity, R , measured at two selected

axis (Fig. 1). It is used to establish a coordinate system fixed I

observation angles and adjusted for chromaticity.

with respect to the retroreflector by which its location and

3.2.8.1 Discussion—This quantity is used to describe the

angular orientation can be specified. When symmetry exists,

effective performance of the object. (See 6.6.)

the retroreflector axis usually coincides with the axis of

3.2.9 second axis for the object, n—axis through the ap-

symmetry of the retroreflector. This is the axis of maximum

proximate center of the object, lying in the plane of the

reflectivity. It is typically normal to the face of retroreflective

illumination axis and observation axis, and perpendicular to the

sheeting. For injection-molded retroreflectors, its direction may

object reference axis (see Fig. 1 and Fig. 2).

vary, and must be defined as a result of testing or by consulting

the manufacturer.

4. Classification of Objects

4.1 To facilitate testing objects, they are classified as fol-

lows:

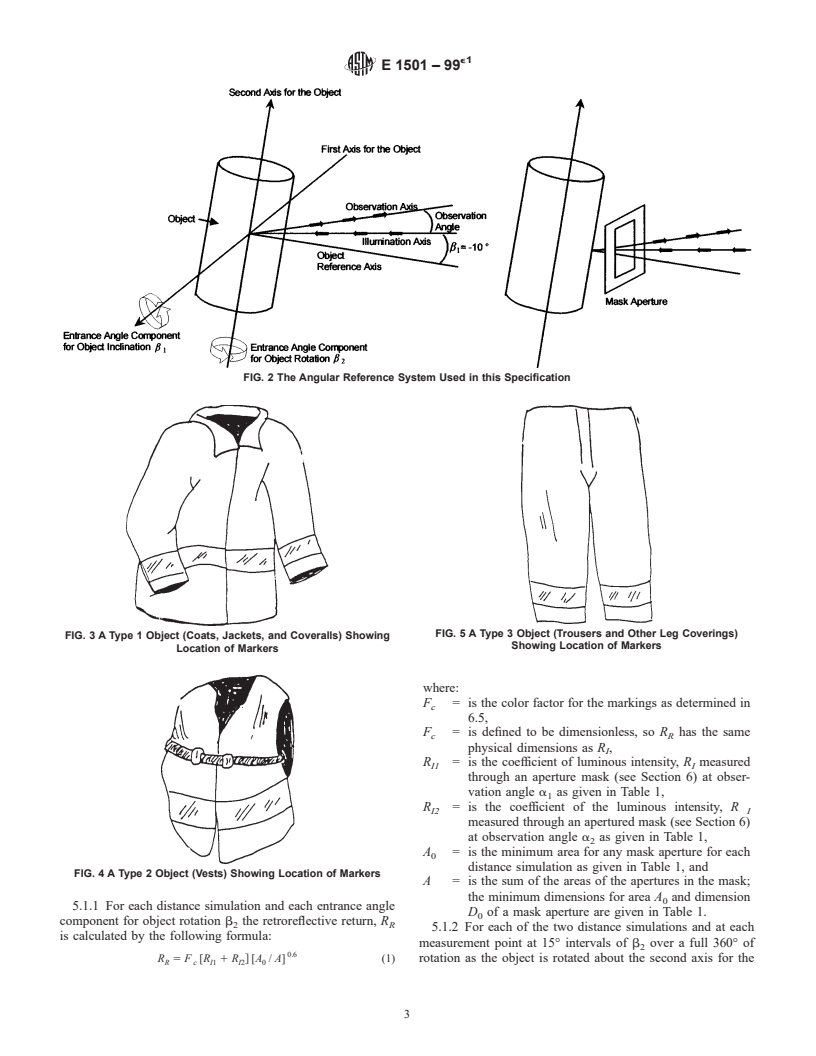

4.1.1 Type 1—Coats, jackets, and coveralls. Sleeved gar-

ments with markings on front, back, and sleeves. A typical

example is shown in Fig. 3.

4.1.2 Type 2—Vests. Sleeveless garments to cover front,

back, and sides of upper torso. Markings are provided on the

front and back. A typical example is shown in Fig. 4.

4.1.3 Type 3—Trousers (short or long), leg bands, leggings,

socks (to be worn with short trousers), and other leg coverings.

A typical example is shown in Fig. 5.

4.1.4 Type 4—School bags and backpacks. Back-carried

using shoulder and/or front straps. Markings are on surfaces

away from the body, including carrying straps. A typical

example is shown in Fig. 6.

4.1.5 Type 5—Hats, helmets, head bands, and other head

gear. Garments worn on the head for protection, warmth, or

increased conspicuity. A typical example is shown in Fig. 7.

4.1.6 Type 6—Shoes and other footwear. Objects worn on

See Publication CIE No. 54. The principal fixed axis is the illumination axis. The

the feet. A typical example is shown in Fig. 8.

first axis is perpendicular to the plane containing the observation axis and the

4.2 Other types 4.1.1-4.1.6 are not limited to the example or

illumination axis. The second axis is perpendicular to both the first axis and the

reference axis. The reference axis is fixed with respect to the retroreflector or

marking placement shown in Figs. 3-8.

object but movable with the components b and b of the entrance angle. All axes,

1 2

angles, and directions of rotation are shown positive.

5. Performance Requirements

FIG. 1 The CIE Angular Reference System for Specifying and

Measuring Retroreflectors 5.1 Retroreflective return (R ):

R

e1

E1501–99

FIG. 2 The Angular Reference System Used in this Specification

FIG. 5 A Type 3 Object (Trousers and Other Leg Coverings)

FIG. 3 A Type 1 Object (Coats, Jackets, and Coveralls) Showing

Showing Location of Markers

Location of Markers

where:

F = is the color factor for the markings as determined in

c

6.5,

F = is defined to be dimensionless, so R has the same

c R

physical dimensions as R ,

I

R = is the coefficient of luminous intensity, R measured

I1 I

through an aperture mask (see Section 6) at obser-

vation angle a as given in Table 1,

R = is the coefficient of the luminous intensity, R

I2 I

measured through an apertured mask (see Section 6)

at observation angle a as given in Table 1,

A = is the minimum area for any mask aperture for each

distance simulation as given in Table 1, and

FIG. 4 A Type 2 Object (Vests) Showing Location of Markers

A = is the sum of the areas of the apertures in the mask;

the minimum dimensions for area A and dimension

5.1.1 For each distance simulation and each entrance angle

D of a mask aperture are given in Table 1.

component for object rotation b the retroreflective return, R

2 R

5.1.2 For each of the two distance simulations and at each

is calculated by the following formula:

measurement point at 15° intervals of b over a full 360° of

0.6

R 5 F [R 1 R # [A / A] (1) rotation as the object is rotated about the second axis for the

R c I1 I2 0

e1

E1501–99

object manufacturer in order to allow a particular design to be

evaluated under conditions favorable to it, in cases of dispute

it is up to the person claiming an object meets the specifications

to define the mask(s) for the measurements that will be made

to verify compliance. (See 6.2.1 for further discussion of

masks.)

5.2 Control of the Position of Test Objects When Tested for

Retroreflective Return:

5.2.1 Objects shall be selected according to the appropriate

classification (Section 4), prepared by the corresponding prepa-

ration method (6.2.8), and tested according to the test methods

of 6.2.5 and 6.2.6.

5.2.2 Objects shall be oriented in their usual upright posi-

tions, with no rotation about the object reference axis. Entrance

angle components for object inclination (b ) and object rota-

tion (b ) shall be set according to 6.2 .

FIG. 6 A Type 4 Object (School Bags and Backpacks) Showing

6. Test Methods

Location of Markers

6.1 Summary of Test Methods:

6.1.1 Retroreflective marking test geometries and proce-

dures.

6.1.1.1 Mask. (See 6.2.1.)

6.1.1.2 Observation angles, a. (See 6.2.2.)

6.1.1.3 Entrance angle component for object inclination, b .

(See 6.2.3.)

6.1.1.4 Entrance angle component for object rotation, b .

FIG. 7 A Type 5 Object (Hats and Other Headgear) Showing

(See 6.2.4.)

Location of Markers

6.1.1.5 Seventy metre simulation test for coefficient of

luminous intensity, R . (See 6.2.5.)

I

6.1.1.6 Two hundred-thirty metre simulation test for coeffi-

cient of luminous intensity, R . (See 6.2.6.)

I

6.1.1.7 Test preparation for pedestrian object by classifica-

tion. (See 6.2.8.)

6.1.2 Retroreflectometer parameters for instrumental mea-

surements of the performance characteristics of retroreflective

markings. (See 6.3.)

6.1.3 Parameters for measuring colorimetric characteristics

FIG. 8 A Type 6 Object (Shoes and Other Footwear) Showing

of retroreflective markings under nighttime conditions. (See

Location of Markers

6.4.)

6.1.4 Calculating color factor, F . (See 6.5.)

c

TABLE 1 Measurement Parameters for Determining R Which are

R

6.1.5 Calculating retroreflective return, R . (See 5.1 and

R

Specific to Simulated Viewing Distances

6.6.)

Minimum Minimum

Distance Observation Angles 6.2 Retroreflective Marking Test Geometries:

Aperture Area Aperture

Simulated a a

1 2

6.2.1 For each measurement of R a matte black mask must

A Dimension D

0 0 I

70 m 1.1° 0.5° 0.005 m 0.07 m

be placed immediately before the object. The mask must

(7.56 in. ) (2.75 in.)

exclude from the measurement all but the selected marking(s)

230 m 0.3° 0.15° 0.053 m 0.23 m

or portion(s) of the marking(s) that are to be included in

(82 in. ) (9.06 in.)

determining whether R meets this specification.

R

TABLE 3 Conditions for Measurement of Coefficient of Luminous

object with an entrance angle component for object inclination

Intensity R

I

b of −10°, R shall be equal to or greater than the minimum

1 R

Condition 70 m Simulation 230 m Simulation

value shown in Table 2. Since, within prescribed limits, the

Observation Angle

dimensions of the mask aperture(s) are to be specified by the

a 1.10° 0.30°

a 0.50° 0.15°

Entrance Angle Component for −10° −10°

TABLE 2 Required Minimum Values of R

R

Object Inclination b

Distance Minimum R Entrance Angle Component for –165° to +180° –165° to +180°

R

70 m 0.40 cd/lx Object Rotation b in in

230 m 2.30 cd/lx 15° steps 15° steps

e1

E1501–99

6.2.1.1 During measurement of R the mask shall be posi- 6.2.6.1 Separate measurements of luminous intensity shall

I

tioned perp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.